Hydraulic support control method and system

A technology of hydraulic support and control method, which is applied in mine roof support, earth square drilling, mining equipment, etc., and can solve the problems of increasing labor intensity of workers and reducing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

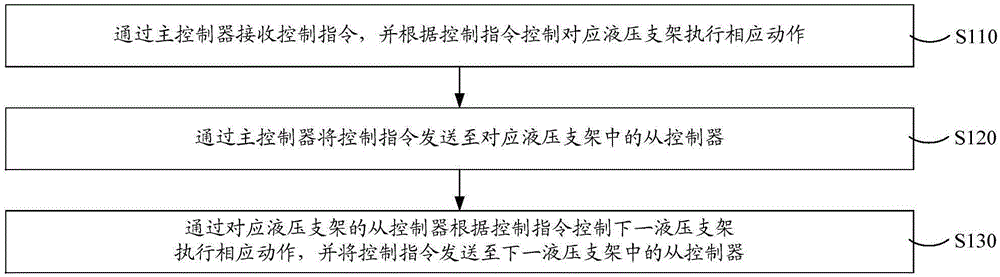

[0021] A hydraulic support control method, such as figure 1 shown, including the following steps:

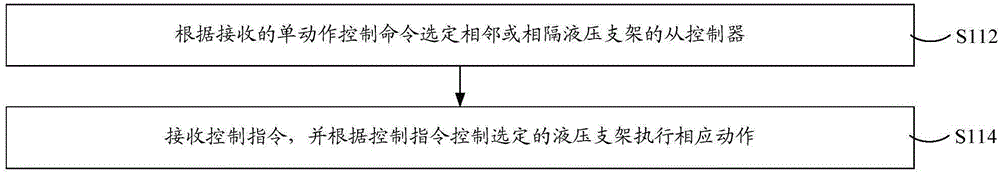

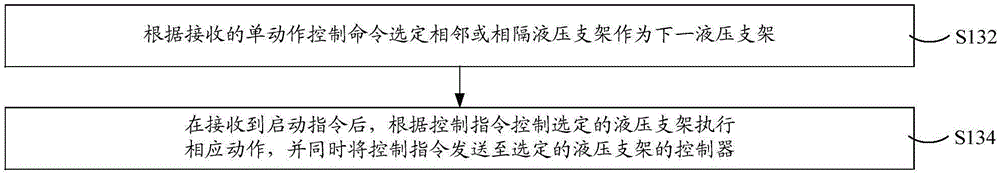

[0022] Step S110: receiving the control instruction through the main controller, and controlling the corresponding hydraulic support to perform corresponding actions according to the control instruction. The control instruction can be adjusted by the action that actually needs to be performed. Specifically, each hydraulic support is provided with a controller and a push rod, the push rod is connected to the chute through a joint, and the controller receives instructions to control the push rod to move. In this embodiment, the controller on one of the hydraulic supports can be used as the main controller to receive the control instructions input by the staff, and correspondingly control the relevant hydraulic supports, for example, control adjacent or spaced hydraulic supports to perform corresponding actions. It can be understood that a single controller may also be used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com