Oilfield electric water injection tool stroke sensor

A travel sensor, sensor body technology, applied in the production of fluids, wellbore/well components, earthwork drilling and other directions, can solve the problems of inability to directly install and use, the structure cannot be matched, etc., to improve the level of automatic control and the accuracy of work The effect of high degree, simple structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

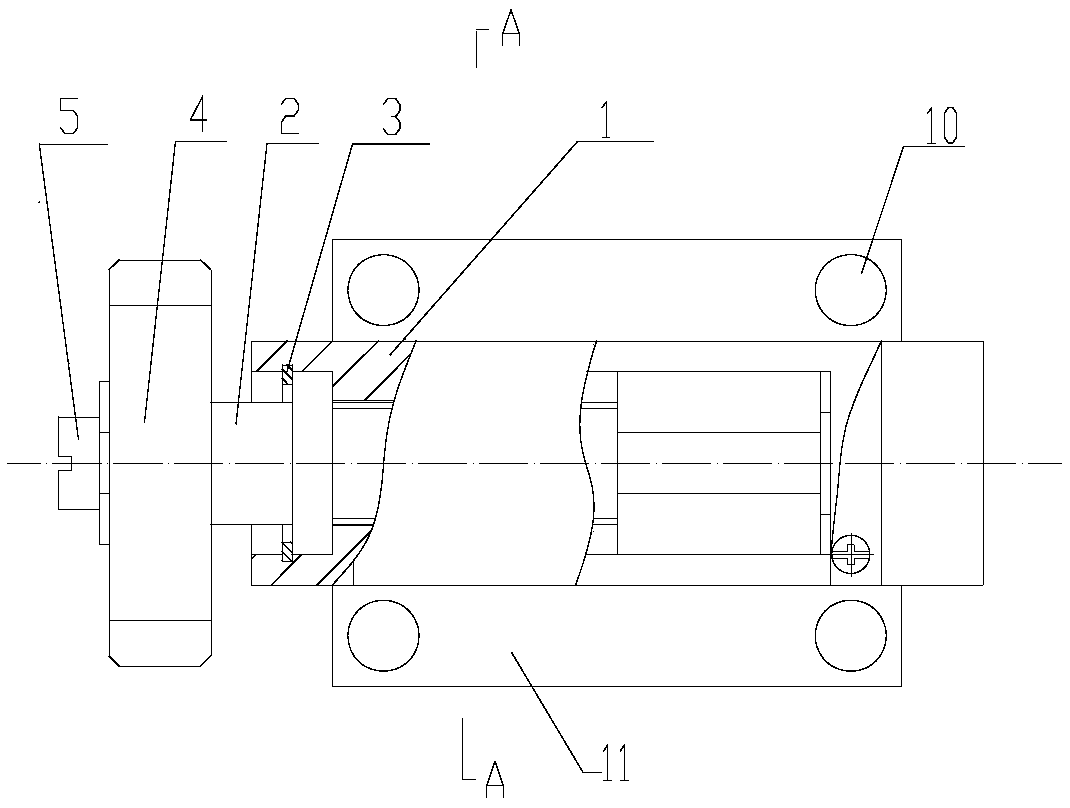

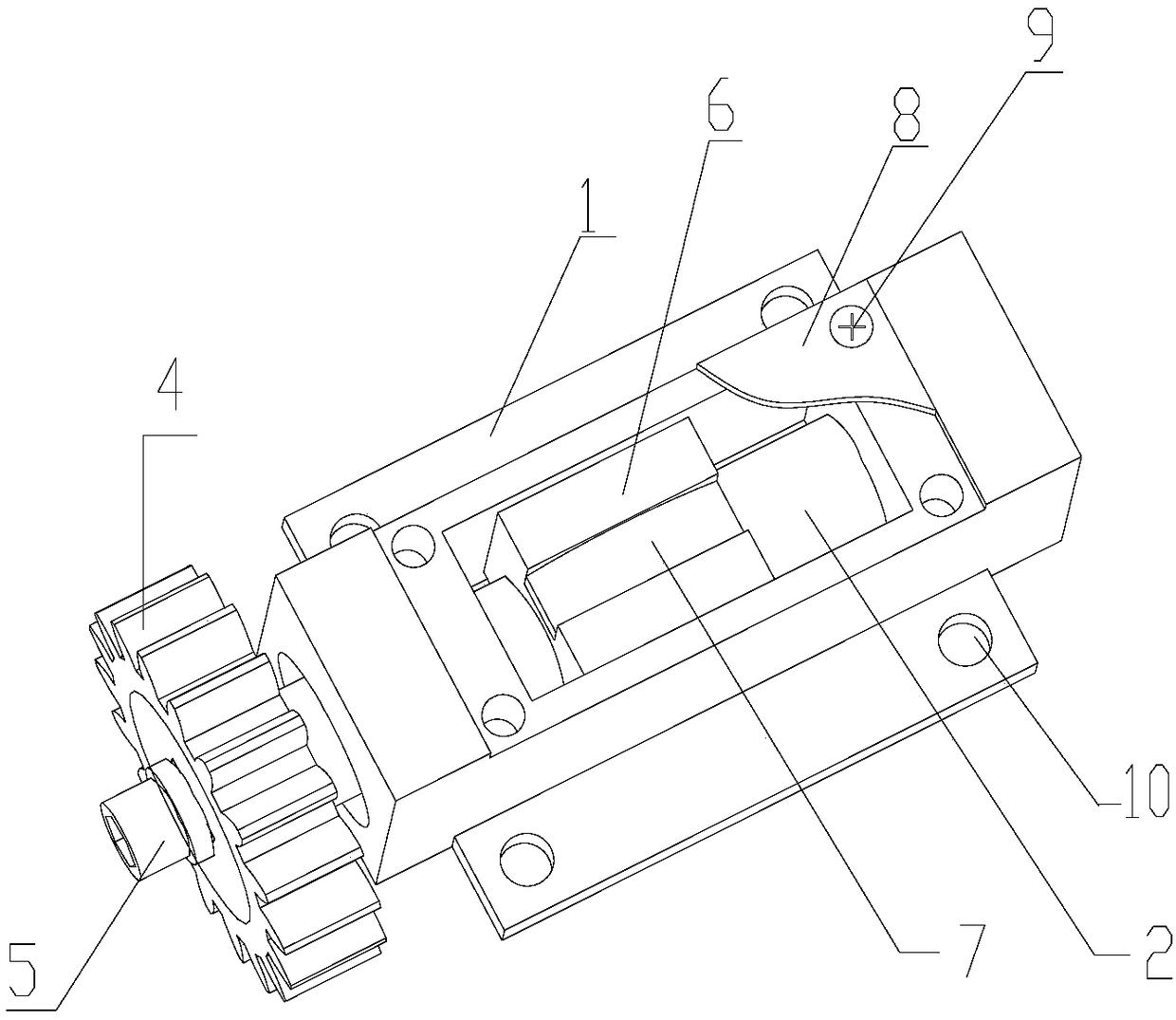

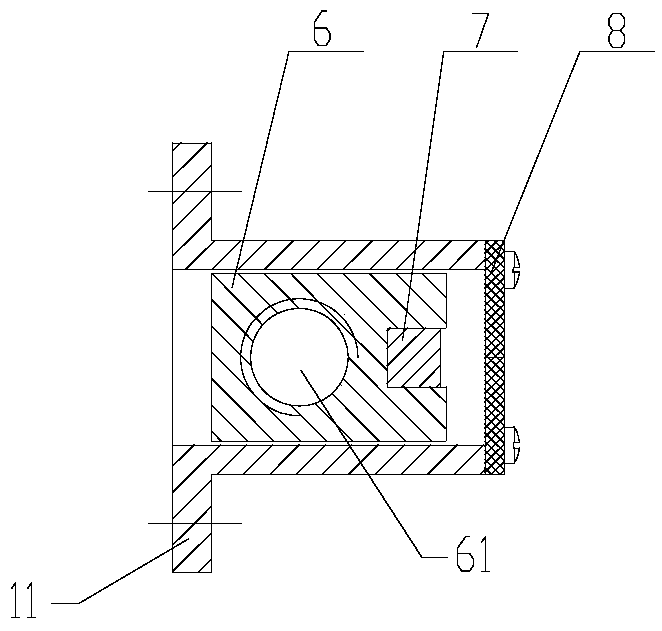

[0017] Combine below figure 1 , figure 2 , image 3 and Figure 4 , the present invention is further described:

[0018] Because the stroke sensors in the prior art cannot be used on the existing oil field electric water injection tool due to structural reasons, the invention focus of the present invention is to install the stroke sensor on the oil field electric water injection tool stroke sensor conveniently, and can Realize accurate stroke control and valve position feedback of water distribution valves in oilfield water injection tools.

[0019] To achieve this purpose, the present invention includes a sensor body 1, which is a cuboid shell with a window 11 on the upper end surface, and the shell with this structure is more convenient for installation. A lead screw transmission device is arranged in the sensor body, the lead screw 2 of the lead screw drive device protrudes from the sensor body 1, and a driven gear 4 is arranged on the lead screw protruding outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com