Steel ball measuring table

A technology of measuring table and steel ball, applied in the field of steel ball manufacturing, can solve the problems that the detection accuracy cannot meet the detection requirements, the experience requirements of the inspection personnel are high, and the detection is inaccurate, so as to improve the detection accuracy and detection speed, and the detection is convenient and fast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

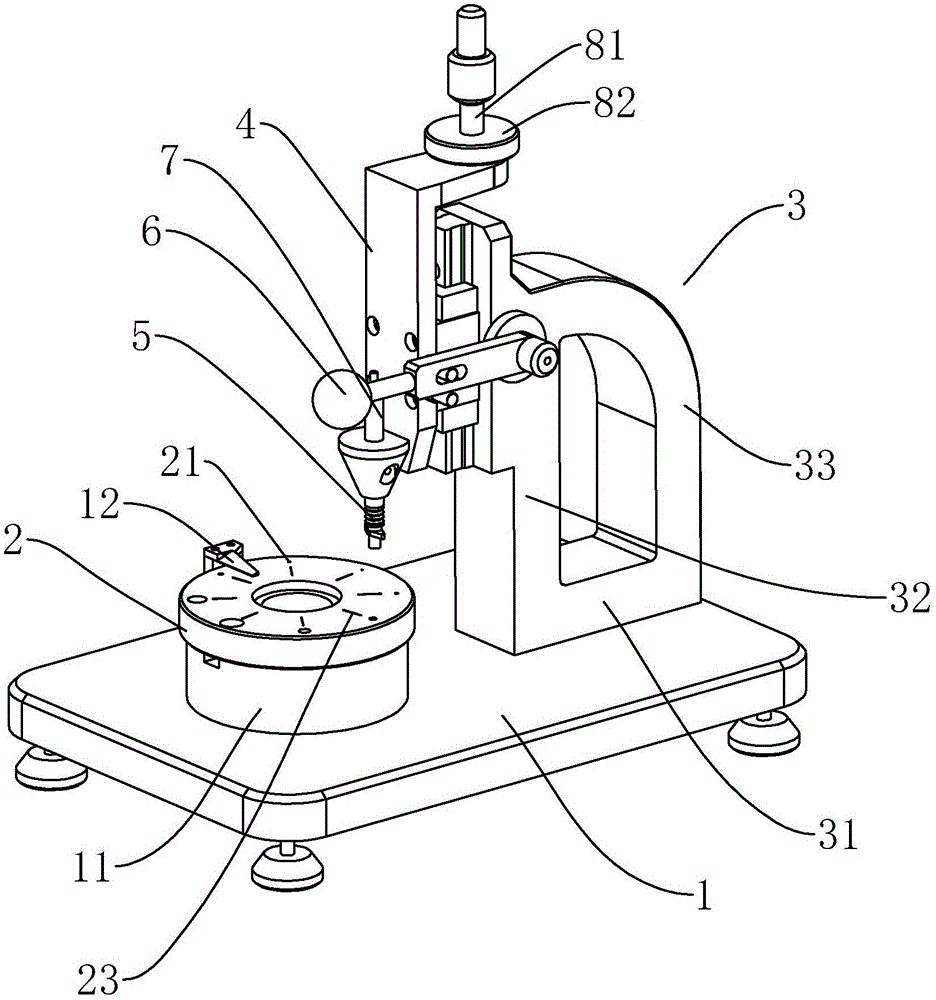

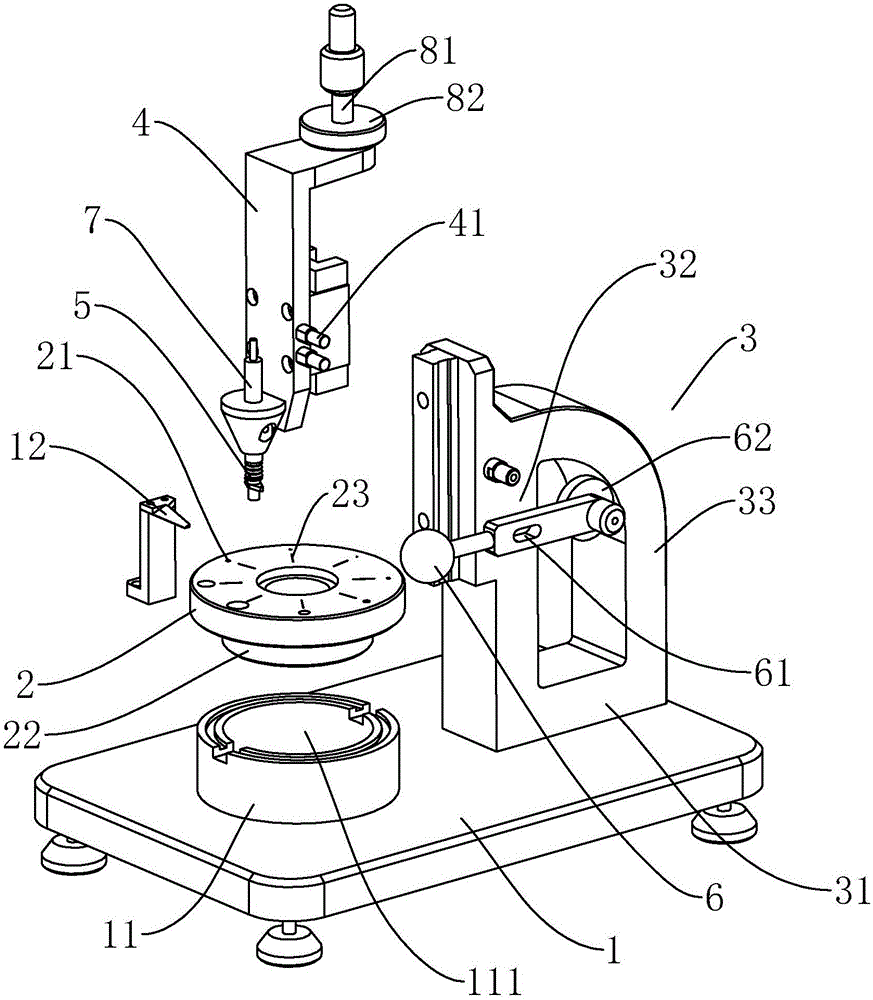

[0019] refer to figure 1 , figure 2 , figure 1 , figure 2 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a steel ball measuring platform includes a base 1, a workbench 2 and a detection arm assembly arranged on the base 1, and the workbench 2 is provided with Several detection positions 21 for placing steel balls, the detection arm assembly includes a support arm 3, a detection slide 4 slidably arranged on the support arm 3, in this embodiment, the detection slide 4 passes through a vertical The set slide rail mechanism is slidably arranged on the side end surface of the support arm 3, the end of the detection slide 4 is provided with a displacement sensor 5 corresponding to the detection position 21, and the detection slide 4 is also equipped with a The driving device and the adjusting device that limit the height of the detection slide 4 to move down.

[0020] Preferably, the support arm 3 includes a base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com