Fixture and system for debugging parameters of naked-eye 3D display device

A display device, 3D technology, applied in the naked-eye 3D field, can solve problems such as low work efficiency, 3D parameter differences, and unfavorable mass production of products, and achieve the effect of improving debugging efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

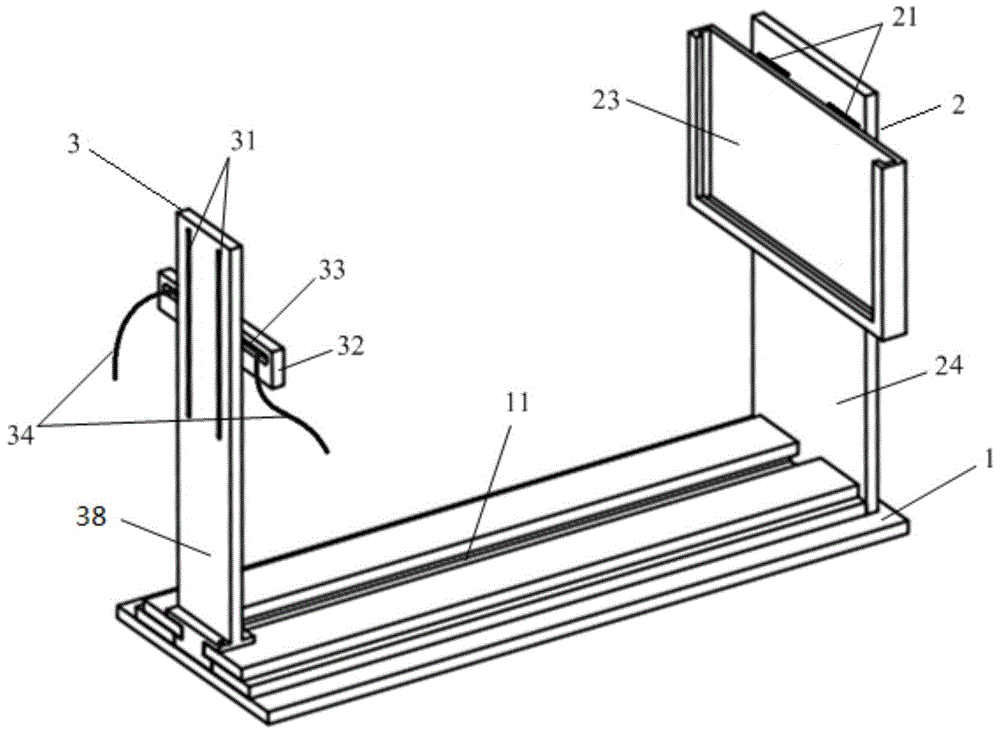

[0051] Based on the structure of the above-mentioned jig, a specific embodiment of the jig for debugging the parameters of the naked-eye 3D display device is also provided in the embodiment of the present invention, and the realization structure is as follows:

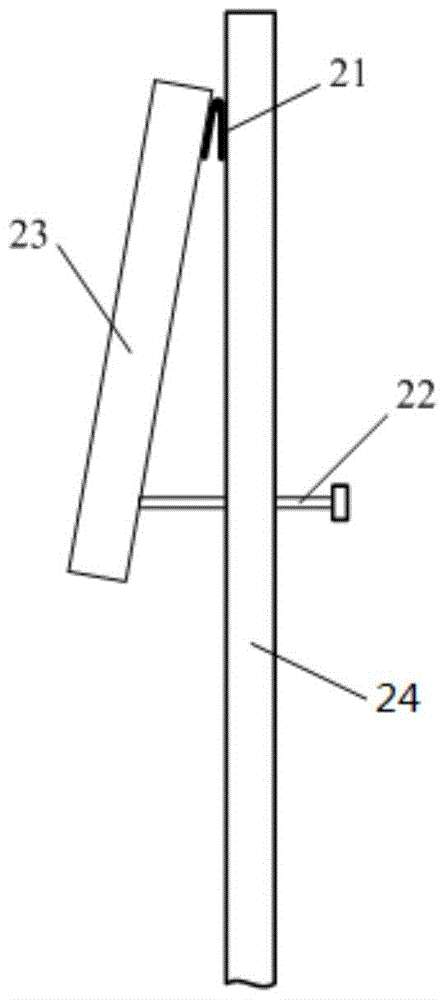

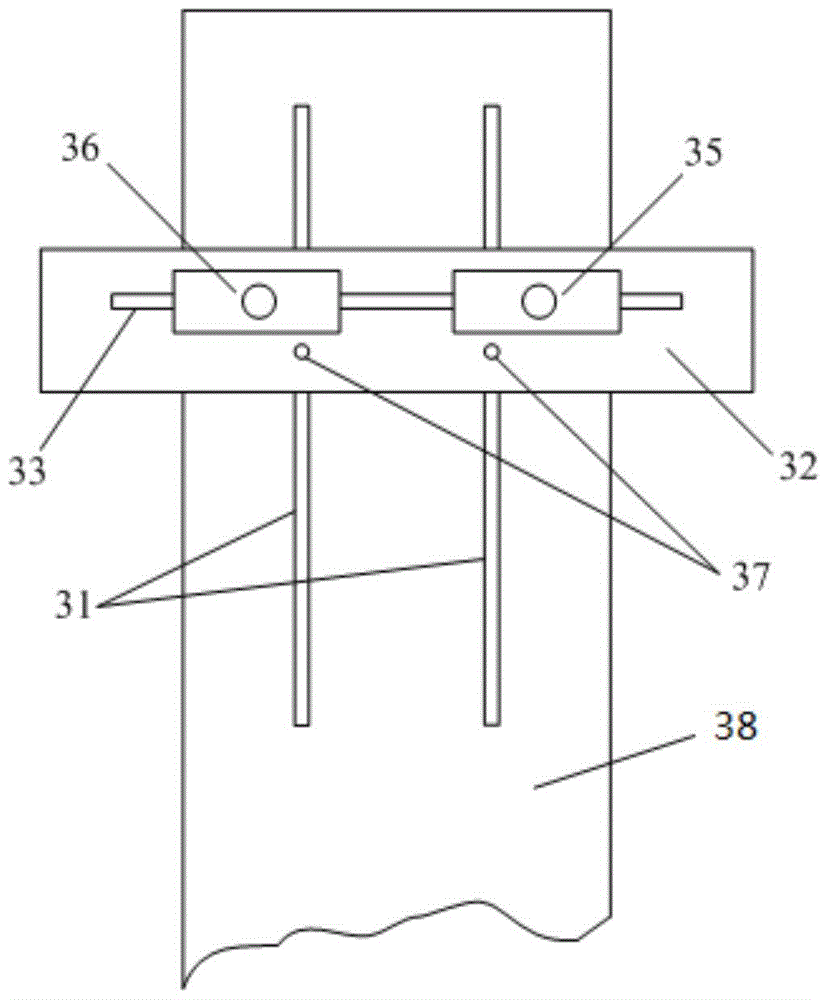

[0052] Such as figure 1 and figure 2 As shown, the base 1 is provided with a slide rail 11, the fixed bracket 24 is fixedly connected with the base 11, and the movable bracket 38 is slidably connected with the base 11 through the slide rail 11, wherein the fixed bracket 24 and the movable bracket 38 are respectively located at the sides of the slide rail 11. ends. The fixed bracket 24 is provided with a hinge 21 and an adjustable screw rod 22, the loading bracket 23 is connected with the fixed bracket 24 through the hinge 21, and the adjustable screw rod 22 passes through the screw hole arranged on the fixed bracket 24 to offset against the back side of the loading bracket 23 . Adjusting the length that the adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com