Efficient manufacturing method of flat belts

A production method and flat belt technology, which are applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy slippage of yarn, high labor intensity, and difficulty for ordinary consumers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

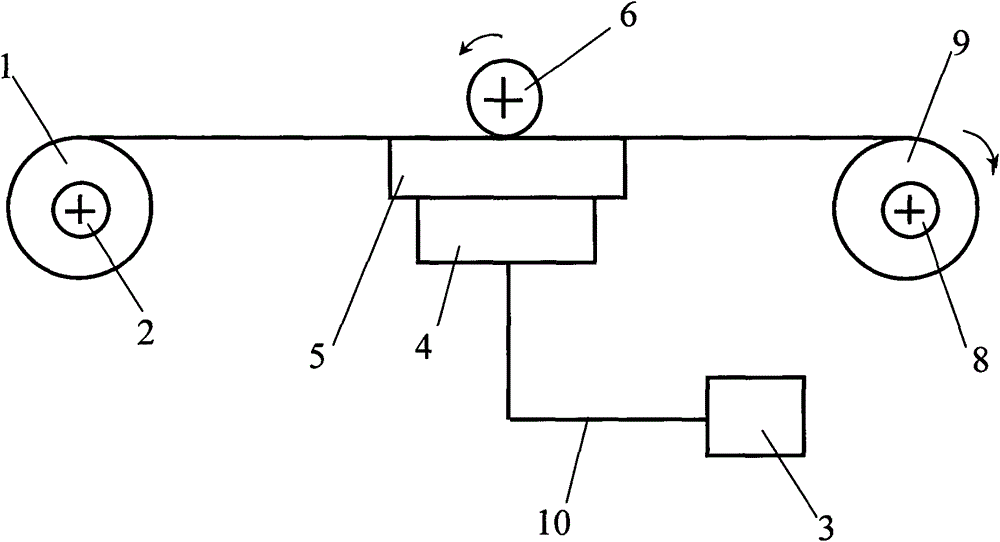

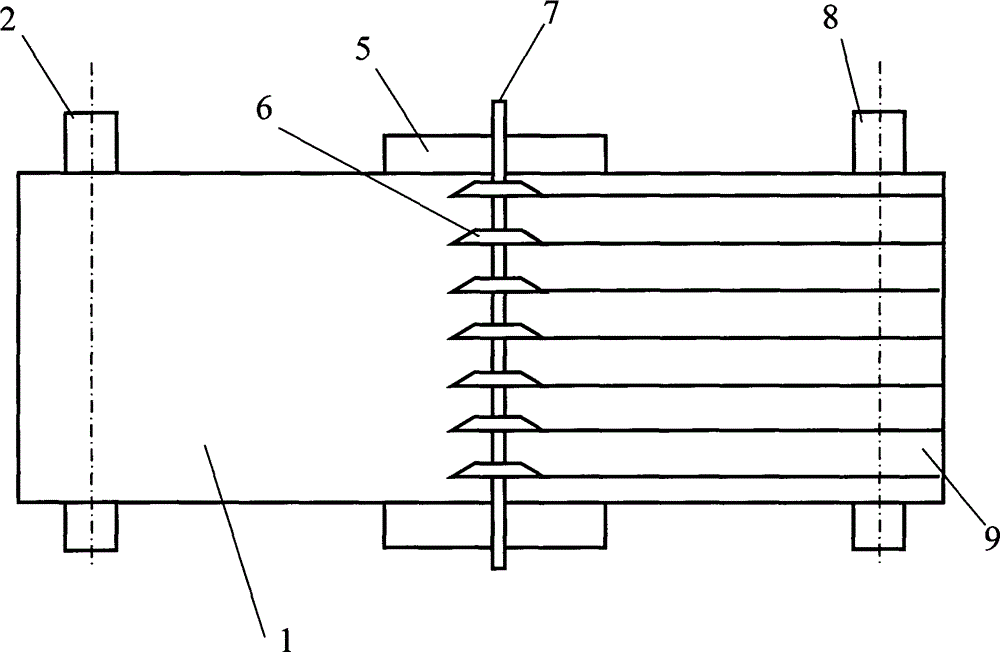

[0011] Such as figure 1 , figure 2 As shown, the knitted fabric 1 is drawn by the take-up roller 8 and passes between the blade 6 and the spacer 5, the blade 6 and the take-up roller 8 rotate synchronously, and the knife holder 7 exerts an appropriate pressure on the blade 6, so that the blade 6 is compressed The knitted cloth between it and pad 5.

[0012] The high frequency power used in this example is 1KW, 15KHZ.

[0013] The high-frequency power supply 3 is connected to the transducer 4 through the cable 10, and the transducer 4 is connected to the cushion block 5. Frequency vibration generates heat instantly, melts and cuts the knitted fabric between pad 5 and blade 6, and at the same time of cutting, performs edge fusion treatment so that the flat belt has no burrs and the edge will not be off-line, which is quite at the edge.

[0014] The cut strip 9 is wound up on the take-up roller 8, and the take-up line speed can reach up to 30 meters per minute, and the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com