Electro-hydraulic power braking system for automobile

An electronically controlled hydraulic and braking system technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of ball check valve wear and sticking in the pump, large pedal force, etc., and achieve convenient troubleshooting and design Reasonable and novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

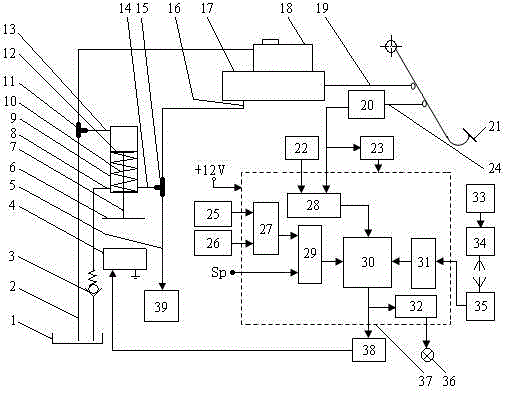

[0017] Such as figure 1 As shown, the automotive electronically controlled hydraulic power-assisted braking system includes a signal sensing part, a calculation and control unit and a signal execution part.

[0018] The signal sensing part includes a displacement sensor 20, a vehicle speed sensor 25, a wheel speed sensor 26, a tire pressure and tire temperature sensor 33, a signal transmitter 34, a signal receiver 35, a time signal generator 22, and a trigger 23. The linkage lever 24 is connected to the brake pedal 21, the signal of the wheel speed sensor 26 and the signal of the vehicle speed sensor 25 are connected to the calculation and control unit 37 through a wire, one signal of the displacement sensor 20 is directly connected to the calculation and control unit 37 through a wire, and the other signal is through the trigger 23 is connected to the calculation and control unit 37, the signal of the tire pressure and tire temperature sensor 33 is sent wirelessly by the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com