Concrete screw

A concrete and screw technology, applied in the direction of screws, threaded fasteners, threaded products, etc., can solve problems such as inapplicability, and achieve the effect of simplifying installation and reducing forming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

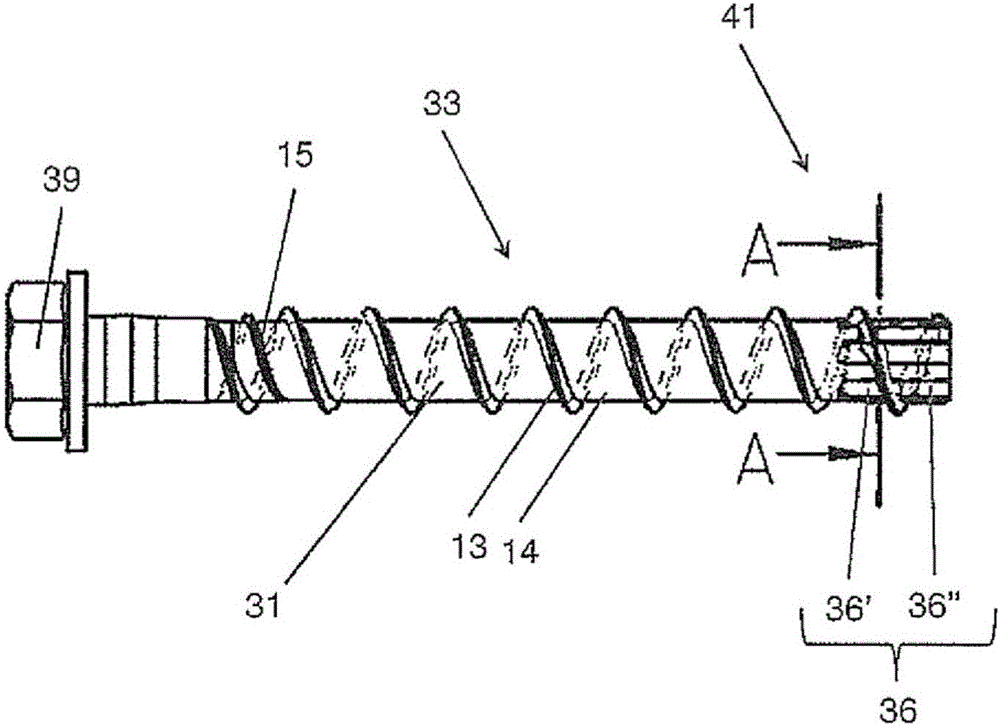

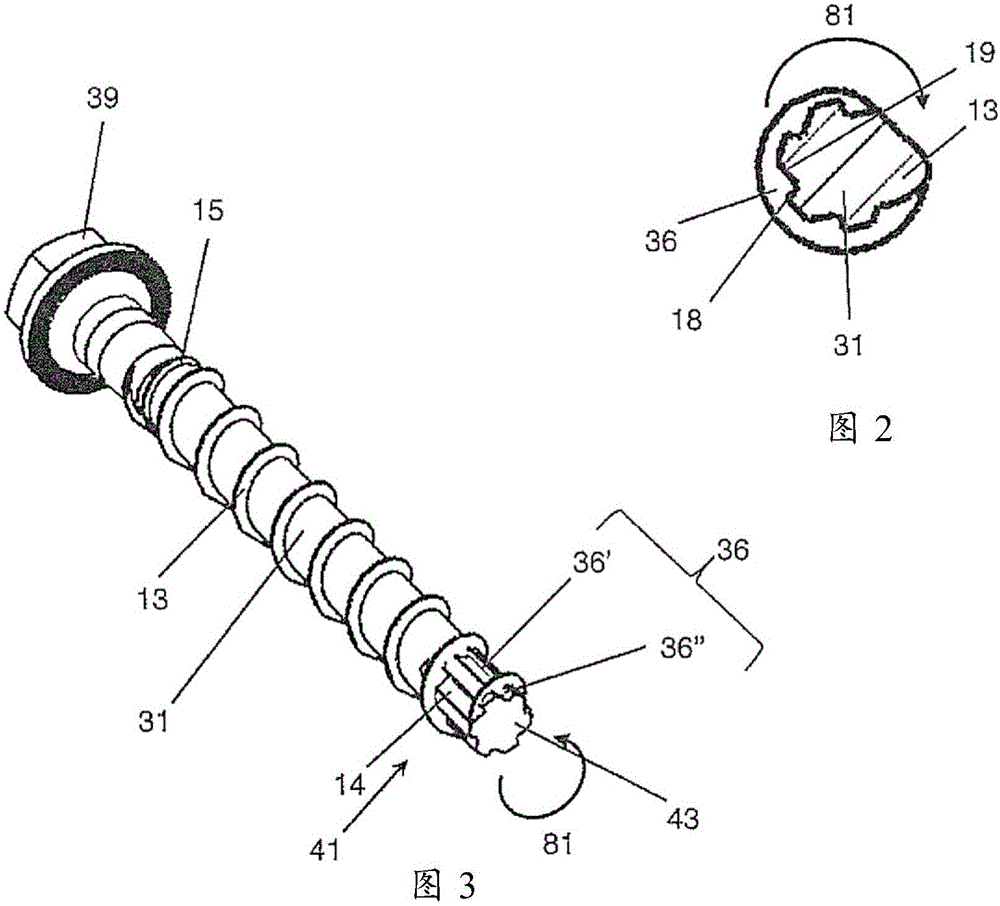

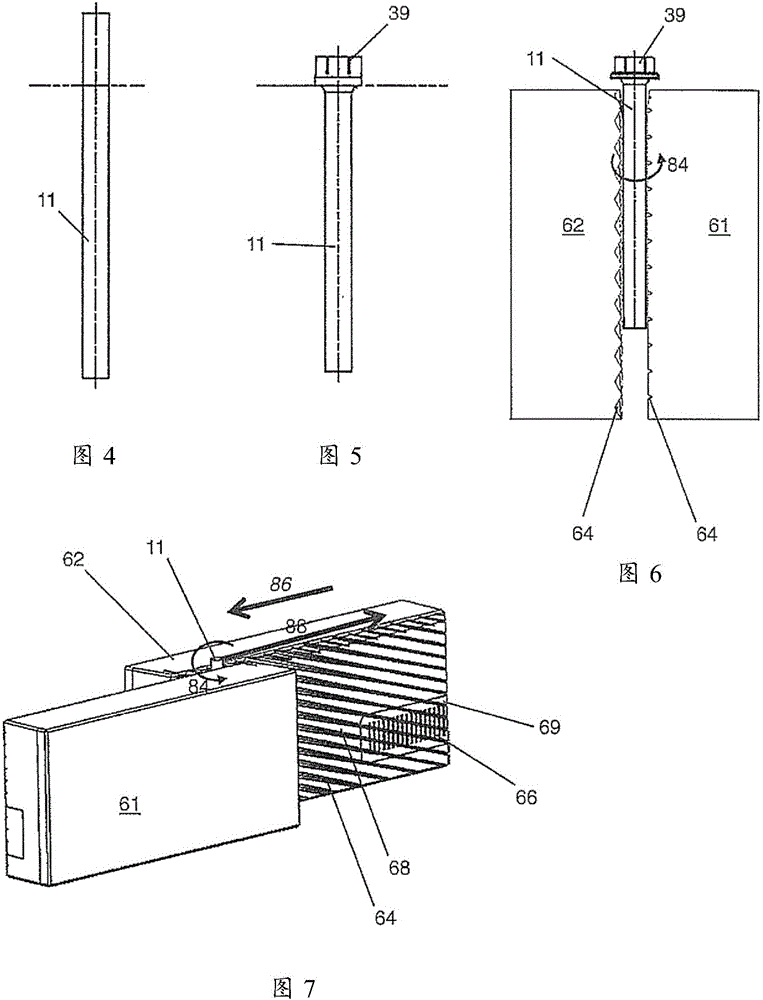

[0038] exist Figures 1 to 3 An embodiment of a concrete screw according to the invention is shown in . The screw has a cylindrical shank 31 , at one end of which a screw head 39 is formed, which has a polygonal configuration in the form of an external hexagon for a form-fitting, rotationally fixed connection to a mounting tool, for example a percussion screwdriver. At the opposite end of the screw head, ie in the region of the tip which is first introduced into the borehole, the shank of the concrete screw has a substantially flat end face 43 .

[0039] A thread 33 is formed on the outer side of the shaft 31 , the thread having a helical thread helix 13 and a helical thread root 14 delimited by the thread helix 13 . The thread root 14 is to be understood in particular as the surface area of the shaft 31 which, viewed in the longitudinal direction of the shaft 31 , is bounded by axially opposite sides of the thread helix 13 .

[0040] The thread helix 13 starts in the regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com