Multi-parameter adjustable electrolytic cell device for loading process

A loading process and multi-parameter technology, applied in the field of corrosion, can solve the problems of variable gauge corrosion, limited to cantilever bending, unsuitable for stress corrosion and corrosion fatigue tests, etc., and achieve good safety in use, reliable design principles, and controllable measurement good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

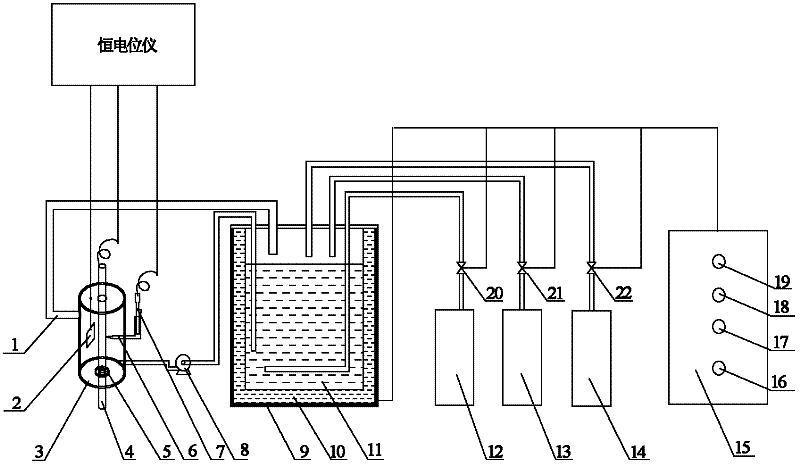

[0011] The main structure of this embodiment includes a thermal insulation hose 1, an auxiliary electrode 2, a double-layer plexiglass tank 3, a sample 4, an anti-leakage device 5, a Lujin capillary (salt bridge) 6, a reference electrode 7, a micro water pump 8, Solution mixing tank 9, temperature regulating circulating water 10, corrosion solution 11, salinity regulating liquid storage bottle 12, pH value regulating liquid storing bottle 13, dissolved oxygen regulating gas cylinder 14, automatic control device 15, temperature regulating switch 16, salt Degree adjustment switch 17, pH value adjustment switch 18, dissolved oxygen amount adjustment switch 19, salinity control valve 20, pH value control valve 21 and dissolved oxygen amount control valve 22; Sample 3, the upper end of the sample 3 is connected with the potentiostat, the upper side of the inner cavity of the anti-leakage device 4 is provided with an auxiliary electrode 2 connected with the potentiostat, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com