Oil-immersed power transformer top-level oil temperature monitoring method based on thermistor

A technology for power transformers and thermistors, which is applied in the directions of thermometers, thermometers, and instruments that use electrical/magnetic components directly sensitive to heat, can solve the threat of safe operation of oil-immersed power transformers and reduce the operation of oil-immersed power transformers. life and other issues, to achieve the effect of simple structure, high accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

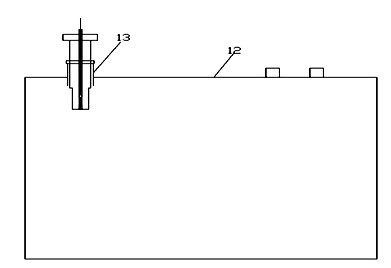

[0028] Embodiment 1: as figure 1 Shown: This method for monitoring oil temperature on the top layer of oil-immersed power transformer based on thermistor is to firstly connect the thermistor temperature sensor to the multimeter 11, and then insert the thermistor temperature sensor into the oil-immersed power transformer through the test hole 13 12 in the top layer of oil; after being stabilized, according to the thermistor resistance measured by the multimeter; then through the relationship between resistance and temperature , calculate the temperature of the oil on the top layer of the oil-immersed power transformer; finally, compare the measured temperature with the temperature rise standard of the oil-immersed power transformer to judge whether the oil-immersed power transformer is in normal working condition.

[0029] The national standard GB1094.2-1996 "Power Transformer Part 2 Temperature Rise" for oil-immersed power transformers stipulates that for transformers using...

Embodiment 2

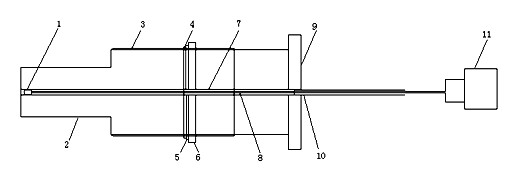

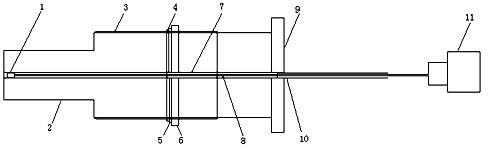

[0031] Embodiment 2: as figure 1 Shown: the specific method and process of this thermistor-based oil-immersed power transformer top layer oil temperature monitoring method are the same as in embodiment 1. In order to better realize this method, an adjustable thermistor temperature sensor is adopted in this embodiment, such as figure 2 Shown: It consists of thermistor 1, copper tube 2, threaded copper tube 3, copper pad 4, fluorosilicone sealing ring 5, nut 6, wire hole 7, lead wire 8, handle 9, polytetrafluoroethylene Sleeve 10, universal meter 11; Copper pipe 2, threaded copper pipe 3 and handle 9 are integrally formed structure, and wire hole 7 is processed inside, and the bottom end of copper pipe 2 is sealed; The copper tube 3 is covered with a copper pad 4, a fluorosilicone sealing ring 5 and a nut 6 in sequence; through the wire hole 7, the thermistor 1 is placed at the bottom of the wire hole 7, and the transmission line is protected with a polytetrafluoroethylene sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com