Patents

Literature

32results about How to "Realize automatic debugging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filter automatic debugging system on the basis of flexible transmission device

InactiveCN105182109ARealize automatic debuggingAvoid influenceElectrical testingEngineeringHuman power

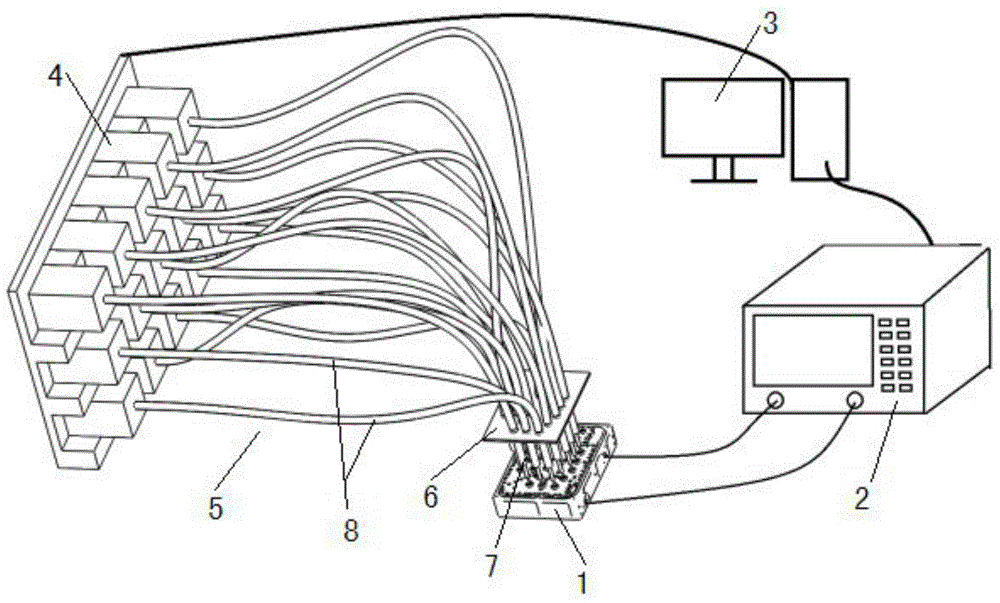

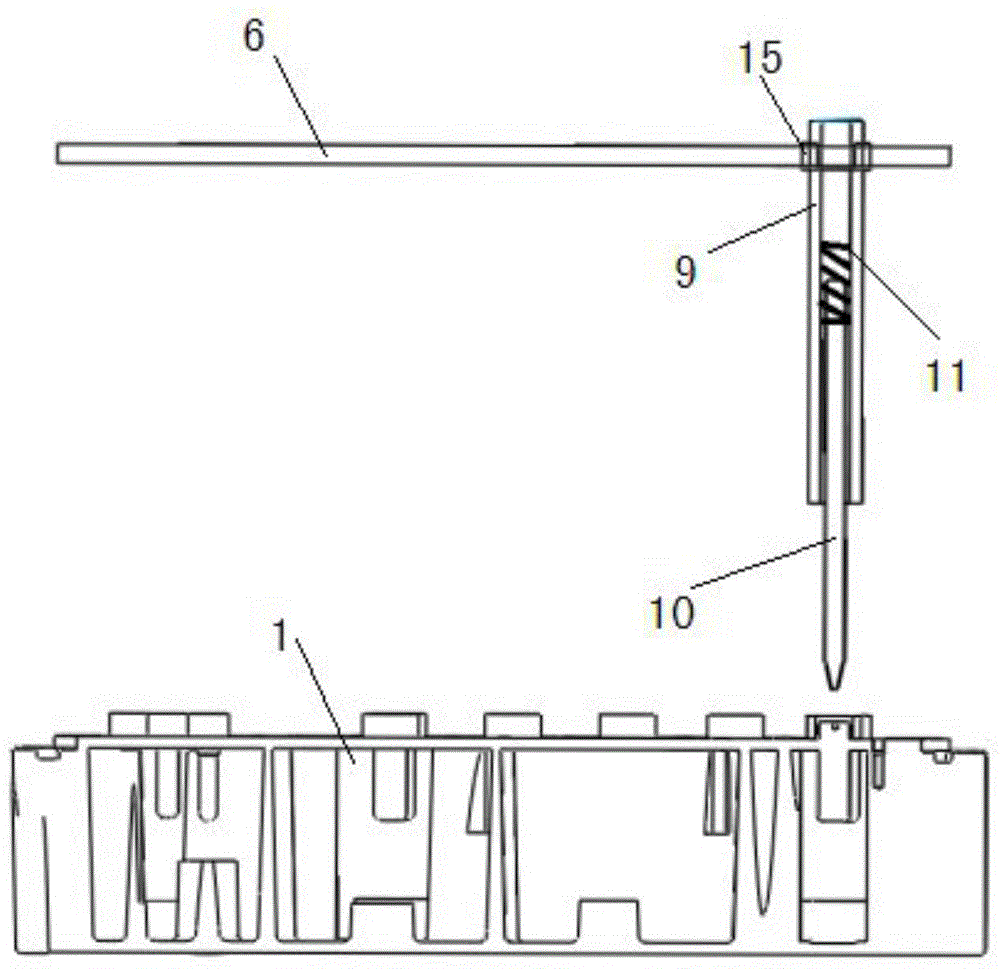

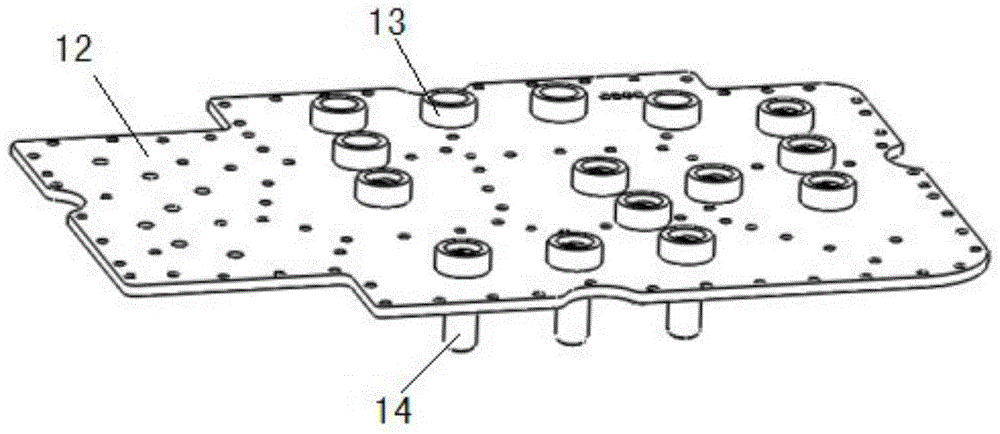

The present invention relates to the field of the filter debugging technology, especially to a filter automatic debugging system on the basis of a flexible transmission device. The filter automatic debugging system on the basis of the flexible transmission device comprises a vector network analyzer, a computer, a motor platform and a telescopic debugging cutter head. The telescopic debugging cutter head includes a sleeve and a debugging cutter head, the debugging cutter head is arranged in the sleeve and has a tip for debugging which protrudes out of the bottom of the sleeve, there is provided radial spacing between the inner wall of the sleeve and the outer wall of the debugging cutter head, and the top of the sleeve is fixedly connected with a flexible bar. Electrical characteristics of the filter are measured through the vector network analyzer and are converted to the amount of tuning through the computer, and a motor rotation torque is transmitted to the telescopic debugging cutter head so as to realize automatic debugging of the filter. According to the invention, workers may liberate from the repetitive and boring debugging work, manpower is saved, and the influence on the filtering debugging caused by manpower factors is avoided, therefore the consistency of products is better and it has important significance to reduce the production cost and stabilize the productivity.

Owner:WUHAN FINGU ELECTRONICS TECH

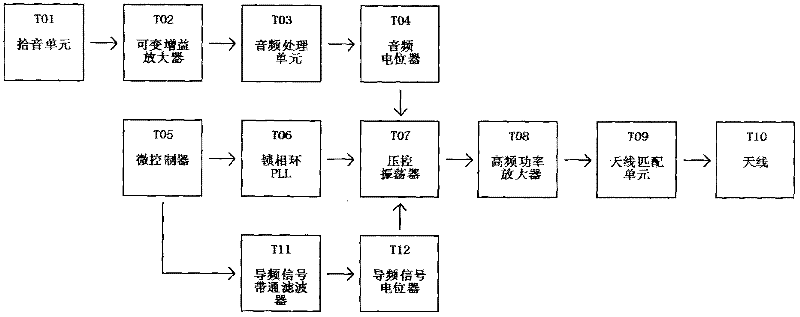

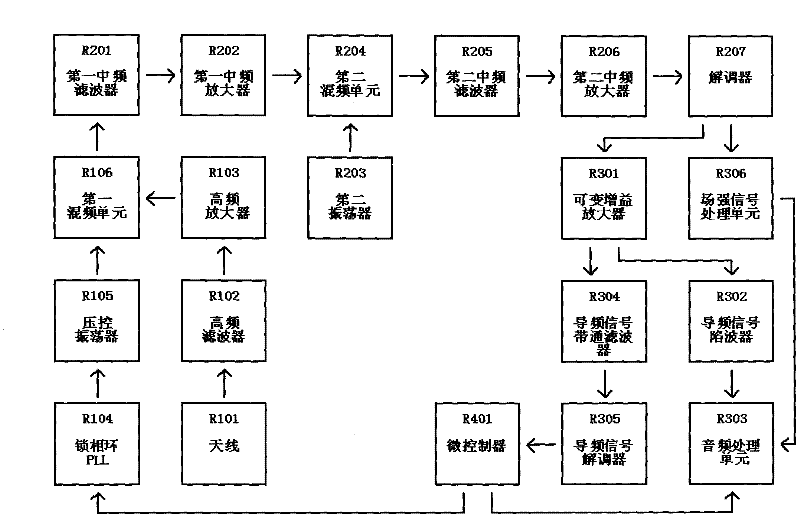

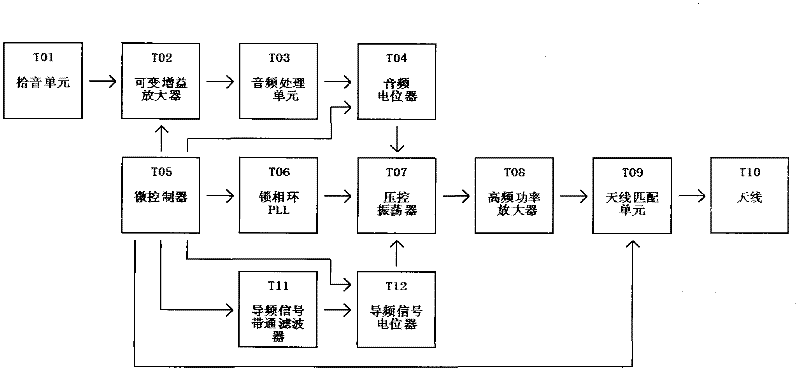

Method for realizing automatic debugging of wireless microphone and automatic debugging system

InactiveCN102355620ARealize automatic debuggingElectrostatic transducer microphonesWireless microphoneTest fixture

The invention relates to an automatic debugging system for testing a wireless microphone, which comprises a transmitter test fixture, a receiver test fixture, a testing computer, testing computer software and instrument equipment which can be connected to the computer for realizing control on the basis of the computer software. The invention also relates to a method for automatically debugging the wireless microphone through the debugging system. By the debugging system and the debugging method, the complete automatic debugging in the process of producing the wireless microphone is realized.

Owner:周意春

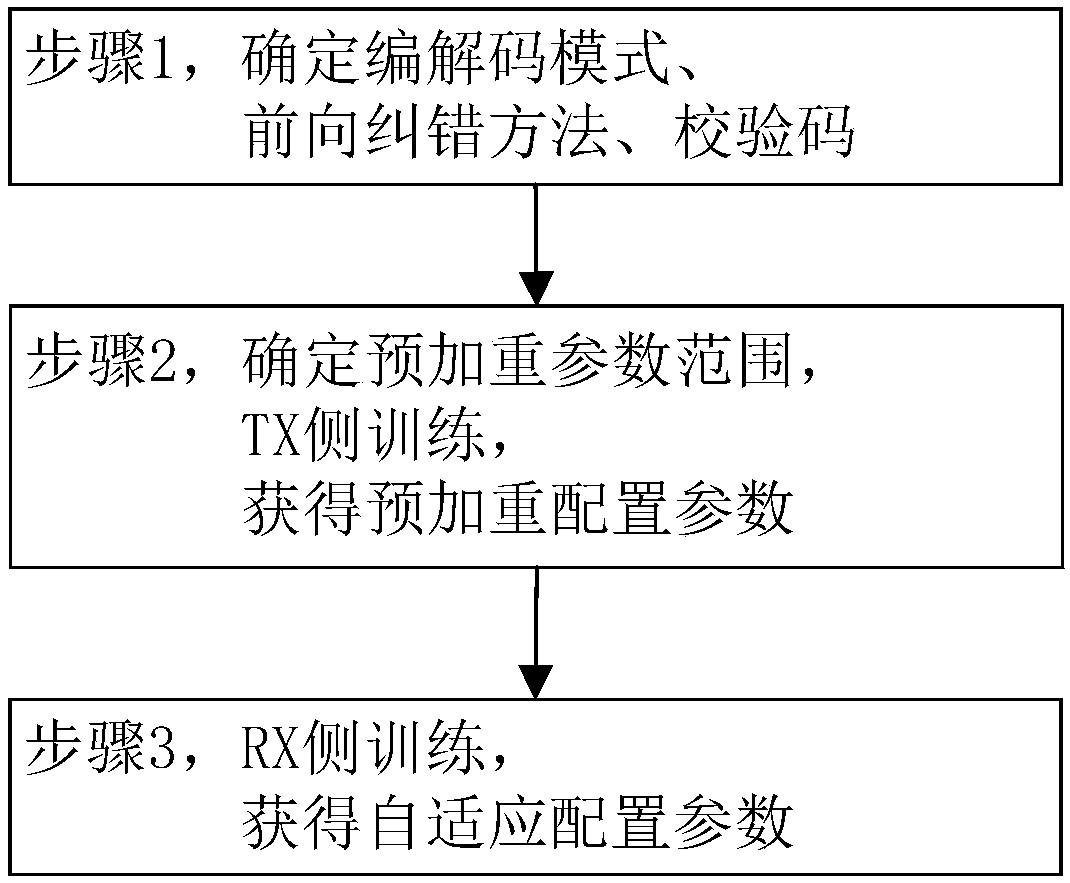

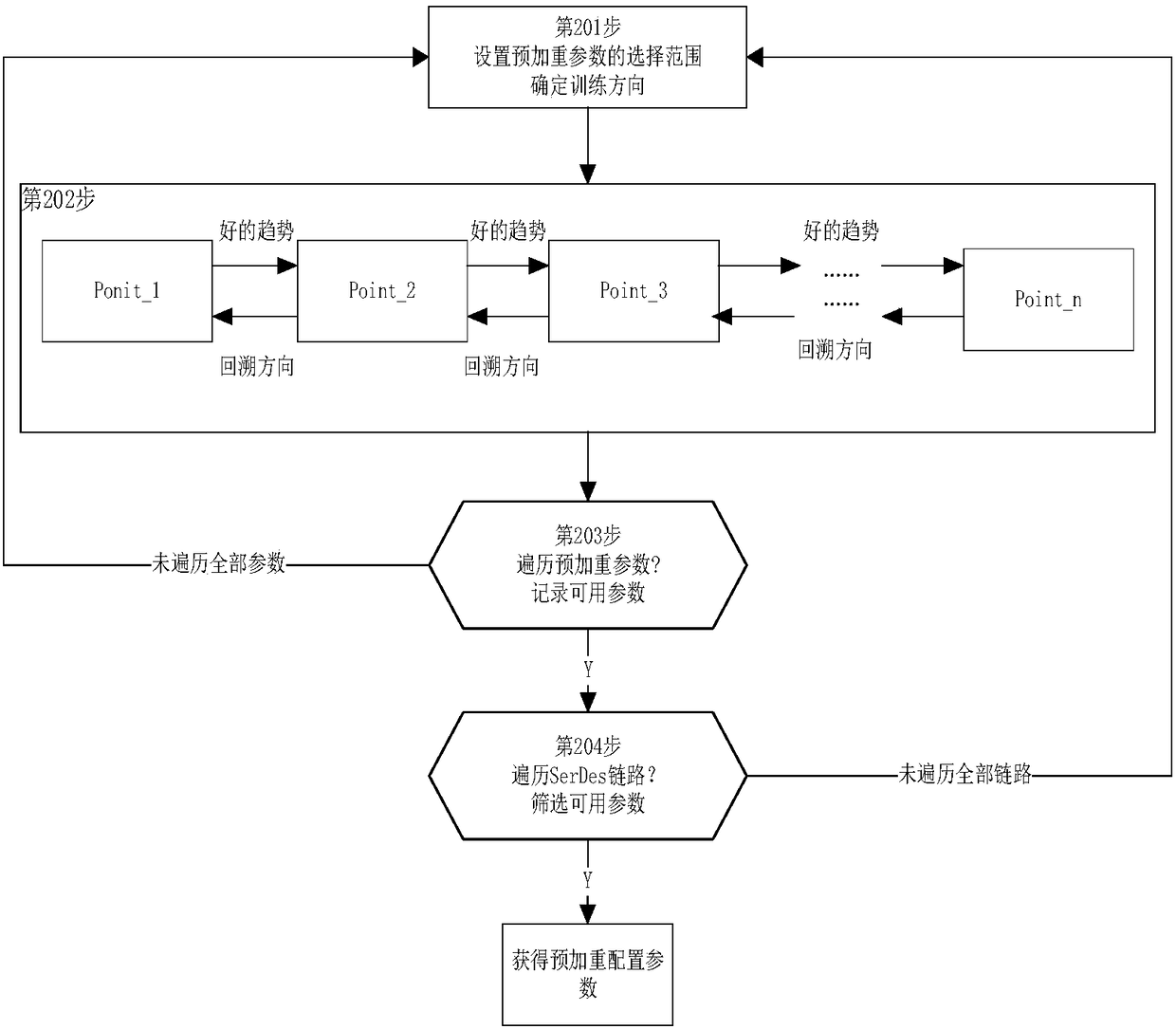

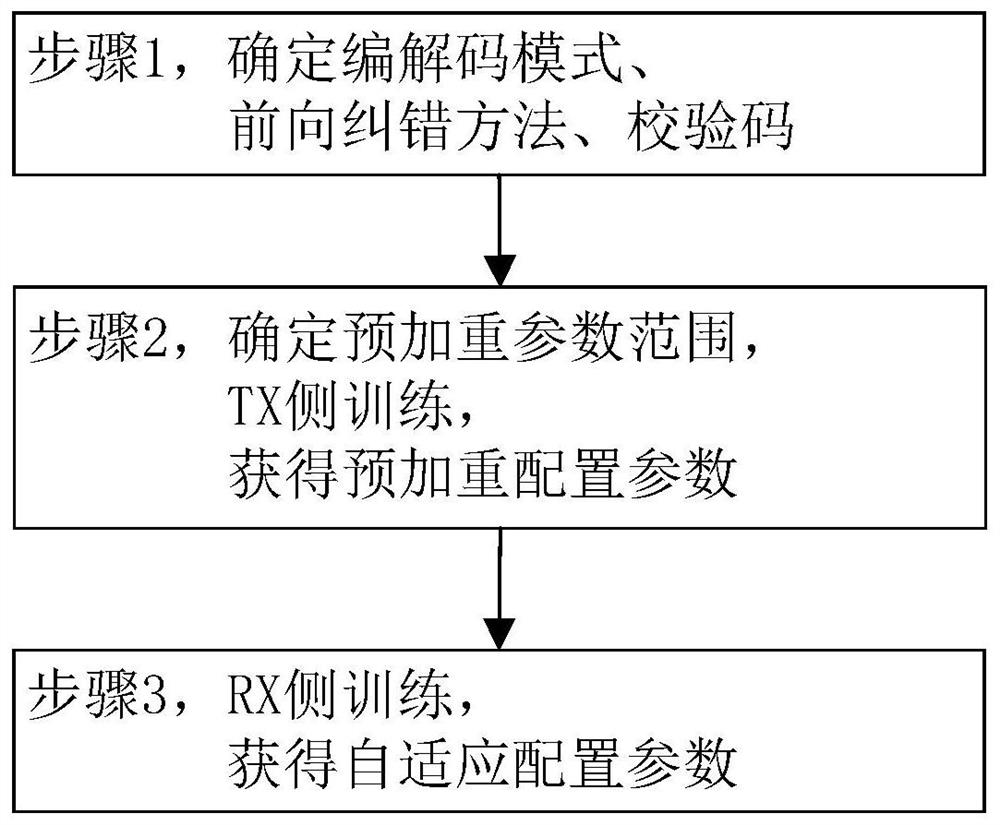

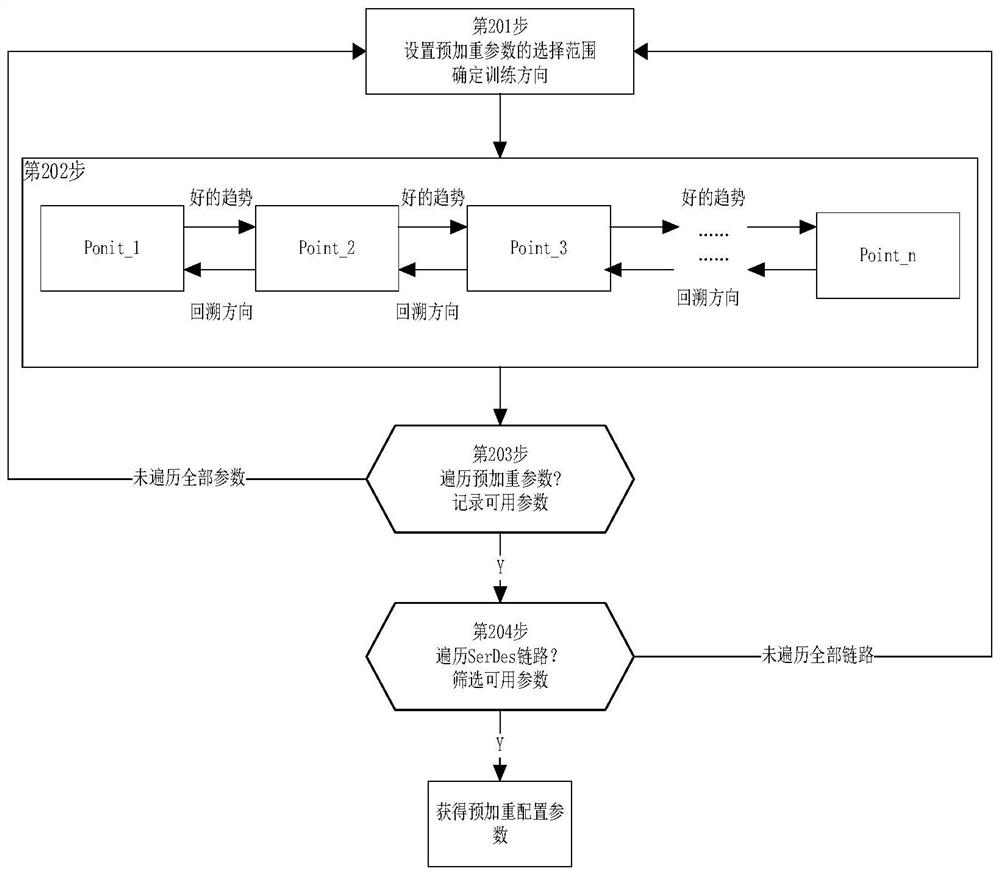

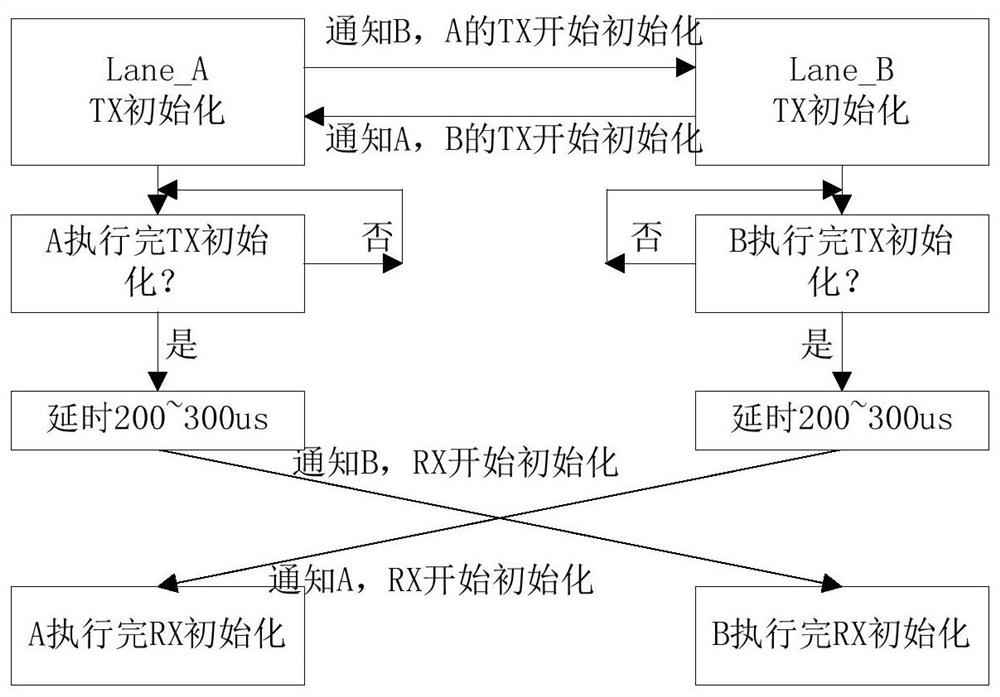

SerDes link parameter automatic debugging method

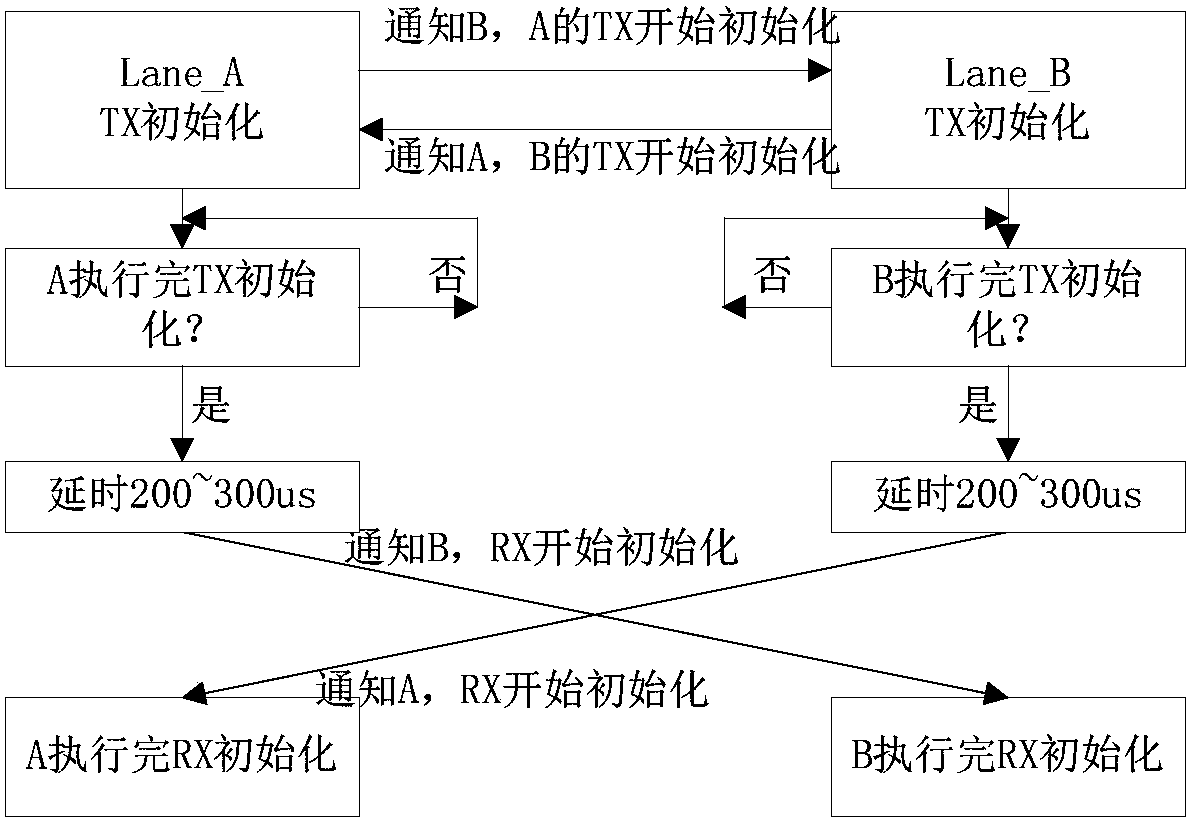

ActiveCN108933600AImprove training efficiencyPrevent deviationParallel/series conversionCoding detailsHigh rateSelf adaptive

Provided is a SerDes link parameter automatic debugging method. The method includes steps: selecting corresponding coding and decoding modes, a forward error correction method and a check code for a link clock and a channel characteristic, then determining a pre-emphasis parameter of a TX side of a link through a backtracking method, experiencing a code stream learning process, and determining anadaptive configuration parameter through training at an RX side of the link. According to the method, strict sequential control of the training of the TX side and the RX side is performed, the link parameter configuration deviation caused by interference generated by bidirectional communication of the link is avoided, and the accuracy of the set parameter of the link can be effectively guaranteed;furthermore, the TX side performs backtracking training on the pre-emphasis parameter currently selected by the link according to an error reporting condition of the FEC decoding of the RX side link,the parameter configuration selected by each time of training can be determined according to the characteristic of the link, and the training efficiency is improved. The method is applicable to various router backboards, and automatic debugging of various link parameters is realized for high-rate SerDes links.

Owner:SANECHIPS TECH CO LTD

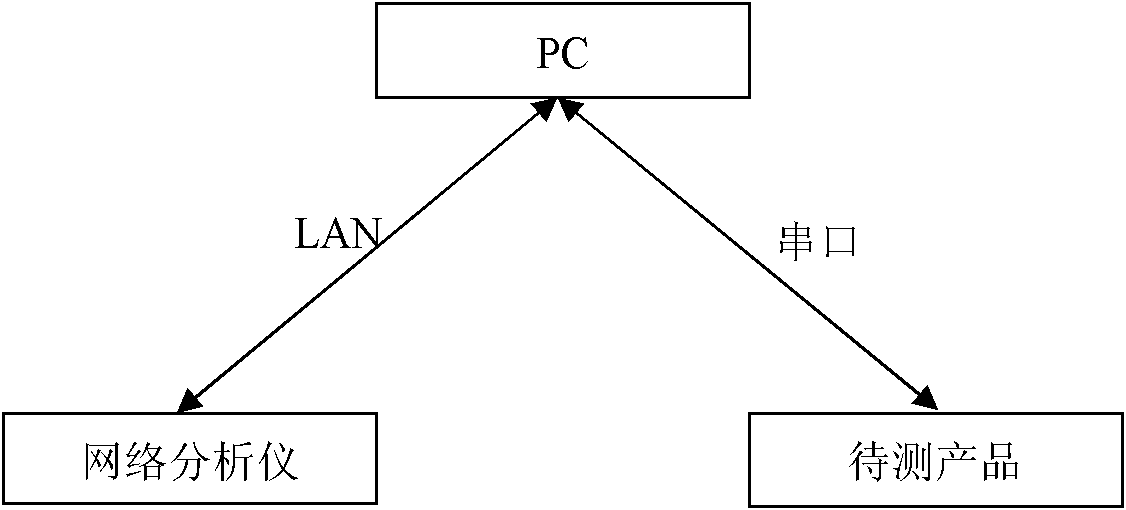

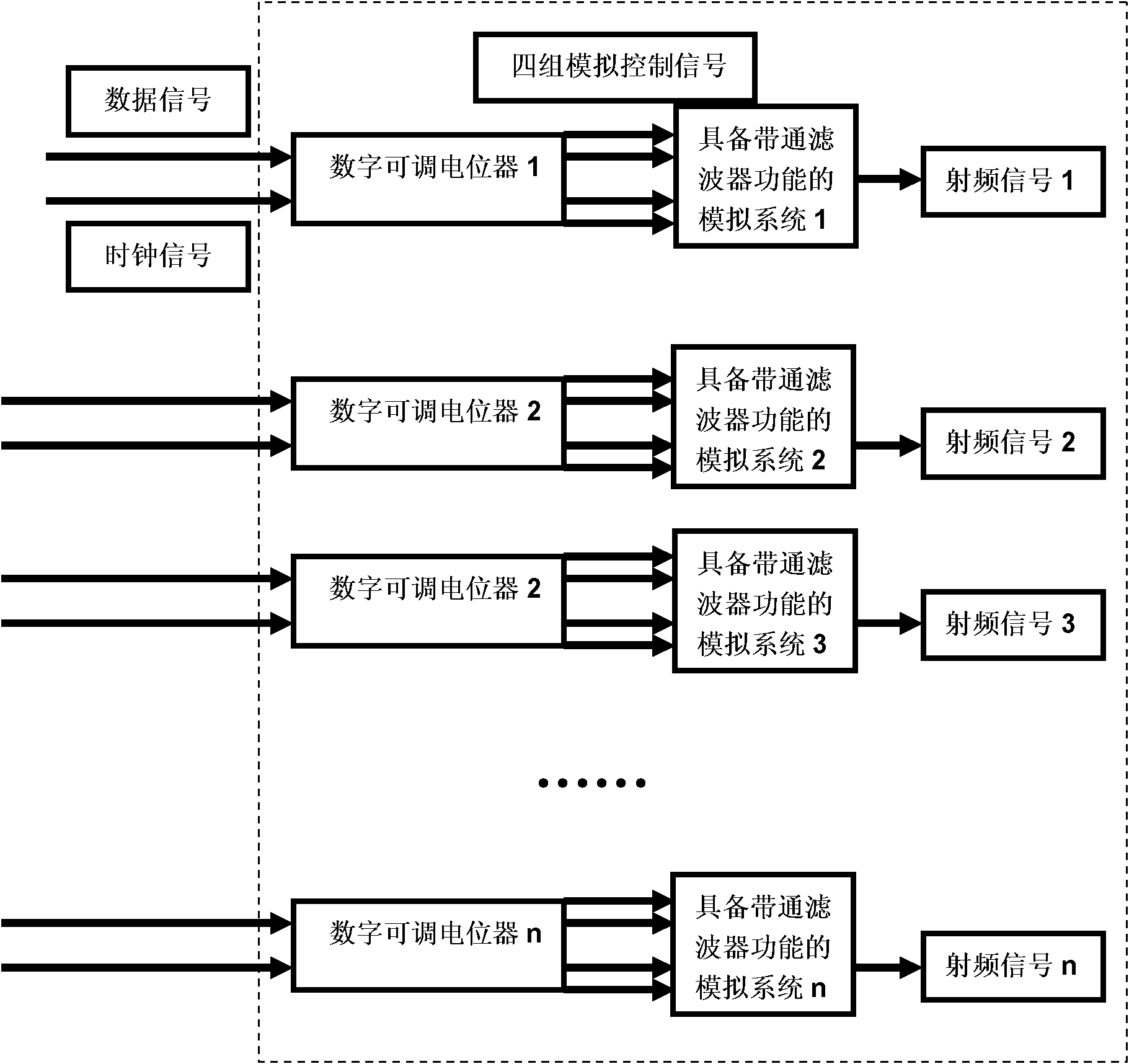

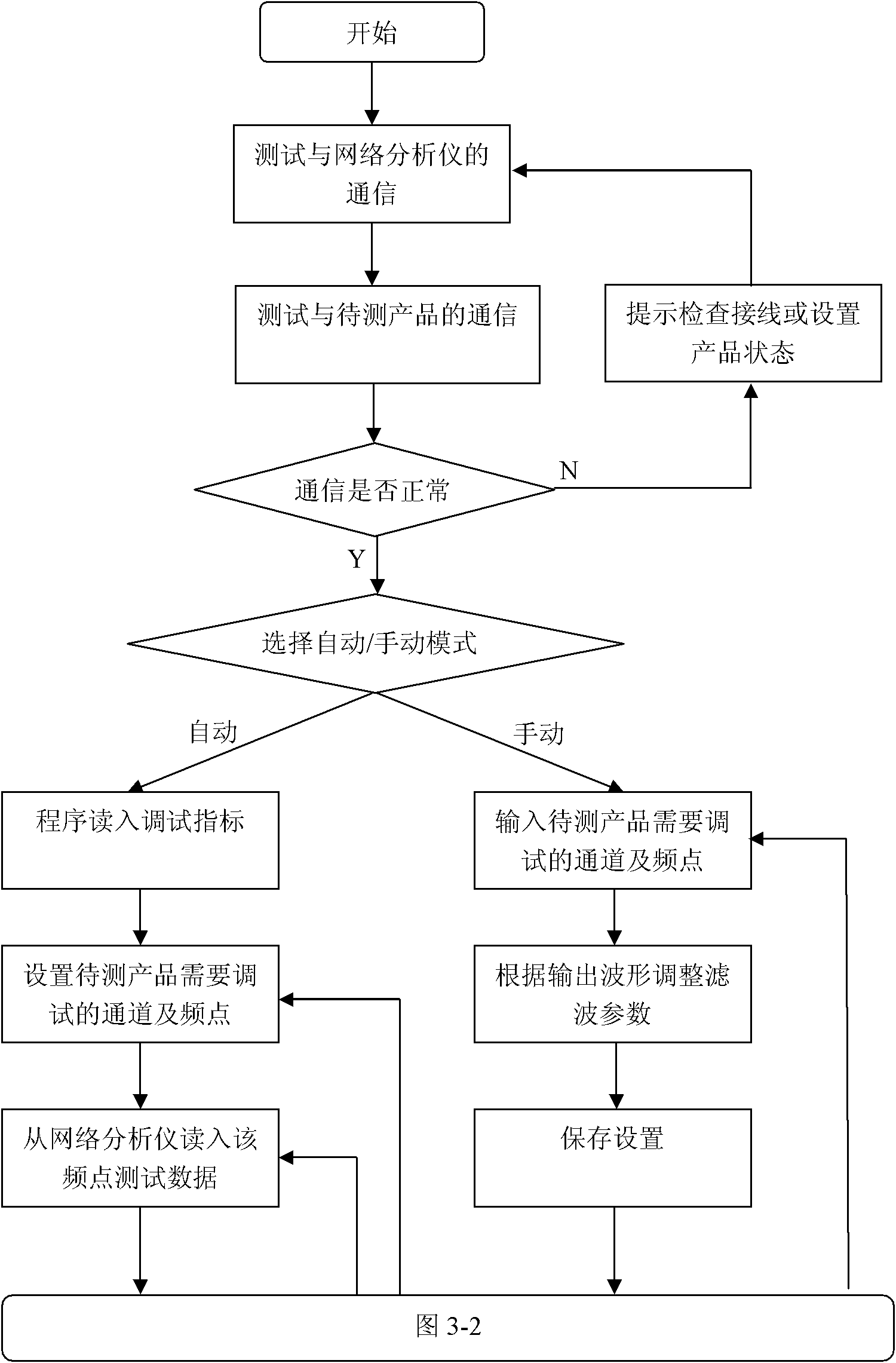

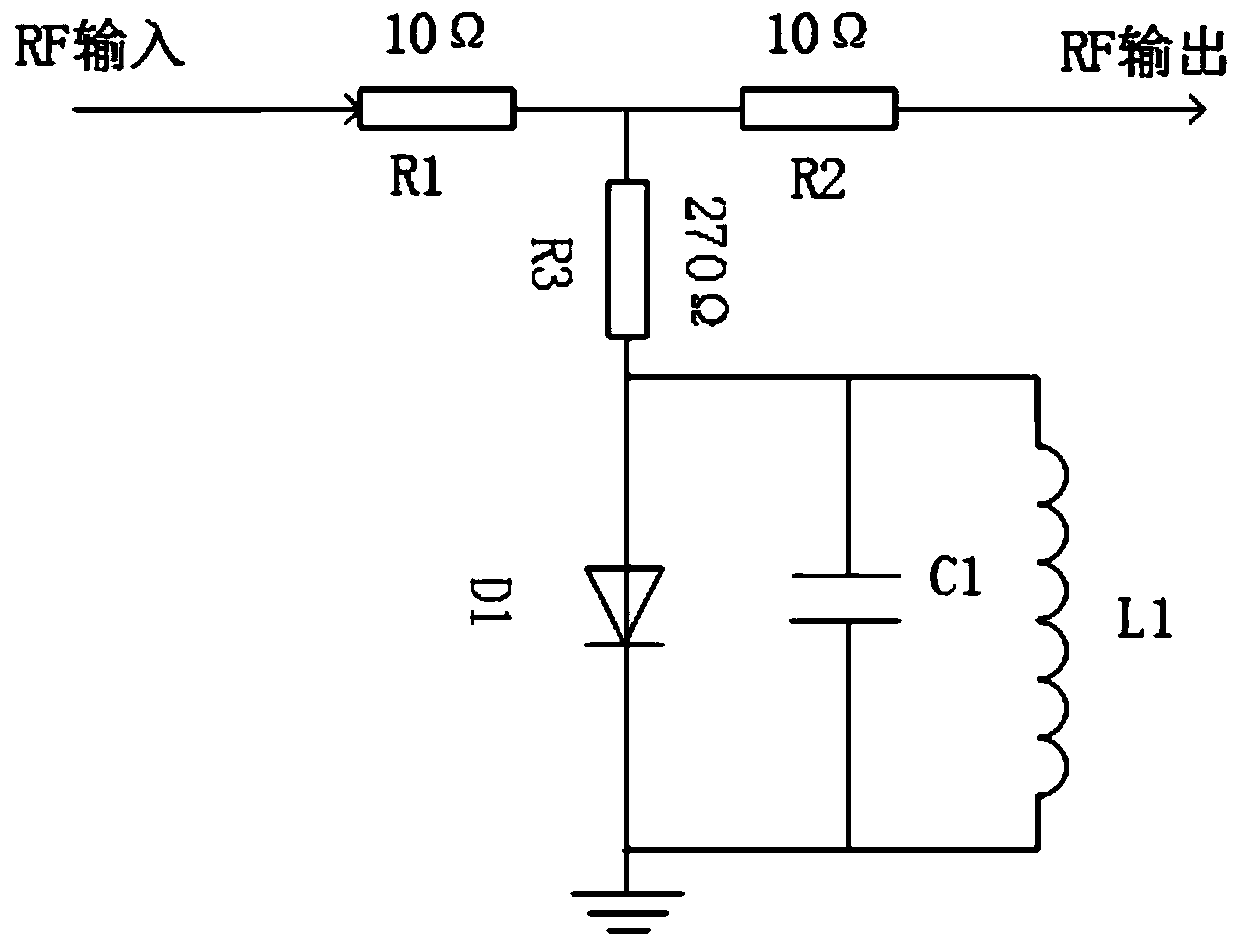

Automatic debugging system for radio-frequency signal products

ActiveCN102164012ARealize automatic debuggingIncrease productivityTransmitters monitoringReceivers monitoringVIT signalsVoltage

The invention discloses an automatic debugging system for radio-frequency signal products, in which a product to be tested, a vector network analyzer and a computer are arranged, wherein the inside of the computer is provided with a preset table and debugging packets corresponding to each channel, the preset table is used for presetting the frequency point, bandwidth and OOB (out of band) signal curbing and signal gain factor indexes of each corresponding frequency channel within the radio-frequency signal range, and the frequency points in the preset table correspond to the frequency points of all frequency channels to be tested one by one; each channel has n debugging packets, each debugging packet contains groups of debugging control signals which are in a channel and correspond to each frequency channel, each group of debugging control signals refers to four analog voltages, and the four analog voltages are respectively used for debugging the frequency point, bandwidth and OOB (out of band) signal curbing and signal gain factor indexes of the debugging channel; and the computer is connected with the product to be tested by a communication bus, and connected with the vector network analyzer by an LAN line.

Owner:SUMEC MACHINERY & ELECTRIC

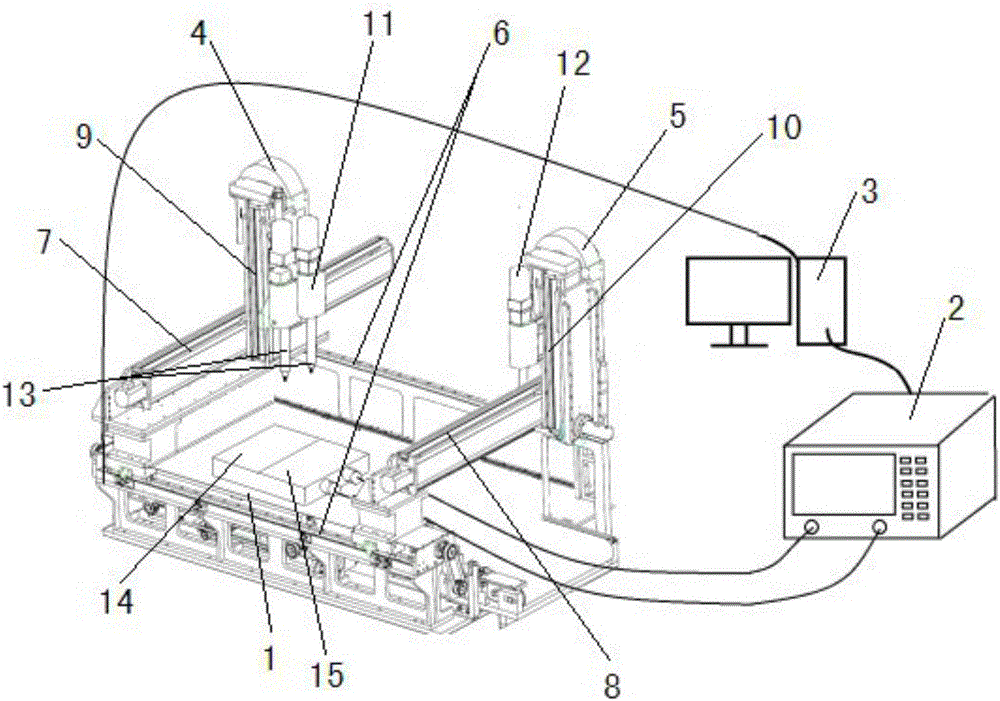

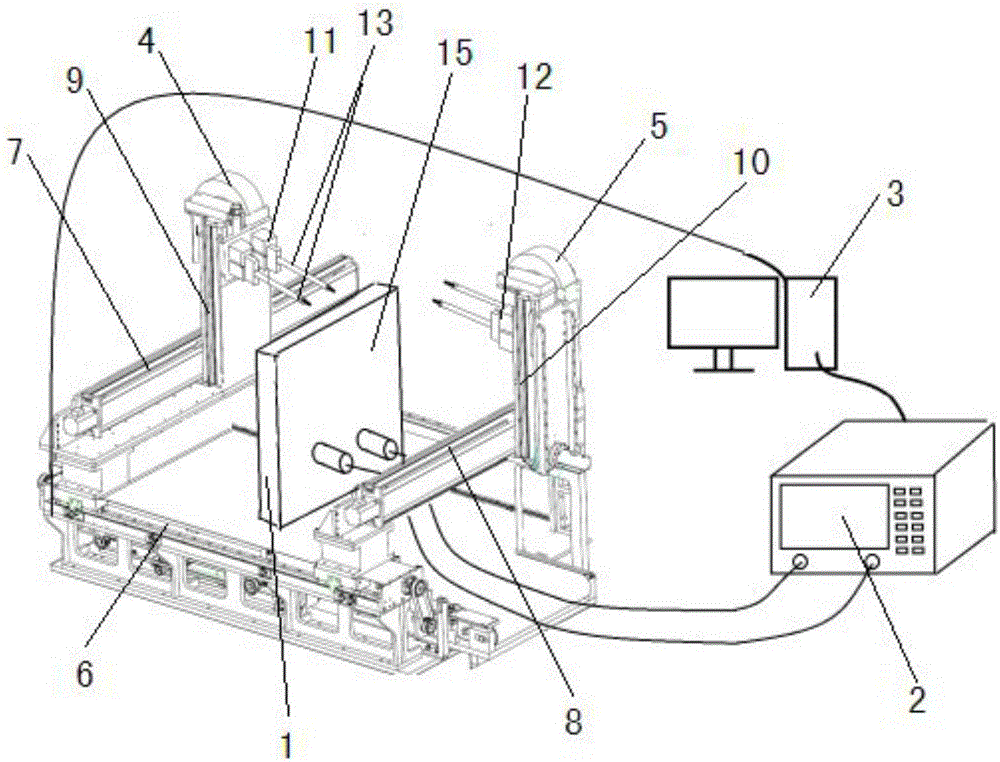

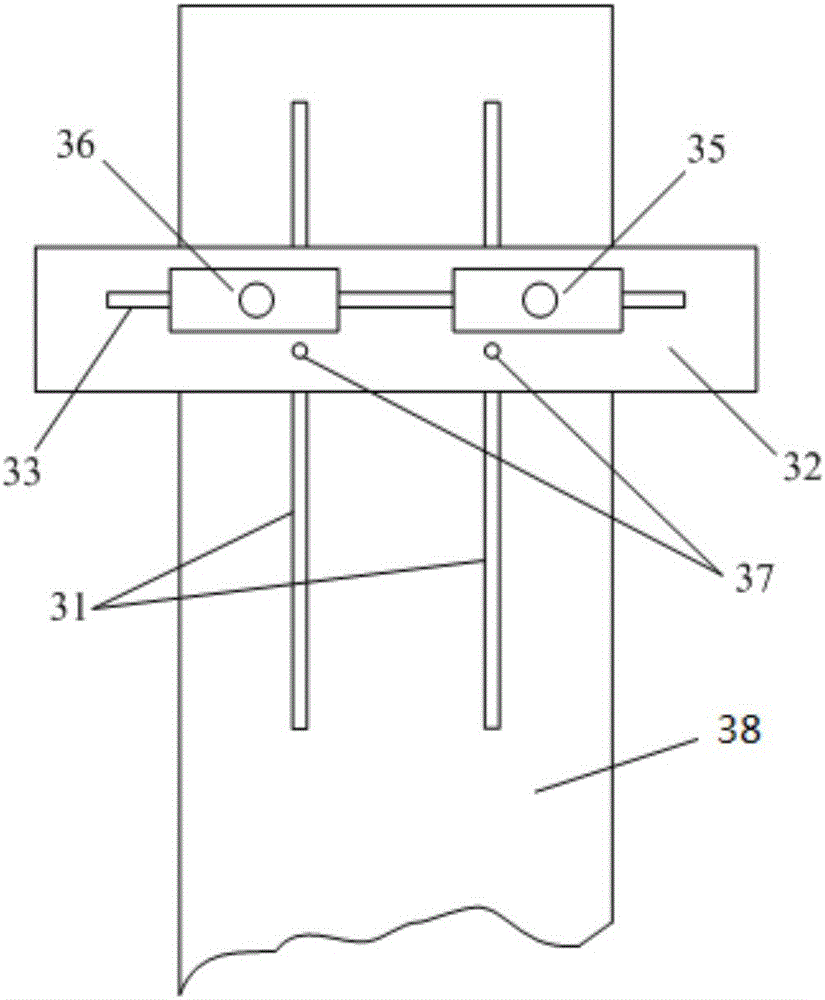

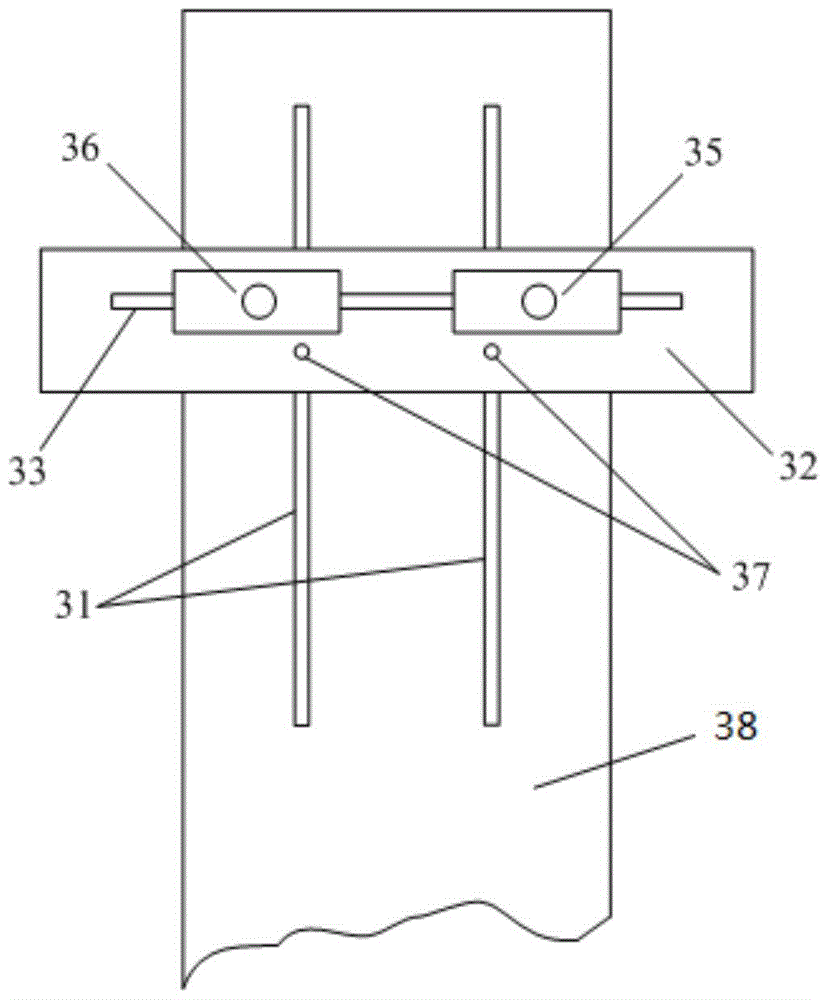

Filter automatic debugging system based on double three-axis motion mechanical arm

InactiveCN105067921ARealize automatic debuggingImprove consistencyElectrical testingComputer engineering

The invention relates to the field of filter debugging technologies, in particular to a filter automatic debugging system based on double three-axis motion mechanical arms. The filter automatic debugging system comprises a vector network analyzer, a computer and mobile debugging mechanisms, wherein an input end of the vector network analyzer is connected with a debugged filter, an output end is connected with the computer, and the vector network analyzer is used for measuring electrical characteristics of the debugged filter; an input end of the computer is connected with the vector network analyzer, an output end is connected with the mobile debugging mechanisms, and the computer is used for acquiring the electrical characteristics measured by the vector network analyzer, calculating tuning amount of a tuning screw in the filter and transmitting the tuning amount to the mobile debugging mechanisms; and the mobile debugging mechanisms are connected with the output end of the computer, a debugging tool bit group which can move along x, y and z directions is arranged on each mobile debugging mechanism, and the mobile debugging mechanisms are used for debugging coordinating screws of the filter. The mobile debugging mechanisms are used for debugging two debugging regions of the filter respectively, thus the filter automatic debugging system based on the double three-axis motion mechanical arms can achieve automatic debugging, liberates manpower, and has high debugging efficiency.

Owner:WUHAN FINGU ELECTRONICS TECH

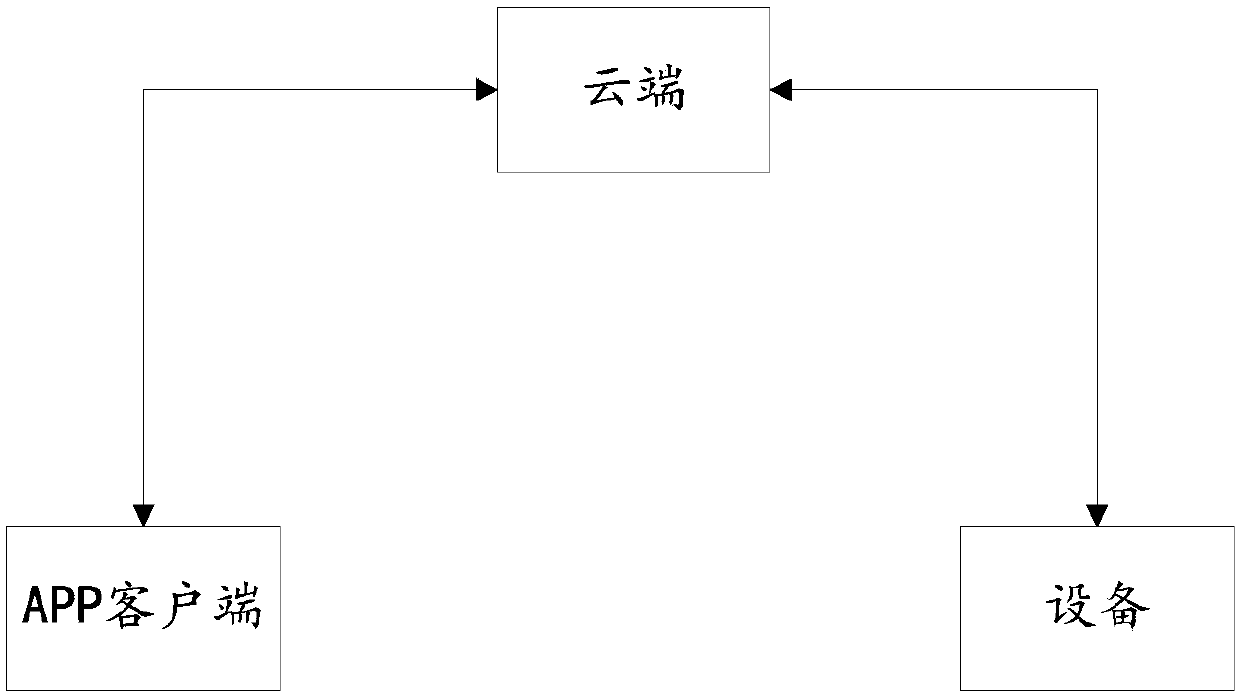

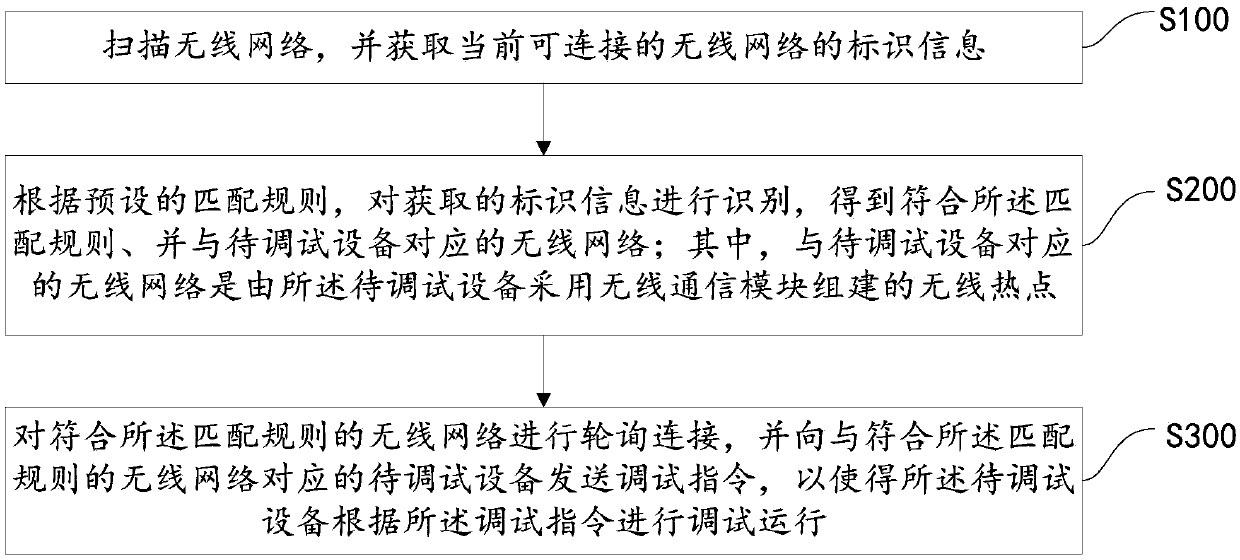

Equipment debugging method, device and system, and storage medium

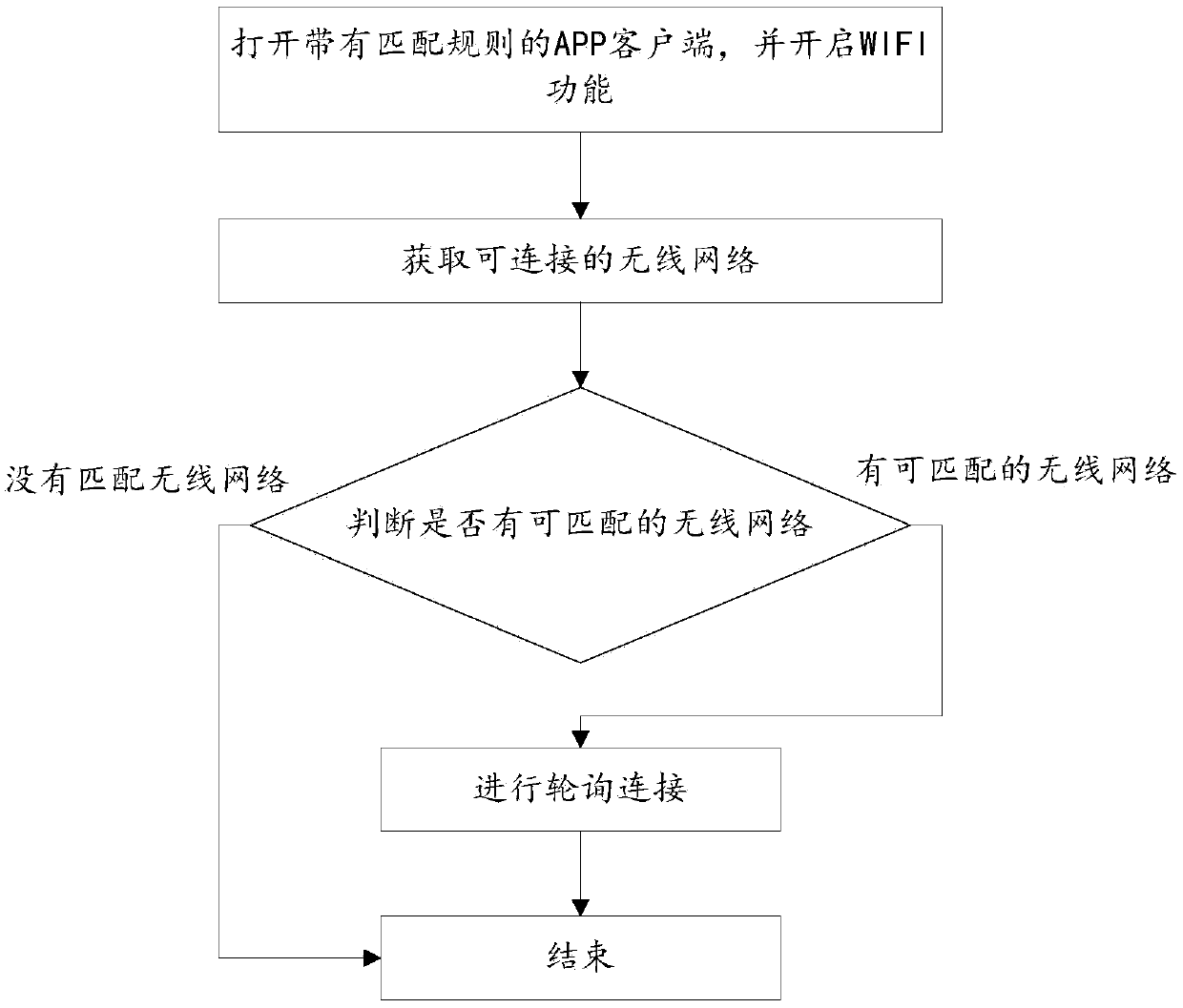

ActiveCN109548045AEnable connectivityRealize automatic debuggingAssess restrictionConnection managementThe InternetData transmission

The invention discloses an equipment debugging method, device and system, and a storage medium. The method comprises the steps of scanning an wireless network, and acquiring identifier information ofa currently connectable wireless network; recognizing the acquired identifier information according to a preset matching rule to acquire the wireless network corresponding to equipment to be debuggedaccordant with the matching rule, wherein the wireless network corresponding to the equipment to be debugged is a wireless hotspot built by the equipment to be debugged through using a wireless communication module; and polling and connecting the wireless network accordant with the matching rule, and sending a debugging command to the equipment to be debugged corresponding to the wireless networkaccordant with the matching rule, thus allowing the equipment to be debugged to perform debugging and running according to the debugging command. The client and the equipment do not need to be connected with the Internet, the data transmission speed and the debugging efficiency can be effectively improved, meanwhile, the whole debugging process dose not need artificial participation, the automaticcommunication connection and automatic debugging of the client and the debugging equipment are achieved, and the automation degree of equipment debugging is high.

Owner:GUANGDONG VANWARD NEW ELECTRIC CO LTD

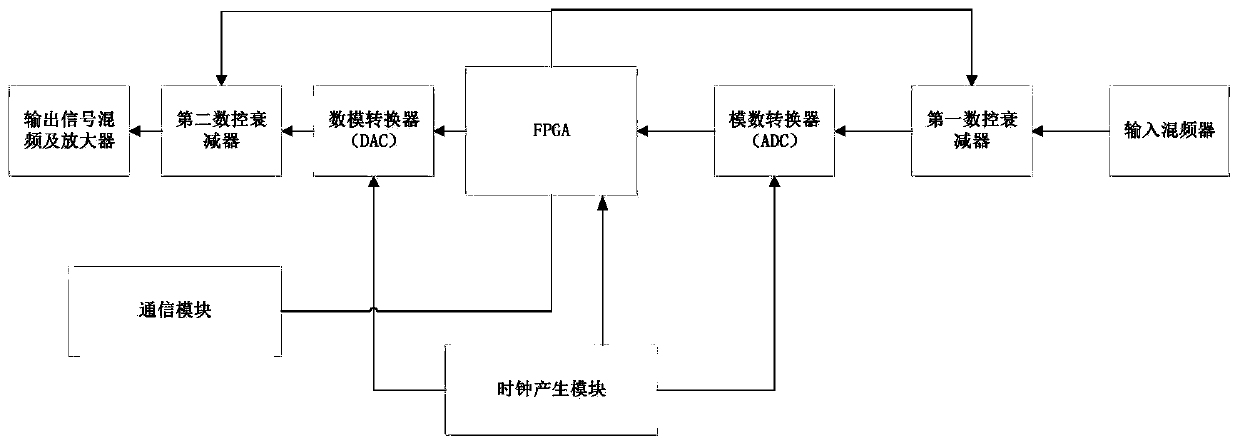

Automatic debugging and testing system and method for intermodulation of power amplifier module

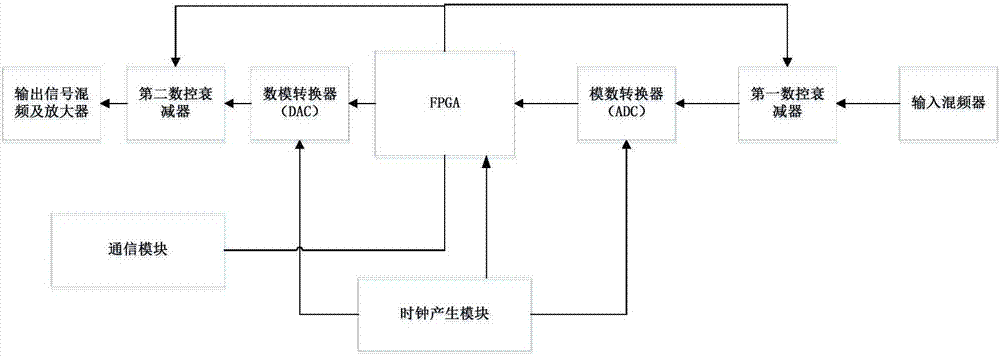

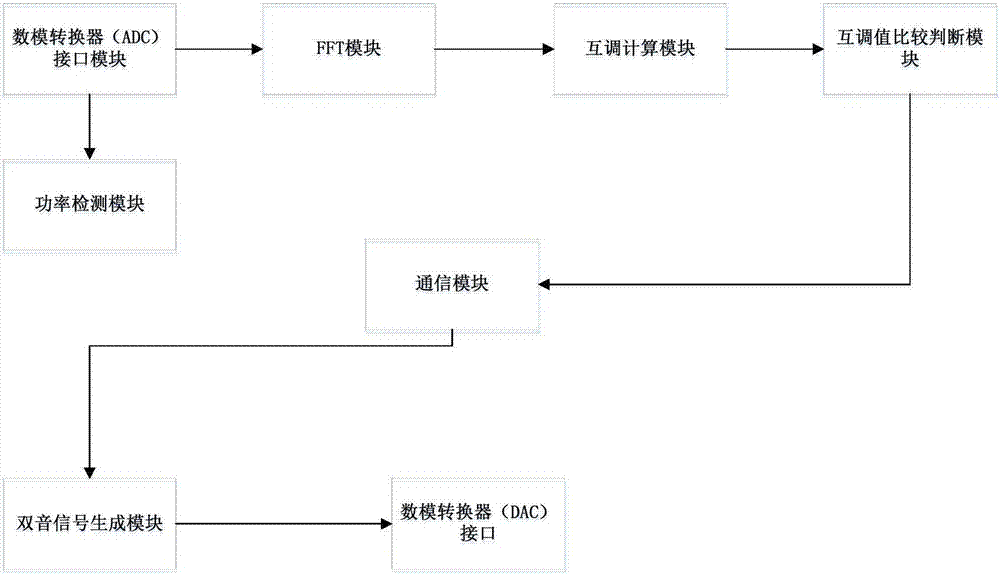

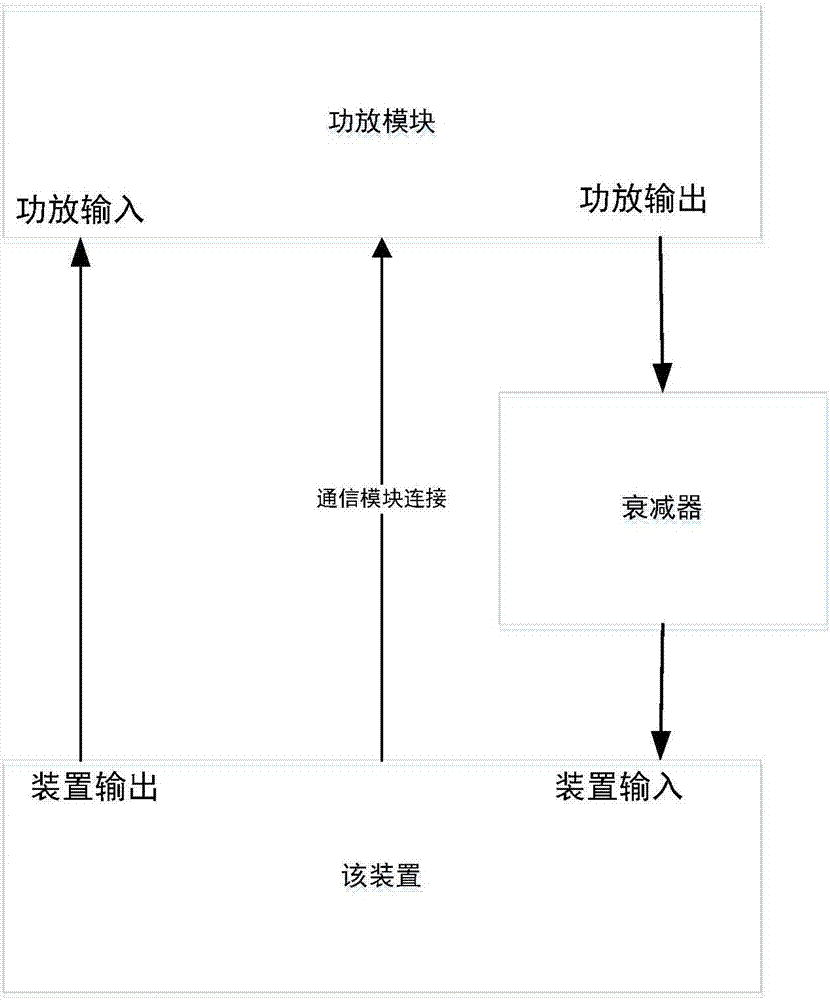

ActiveCN107222268AReduce manufacturing costRealize automatic debuggingTransmitters monitoringAudio power amplifierEngineering

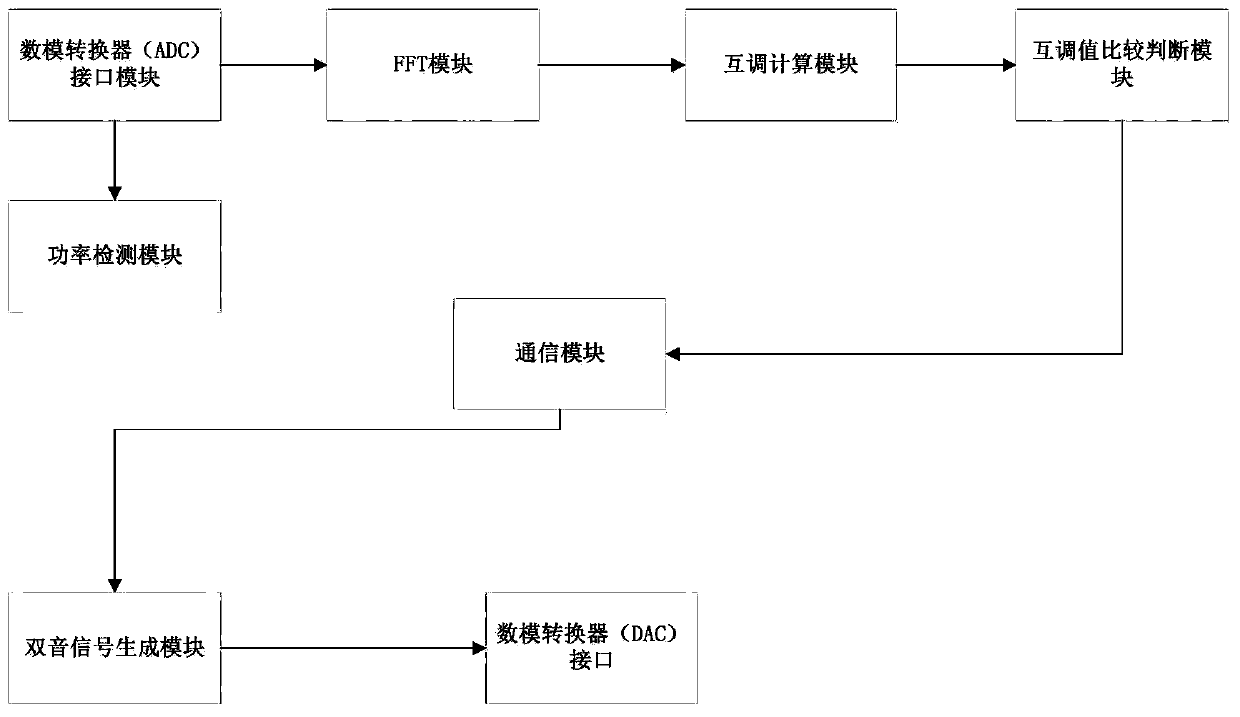

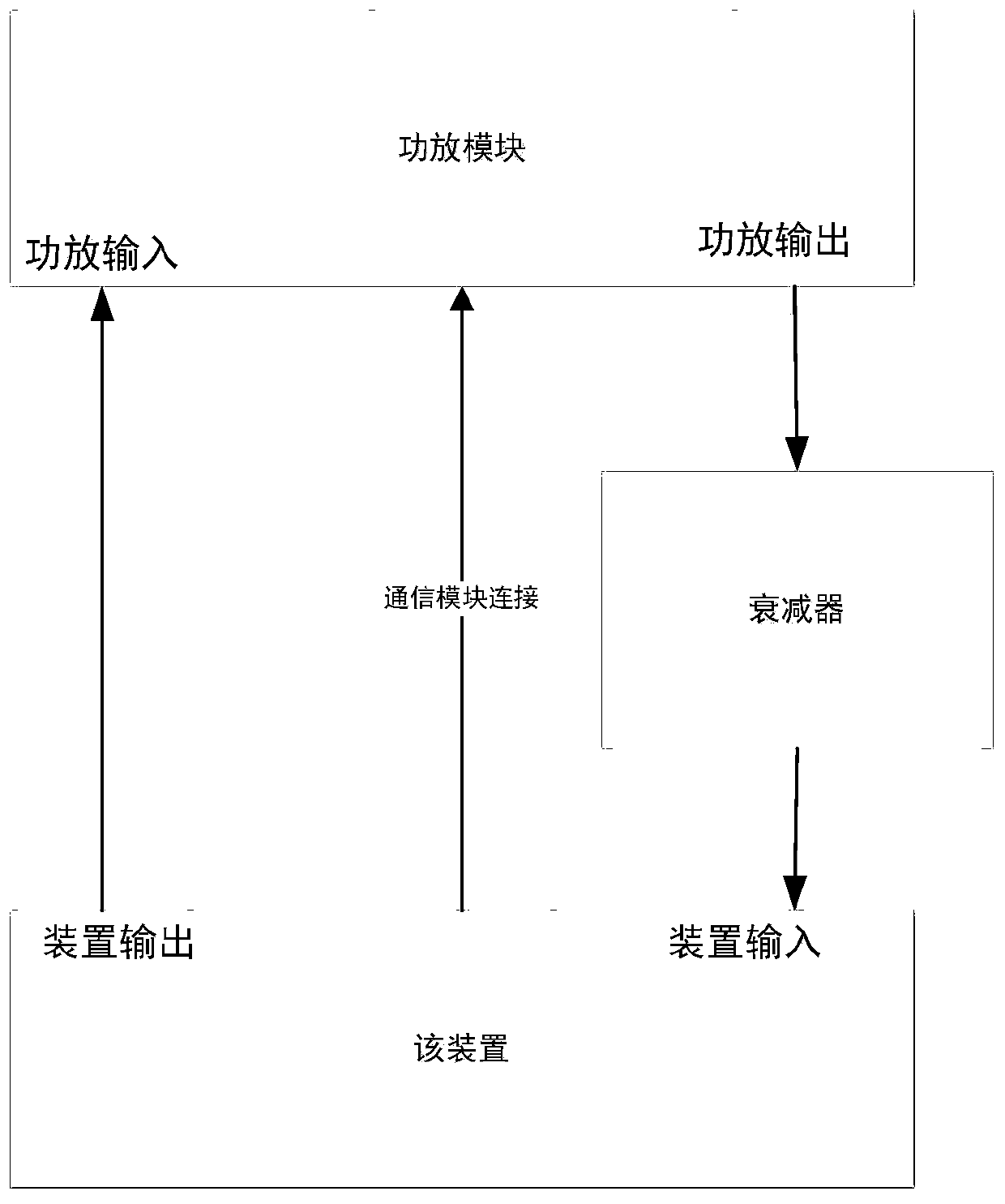

The invention discloses an automatic debugging and testing system and a method for intermodulation of a power amplifier module. The system comprises an input mixer, an analog-to-digital converter (ADC), a digital attenuator, a digital-to-analog converter (DAC), an output signal mixing and amplifier, an FPGA chip, a communication module and a clock generation module, wherein inner program modules of the FPGA chip comprise an ADC interface module, an FFT module, a power detection module, a dual tone signal generation module, an intermodulation calculation module, an intermodulation value comparison and judgment module and a DAC interface. Automation of debugging and testing during the power amplifier module production process can be realized, the efficiency is improved, and the power amplifier module production cost is reduced.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

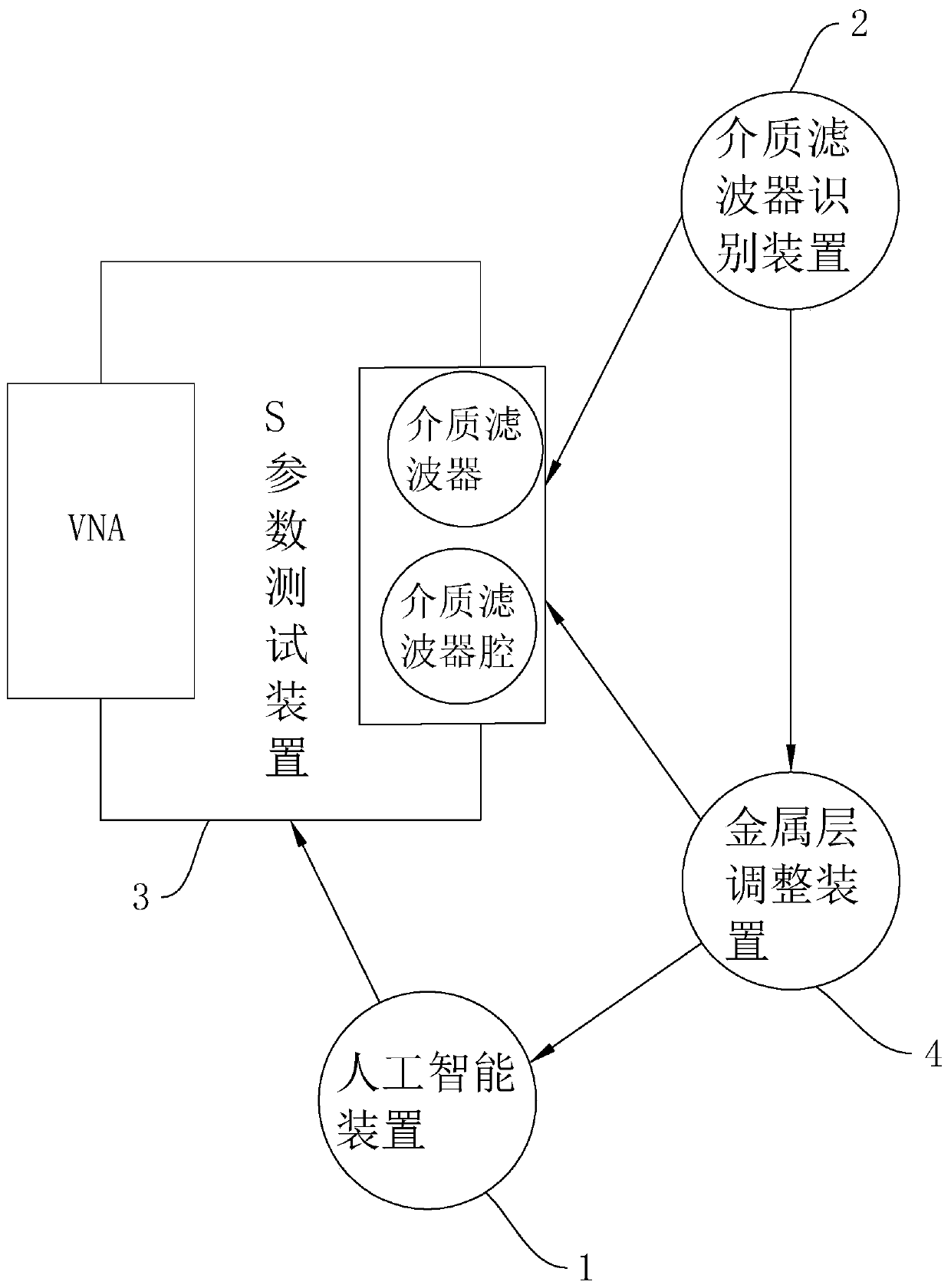

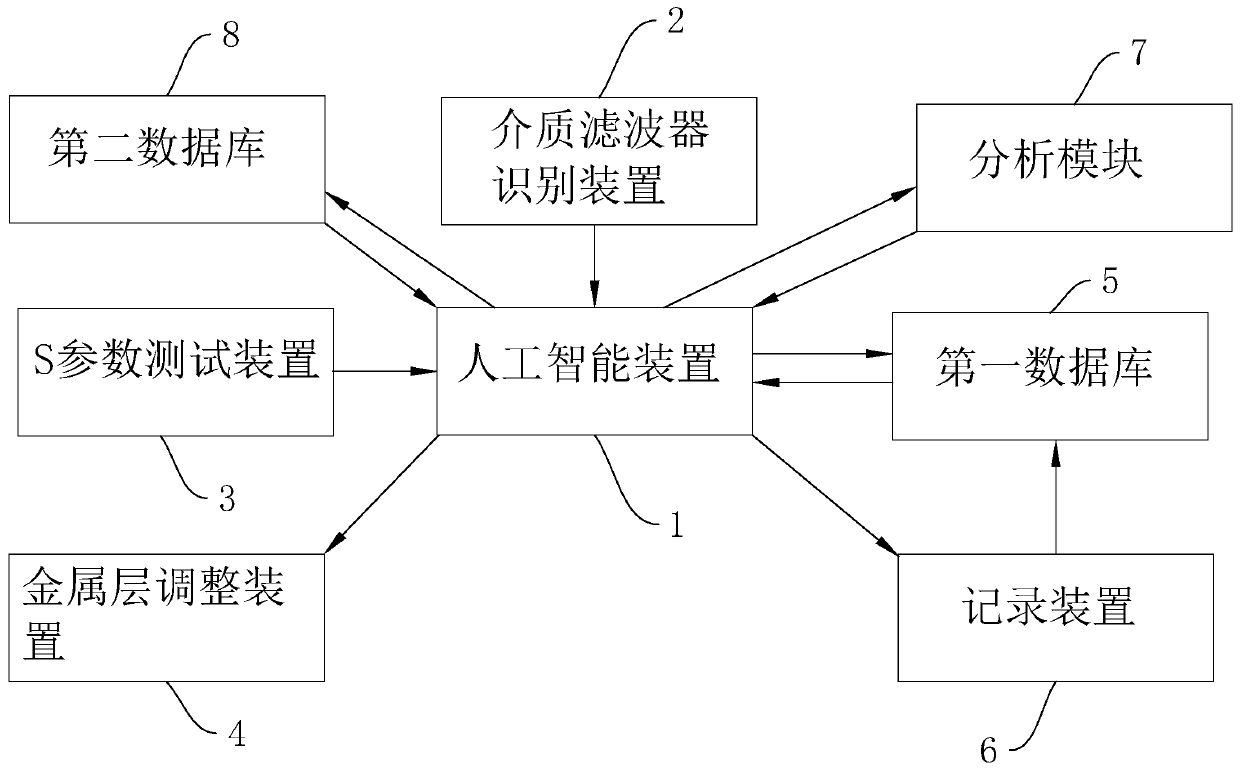

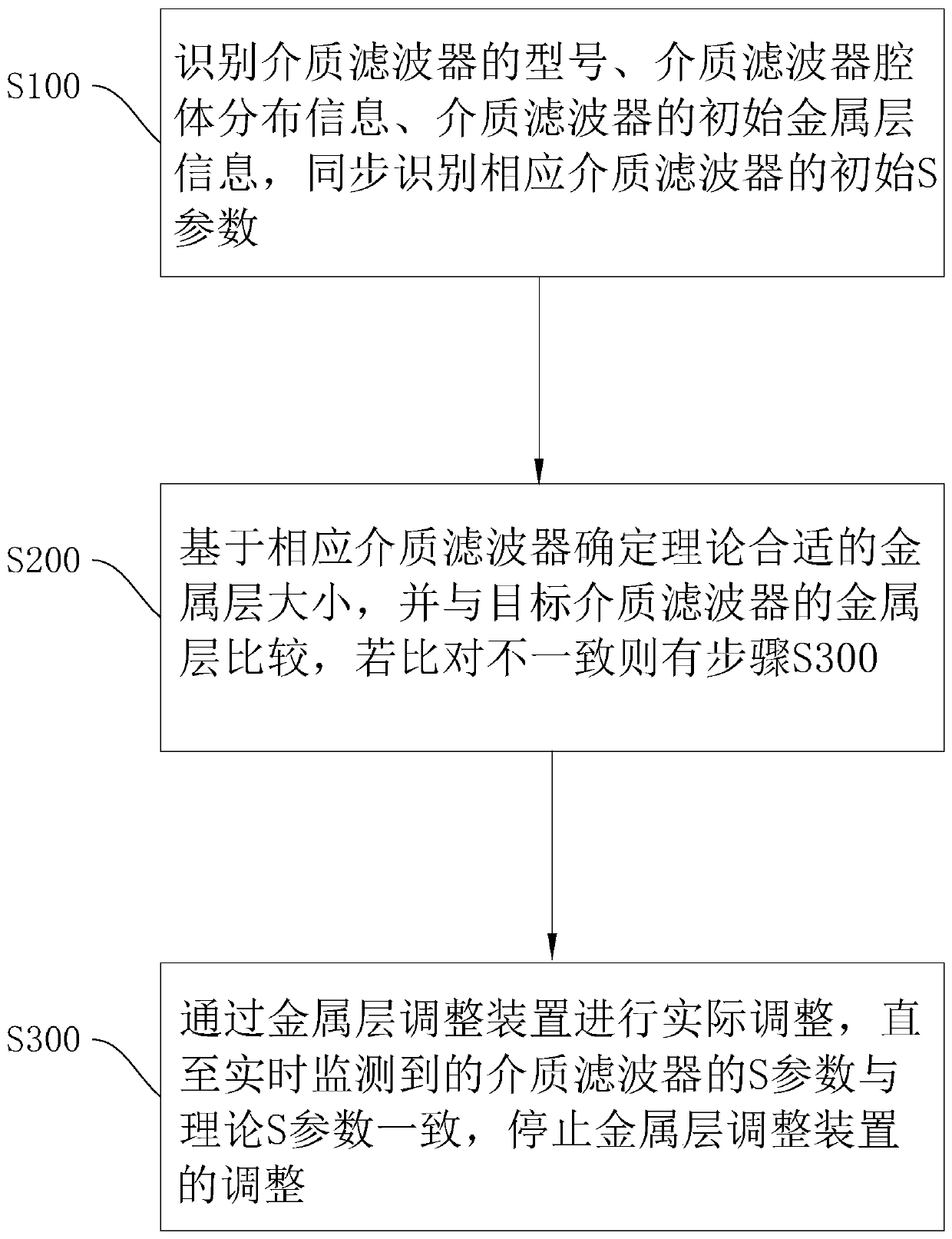

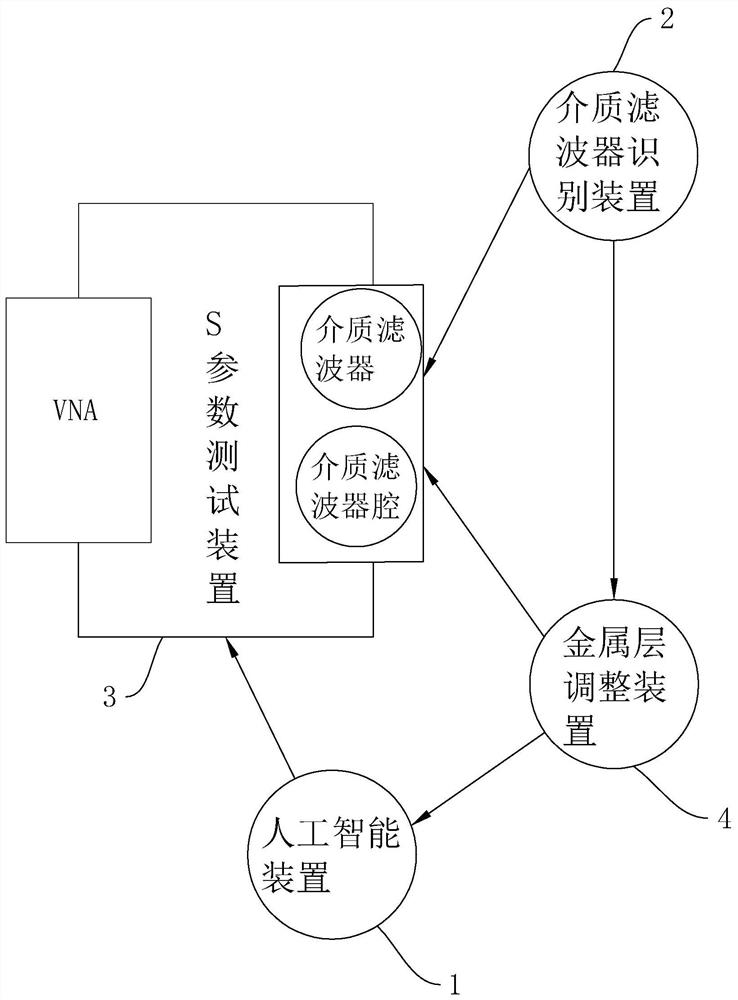

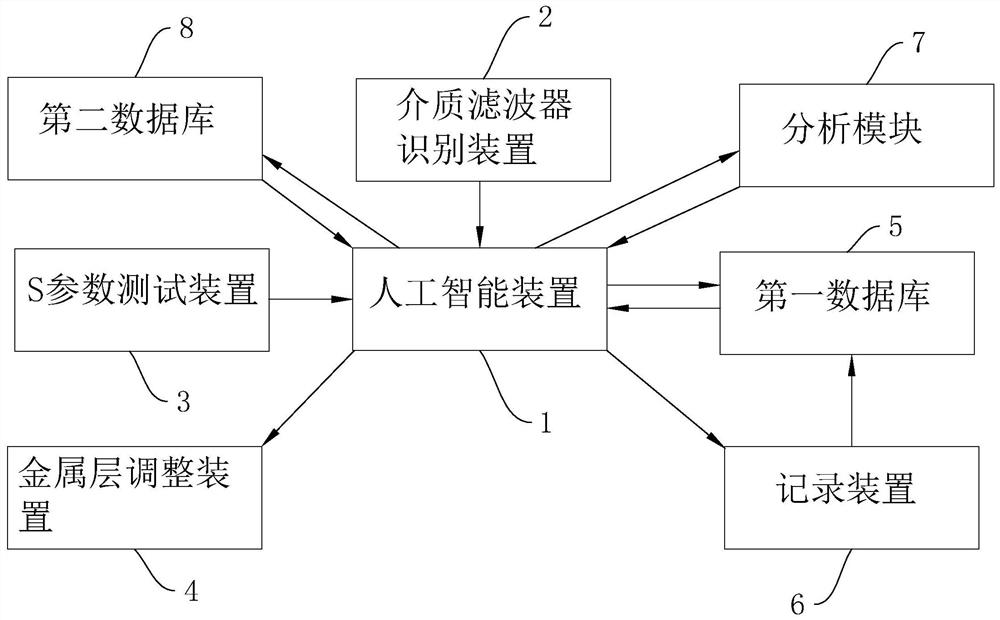

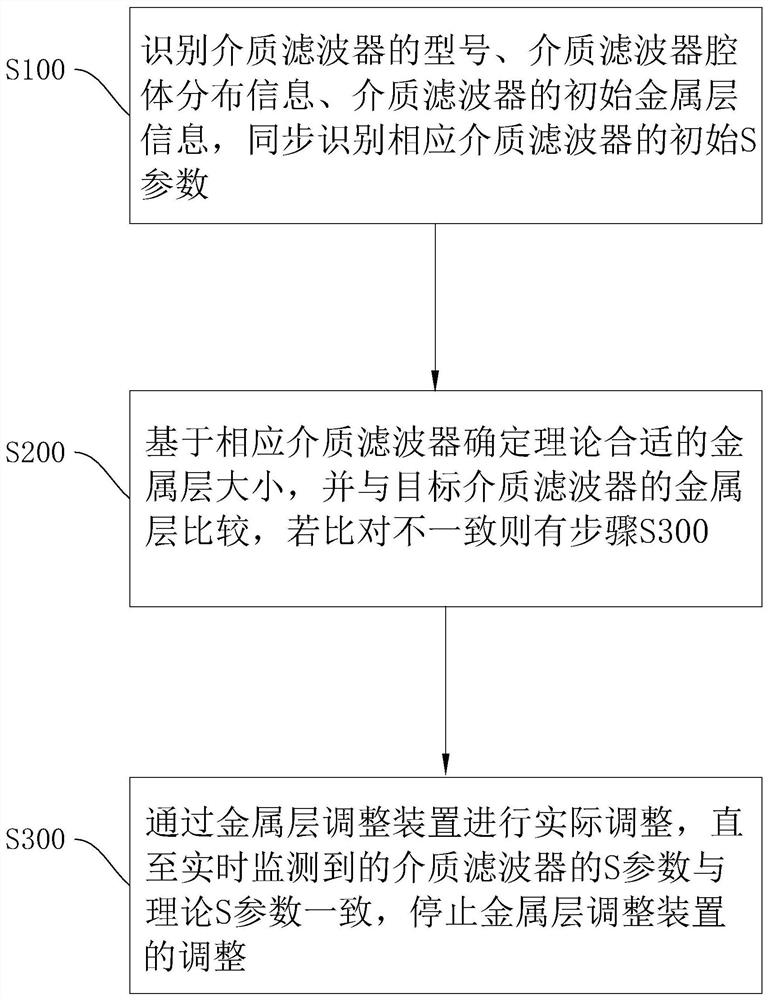

Automatic debugging system and method for dielectric filter

ActiveCN111313136ARealize automatic debuggingReduce labor costsWaveguide type devicesDielectricTest set

The invention relates to an automatic debugging system and method for a dielectric filter, relates to the field of 5G mobile communication dielectric filters, and solves the problem that due to the production characteristics and index requirements of the dielectric filter, each dielectric filter basically needs to be debugged, which is more troublesome. The method comprises: processing the targetdielectric filter through the metal layer adjusting device by an artificial intelligence device based on a metal layer data difference between metal layer information of a target dielectric filter andinitial metal layer information, and stopping processing until the S parameter data acquired by the artificial intelligence device through the S parameter testing device is consistent with the theoretical S parameter data. Through an artificial intelligence AI mode, automatic debugging of the dielectric filter is realized, the labor cost is reduced, and the productivity is improved.

Owner:深圳润芯信息技术有限公司

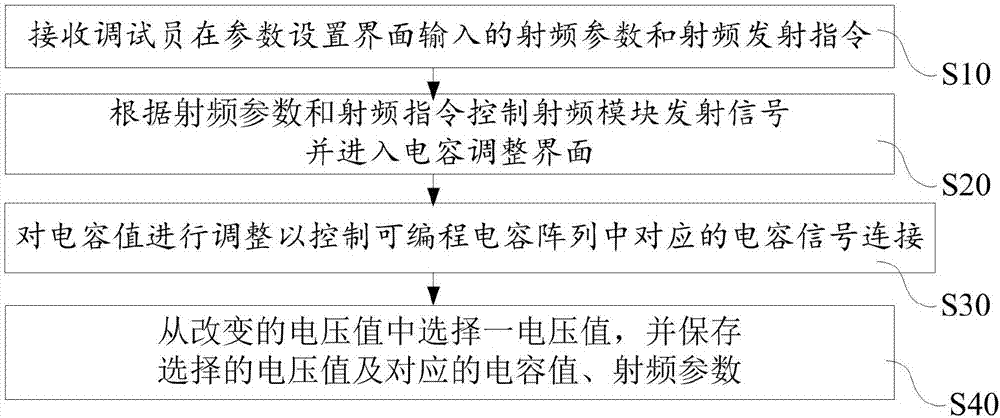

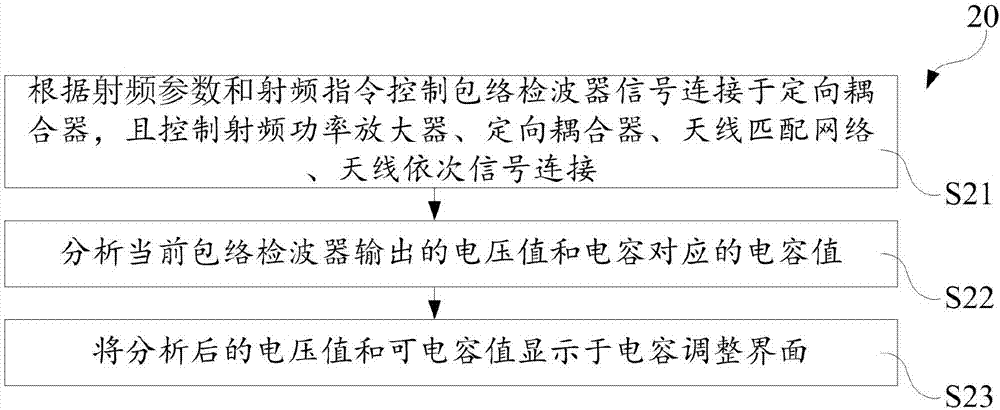

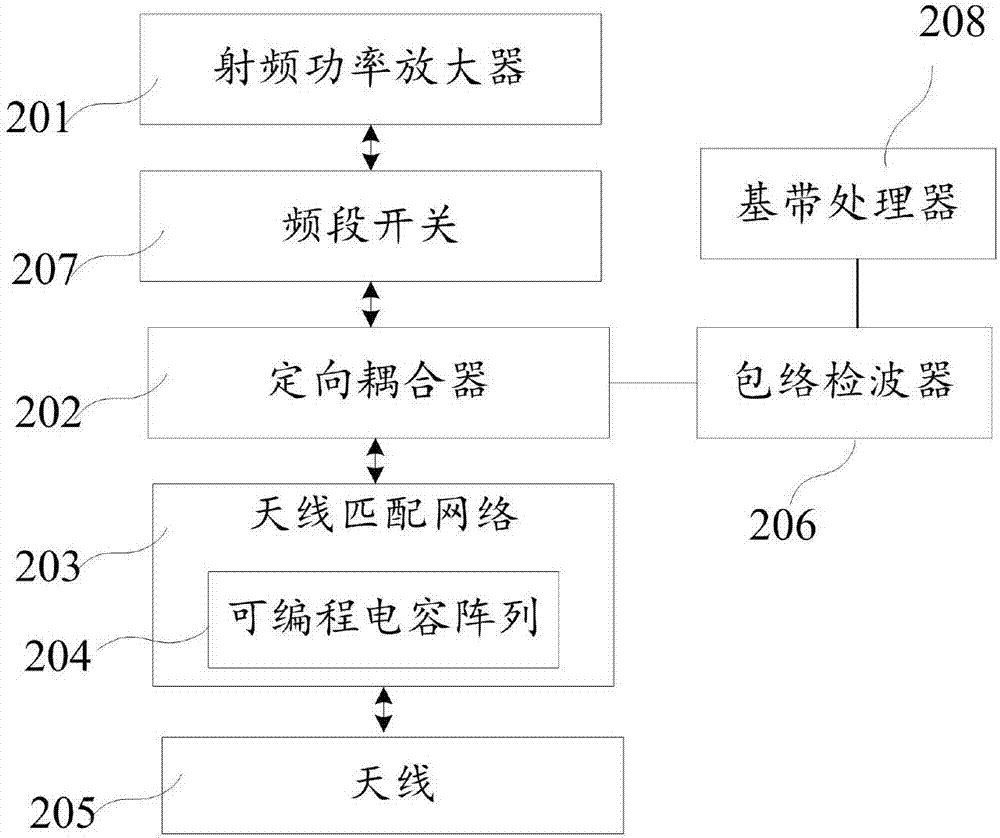

Antenna matching debugging method and terminal thereof

InactiveCN106899360ASemi-automaticRealize automatic debuggingTransmitters monitoringReceivers monitoringRadio frequencyCapacitance

The invention discloses an antenna matching debugging method and terminal thereof. The antenna matching debugging method comprises the following steps: receiving a radio frequency parameter and a radio frequency emission instruction input in a parameter setting interface by a debugging personnel; controlling a radio frequency module to emit a signal according to the radio frequency emission instruction, and entering a capacitance adjusting interface, wherein the adjusting interface comprises a voltage value and an adjustable capacitance value; adjusting the capacitance value so as to conduct the capacitance in the programmable capacitance array, thereby enabling a voltage value to be changed along the adjusting of the capacitance value; selecting a voltage value according to the changed voltage value, and saving the saved voltage value, the corresponding capacitance value and the radio frequency parameter. By use of the above method disclosed by the invention, the semi-automatic or automatic debugging of the antenna matching debugging can be realized, the operation is simple, convenient and high in debugging efficiency. Correspondingly, the terminal capable of debugging the antenna has the above mentioned effect as well.

Owner:GUIZHOU FORTUNESHIP TECH CO LTD

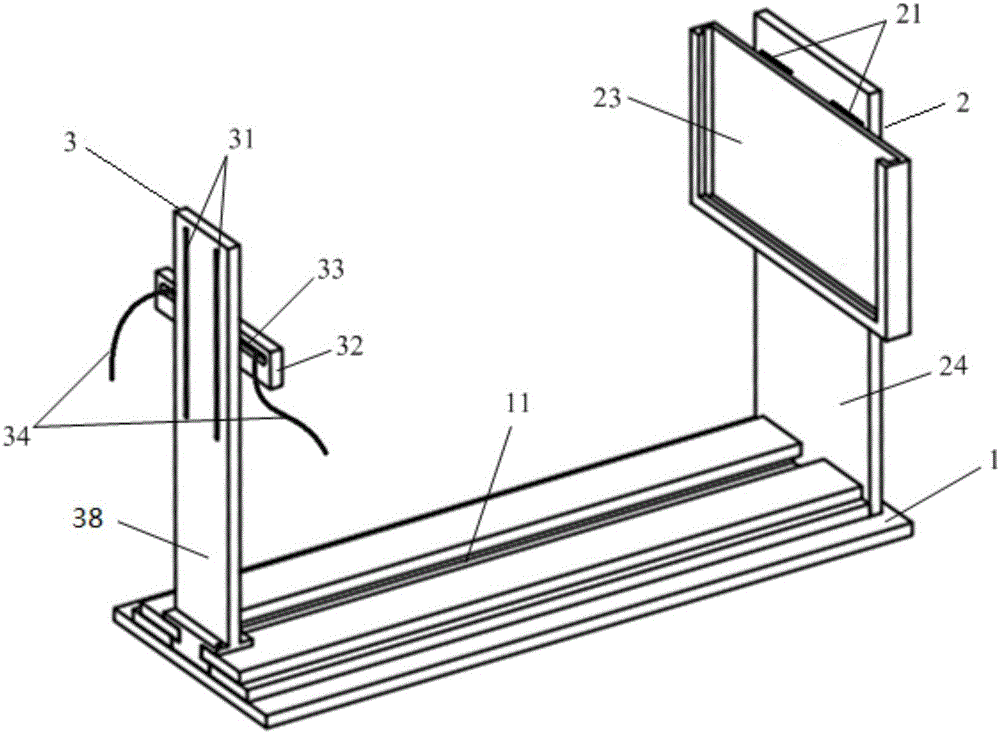

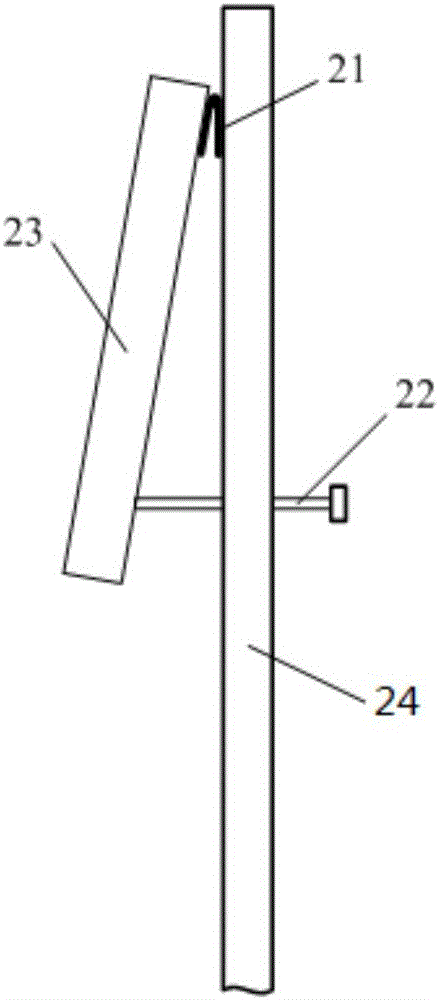

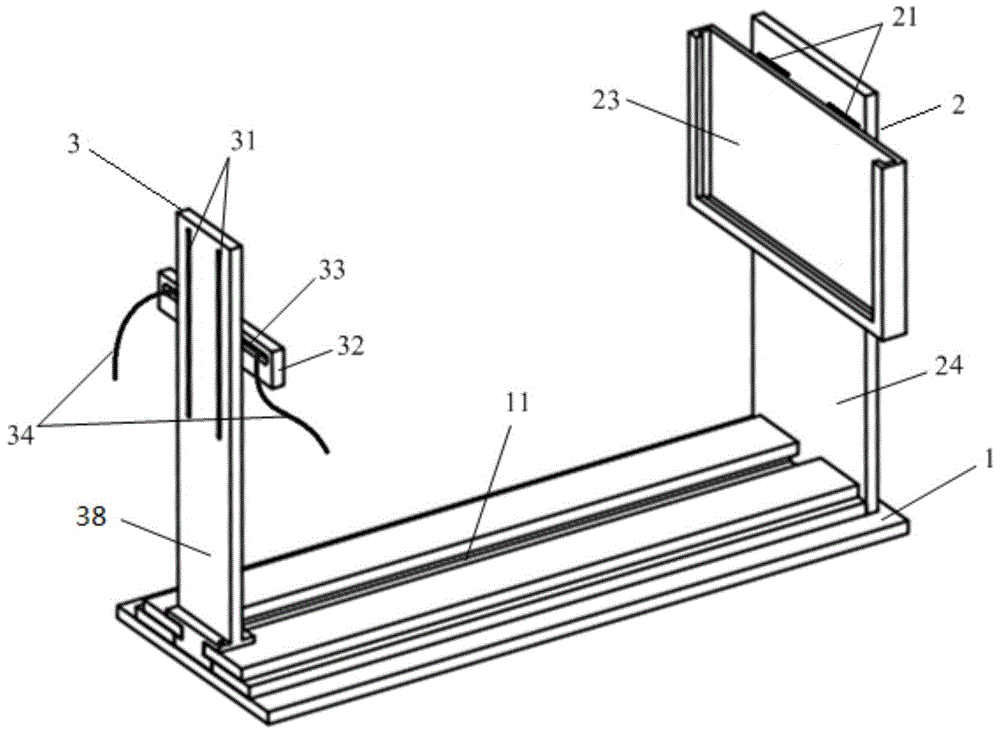

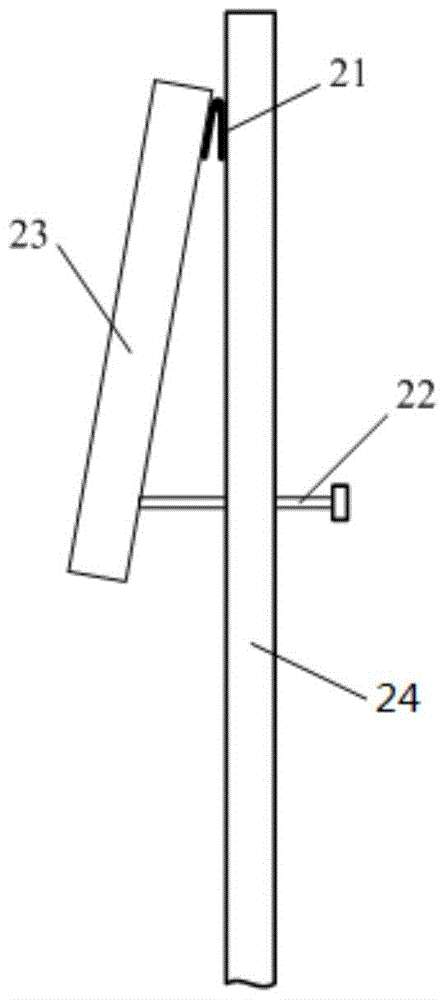

Tool and system for debugging parameter of naked-eye 3D display device

InactiveCN105007482ARealize automatic debuggingMeet the actual needs of debuggingTelevision systemsSteroscopic systems3 d displayNaked eye

The invention relates to the field of the naked-eye 3D technology, especially to a tool and system for debugging a parameter of a naked-eye 3D display device. The tool comprises a first support unit, a pedestal, and a second support unit. The first support unit that is arranged at one side of the pedestal and is fixedly connected with the pedestal is used for placing a to-be-measured display device; the second support unit that is opposite to the first support unit and is connected with the pedestal in a sliding mode is provided with a camera unit for obtaining a 3D display parameter of the to-be-measured display device. With the tool and system, the naked-eye 3D display device parameter debugging accuracy and debugging efficiency can be improved.

Owner:CHONGQING DROMAX PHOTOELECTRIC

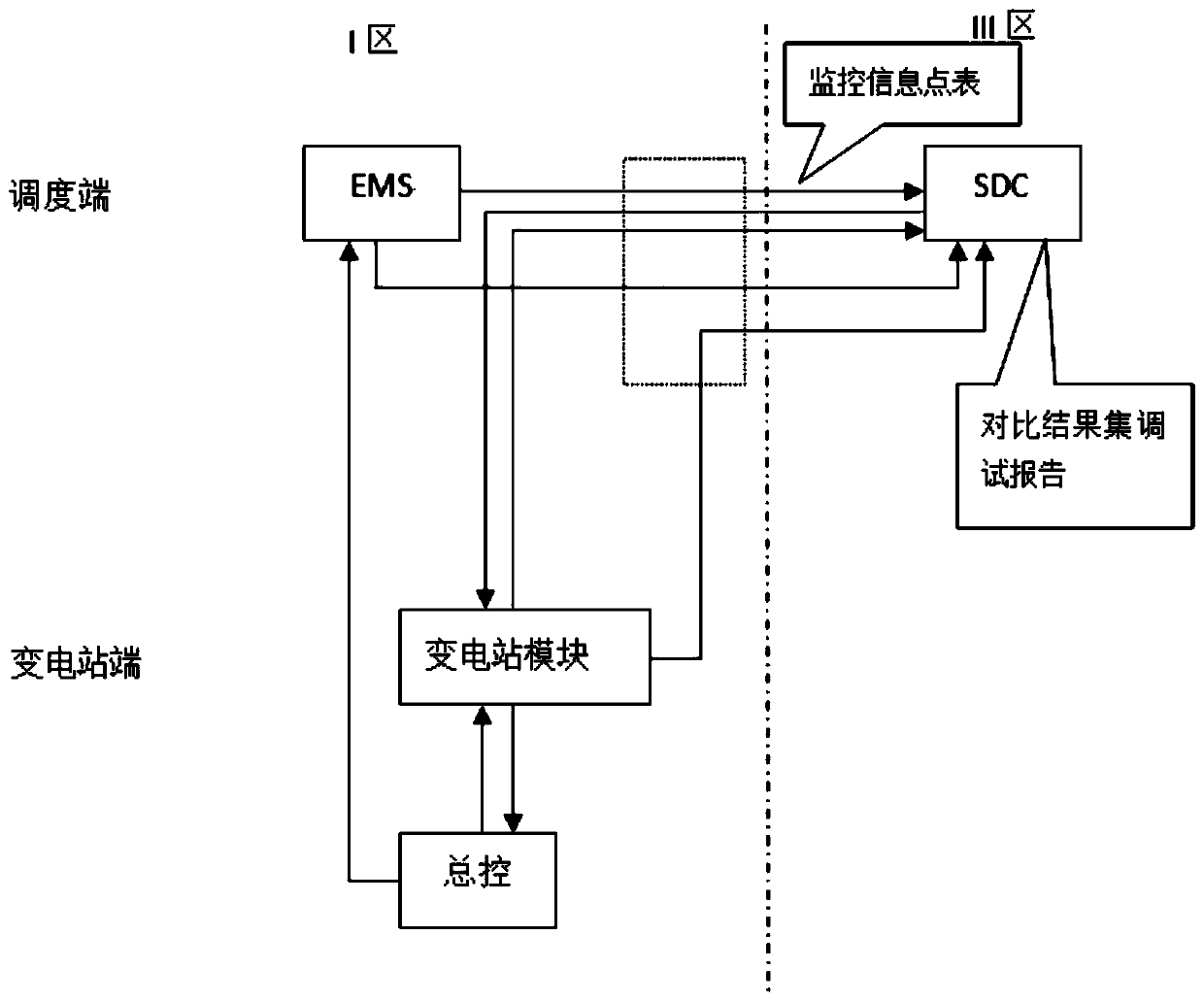

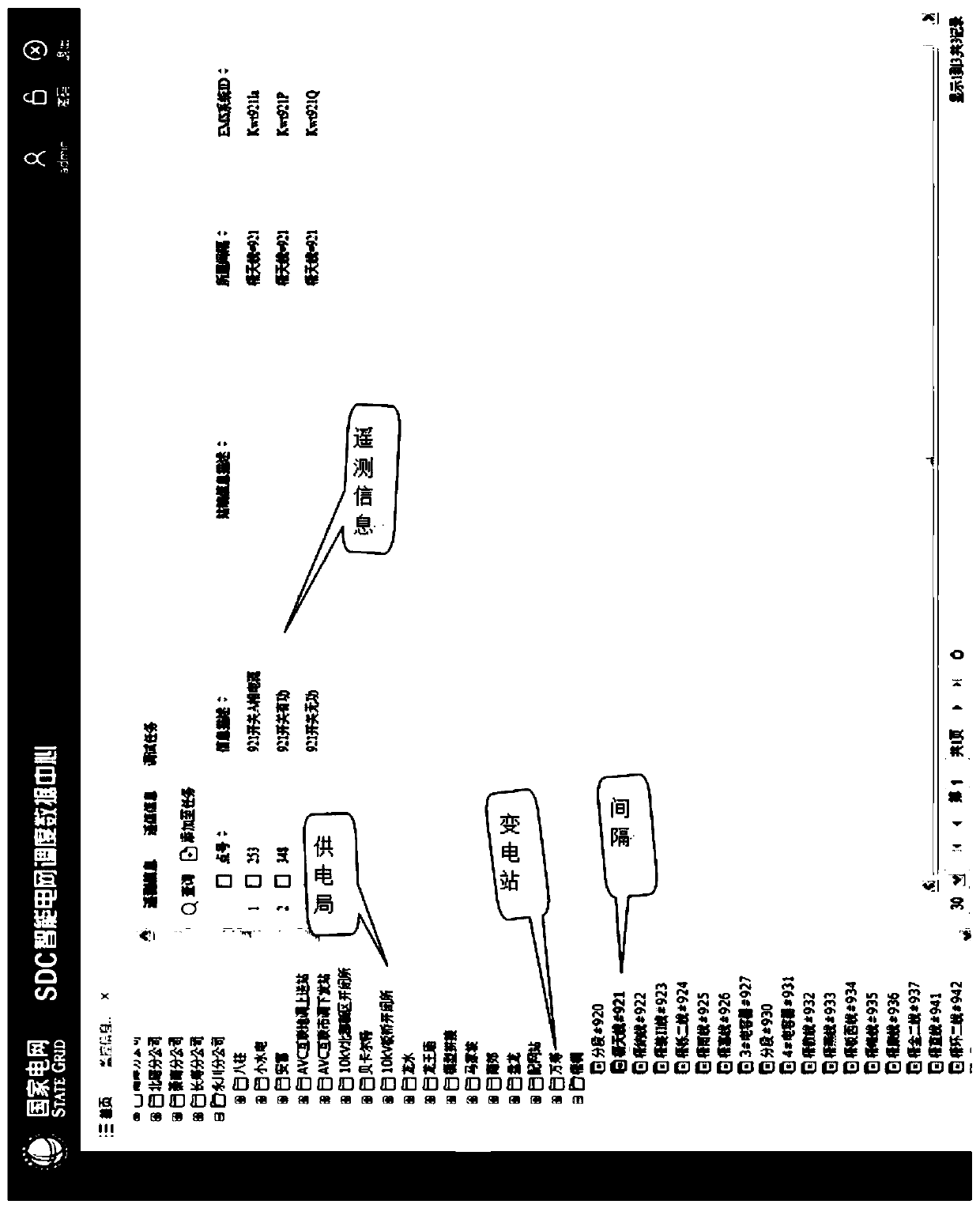

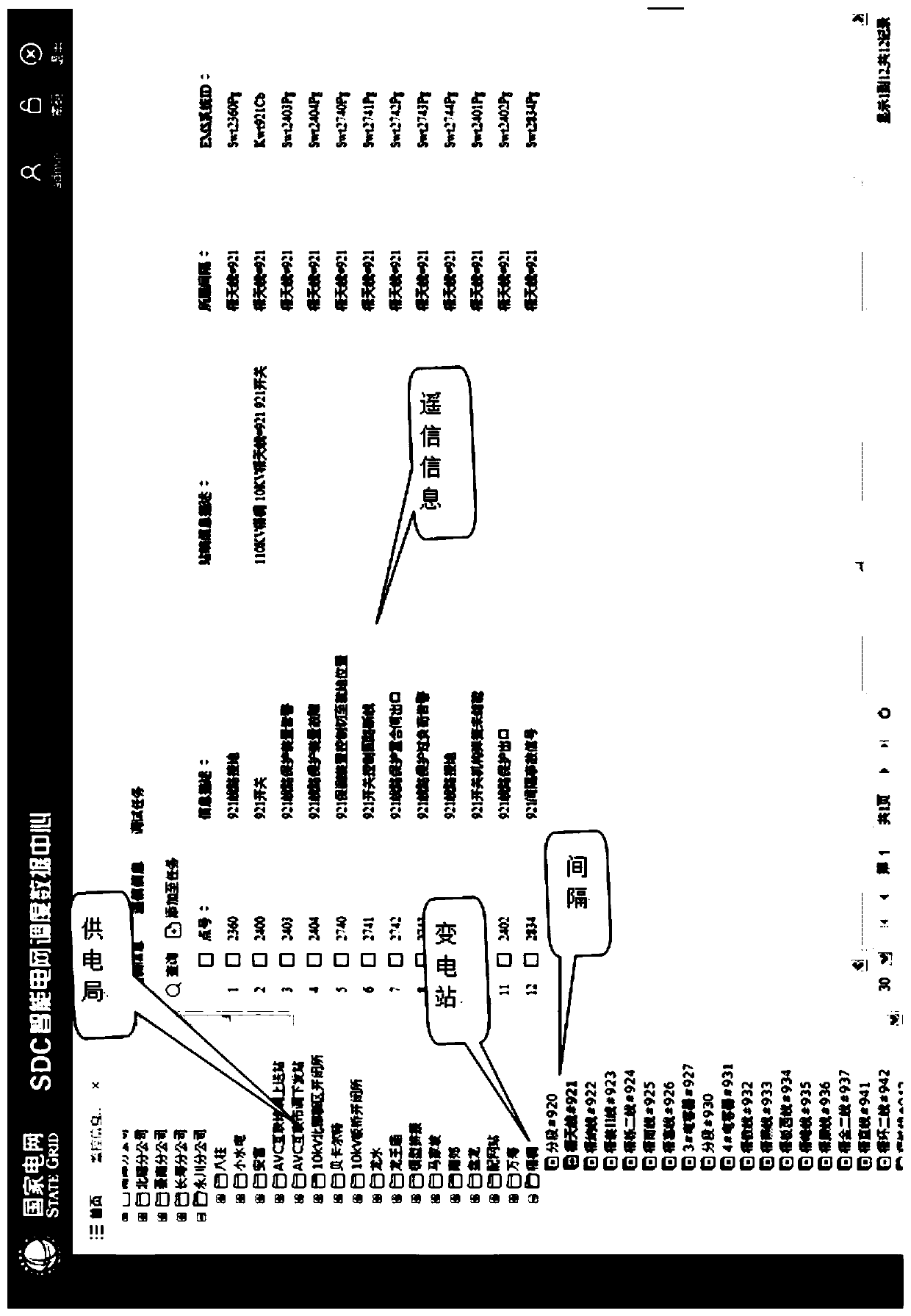

Automatic debugging system and debugging method for monitoring information

ActiveCN109768619ARealize automatic debuggingReduced commissioning timeCircuit arrangementsInformation technology support systemMaster controllerEmbedded system

The invention discloses an automatic debugging system and debugging method for monitoring information. The automatic debugging system for monitoring information mainly comprises an EMS system, a substation module and an automatic debugging main system, wherein the automatic debugging main system is used for generating a debugging task so that the substation module sends warning information to theEMS system and the automatic debugging system, and the automatic debugging main system is used for comparing the warning information so as to complete debugging and generating a debugging report. Thedebugging method comprises the main steps of 1) building a debugging task, and issuing the debugging task to the substation module; 2) generating a driving signal by the substation module according tothe debugging task, and sending monitoring warning content to the EMS system and the automatic debugging main system by a driving master controller according to a monitoring information point table;and 3) comparing monitoring warning content recorded by the EMS system by the automatic debugging main system, performing difference analysis so as to evaluate a signal debugging condition between thesubstation and the EMS system and generate the debugging report. By the automatic debugging system, automatic debugging of substation monitoring information is achieved, and the efficiency is substantially improved.

Owner:重庆甘润科技有限公司 +1

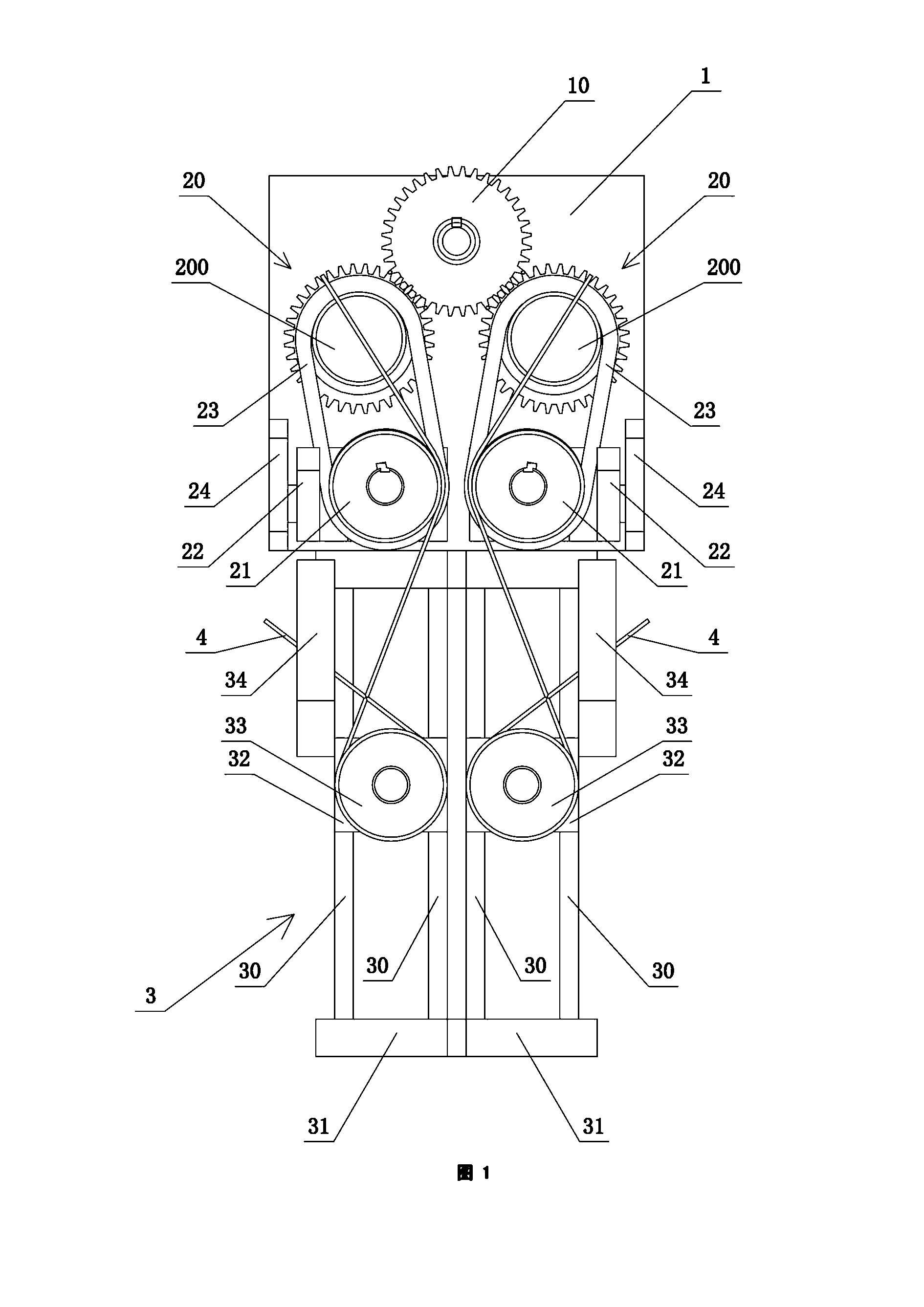

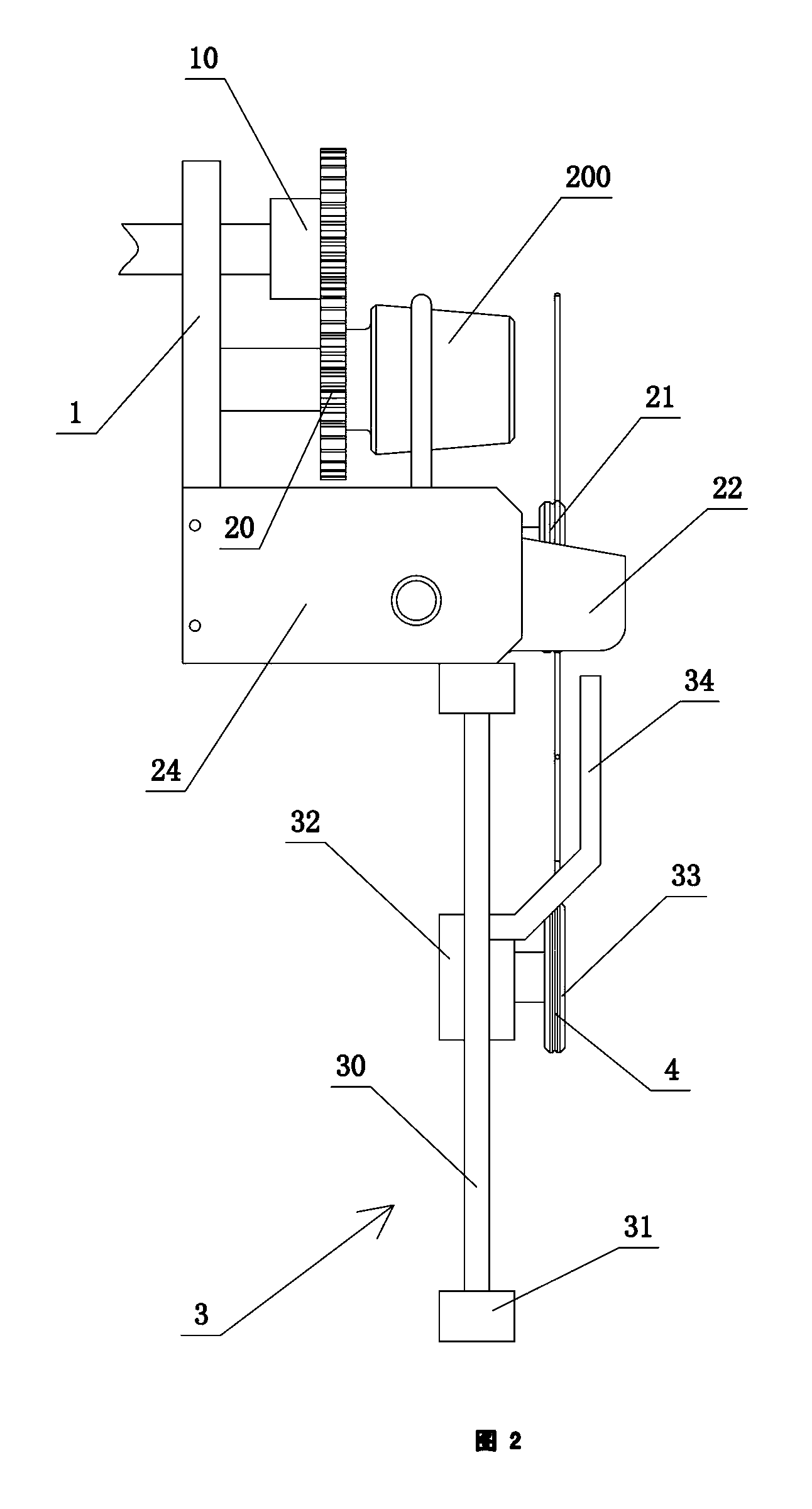

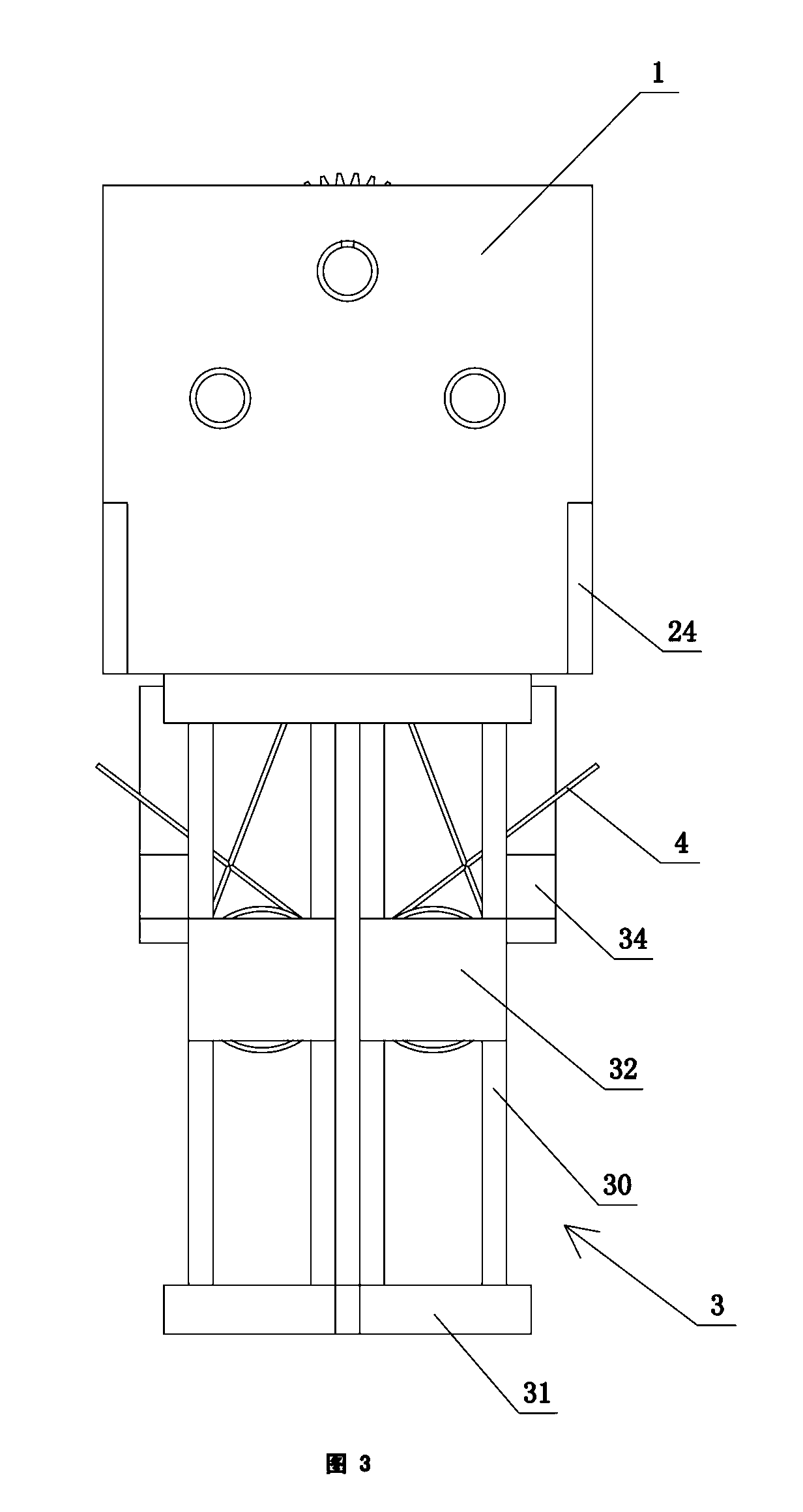

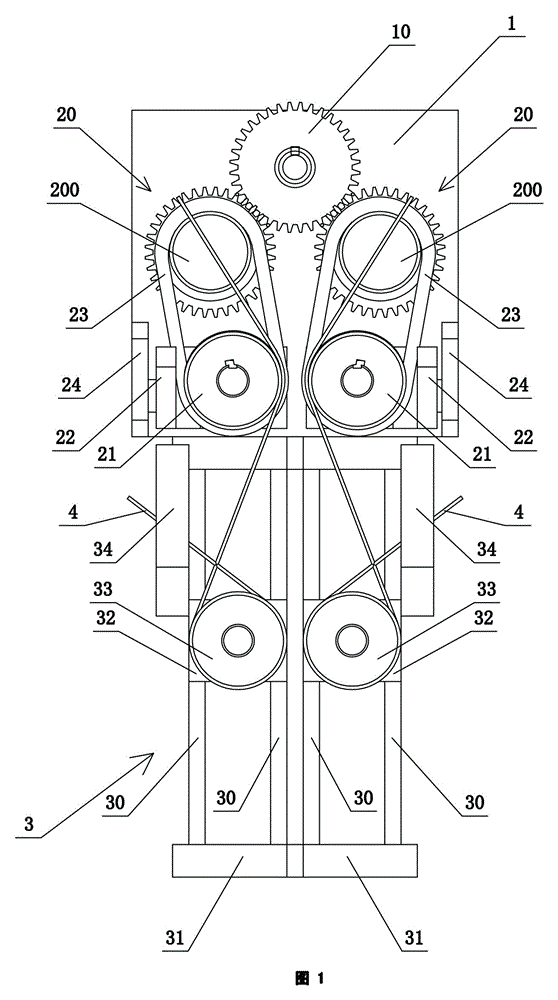

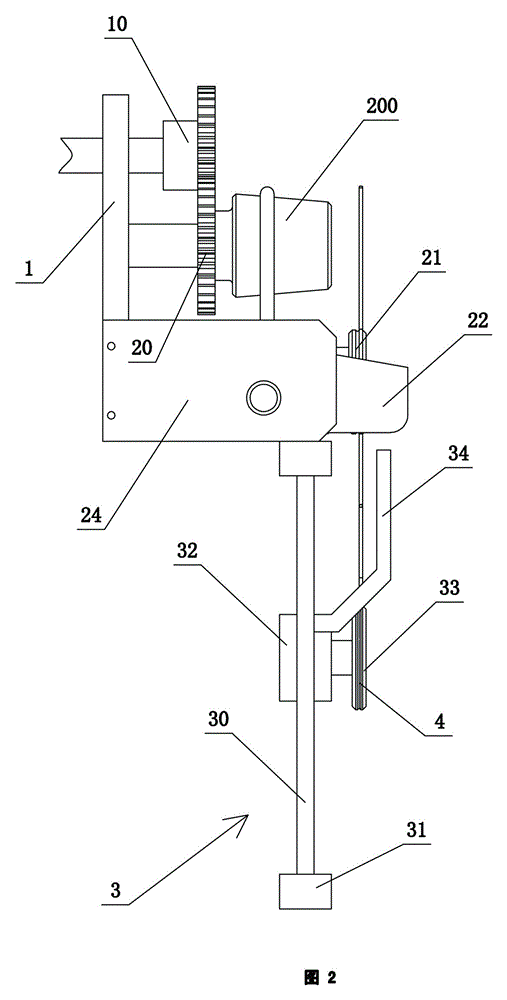

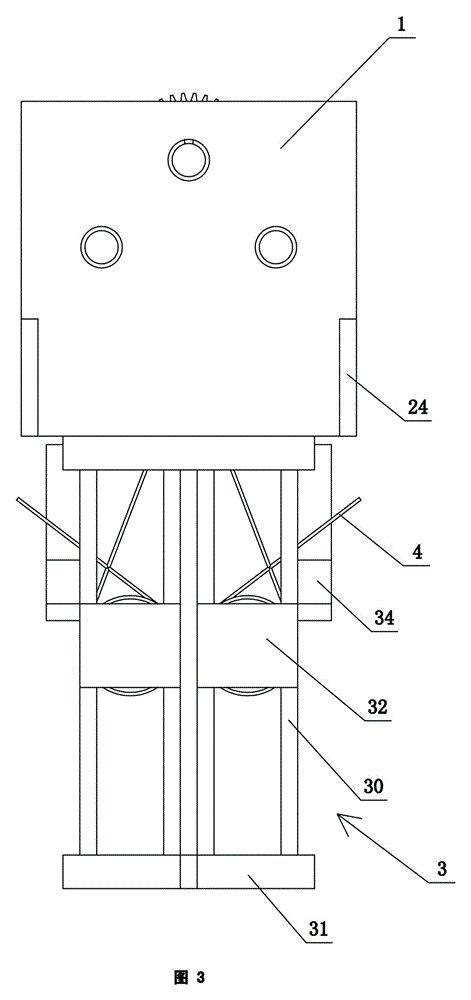

Monofilament tension control mechanism

ActiveCN103010836AAutomatic tension adjustmentRealize automatic real-time controlFilament handlingEngineeringTension control

The invention relates to a monofilament tension control mechanism comprising a main substrate, an automatic adjusting component which is arranged on the main substrate and a comb chain device which is matched with the automatic adjusting component; a main driving wheel is assembled on the main substrate; the automatic adjusting component comprises a driven inclined wheel, a swing wheel, a swing arm, an adjusting belt and a swing wheel support plate which is fixedly connected onto the side wall of the main substrate; the driven inclined wheel is meshed with the main driving wheel; the front part of the driven inclined wheel is provided with a rotary part which is used for driving the adjusting belt to rotate and is in a conical shape; the swing wheel is connected onto one end of the swing arm; one end of the swing arm can drive the swing wheel to be connected with the swing wheel support plate in the way of swinging back and forth, and the other end of the swing arm is connected onto the swing wheel; the adjusting belt is sleeved on the rotary part and the swing wheel; the comb chain device comprises a rail frame with a guide rail rod, a slider capable of sliding on the guide rail rod and a monofilament cartridge which is rotationally arranged on the front end surface of the slider; and one side of the slider is provided with a contact rod which is in touch fit with one end of the swing arm. According to the monofilament tension control mechanism, the structure is novel, the practicality is high, and the tension of a monofilament can be adjusted and ensured in real time.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

A power amplifier module intermodulation automatic debugging and testing system and method

ActiveCN107222268BReduce manufacturing costRealize automatic debuggingTransmitters monitoringConvertersComputer architecture

The invention discloses an automatic debugging and testing system and a method for intermodulation of a power amplifier module. The system comprises an input mixer, an analog-to-digital converter (ADC), a digital attenuator, a digital-to-analog converter (DAC), an output signal mixing and amplifier, an FPGA chip, a communication module and a clock generation module, wherein inner program modules of the FPGA chip comprise an ADC interface module, an FFT module, a power detection module, a dual tone signal generation module, an intermodulation calculation module, an intermodulation value comparison and judgment module and a DAC interface. Automation of debugging and testing during the power amplifier module production process can be realized, the efficiency is improved, and the power amplifier module production cost is reduced.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

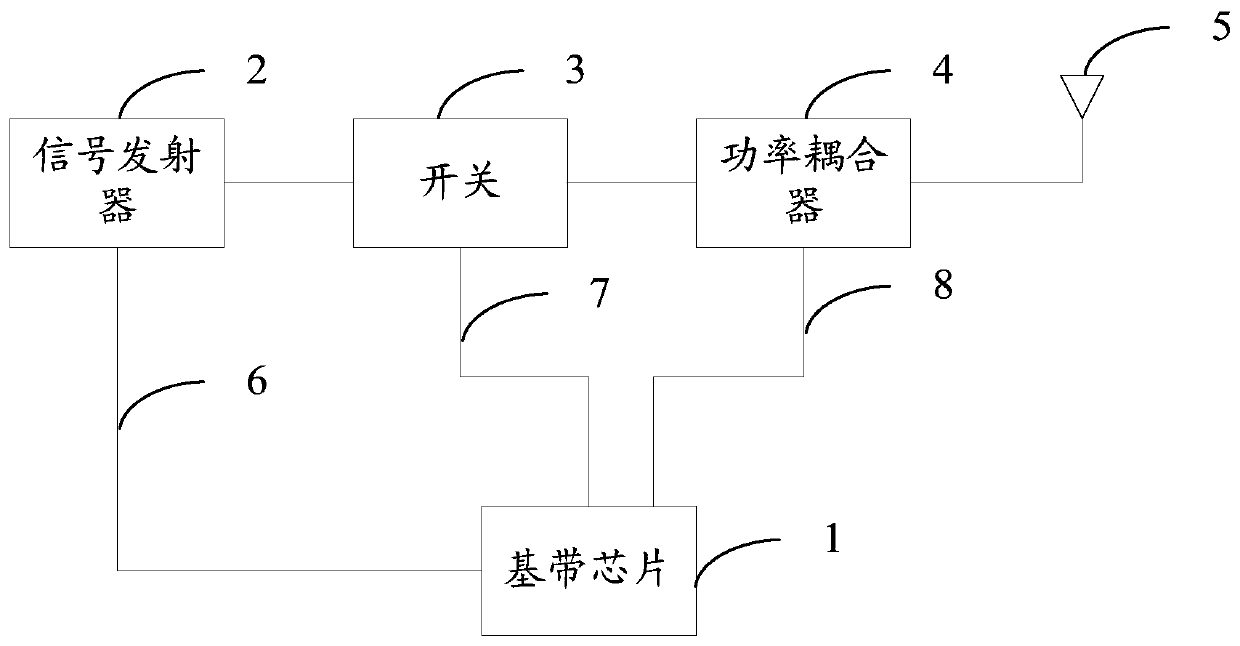

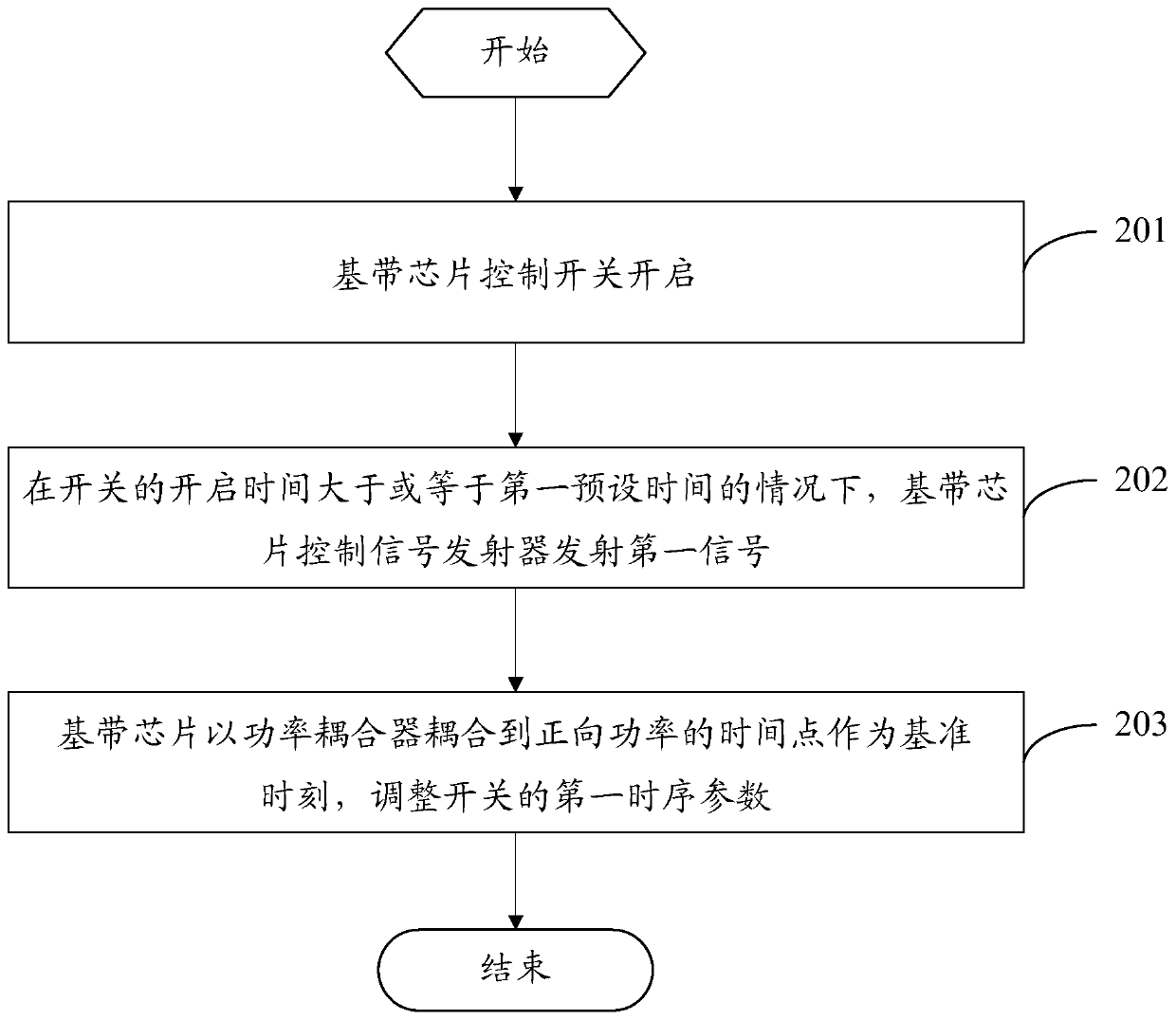

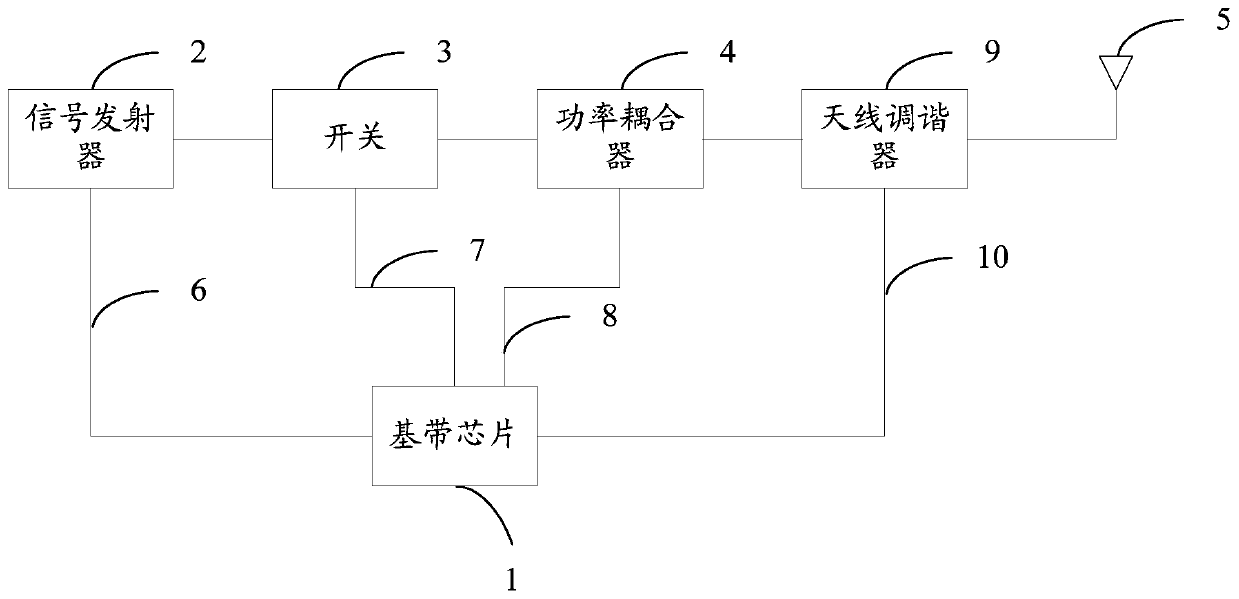

Time sequence control circuit, time sequence control method and terminal

ActiveCN109743120ARealize dynamic adjustmentRealize automatic debuggingTransmitters monitoringElectricityComputer terminal

The invention provides a time sequence control circuit, a time sequence control method and a terminal, the time sequence control circuit comprises a baseband chip, a signal transmitter, a switch, a power coupler and an antenna, and the signal transmitter, the switch, the power coupler and the antenna are electrically connected in sequence; The baseband chip is electrically connected with the signal transmitter through a first control circuit; The baseband chip is electrically connected with the switch through a second control circuit; The baseband chip is electrically connected with the powercoupler through a third control circuit; The baseband chip adjusts a first time sequence parameter of the switch by detecting a time point at which the power coupler is coupled to forward power; Wherein the forward power is power from the switch to the power coupler. According to the invention, the time sequence control circuit is arranged to realize the purpose of dynamically adjusting the switchtime sequence. Therefore, the time sequence control method provided by the invention has a relatively good time sequence control effect.

Owner:VIVO MOBILE COMM CO LTD

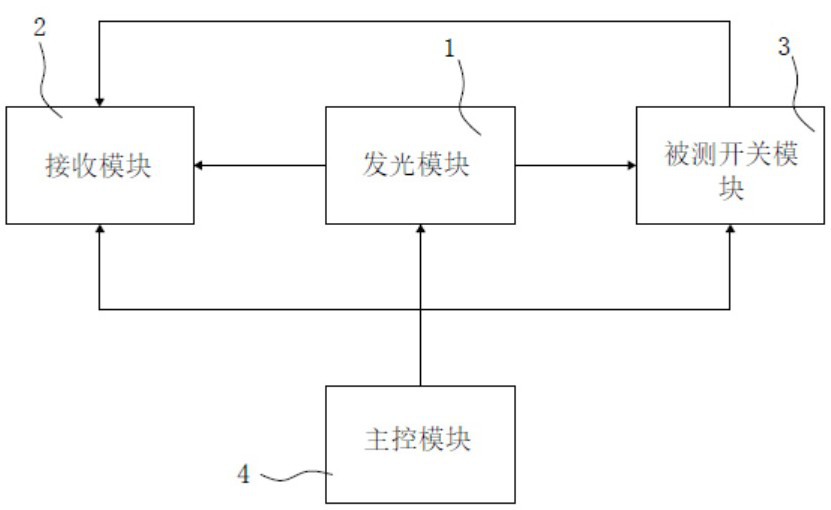

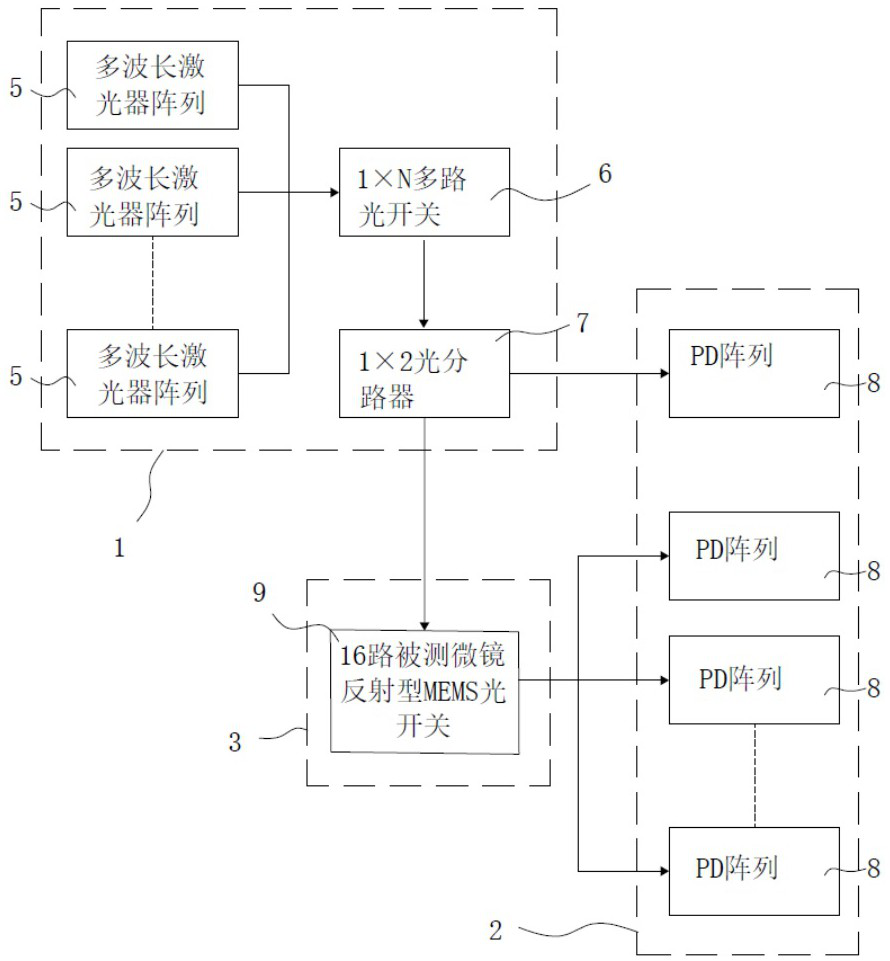

A kind of mems optical switch automatic scanning device and method

ActiveCN112578504BRealize automatic debuggingAutomatic and high-speed production commissioningCoupling light guidesOptical powerEngineering

The invention discloses an automatic scanning device of a MEMS optical switch and a method thereof, which scan the optical switch point by point and line by line in the full voltage range, and monitor the change of the optical power of its channel, so as to realize the automatic adjustment of the channel parameters of the optical switch. It can automatically and quickly debug the channel voltage parameters of the MEMS optical switch, and it is also extremely convenient to assist in adjusting the channel voltage parameters of the MEMS optical switch in the application, which greatly improves the maintenance and use efficiency of the MEMS optical switch.

Owner:ANNING BUREAU OF ULTRA HIGH VOLTAGE TRANSMISSION

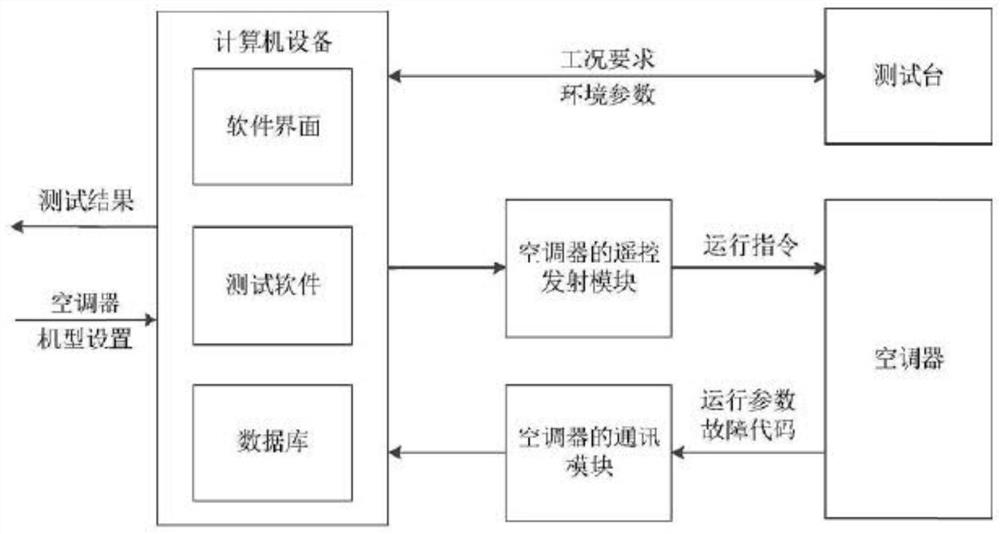

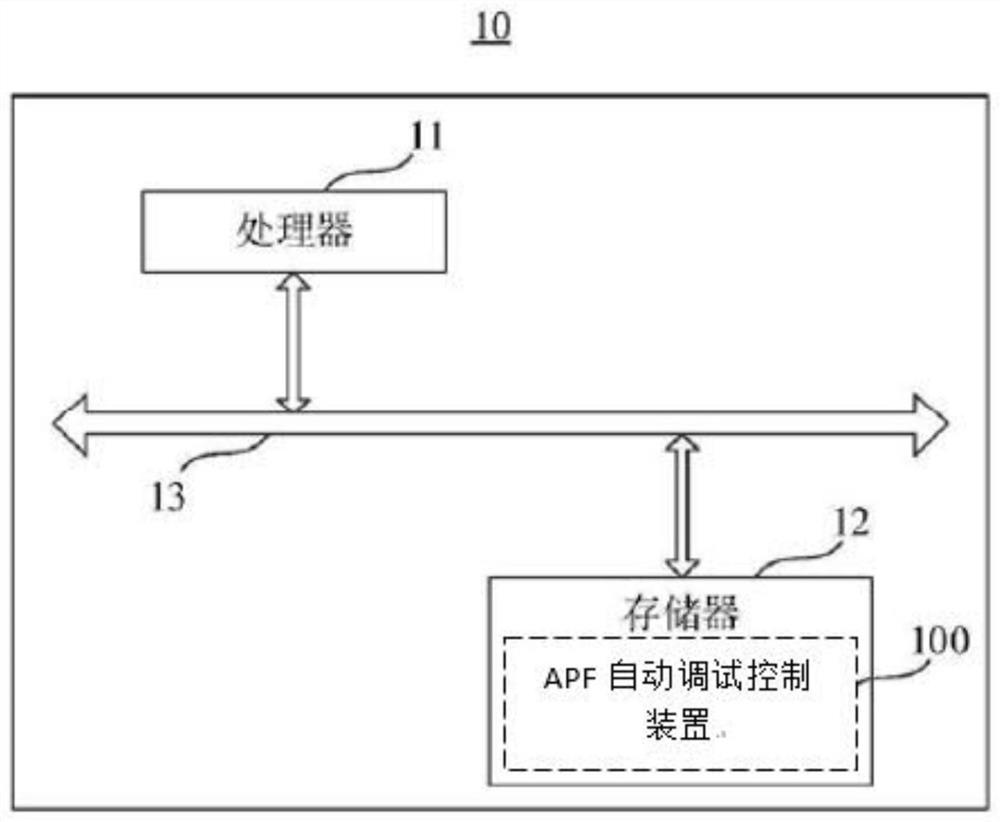

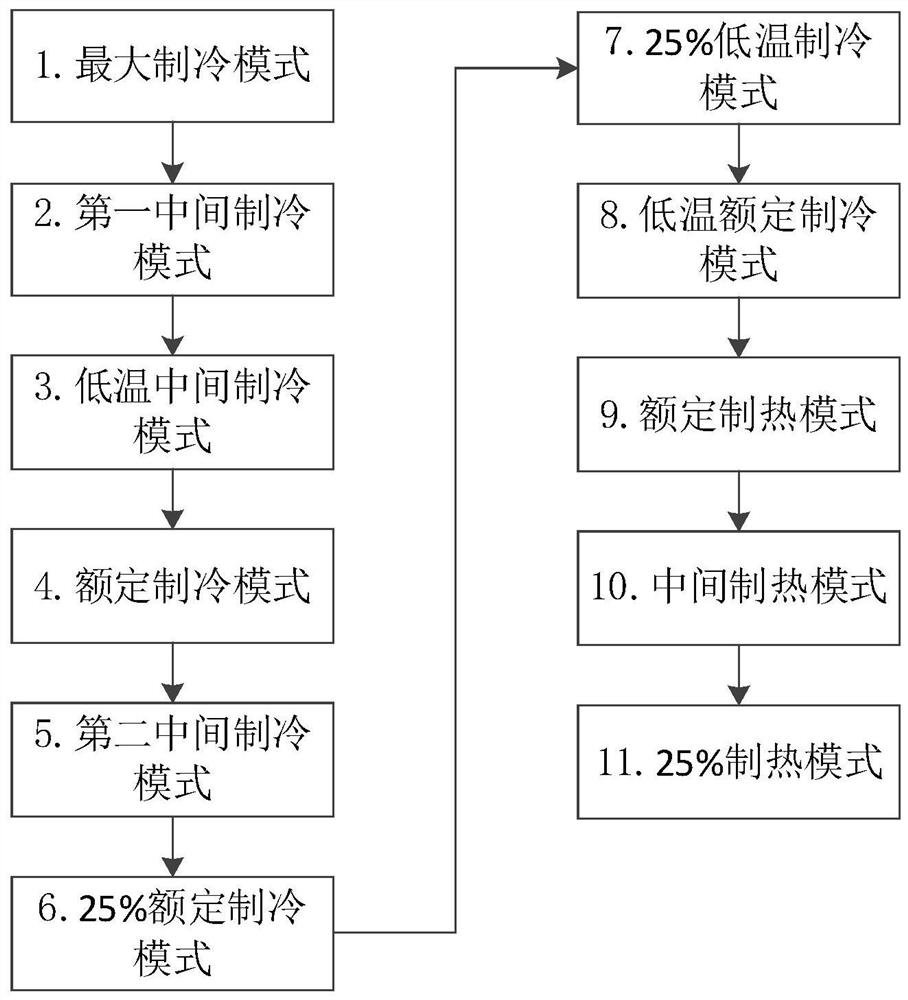

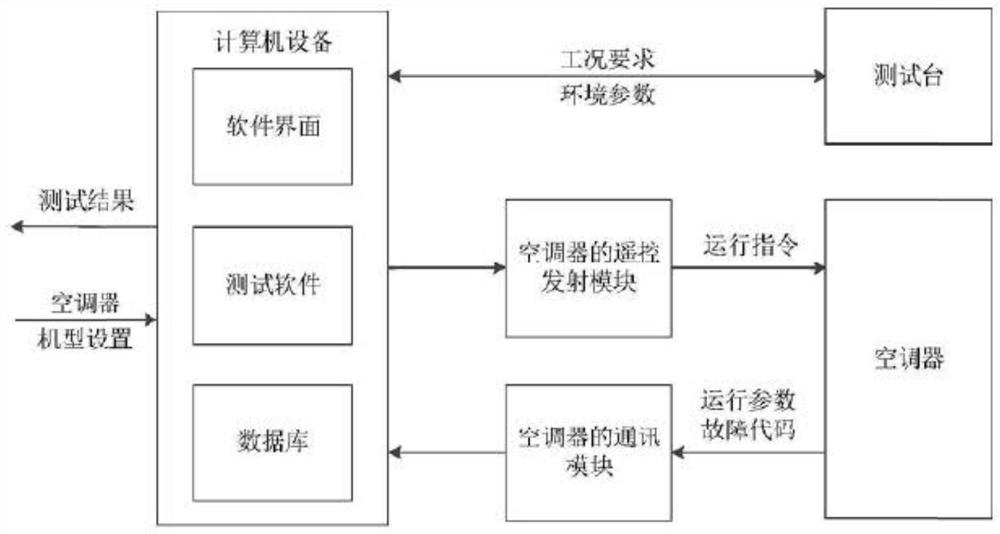

APF automatic debugging control method and device, computer equipment and computer readable storage medium

ActiveCN113790508ARealize automatic debuggingImprove debugging efficiencyMechanical apparatusActive power filteringControl engineeringProcess engineering

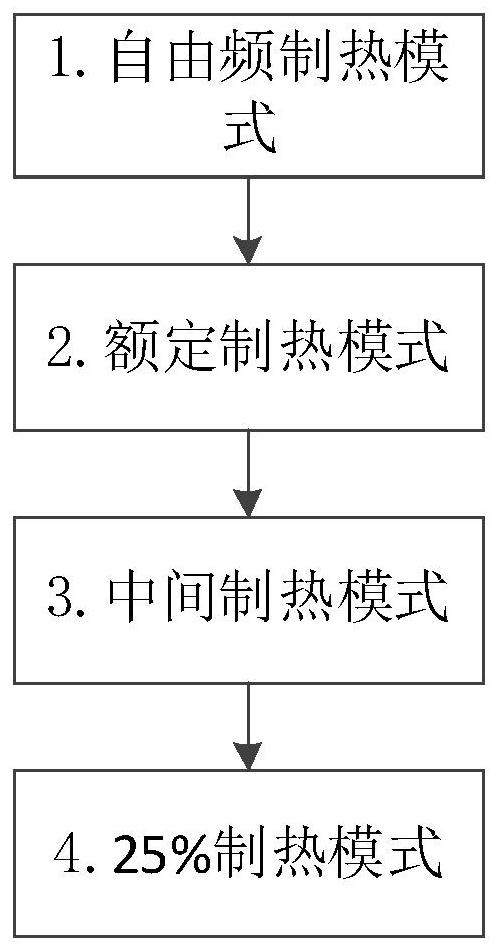

The invention provides an APF automatic debugging control method and device, computer equipment and a computer readable storage medium, and relates to the technical field of air conditioners. The APF automatic debugging control method comprises the steps that S1, debugging of the maximum refrigeration mode is carried out, and the minimum valve step is determined; S2, the minimum valve step is kept, debugging of the first intermediate refrigeration mode is carried out, and the minimum frequency of the low-temperature intermediate refrigeration mode is determined; S3, debugging of the low-temperature intermediate refrigeration mode is carried out, and the low-temperature intermediate refrigeration valve step enabling the APF to be maximized is determined; and S4, debugging of the rated refrigeration mode is carried out, and the optimal valve step considering the low-temperature intermediate refrigeration mode and the rated refrigeration mode is determined. The method can be suitable for the new national standard and can also be suitable for an air conditioner with the determined throttling specification, debugging logics of various operation modes are mutually connected and automatically completed, manual participation is not needed, the debugging efficiency is high, and the APF can be improved to the maximum degree.

Owner:NINGBO AUX ELECTRIC +1

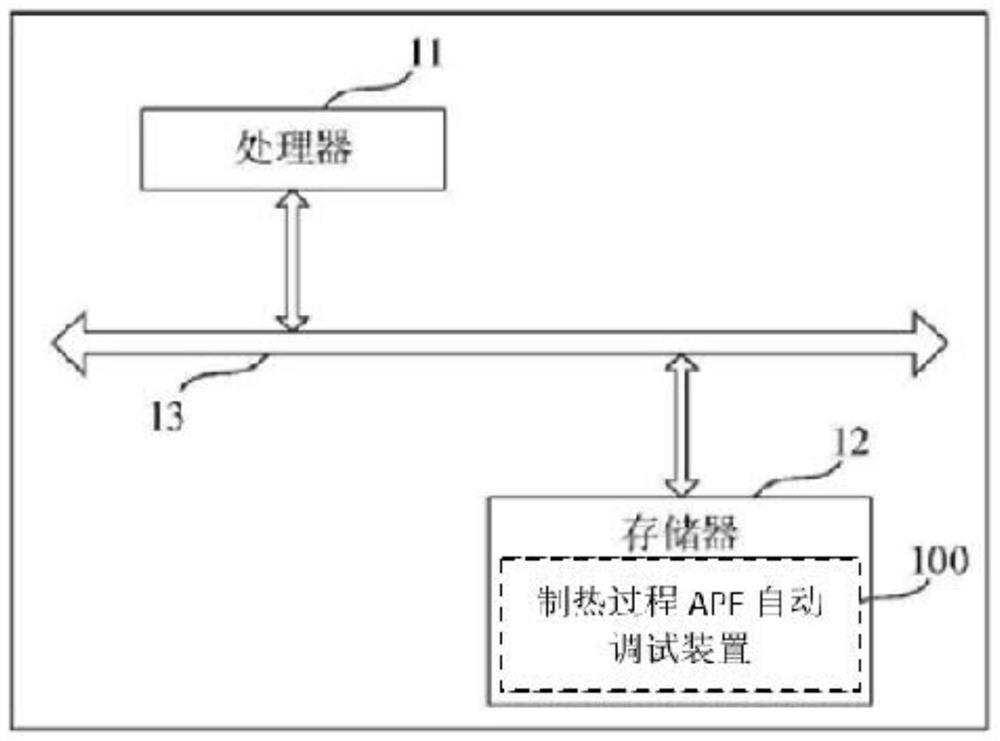

Heating process APF automatic debugging control method and device, computer equipment and computer readable storage medium

ActiveCN113819569ARealize automatic debuggingImprove debugging efficiencyMechanical apparatusSpace heating and ventilation safety systemsControl engineeringProcess engineering

The embodiment of the invention provides a heating process APF (Annual Performance Factor) automatic debugging control method and device, computer equipment and a computer readable storage medium, and relates to the technical field of air conditioners. The heating process APF automatic debugging control method comprises the steps that S1, free frequency heating mode debugging is conducted, and the minimum heating valve step meeting the heating capacity requirement is determined; and S2, a rated heating mode is debugged, the current valve step is determined according to the minimum heating valve step and the target exhaust temperature, and then the optimal heating valve step is determined according to the current valve step. According to the method, the logic for determining the optimal heating valve step is optimized, the situation that the determined optimal heating valve step is optimal during APF frequency locking debugging is ensured, the situation that the heating capacity is low or the exhaust temperature is too high cannot occur in the free frequency heating mode, the debugging logic of various operation modes is mutually connected and automatically completed, manual participation is not needed, APF automatic debugging can be realized, and the debugging efficiency is high.

Owner:NINGBO AUX ELECTRIC +1

A dielectric filter automatic debugging system and method

ActiveCN111313136BRealize automatic debuggingReduce labor costsWaveguide type devicesDielectricTest set

The invention relates to a dielectric filter automatic debugging system and method, relates to the field of 5G mobile communication dielectric filters, and solves the troublesome problem that each dielectric filter basically needs to be debugged due to the production characteristics and index requirements of the dielectric filter , which includes: the artificial intelligence device is based on the metal layer data difference between the metal layer information of the target dielectric filter and the initial metal layer information, and processes the target dielectric filter through the metal layer adjustment device until the artificial intelligence device obtains it through the S parameter testing device Stop processing when the S-parameter data of the machine is consistent with the theoretical S-parameter data. The invention realizes the automatic debugging of the dielectric filter through artificial intelligence AI, reduces the labor cost, and improves the production capacity.

Owner:深圳润芯信息技术有限公司

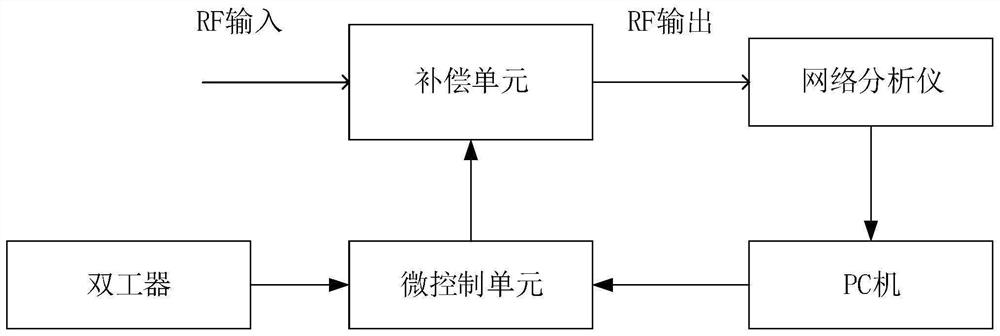

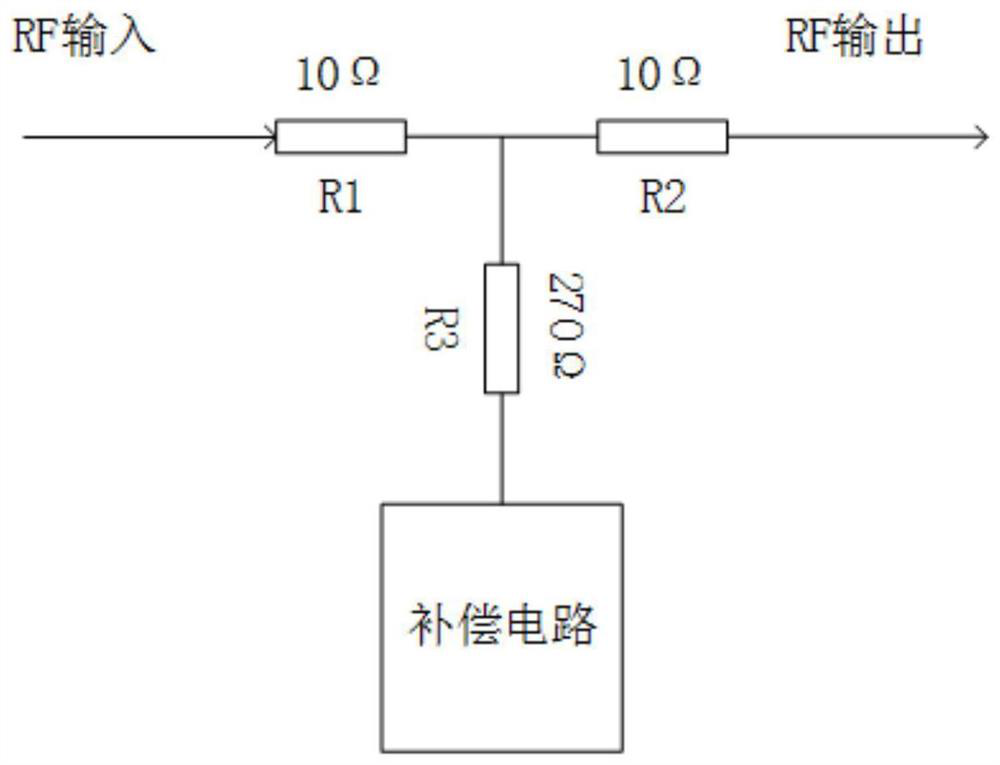

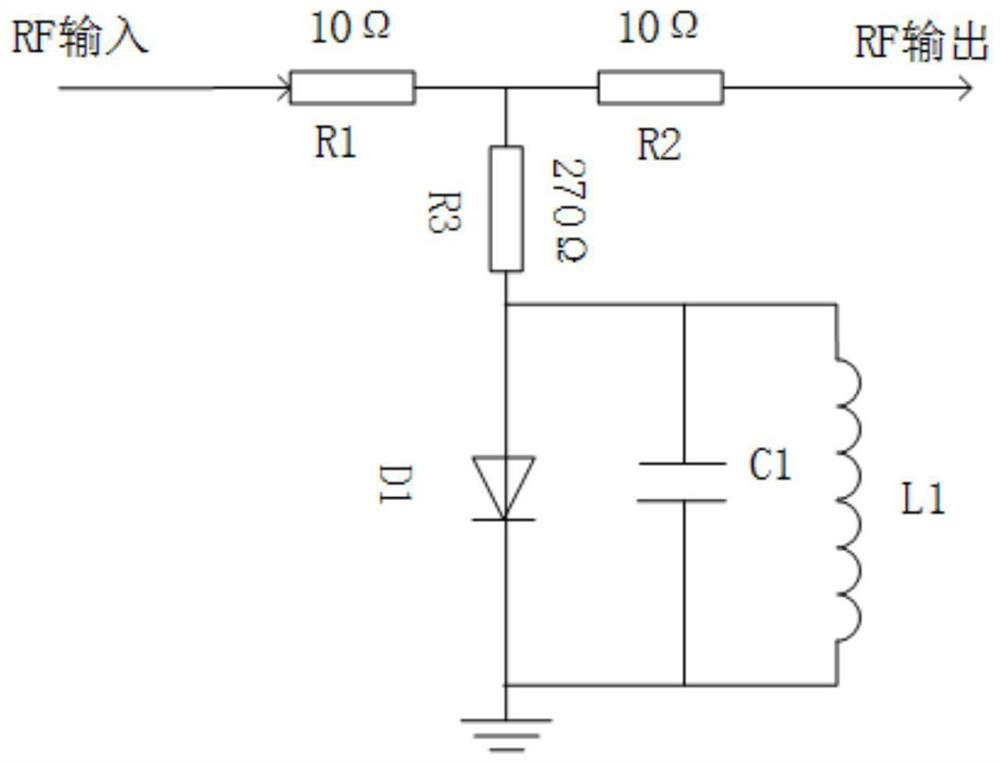

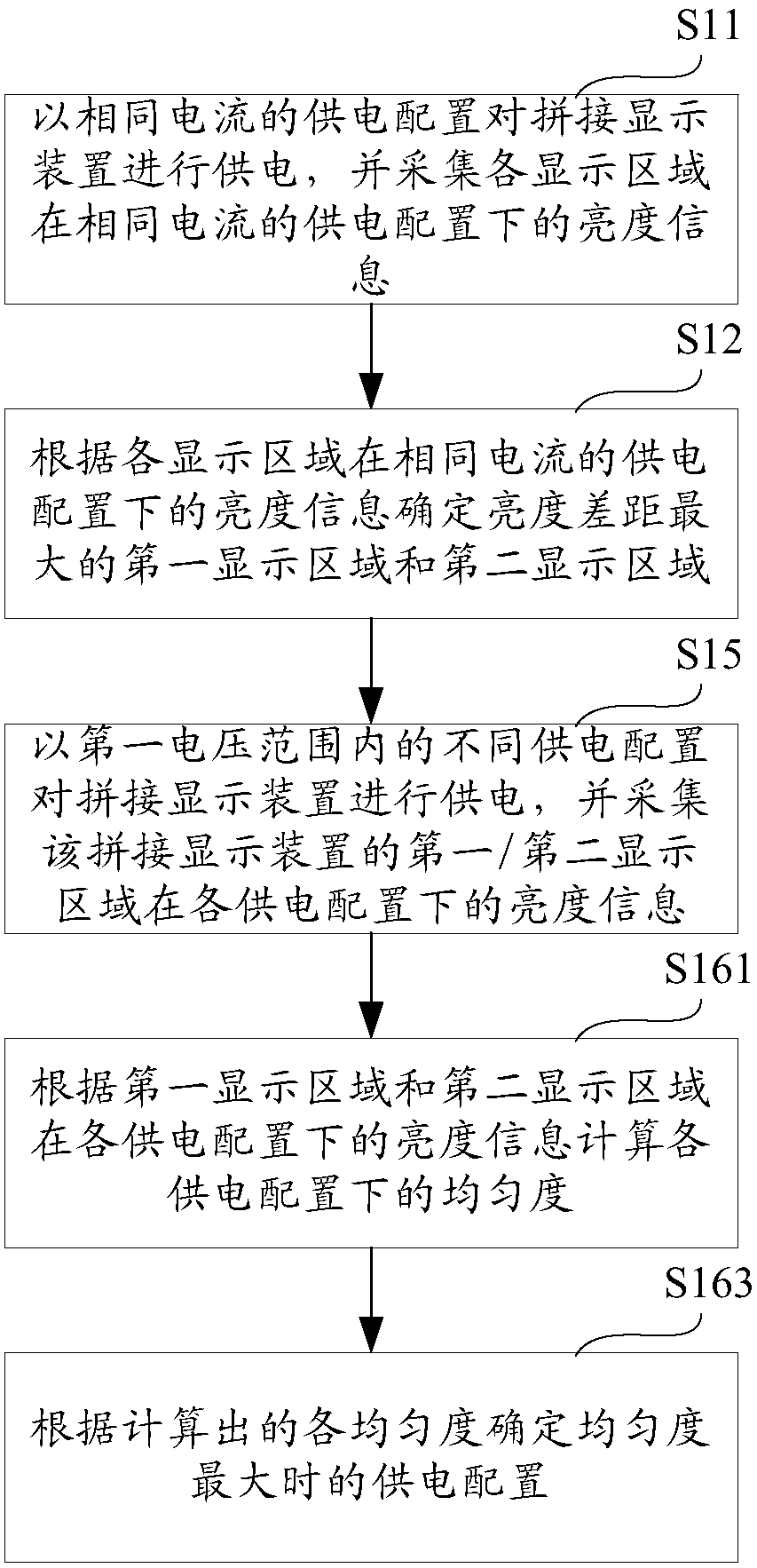

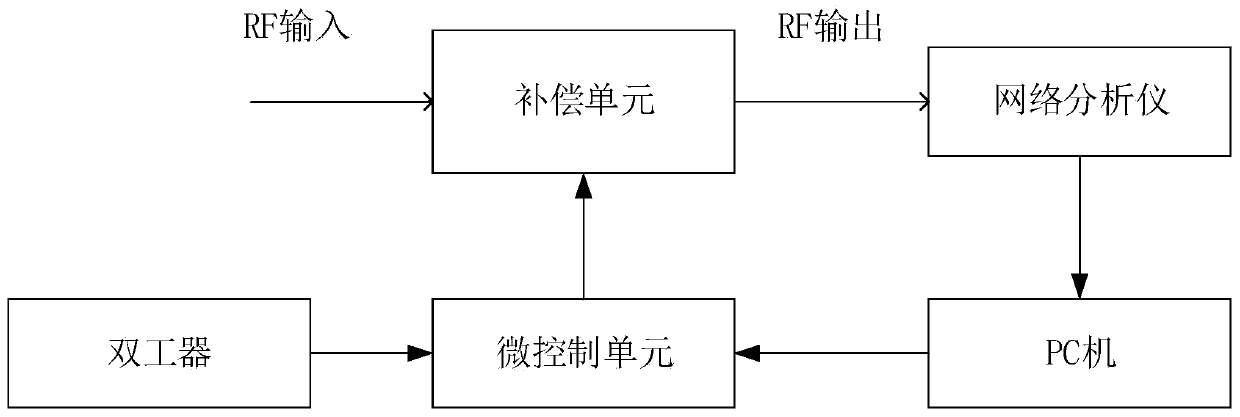

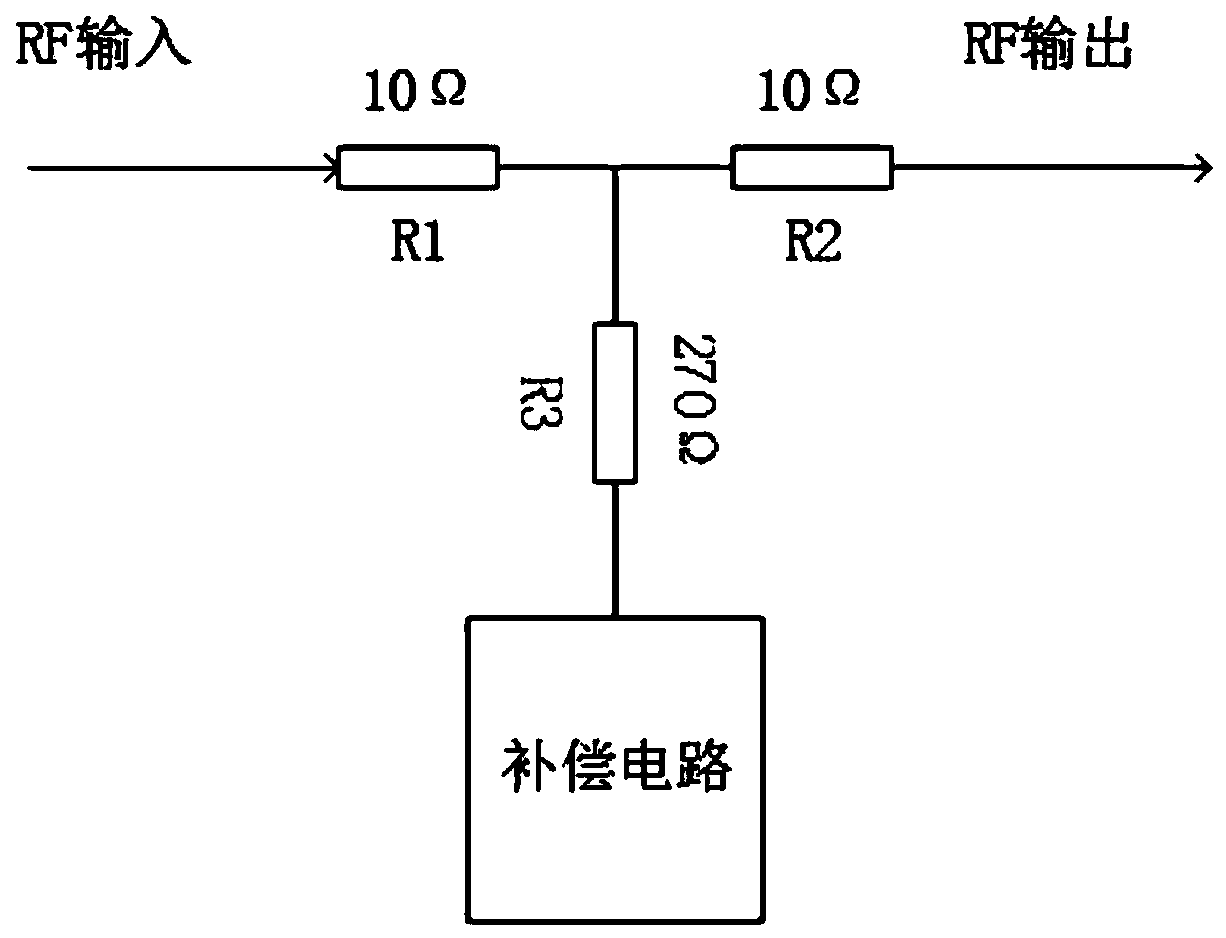

Compensation system and method for automatic tuning of output level of multi-band hfc equipment

ActiveCN111077815BHigh precision indexRealize automatic debuggingProgramme controlComputer controlMulti bandControl signal

The invention discloses a compensation system and method for automatically tuning the output level of multi-band HFC equipment, wherein the compensation system includes a duplexer, a micro control unit, a compensation unit, a network analyzer and a PC; the micro control unit and the duplexer connected to the duplexer to obtain the voltage value on the duplexer; the micro-control unit also receives the configuration data output by the PC, and the micro-control unit outputs a control signal to the compensation unit according to the voltage value and the configuration data; the compensation unit receives the Control the signal, compensate the input RF signal, and output the compensated RF signal to the network analyzer; the network analyzer receives the compensated RF signal for testing, and outputs the test curve to the PC; the PC receives the test curve and the standard The curves are analyzed and compared to obtain a comparison result, and corresponding configuration data is output to the micro control unit according to the comparison result. The invention can realize automatic testing and debugging of the output level of the equipment, and improves the precision of the output level.

Owner:成都芯通软件有限公司

A method for automatic debugging of serdes link parameters

ActiveCN108933600BPrevent deviationGuaranteed accuracyParallel/series conversionCoding detailsInterference (communication)Algorithm

A SerDes link parameter automatic debugging method, selects the corresponding encoding and decoding mode, forward error correction method and check code according to the link clock and channel characteristics, and then determines the pre-emphasis parameters suitable for the TX side of the link through a backtracking method, After the above code stream learning process, the adaptive configuration parameters are determined through training on the RX side of the link. Since the method implements strict timing control on the training of the TX side and the RX side, the link parameter configuration deviation caused by the interference generated during the two-way communication of the link is avoided, and the accuracy of the set link parameters can be effectively guaranteed. At the same time, since the TX side performs backtracking training on the currently selected pre-emphasis parameters of the link according to the error reported by the FEC decoding of the link on the RX side, the parameter configuration selected for each training can be determined according to the link characteristics, and the training efficiency is improved. The method is applicable to various router backplanes, and realizes automatic debugging of each link parameter for high-speed SerDes links.

Owner:SANECHIPS TECH CO LTD

A monofilament tension control mechanism

ActiveCN103010836BRealize automatic debuggingRealize automatic real-time controlFilament handlingEngineeringYarn tension

The invention relates to a monofilament tension control mechanism comprising a main substrate, an automatic adjusting component which is arranged on the main substrate and a comb chain device which is matched with the automatic adjusting component; a main driving wheel is assembled on the main substrate; the automatic adjusting component comprises a driven inclined wheel, a swing wheel, a swing arm, an adjusting belt and a swing wheel support plate which is fixedly connected onto the side wall of the main substrate; the driven inclined wheel is meshed with the main driving wheel; the front part of the driven inclined wheel is provided with a rotary part which is used for driving the adjusting belt to rotate and is in a conical shape; the swing wheel is connected onto one end of the swing arm; one end of the swing arm can drive the swing wheel to be connected with the swing wheel support plate in the way of swinging back and forth, and the other end of the swing arm is connected onto the swing wheel; the adjusting belt is sleeved on the rotary part and the swing wheel; the comb chain device comprises a rail frame with a guide rail rod, a slider capable of sliding on the guide rail rod and a monofilament cartridge which is rotationally arranged on the front end surface of the slider; and one side of the slider is provided with a contact rod which is in touch fit with one end of the swing arm. According to the monofilament tension control mechanism, the structure is novel, the practicality is high, and the tension of a monofilament can be adjusted and ensured in real time.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

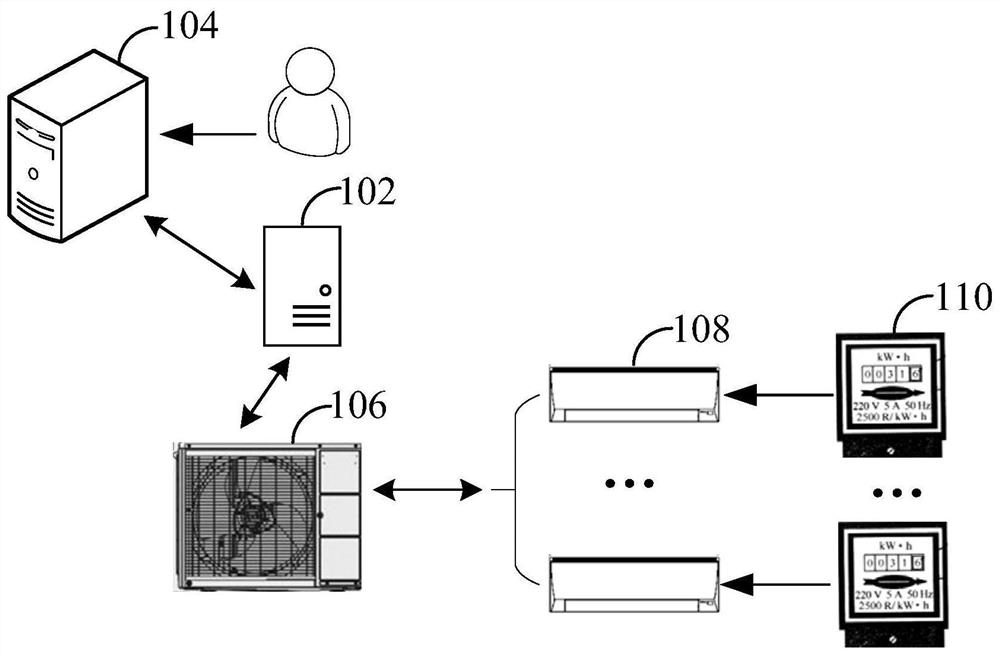

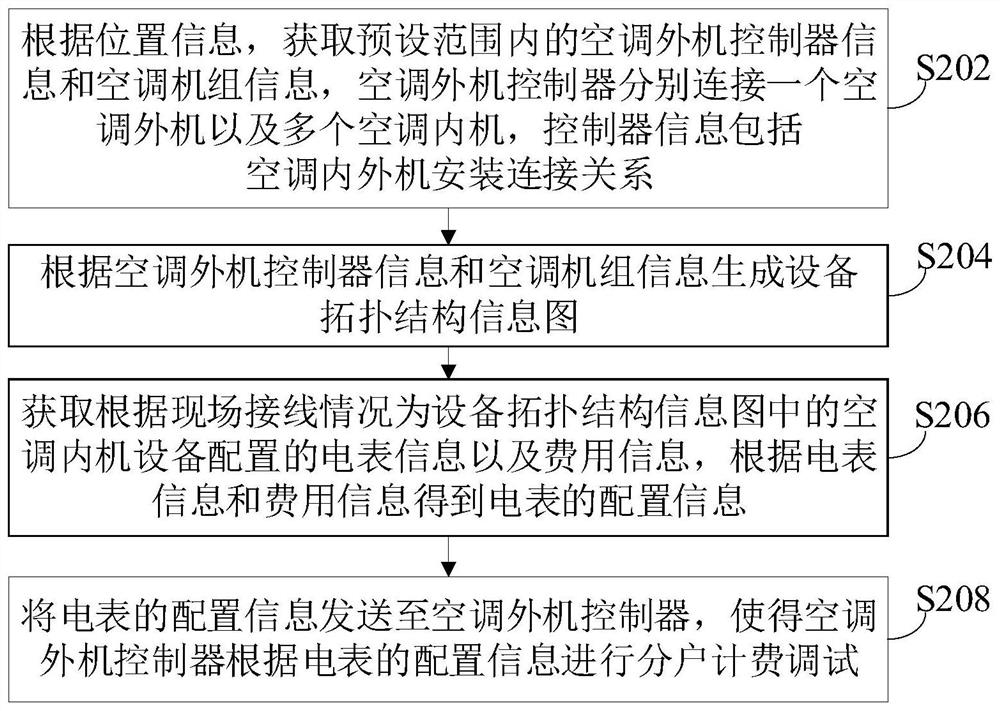

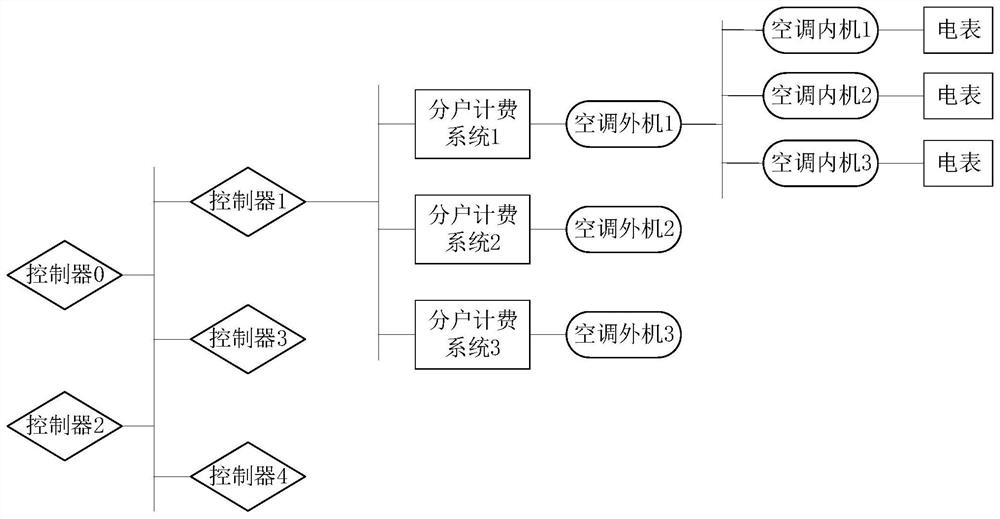

Household billing and debugging method, device and computer equipment for multi-connected air conditioners

ActiveCN110595001BIntuitive debugging processRealize automatic debuggingMechanical apparatusControl engineeringAir conditioning

The invention relates to a family-split billing and debugging method and device of a multi-split air conditioner and a computer device. The method includes the steps of obtaining information of an airconditioner outdoor unit controller and information of an air conditioning unit within a preset range according to position information, generating a device topological structure information graph according to the information of the air conditioner outdoor unit controller and the information of the air conditioning unit, obtaining ammeter information and fee information configured for an air conditioner indoor unit device in the device topological structure information graph according to the field connection conditions, and obtaining configuration information of an ammeter according to the ammeter information and the feed information. The configuration information of the ammeter is sent to the air conditioner outdoor unit controller so that the air conditioner outdoor unit controller canconduct multi-split billing and debugging according to the configuration information of the ammeter. By means of the method, the topological structure among all the devices on the engineering field can be restored, the debugging process is more visual, the automatic debugging of a multi-split billing system can be realized without field debugging by professionals, debugging cost is reduced, and debugging efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

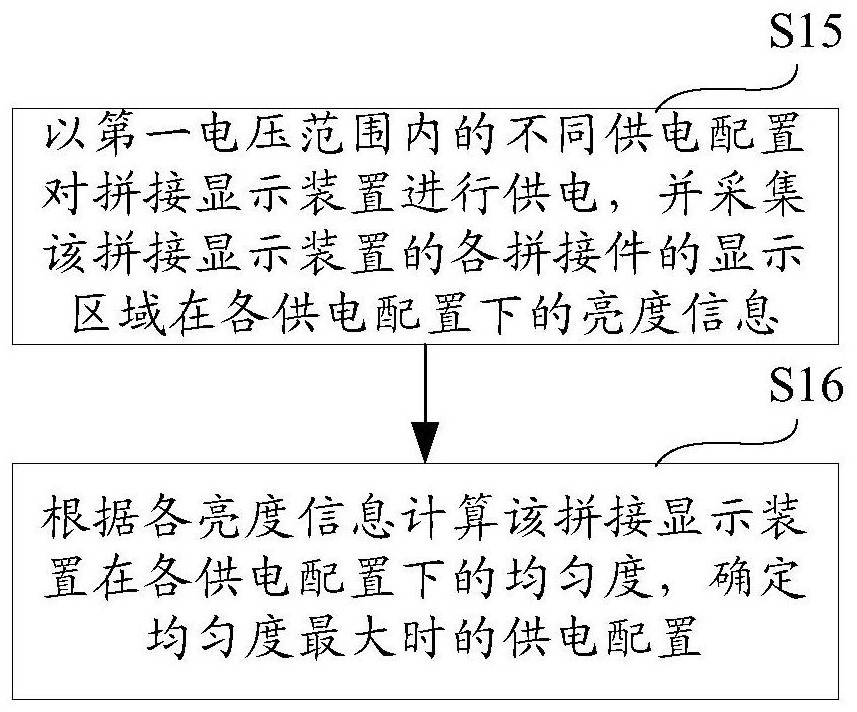

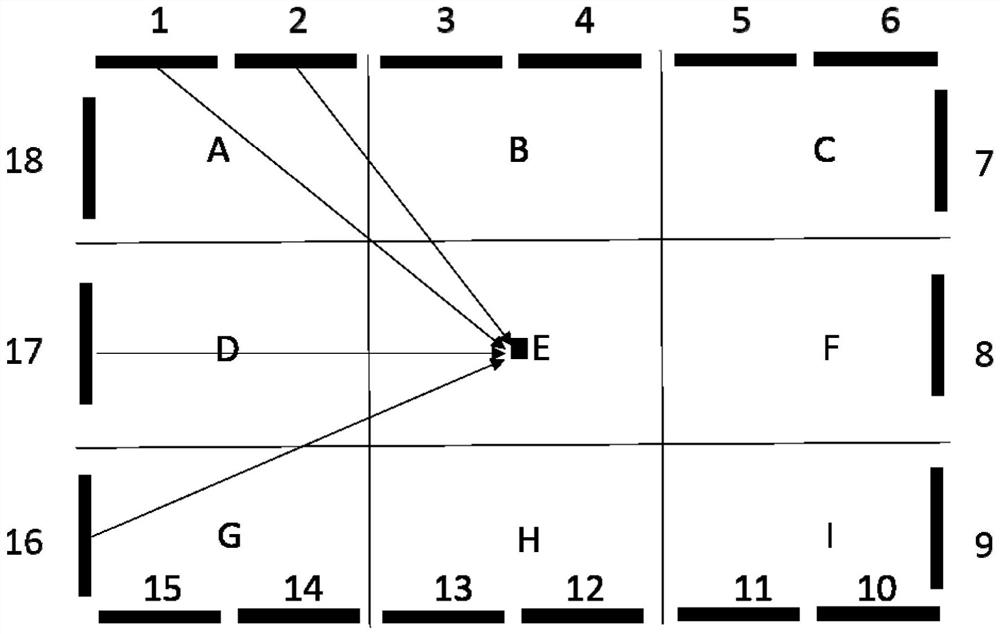

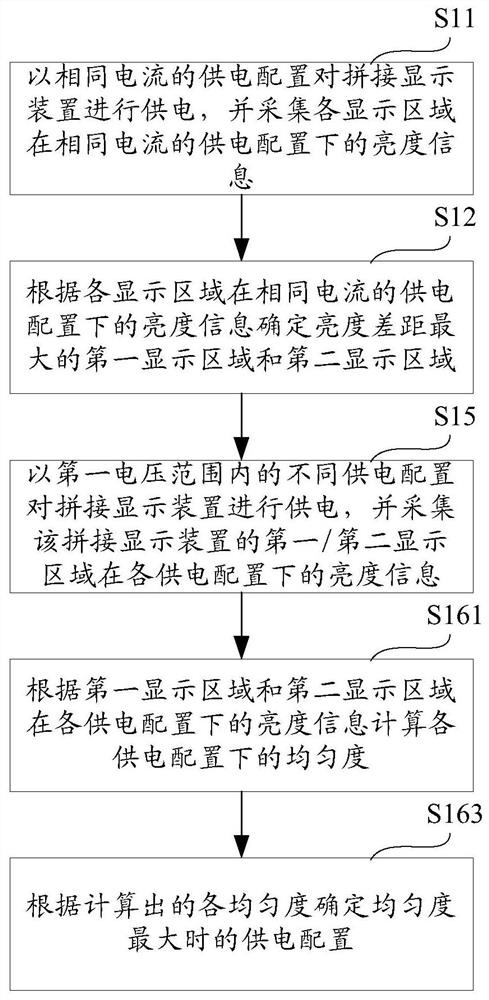

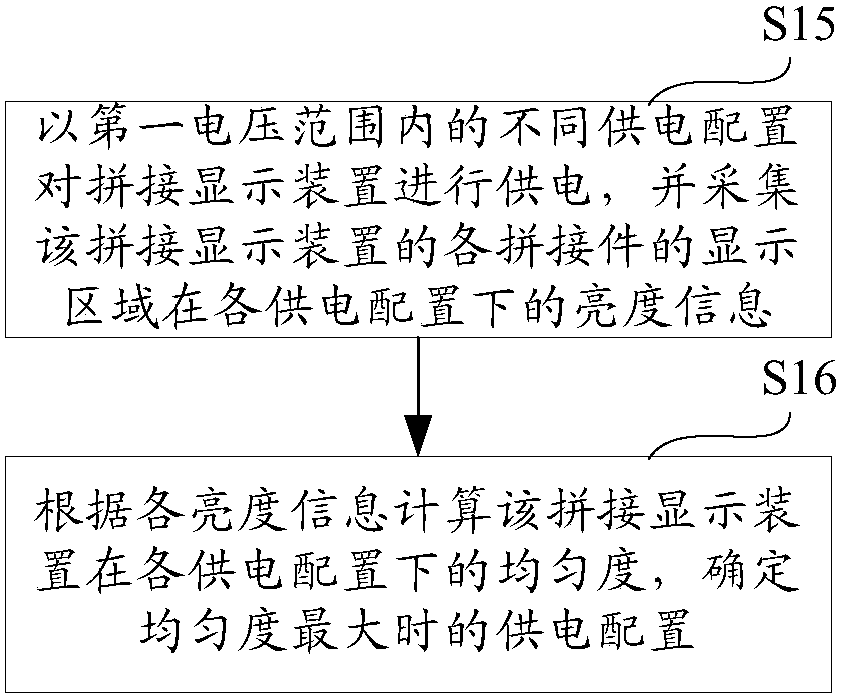

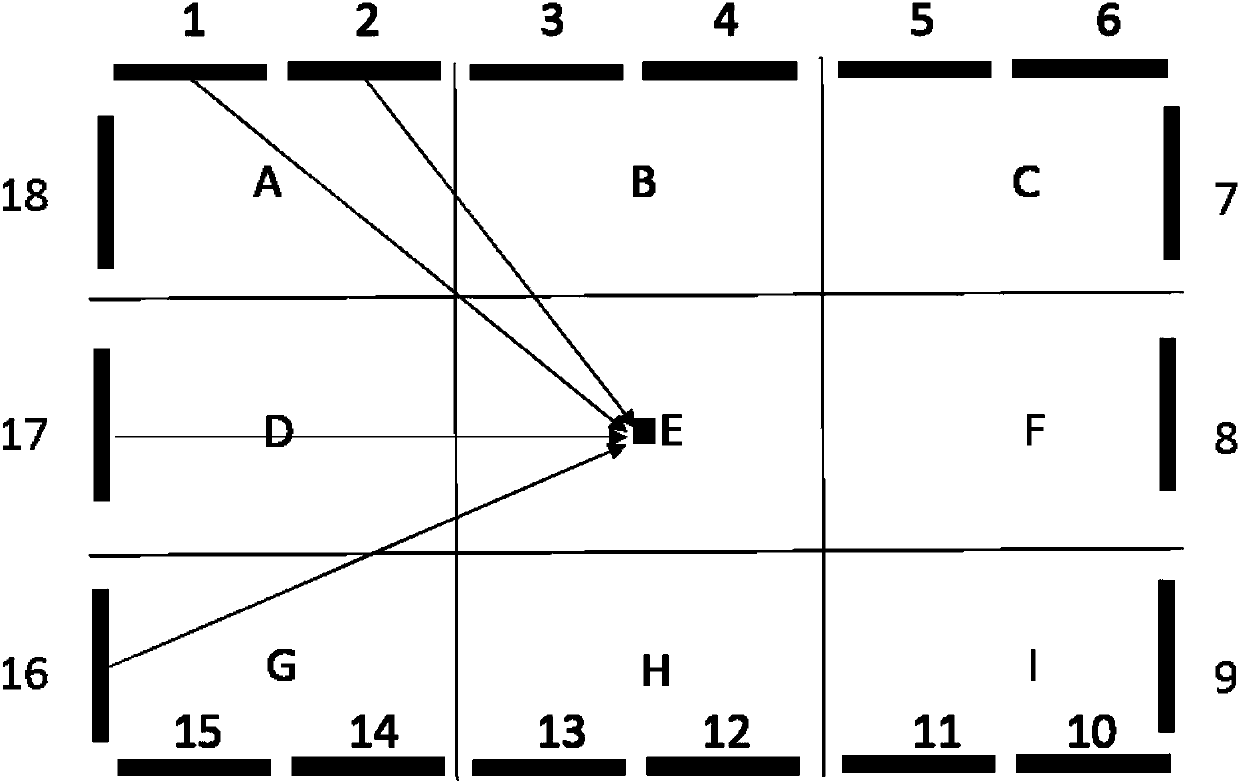

Uniformity debugging method and device, equipment and computer-readable storage medium

InactiveCN107562398BRealize automatic debuggingSimple calculationStatic indicating devicesDigital output to display deviceComputer hardwareDisplay device

The present invention provides a uniformity debugging method, device, equipment, and computer-readable storage medium. The method includes: supplying power to a splicing display device with different power supply configurations within a first voltage range, and collecting each splicing display of the splicing display device. The brightness information of the display area of the component under each power supply configuration; calculate the uniformity of the spliced display device under each power supply configuration according to each brightness information, and determine the power supply configuration with the maximum uniformity. The uniformity debugging method and device, equipment, and computer-readable storage medium provided by the present invention obtain corresponding brightness information by automatically traversing different power supply configurations that meet the brightness requirements, and calculate each uniformity according to each brightness information, and finally determine the maximum uniformity The power supply configuration corresponding to the degree can realize automatic debugging of the uniformity of the splicing display device.

Owner:BOE TECH GRP CO LTD

Uniformity debugging method and device, equipment and computer readable storage medium

ActiveCN107562398ASimple calculationImprove debugging efficiencyStatic indicating devicesDigital output to display deviceVoltage rangeDisplay device

The invention provides a uniformity debugging method and device, equipment and a computer readable storage medium. The method comprises the steps of supplying power to a splicing display device with different kinds of power supply configuration in a first voltage range and acquiring brightness information of display areas of all splicing parts of the splicing display device under all power supplyconfiguration; calculating the uniformities of the splicing display device under all the power supply configuration according to all the brightness information and determining the power supply configuration when the uniformity is the largest. By automatically traversing the different kinds of power supply configuration which meet brightness requirements, the corresponding brightness information isobtained, according to all the brightness information, all the uniformities are calculated, the power supply configuration corresponding to the largest uniformity is finally determined, and automaticdebugging of the uniformities of the splicing display device is achieved.

Owner:BOE TECH GRP CO LTD

Compensation system and method capable of automatically tuning output level of multi-band HFC equipment

ActiveCN111077815AHigh precision indexRealize automatic debuggingProgramme controlComputer controlMulti bandControl signal

The invention discloses a compensation system and method capable of automatically tuning the output level of multi-band HFC equipment. The compensation system comprises a duplexer, a micro-control unit, a compensation unit, a network analyzer and a PC. The micro-control unit is connected with the duplexer to obtain a voltage value on the duplexer; the micro-control unit also receives configurationdata output by the PC, and outputs a control signal to the compensation unit according to the voltage value and the configuration data; the compensation unit receives the control signal, compensatesan input radio frequency signal, and outputs the compensated radio frequency signal to the network analyzer; the network analyzer receives the compensated radio frequency signal for testing to obtaina test curve and outputs the test curve to the PC; and the PC receives the test curve and the standard curve, analyzes and compares the test curve and the standard curve to obtain a comparison result,and outputs corresponding configuration data to the micro-control unit according to the comparison result. According to the invention, the output level of the equipment can be automatically tested and debugged, and the output level precision is improved.

Owner:成都芯通软件有限公司

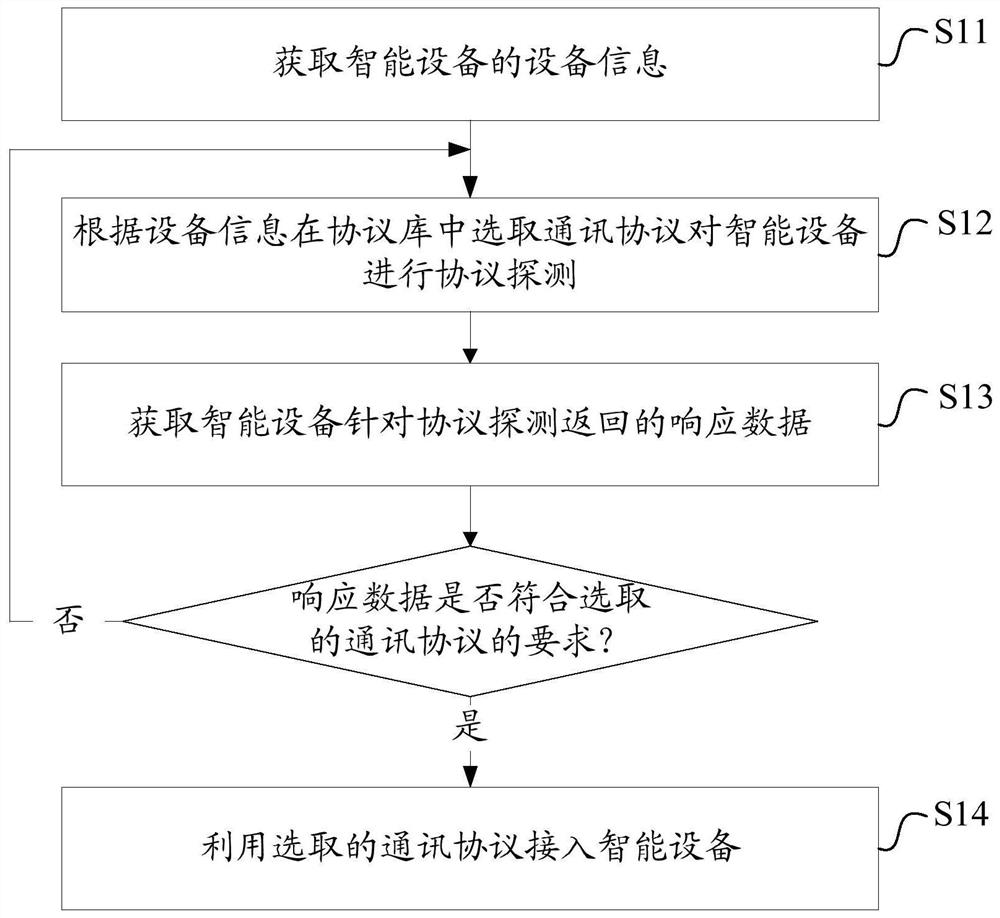

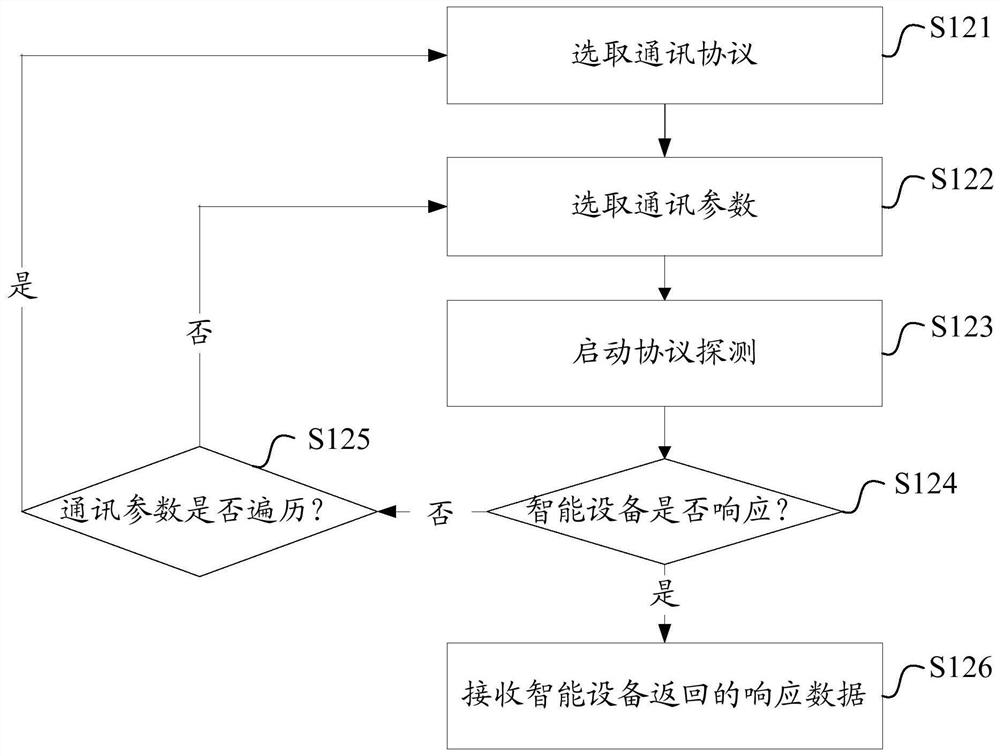

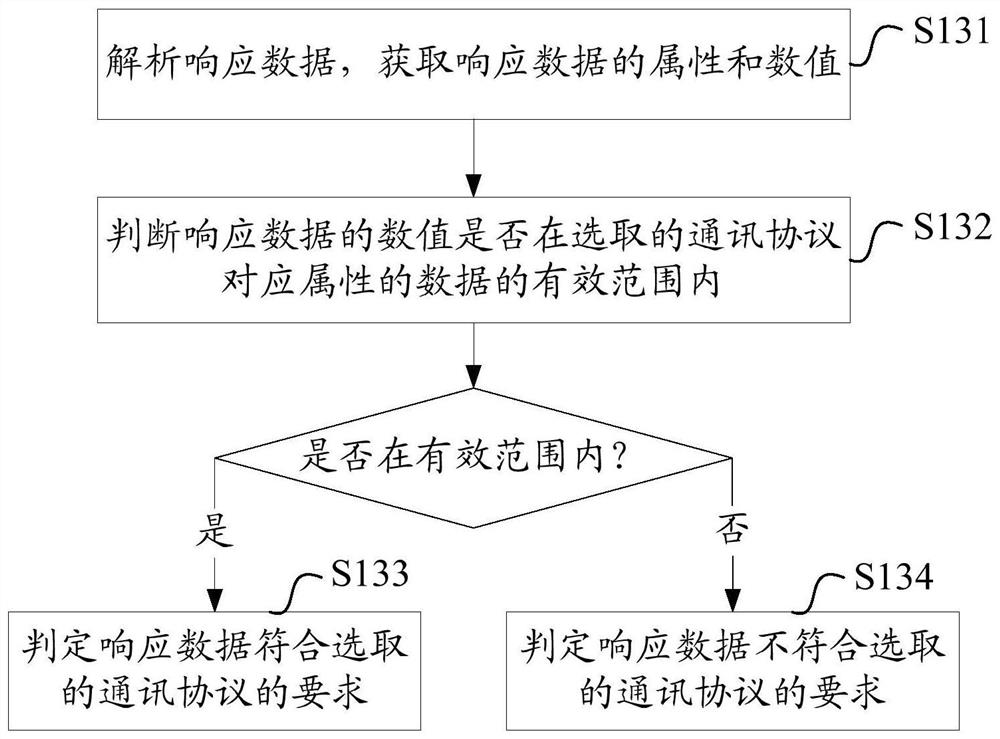

Smart device access method and system

ActiveCN108235801BRealize automatic debuggingImprove debugging efficiencyData switching networksElectric digital data processingAccess methodCommunications protocol

The invention discloses an access method and system for an intelligent device. The method includes the following steps: acquiring device information of the intelligent device; selecting a communication protocol in a protocol library according to the device information, and performing protocol detection on the intelligent device; Obtain the response data returned by the smart device for the protocol detection, and determine whether the response data meets the requirements of the selected communication protocol; when the response data meets the requirements of the selected communication protocol, use the selected communication protocol to access The smart device. Therefore, by automatically detecting the protocol of the smart device, the corresponding communication protocol is quickly matched for the smart device and connected to the smart device, and the automatic debugging and fast connection of the smart device are realized. Compared with the cumbersome manual debugging process, a great It improves the debugging efficiency of smart devices, ensures the accuracy of the loaded communication protocol, and greatly reduces the debugging cost of smart devices.

Owner:SHENZHEN ZTE NETVIEW TECH

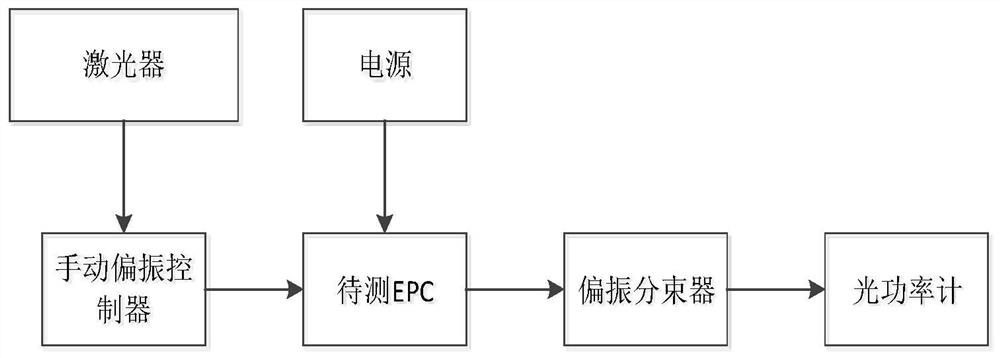

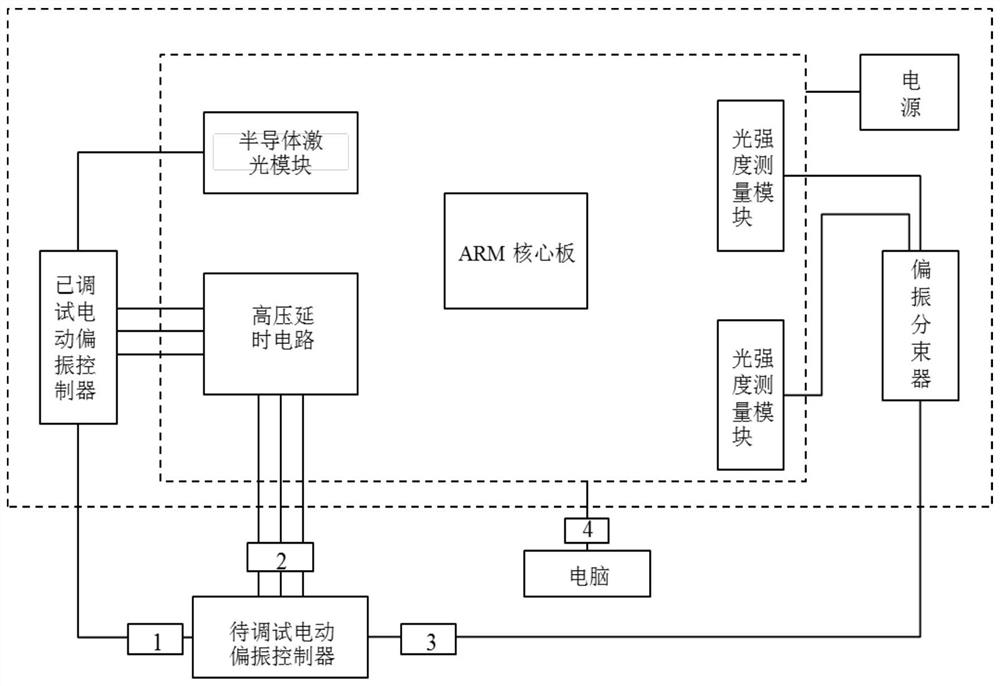

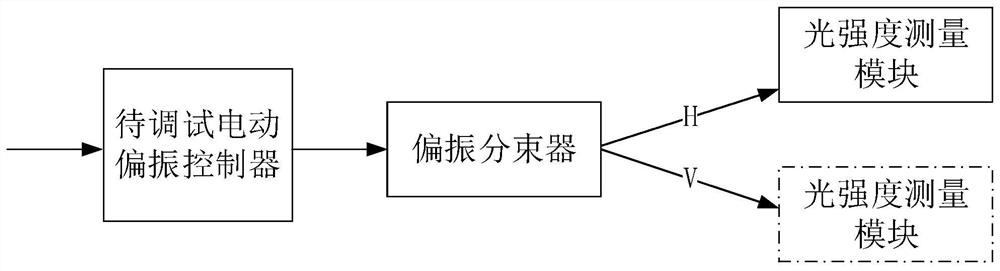

Electric polarization controller automatic debugging device and debugging method thereof

ActiveCN112098048AFast outputAccurately obtain the maximum light intensity differenceTesting optical propertiesNon-linear opticsHemt circuitsEngineering

The invention provides an electric polarization controller automatic debugging device which comprises a polarization beam splitter, a power supply, a core board, a semiconductor laser module, a debugged electric polarization controller, a high-voltage delay circuit, a first light intensity measurement module and a second light intensity measurement module. The semiconductor laser module is connected to the debugged electric polarization controller, the debugged electric polarization controller is connected to the EPC to be debugged, the EPC to be debugged is connected to the polarization beamsplitter at the same time, the polarization beam splitter is connected with the first light intensity measurement module and the second light intensity measurement module, and the high-voltage delay circuit is connected between the debugged electric polarization controller and the EPC to be debugged. The semiconductor laser module, the high-voltage delay circuit, the first light intensity measurement module and the second light intensity measurement module are connected to the core board, and the power supply is used for supplying power. The invention further provides an electric polarizationcontroller automatic debugging method. The device has the advantages that automatic debugging is achieved, and the defects that manual adjustment has high requirements for operators, time is wasted inoperation and efficiency is low are overcome.

Owner:QUANTUMCTEK

Fixture and system for debugging parameters of naked-eye 3D display device

InactiveCN105007482BRealize automatic debuggingMeet the actual needs of debuggingTelevision systemsSteroscopic systemsDisplay deviceEngineering

Owner:CHONGQING DROMAX PHOTOELECTRIC

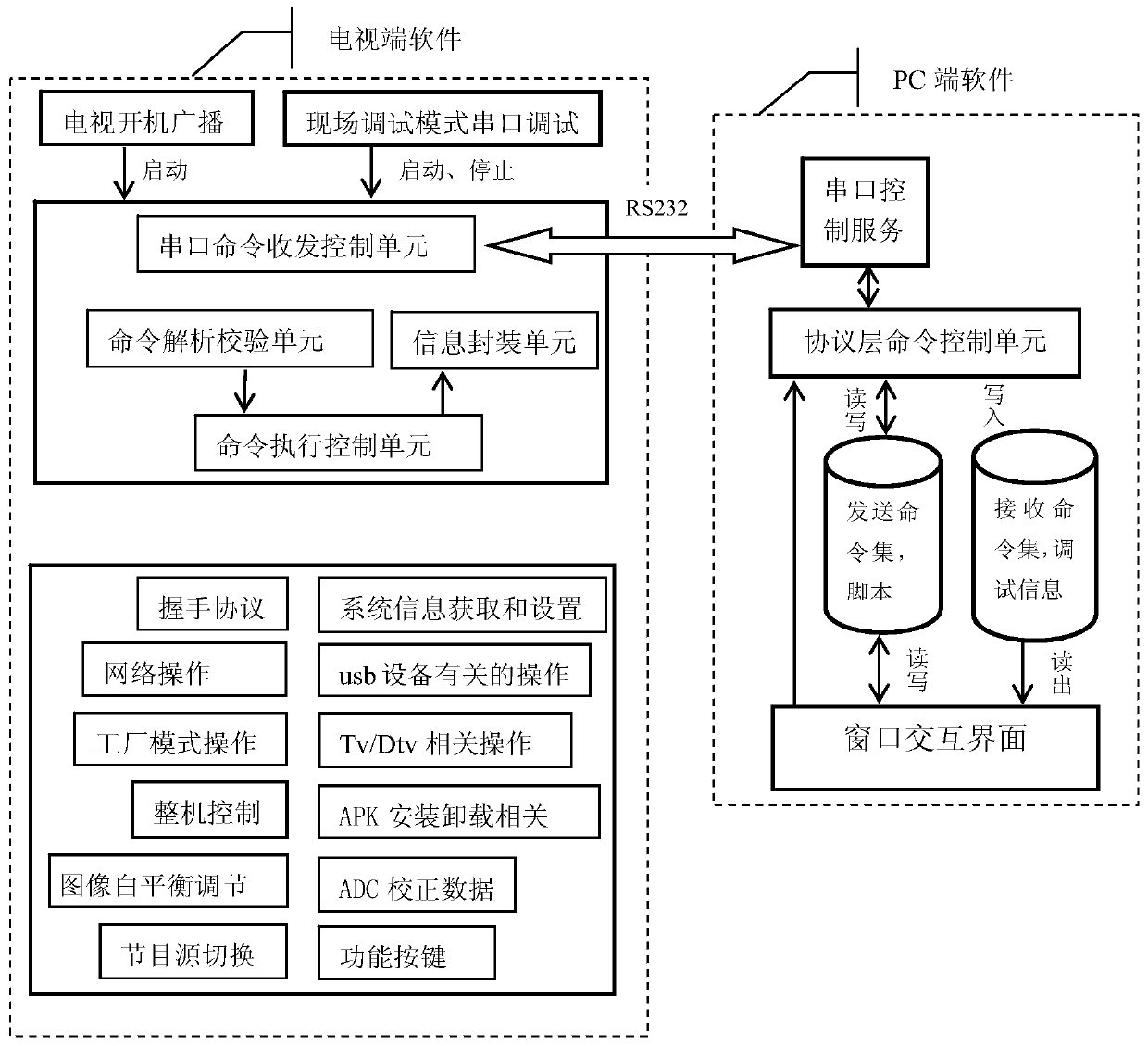

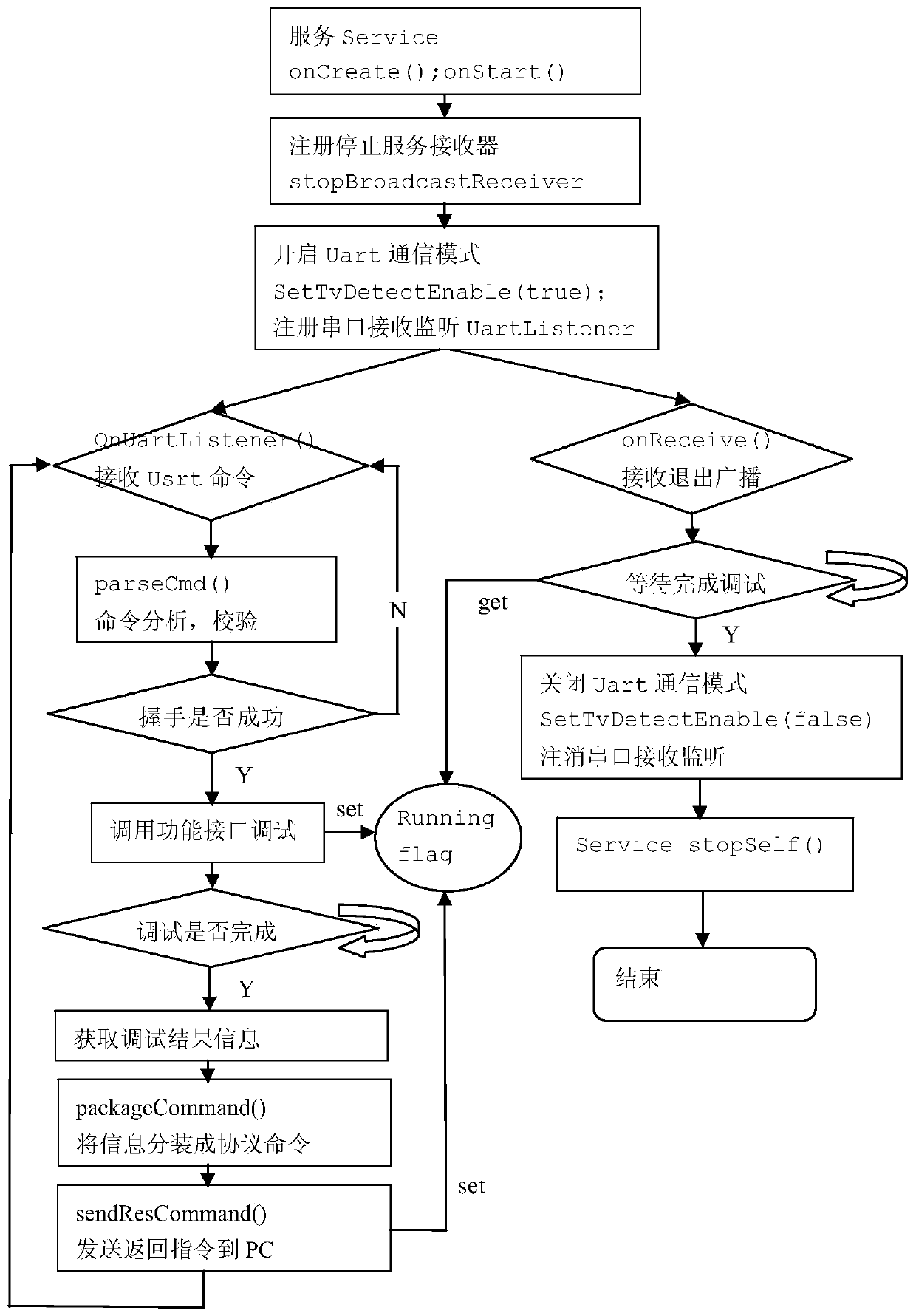

Automatic Commissioning System for Smart TV

ActiveCN109040752BRealize automatic debuggingImplement debuggingTelevision systemsSelective content distributionService controlSoftware engineering

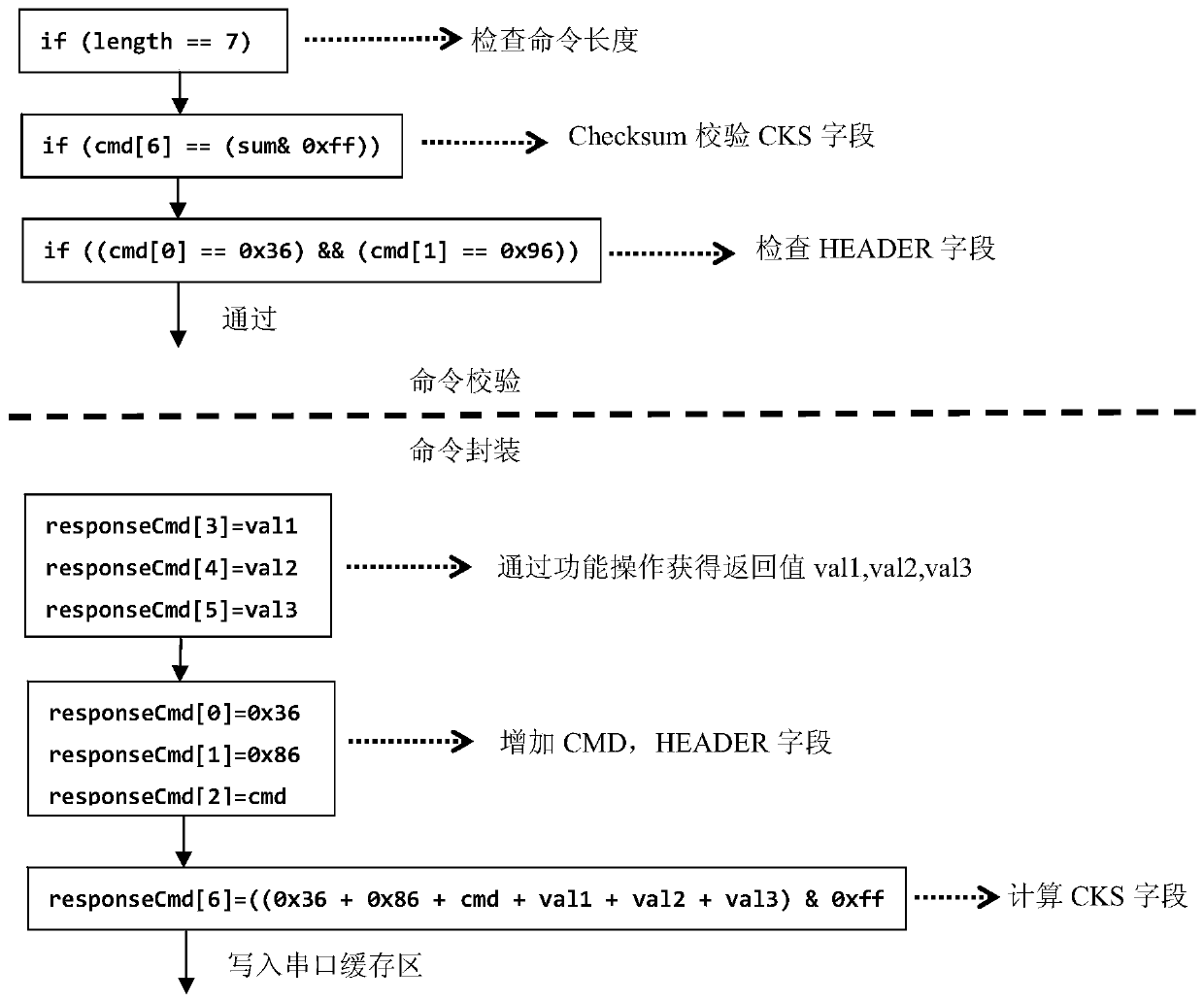

The invention relates to the technical field of intelligent television software, and discloses an automatic debugging system for the intelligent television, which is used for automatic debugging of the intelligent television and reduces the time input of the site debugging management personnel or the factory tester. The system comprises a PC terminal software and a TV terminal software. The TV terminal software comprises a service processing module and a sub-function module. The service control module comprises a serial port command sending / receiving control unit, a command analyzing / checkingunit, an information encapsulating unit and a command executing control unit. The command execution control unit distributes the command parsed and verified by the command parsing and verifying unit to different sub-function modules to execute the corresponding function debugging; And after receiving the debugging results fed back by the sub-functional modules, the control information encapsulation unit encapsulates the debugging results into serial port commands, and finally sends the debugging results to the PC software in the form of serial port commands. The invention is suitable for factory debugging of intelligent television.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Debugging method, device and storage medium

ActiveCN114564414BEfficient managementRealize automatic debuggingSoftware testing/debuggingProgram loading/initiatingReference configurationDocumentation

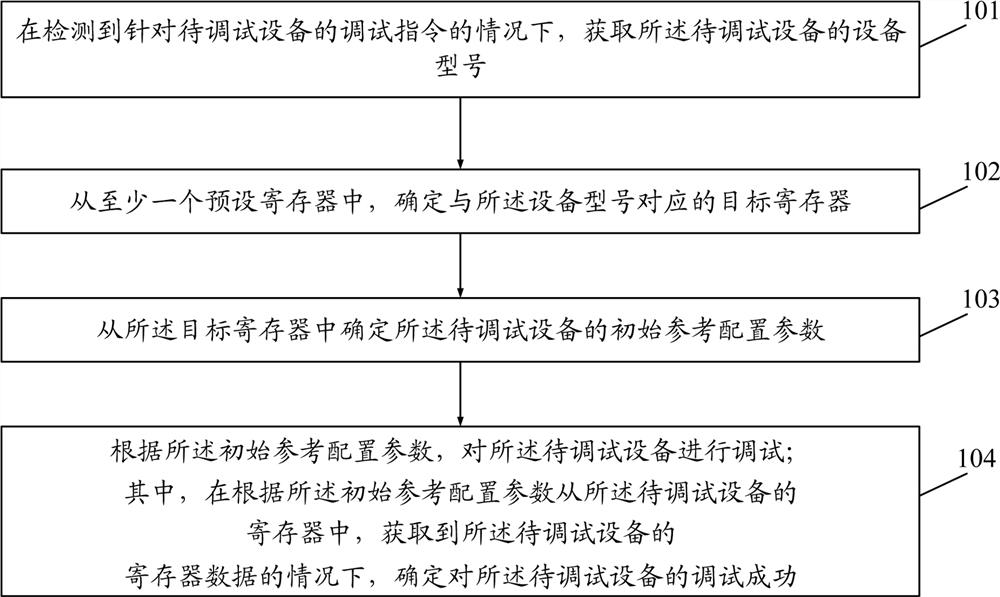

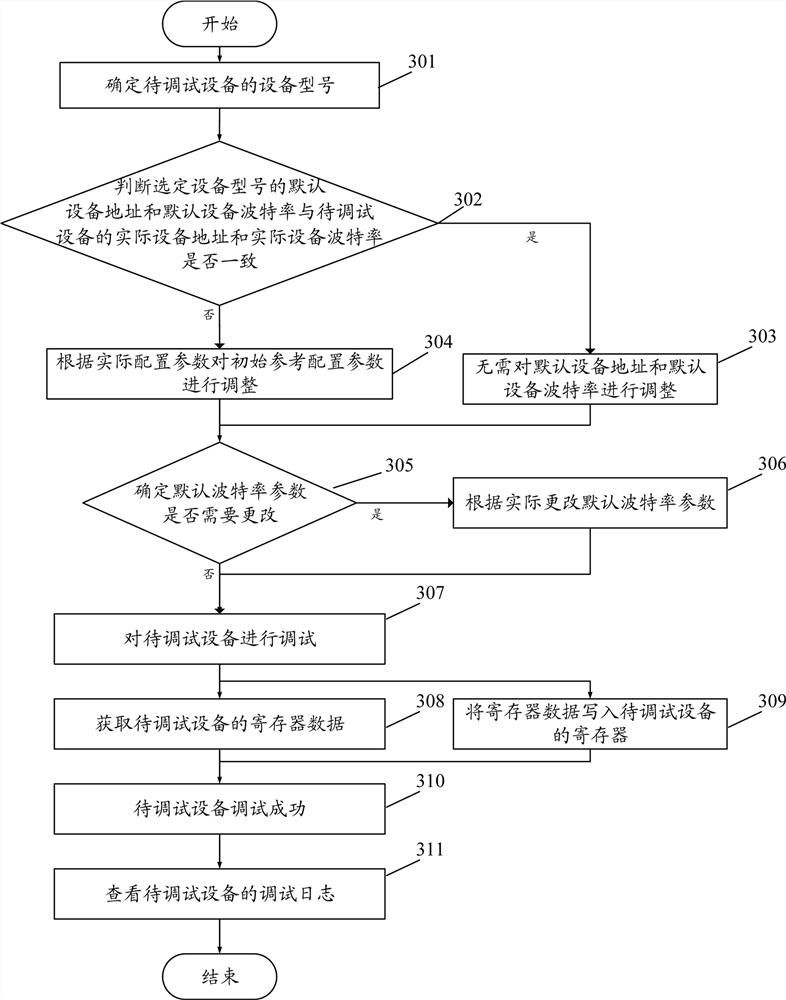

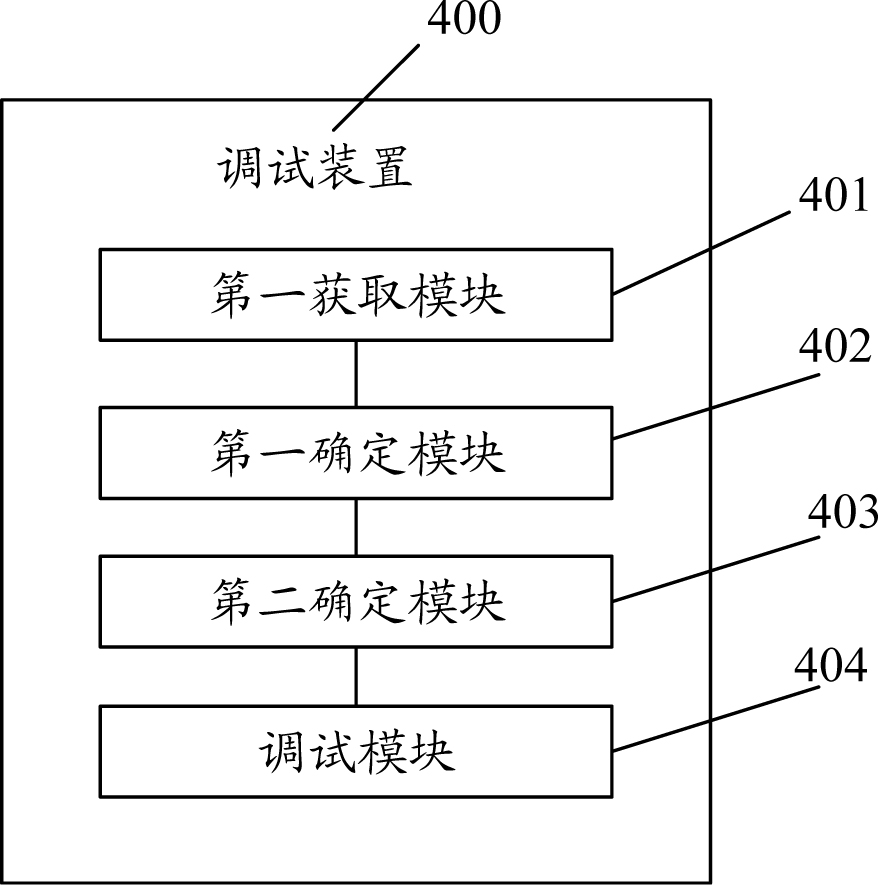

The embodiments of the present application disclose a debugging method, a device, and a storage medium. The method includes: when a debugging instruction for the device to be debugged is detected, acquiring the device model of the device to be debugged; from at least one preset register, determining a target register corresponding to the device model; The initial reference configuration parameters of the device to be debugged are determined in the target register; the device to be debugged is debugged according to the initial reference configuration parameters; wherein, according to the initial reference configuration parameters, the device to be debugged is obtained from the register of the device to be debugged. In the case of obtaining the register data of the device to be debugged, it is determined that the debug of the device to be debugged is successful. In this way, when debugging the device to be debugged, it is not necessary to check the original technical documents of the device to be debugged, and the automatic debugging of the device to be debugged can be realized through the electronic device, which can not only realize the efficient management of data, but also improve the convenience of user operation. .

Owner:武汉慧联无限科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com