Expansion joint failure test method

A test method and technology of expansion joints, which can be used in the direction of measuring the acceleration and deceleration rate of fluids and using liquid/vacuum for liquid tightness measurement. The effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

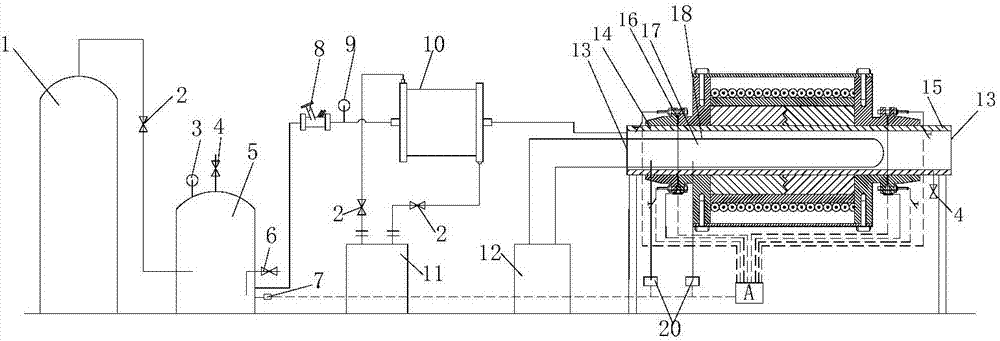

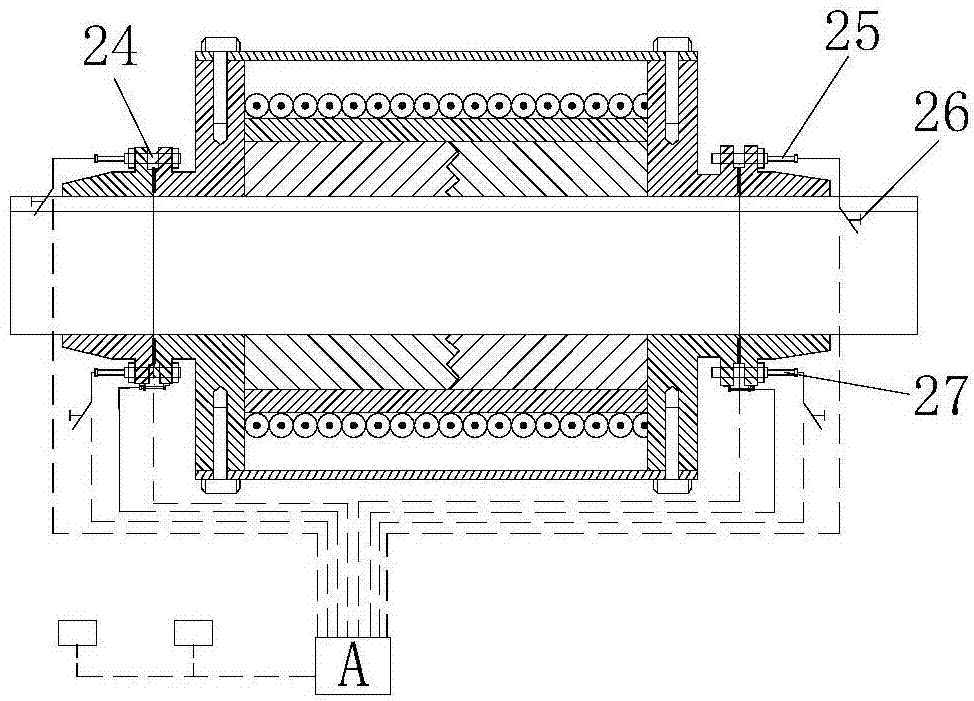

[0028] Such as figure 1 As shown, a failure test device of an expansion joint includes left and right pipes, the left pipe flange connected to the left pipe, the right pipe flange connected to the right pipe, and the left pipe flange connected by bolts and gaskets. The expansion joint between the flange and the right flange of the pipeline, wherein, the non-connecting ends of the left pipeline and the right pipeline are closed and a sealed cavity is formed inside, and a heating mechanism is provided inside the sealed cavity; There is a high-pressure gas storage tank, and the high-pressure gas storage tank is connected to the balance valve and the flow meter in turn through the pipeline and finally communicates with the sealed cavity. The test device also includes sensors for measuring the temperature and pressure inside the sealed cavity; the expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com