Automatic frequency adjustment vibration cloth bag dust-cleaning system

A bag dust removal and automatic frequency modulation technology, applied in the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of automation of dust removal equipment, rare controllable technology, etc., and achieve convenient replacement and switching of working conditions and automatic adjustment. Strong performance, improve the effect of vibration mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

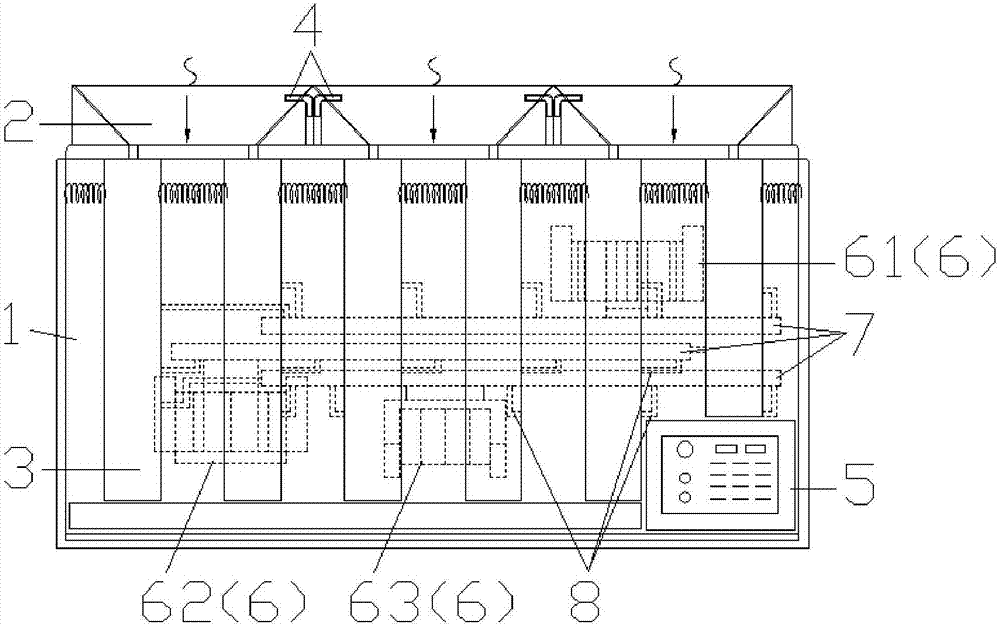

[0019] Such as figure 1 , an automatic frequency modulation vibration bag dust removal system, including a box body 1, a dust collection port 2, a cloth bag 3, a water spray port 4, a controller 5, and a vibration motor 6, and several dust collection ports 2 are installed on the upper part of the box body 1, Each dust collection port 2 is externally connected with a dust suction fan (not shown in the figure). The dust collection port 2 is in the shape of a bucket with a wide top and a narrow bottom. A water spray port 4 is installed nearby, the end of the water spray port 4 has an atomizer, and the water spray port 4 is connected to an external water pump; the number of the dust collection ports 2 is 2 to 4, and the cloth bag 3 is placed in the box 4 to 8 are evenly arranged side by side, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com