Flue gas desulfurization device based on ammonia-ammonium sulfate method

A technology of ammonium sulfate method and desulfurization device, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of poor mixing of air bubbles and absorption liquid, corrosion of operating costs, and the need for mechanical power. Flue gas escapes along the tower wall, reduces investment cost and energy consumption, and reduces the floor area of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the drawings and embodiments, but the following content does not constitute a limitation on the protection scope of the present invention.

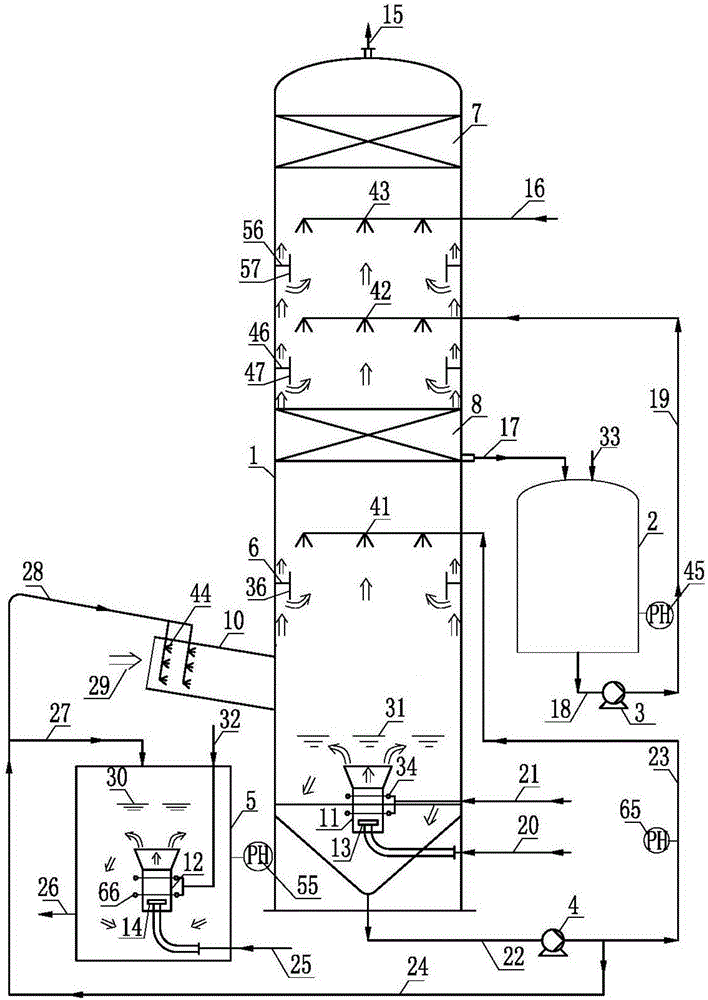

[0044] Such as figure 1 As shown, the ammonia-ammonium sulfate method flue gas desulfurization device includes a flue gas desulfurization absorption tower 1 and an external circulation tank 2, and can also include an oxidation tank 5. The flue gas desulfurization absorption tower 1 includes oxidation section and pre-absorption from bottom to top. Section, external circulation absorption section, washing section and demisting section.

[0045] The oxidation section is located at the lower part of the absorption tower, and a discharge port is provided in the lower part of the oxidation section. The discharge port is connected to the inlet of the outer circulation pump 4 of the lower absorption section through a pipeline, and the outlet of the outer circulation pump 4 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com