Leakage-detecting device for bolted flange connection system

A connection system and bolt flange technology, applied in the field of leak detection devices, can solve problems such as bolt elongation, bolt flange connection system leakage, safety accidents, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

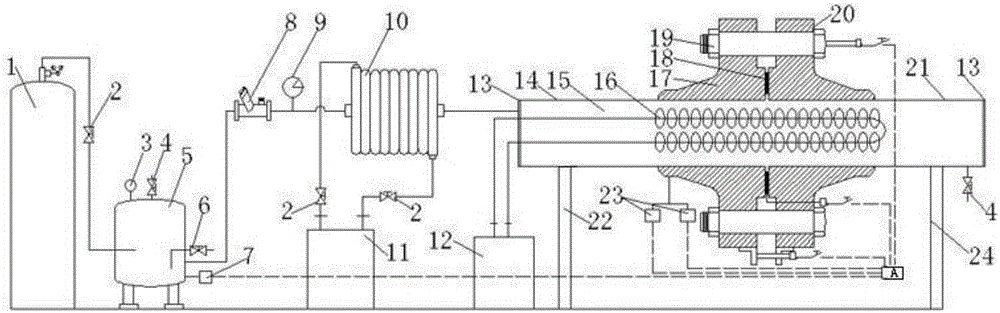

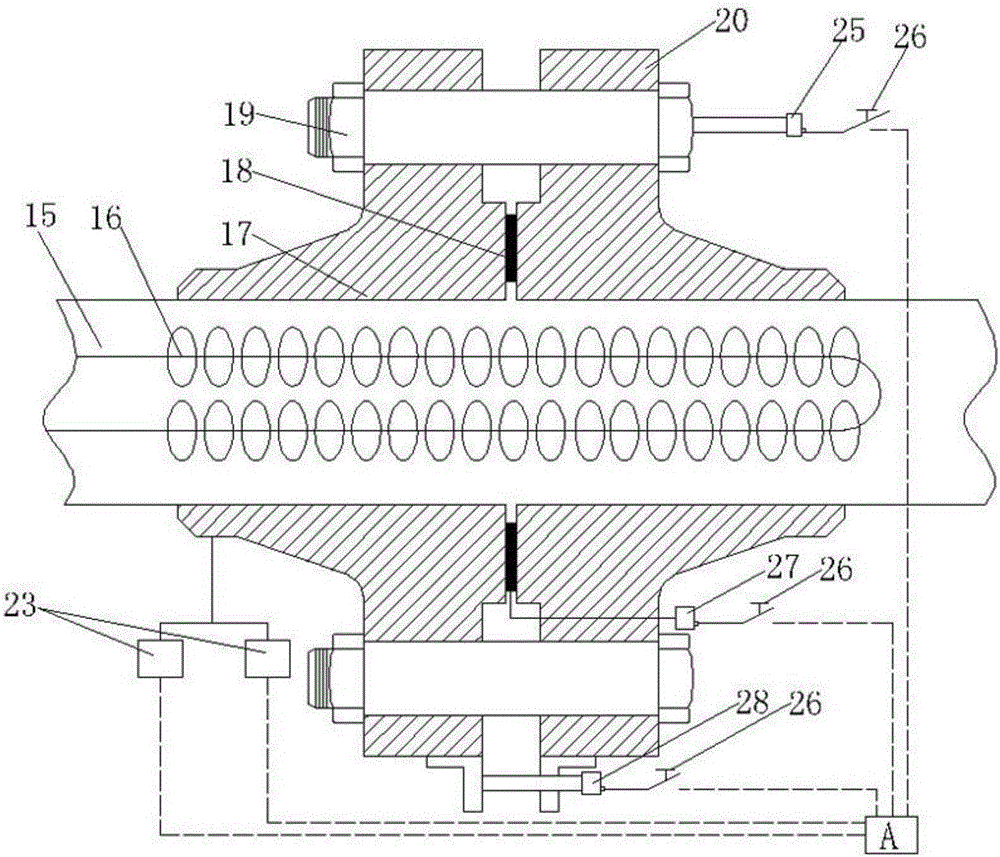

[0026] Such as figure 1 As shown, a leak detection device of a bolted flange connection system includes interconnected left pipe 14 and right pipe 21 (left pipe 14 and right pipe 21 are supported horizontally by left bracket 22 and right bracket 24 respectively, ensuring that the pipeline as a whole The bottom of the right pipeline 21 is also provided with a pressure relief valve 4), the left flange 17 and the right flange 20 connecting the left pipeline 14 and the right pipeline 21, and the bolts 19 for pressing the left flange 17 and the right flange 20 And the gasket 18 that is used for sealing, the non-connecting end of described left pipeline 14 and right pipeline 21 all is closed by blind plate 13 welding and forms sealed cavity 15 inside, and the inside of sealed cavity 15 is provided with heating mechanism (in this implementation In an example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com