All-in-one machine with register, drying, and printing-down

An all-in-one, plate-matching technology, applied in optics, instruments, printing equipment, etc., can solve problems such as affecting quality, affecting effects, and the lack of close contact between film and printing plate, avoiding cooling time, improving efficiency, The effect of short printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

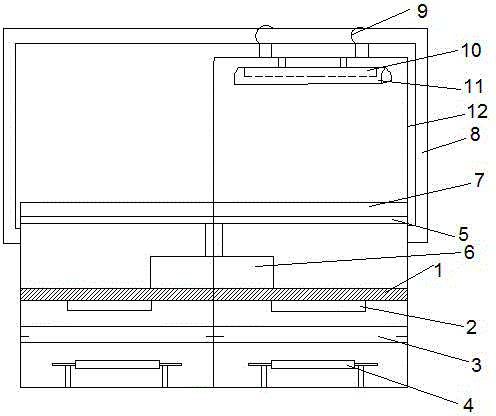

[0012] Such as figure 1 The plate-setting-drying-printing integrated machine shown is characterized in that it includes a pair of plate-setting-drying parts located below and a plate-printing part located above which are respectively arranged side by side. The drying part and the plate-printing part There is a heat insulation layer 1 between the sections; the plate-setting-drying section includes a plate-setting device 2, a plate drying frame 3 and a heating pipe 4 distributed sequentially from top to bottom; the printing section includes a printing chamber 5 , the printing chamber 5 is connected with the vacuum pump 6, and the printing chamber 5 is provided with a sealing cover 7; the printing part is also provided with a bracket 8, and the bracket 8 is hung with a light source lamp 10 through a hook 9, so The light source lamp 10 is provided with a lampshade 11, and the lampshade 11 is arc-shaped, and is used to focus the light source on the plate printing chamber 5 to impro...

Embodiment 2

[0014] Such as figure 1 The plate-setting-drying-plate-printing integrated machine shown is characterized in that it includes a pair of plate-setting-drying parts at the bottom and a plate-printing part at the top, respectively arranged side by side. The drying part and the plate-printing part There is a heat insulation layer 1 between the parts; the plate-setting-drying part includes a plate-setting device 2, a plate drying frame 3 and a heating pipe 4 distributed sequentially from top to bottom; the plate printing part includes a plate printing warehouse 5 , the printing chamber 5 is connected with the vacuum pump 6, and the printing chamber 5 is provided with a sealing cover 7; the printing part is also provided with a bracket 8, and the bracket 8 is hung with a light source lamp 10 through two hooks 9 , The light source lamp 10 is provided with a lampshade 11, the lampshade 11 is arc-shaped, and is used to focus the light source on the plate printing chamber 5 to improve t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap