Pressure relief valve

A pressure reducing valve and valve body technology, which is applied in the field of pressure reducing valves, can solve problems such as difficulty in assembling and attaching pressure reducing valves, and achieve the effect of reliable functionality and good reset force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

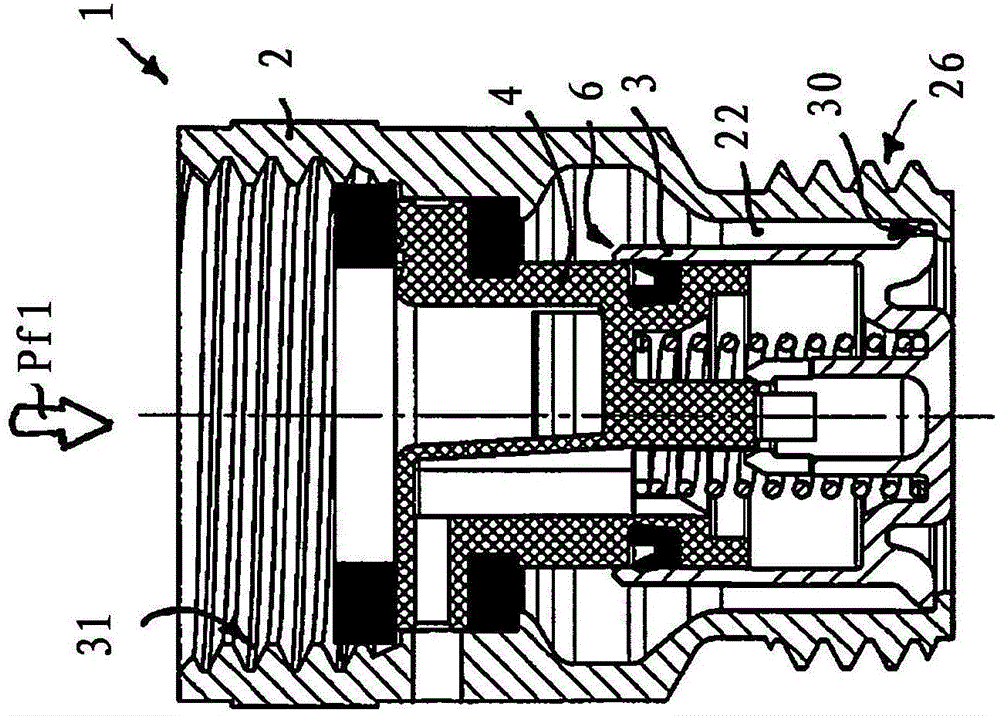

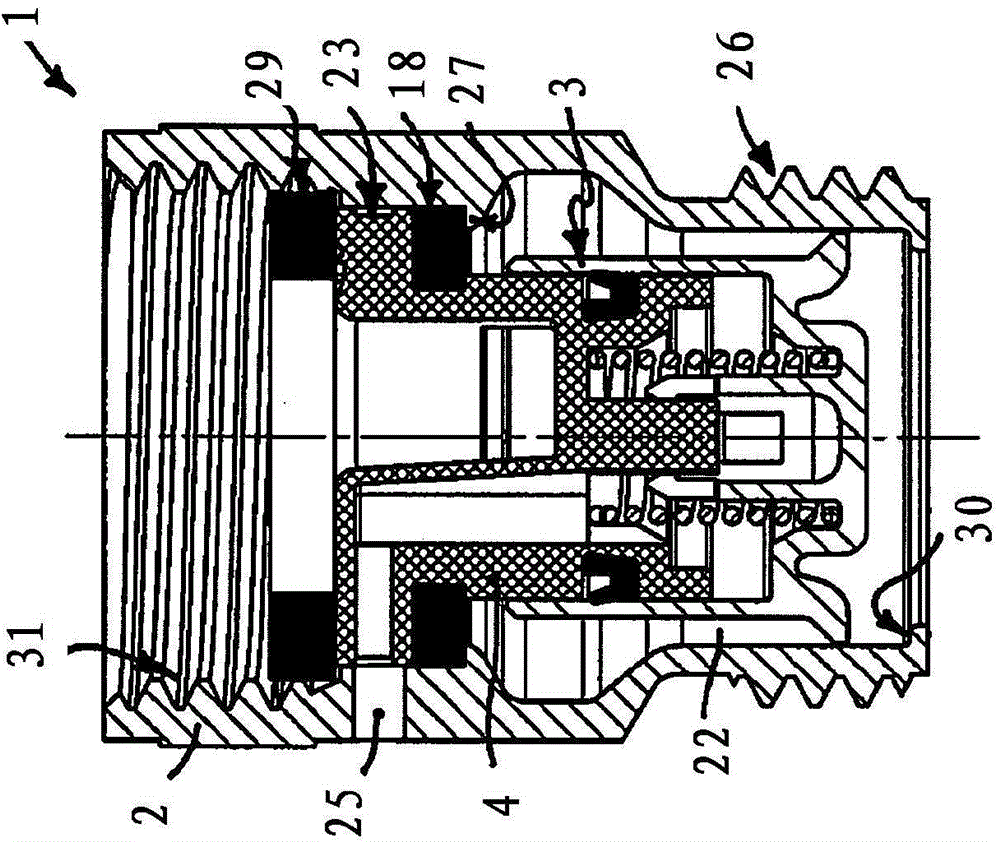

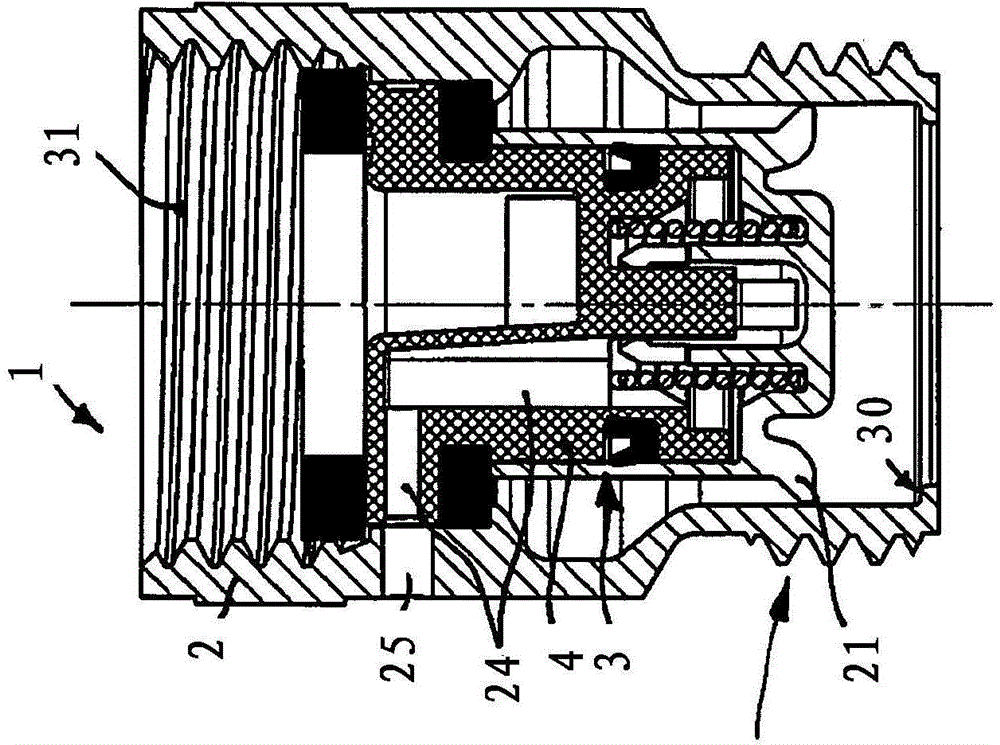

[0029] exist Figures 1 to 8 shows a pressure reducing valve 1 through which flow is made in the direction of the arrow Pf1 , which can be inserted, for example, into a water line in order to limit the water pressure in the line section downstream of the pressure reducing valve to a defined maximum value. The pressure relief valve 1 has a valve housing 2 which can be plugged or interconnected into a fluid line. A pot-shaped valve body 3 is arranged in the housing interior of the valve housing 1 . The pressure relief valve 1 has a valve holder 4 in which at least one throughflow channel 5 is arranged. If the conduit cross-section of the downstream conduit section contracts and the water pressure increases there, the displaceably guided valve body 3 is controlled by the pressure of the medium flowing through it. figure 1 The open position shown in the movement overcomes the reset force of at least one reset element to the image 3 In the closed position shown in , in this clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com