Specific heat liquid level meter

A technology of specific heat and heating liquid, which is applied in the field of material level measurement method and device for realizing the method, can solve the problem of reducing measurement accuracy, the inability of radar level gauge to measure the liquid level of high temperature medium, and the inability to measure the liquid level of non-conductive medium, etc. problems, to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

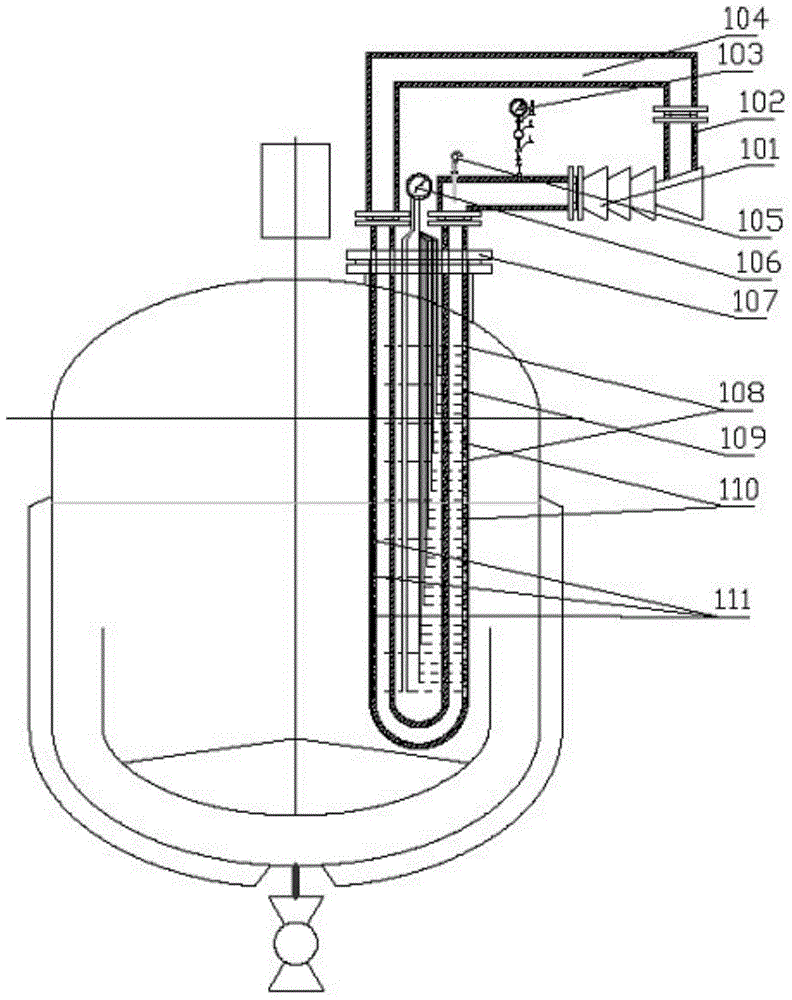

[0060] Such as figure 1 As shown, taking liquid level measurement as an example, this embodiment provides a material level gauge for measuring liquid level, that is, a liquid level gauge. The liquid level gauge utilizes the specific heat and heat transfer coefficient of liquid and gaseous states Different characteristics, combined with the circulating fluid (circulating medium), detect the detection temperature in the liquid phase and the gas phase through several temperature detection elements, and determine the liquid level position according to the change of the detection temperature.

[0061] Specifically, the liquid level gauge includes a "U"-shaped circulation pipe, a cooling device, an insertion part and a transmitter 106; wherein, the cooling device is composed of a compressor 101, a Freon tube 102, a Freon 104, a refrigeration thermometer 105, The pressure transmitter 103 and the insulating material are filled with oblique lines. The insertion part is composed of a f...

Embodiment 2

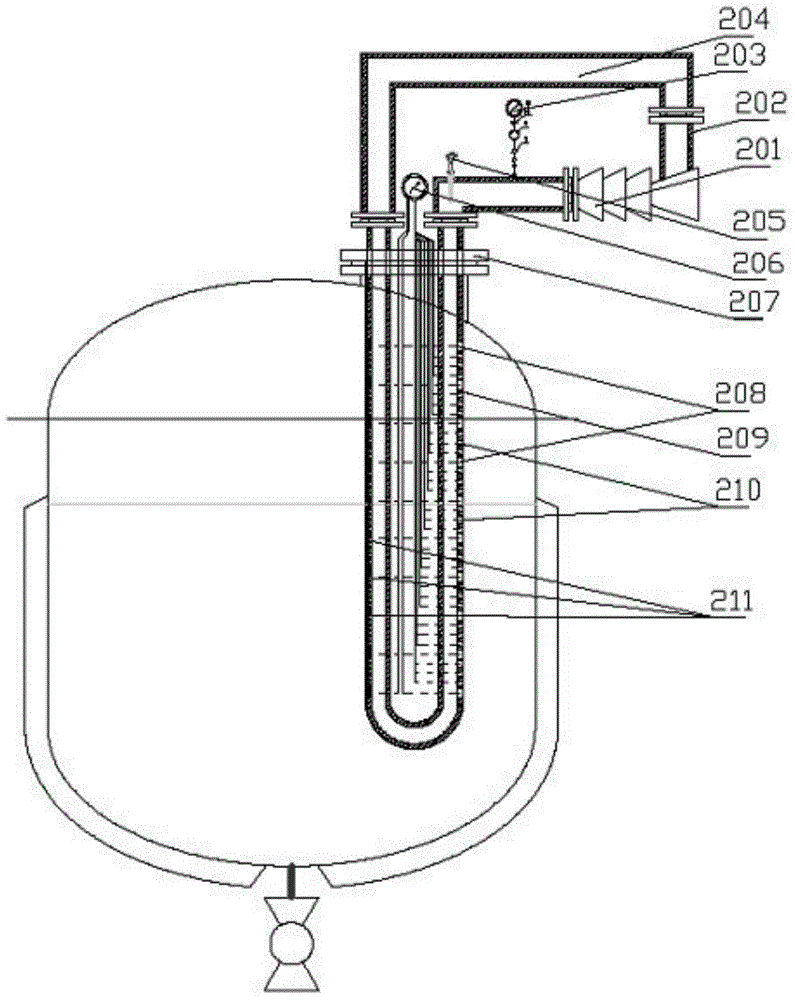

[0068] Such as figure 2 As shown, the liquid level gauge in this embodiment includes a "U"-shaped circulation pipe, a cooling device, an insertion part and a transmitter 206. Wherein, the cooling device is composed of a compressor 201, a freon tube 202, a freon 204, a refrigeration thermometer 205, a pressure transmitter 203 and an oblique line filling of an insulating material. The insertion part is composed of a flange 207 , a material level temperature detection element 208 , an insulating material 209 between temperature sensors, a material level temperature detection element 210 , a medium temperature detection element 211 , and an outer casing 212 . Transmitter 206 receives all temperature sensor signals, pressure transmitter signals and external power supply, provides power and control signals to the compressor, and sends out a 4-20mADC current signal corresponding to the liquid level. The signal lines of each material level temperature detection element are separatel...

Embodiment 3

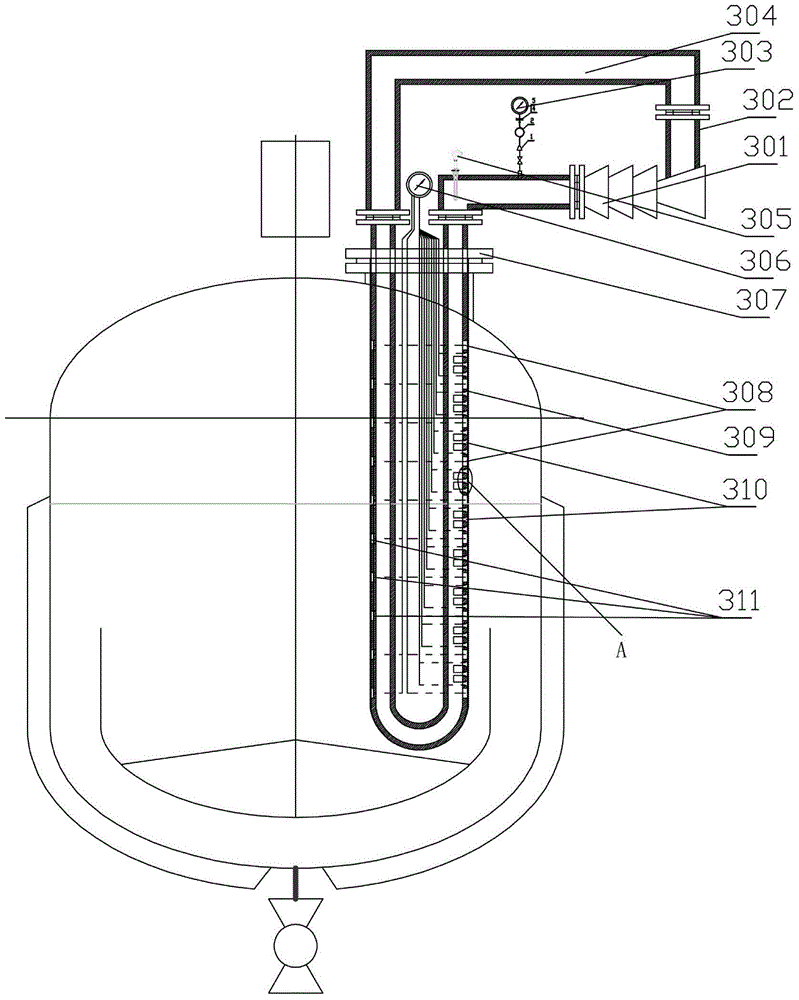

[0070] Such as image 3 As shown, the liquid level gauge in this embodiment includes a "U"-shaped circulation pipe, a cooling device, an insertion part and a transmitter 306. Wherein, the cooling device is composed of a compressor 301, a freon tube 302, a freon 304, a freon thermometer 305, a pressure transmitter 303 and an oblique line filling of insulating material. The insertion part is composed of flange 307, material level temperature detection element 308, heat insulating material 309 between temperature sensors, material level temperature detection element 310, medium temperature detection element 311, and outer casing 312. Because the container is stirred, it also includes a resistant Agitate the support tube (not shown). Transmitter 306 receives all temperature sensor signals, pressure transmitter signals and external power supply, provides power and control signals to the compressor, and sends out 4-20mADC current signals corresponding to the liquid level. The diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com