Water inlet and output pipe of water tank and water tank device

A technology for entering and exiting water pipes and water tanks, which is applied in the directions of packaging, transportation and packaging, pipes/pipe joints/pipe fittings, etc. It can solve the problems of good corrosion resistance and achieve the effect of external structure coordination and external structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

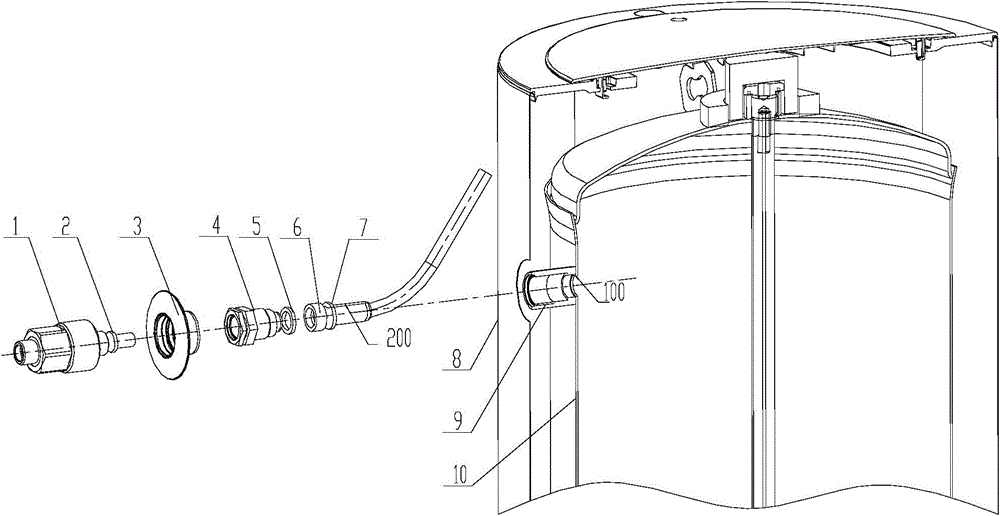

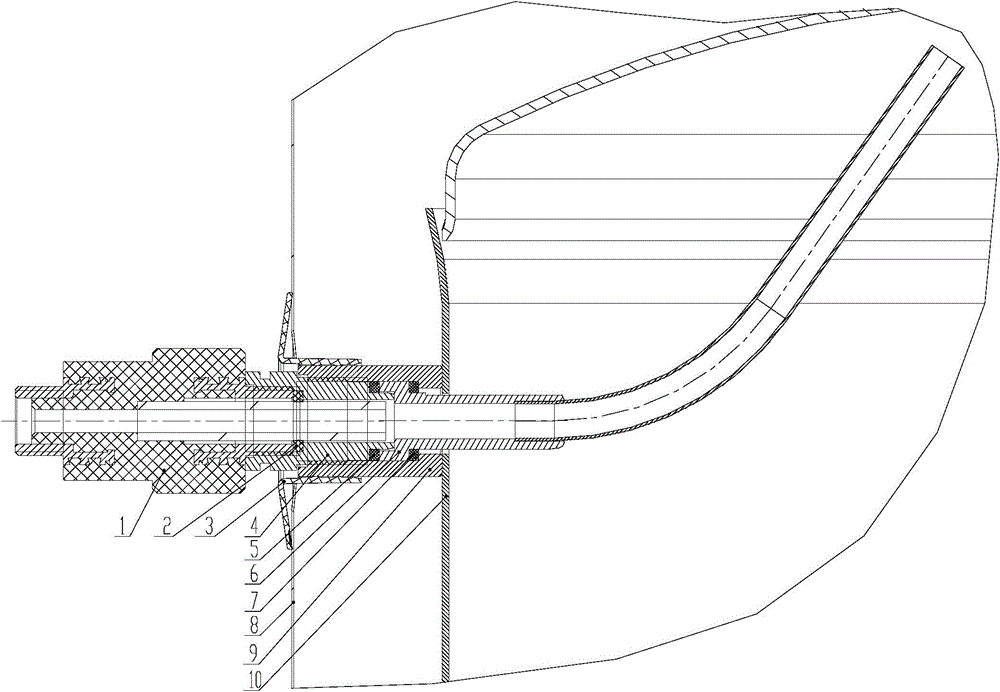

[0029] Such as figure 1 , 2 As shown, the water tank device of this embodiment is composed of the joint assembly, the rubber cover 3, the adapter A4, the water pipe assembly 6, and the mounting seat A9 to form the water tank inlet and outlet pipes, wherein the material of the joint assembly, the adapter A4, and the water pipe assembly is stainless steel, and the mounting seat The A9 material is carbon steel, and the water tank liner 10 is an enamel liner. The enamel material is a composite material that is coated with one or several layers of enamel on the surface of the carbon steel. After firing, the two undergo physical and chemical reactions and are firmly combined.

[0030] Preferably, the side wall of the water tank liner 10 is provided with a water tank inlet and outlet water pipe installation hole, and the section 100 of the installation hole is a "D"-shaped structure; the water pipe joint of the water pipe assembly 6 passes through the installation hole, and the cross...

Embodiment 2

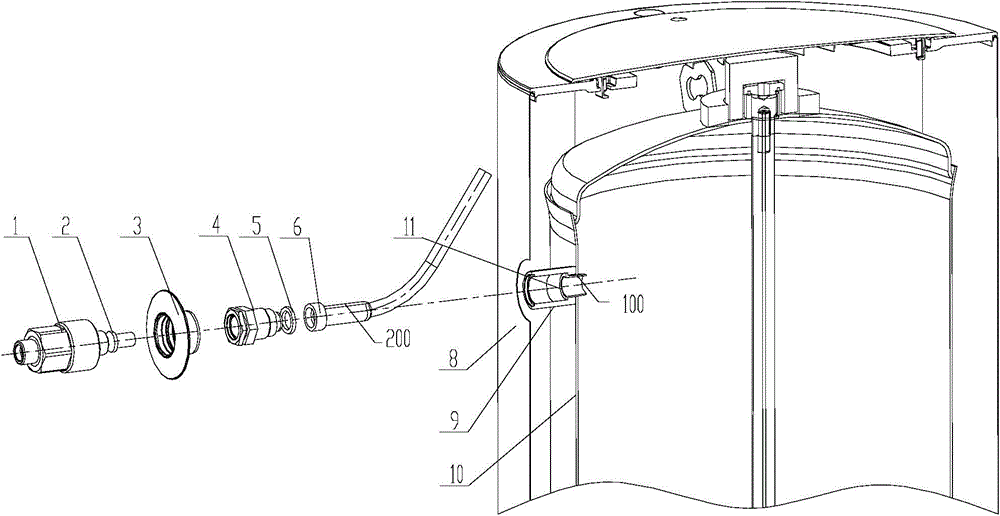

[0033] Such as image 3 , 4 As shown, in the water tank device of this embodiment, preferably, the side wall of the water tank liner 10 is provided with a water tank inlet and outlet water pipe installation hole, and the section of the installation hole is a "D"-shaped structure; the water pipe joint of the water pipe assembly 6 passes through the water tank. The installation hole of the water pipe joint is a "D" shaped structure; the mounting seat A9 is welded and fixed on the outside of the water tank liner 10; a positioning joint 11 is set outside the water pipe joint, and the positioning joint is "D" shaped PA plastic parts; the water pipe joint is inserted into the water tank liner 10 through the middle passage of the mounting seat A9 and the positioning joint, the adapter A4 is threaded to the mounting seat A9, and a gasket B5 is arranged between the two for reliable Sealing; after the thread is tightened, the end face of the adapter A4 presses the end face of the water...

Embodiment 3

[0036] Such as Figure 5 , 6As shown, the water tank device of this embodiment is different from Embodiment 1 in that: the side wall of the water tank liner 10 is provided with a round hole for installing the water tank inlet and outlet pipes, and the cross section of the inner end of the middle channel of the mounting seat B14 is "D". Glyph structure; the water pipe joint passes through the installation round hole, and the cross section of the water pipe joint is a "D" shaped structure and is connected with the inner end of the middle channel of the mounting seat B14; the mounting seat B14 is connected to the water tank liner 10 Fixed connection by welding, the end face of the water pipe joint is installed with a gasket B5, the water pipe assembly is inserted into the water tank liner 10 through the middle channel of the mounting seat B14, the adapter B12 and the mounting seat B14 are connected by threads, and the two are installed Gasket D13 for reliable sealing; the adapte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com