Printing paper warehousing component having temperature/humidity self-control function

A temperature and humidity, printing paper technology, applied in railway car body parts, transport passenger cars, tank cars, etc., can solve problems such as curling, wavy edges, wrinkling, etc., to ensure printing quality, strong automatic adjustment, and reduce economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

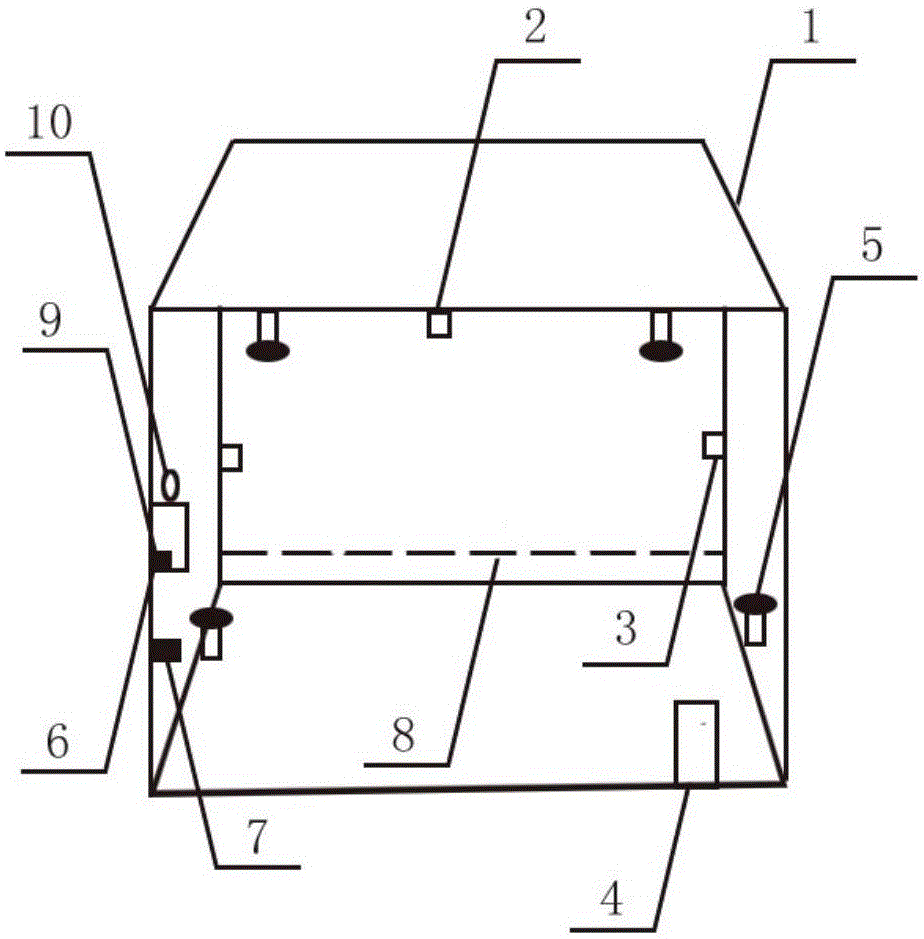

[0012] Embodiment: as shown in the accompanying drawing. The printing paper storage assembly with temperature and humidity automatic control function includes a storage room (1), and the storage room (1) includes a humidity sensing device (2), a temperature sensing device (3), a dehumidification device (4), a spraying device (5 ), the sensing device is connected to the central control device (6) for data analysis, and the indoor temperature and humidity conditions are alleviated through the job distribution of the automatic conversion device (7).

[0013] In the printing paper storage assembly with temperature and humidity automatic control function, a small flowing water groove (8) is arranged on the edge of the storage room (1), which not only provides water for the spraying device (5), but also relieves the temperature and humidity around the storage room.

[0014] The printing paper storage component with automatic temperature and humidity control function is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com