Automatic debugging system for radio-frequency signal products

A radio frequency signal and automatic debugging technology, which is applied in the transmission system, transmitter monitoring, transmission monitoring, etc., can solve the problems of poor product performance consistency, depending on the length of debugging time, and high requirements for debugging workers, so as to achieve good product performance consistency, The effect of reducing the number of debugging workers and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

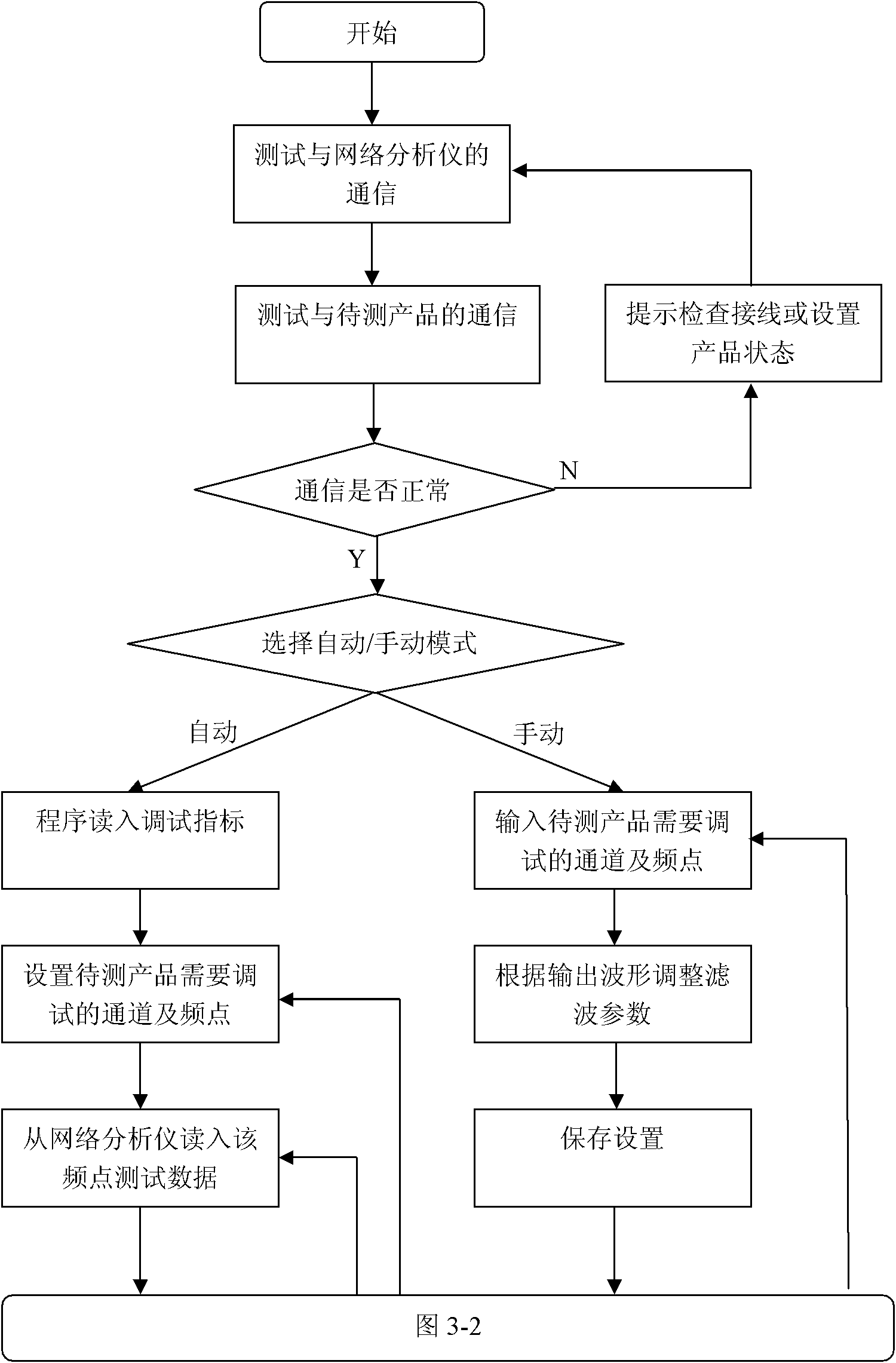

[0047] This embodiment is an automatic debugging method of the radio frequency signal product automatic debugging system in the first embodiment.

[0048] like Figure 3-1 and 3-2 As shown, the PC performs the following steps:

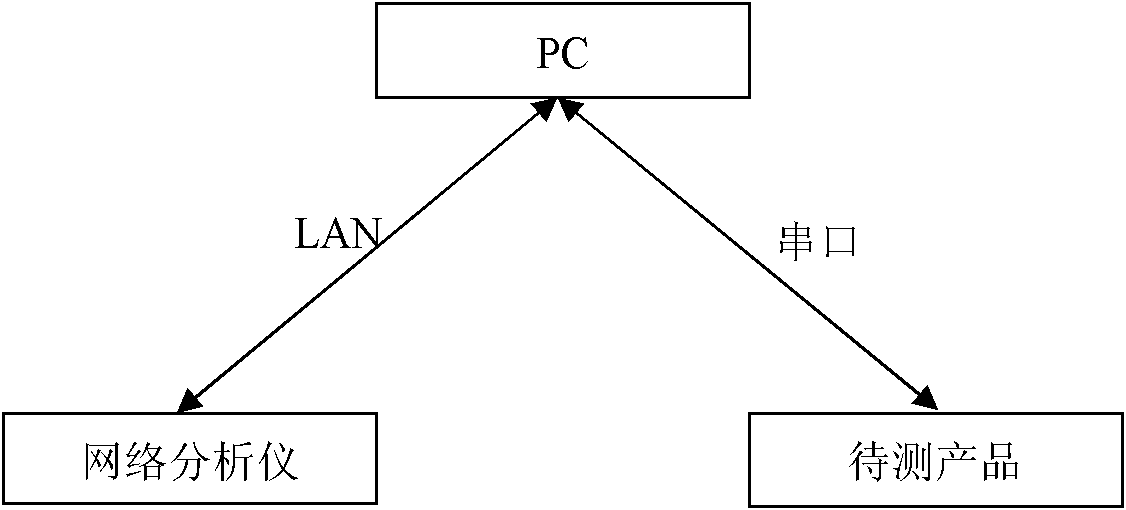

[0049] Step 1 Establish communication between the computer, the vector network analyzer and the product to be tested;

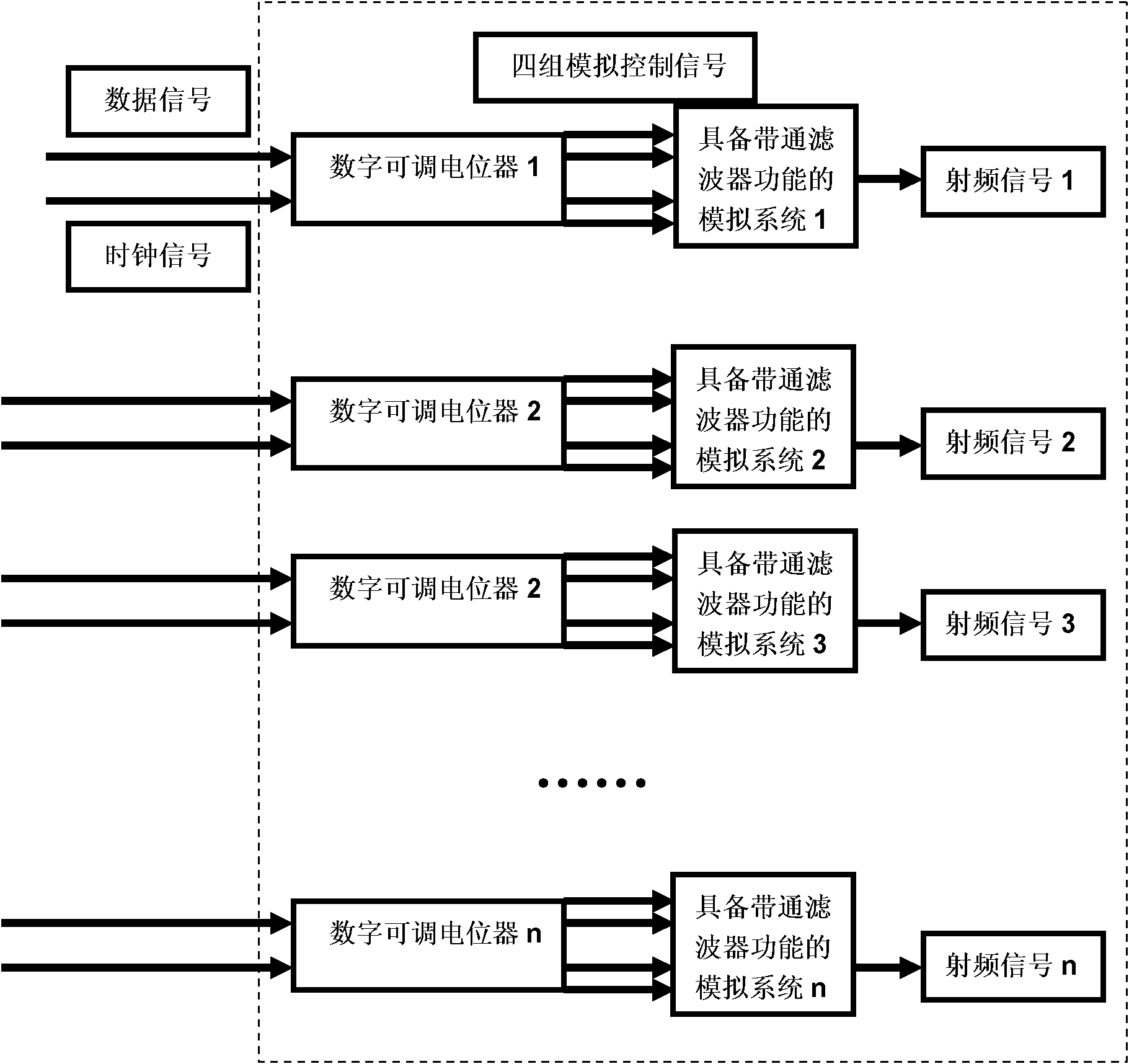

[0050] Step 2 Read in the RF signal channels and channels that need to be debugged this time, and look up the table to preset the frequency point, bandwidth, out-of-band signal suppression and signal gain indicators corresponding to each channel;

[0051] Step 3 Instruct the vector network analyzer to perform the channel performance index test, accept the performance index test data fed back by the vector network analyzer, and judge whether the test data meets the index requirements of the preset table; if it meets the index requirements, perform step 4; if it does not meet the index requirements, go to step 5;

[0052] Step 4 rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com