Organic-inorganic composite up-conversion photoluminescence film and preparation method thereof

An inorganic composite and light conversion technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of inability to accurately control the composition, growth direction, unsuitable for large-area preparation of thin films, and expensive equipment, so as to improve the conversion efficiency of light spots, The effect of low production cost and fast polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing an organic-inorganic composite up-conversion photoluminescent film, which is characterized in that the method comprises the following steps:

[0040] S10: Weigh a certain amount of UA, stir evenly, add a certain amount of MMA, stir magnetically for 10 minutes, mix evenly, and make an organic polymer precursor;

[0041] S20: ultrasonically disperse the inorganic up-conversion photoluminescence crystalline particles in the uniformly mixed organic polymer precursor solution, add a photoinitiator, and stir evenly to form a transparent photoluminescence coating solution;

[0042] S30: Uniformly coat the transparent photoluminescent coating solution in the mold or container, the optional coating methods are: spin coating method, dipping and pulling method, spray coating method, roller coating method, meniscus coating method or die coating method.

[0043] S40: Transfer the mold or container coated with the photolumin...

Embodiment 1

[0049] 1) Weigh 4 g of polyurethane acrylate (UA), stir evenly, add 4 g of methyl methacrylate (MMA) and stir magnetically for 10 minutes, and mix evenly to prepare an organic polymer precursor;

[0050] 2) Weigh 0.16 g of polyethylene glycol-modified NaYF 4 :Yb 3+ , Er 3+ Phosphor powder, ultrasonically dispersed in the well-mixed organic polymer precursor solution, added 0.1 g photoinitiator (TPO), stirred evenly, to form a transparent photoluminescent coating solution;

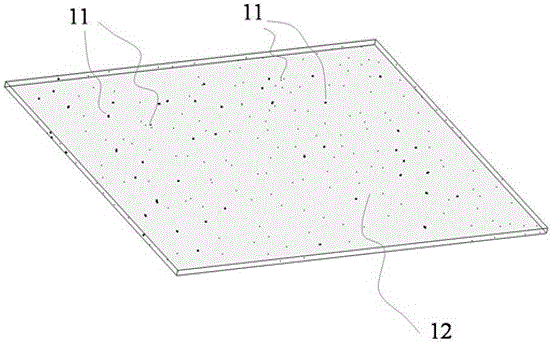

[0051] 3) Apply the transparent photoluminescent coating solution evenly on the polytetrafluoroethylene mold to form a thin layer with a thickness of 0.4 mm;

[0052] 4) Transfer the polytetrafluoroethylene mold coated with the photoluminescence coating solution to the UV curing box, and irradiate it with a UV lamp for 10 minutes, and then the cured organic-inorganic composite up-conversion photoluminescence film Peel from the Teflon mold.

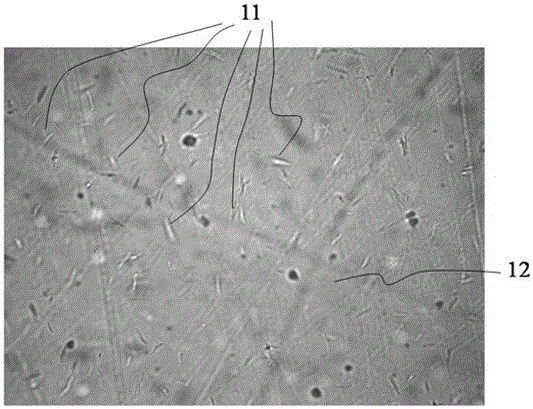

[0053] figure 2 It is a polarized light microscopic image of...

Embodiment 2

[0058] 1) Weigh 4 g of polyurethane acrylate (UA), stir evenly, add 4 g of methyl methacrylate (MMA) and stir magnetically for 10 minutes, and mix evenly to prepare an organic polymer precursor;

[0059] 2) Weigh 0.32 g of polyethylene glycol-modified NaYF 4 :Yb 3+ , Er 3+ Phosphor powder, ultrasonically dispersed in the well-mixed organic polymer precursor solution, added 0.1 g photoinitiator (TPO), stirred evenly, to form a transparent photoluminescent coating solution;

[0060] 3) Apply the transparent photoluminescent coating solution evenly on the polytetrafluoroethylene mold to form a thin layer with a thickness of 0.4 mm;

[0061] 4) Transfer the polytetrafluoroethylene mold coated with the photoluminescence coating solution to the UV curing box, and irradiate it with a UV lamp for 10 minutes, and then the cured organic-inorganic composite up-conversion photoluminescence film Peel from the Teflon mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap