Method and device for measuring the oxygen adsorption capacity per unit mass of semi-coke and its application in the evaluation of spontaneous combustion tendency of active semi-coke

A technology of oxygen adsorption capacity and unit mass, which is applied to the device of oxygen adsorption capacity to measure the oxygen adsorption capacity of semi-coke per unit mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This example is used to illustrate the method for measuring the oxygen adsorption capacity of semi-coke provided by the present invention.

[0057] (1) Take the Hulunbuir coal sample (HLBB coal sample for short, the results of its industrial analysis and elemental analysis are shown in Table 1 and Table 2 below. The benchmarks of industrial analysis and elemental analysis are air-dry base, while elemental analysis is only for organic matter Analyze, excluding ash and moisture) 150g, the average particle size is to be put into pyrolysis furnace less than 6mm, under the condition of isolating air, under T1 condition (heating rate is 10 ℃ / min, final pyrolysis temperature is 520 ℃) heat up the pyrolysis furnace to carry out pyrolysis, and the obtained semi-coke is denoted as HLBB T1;

[0058] Table 1

[0059]

[0060] Table 2

[0061]

[0062] (2) Quickly put the semi-coke HLBB T1 into a metering closed container and cool it to room temperature, then screen the semi-c...

Embodiment 2

[0068] This example is used to illustrate the method for measuring the oxygen adsorption capacity of semi-coke provided by the present invention.

[0069] According to the method of Example 1, the difference is that in step (1), the T2 condition (the heating rate is 5° C. / min, and the final pyrolysis temperature is 600° C.) is used instead of the T1 condition. The obtained semi-coke is denoted as HLBB T2.

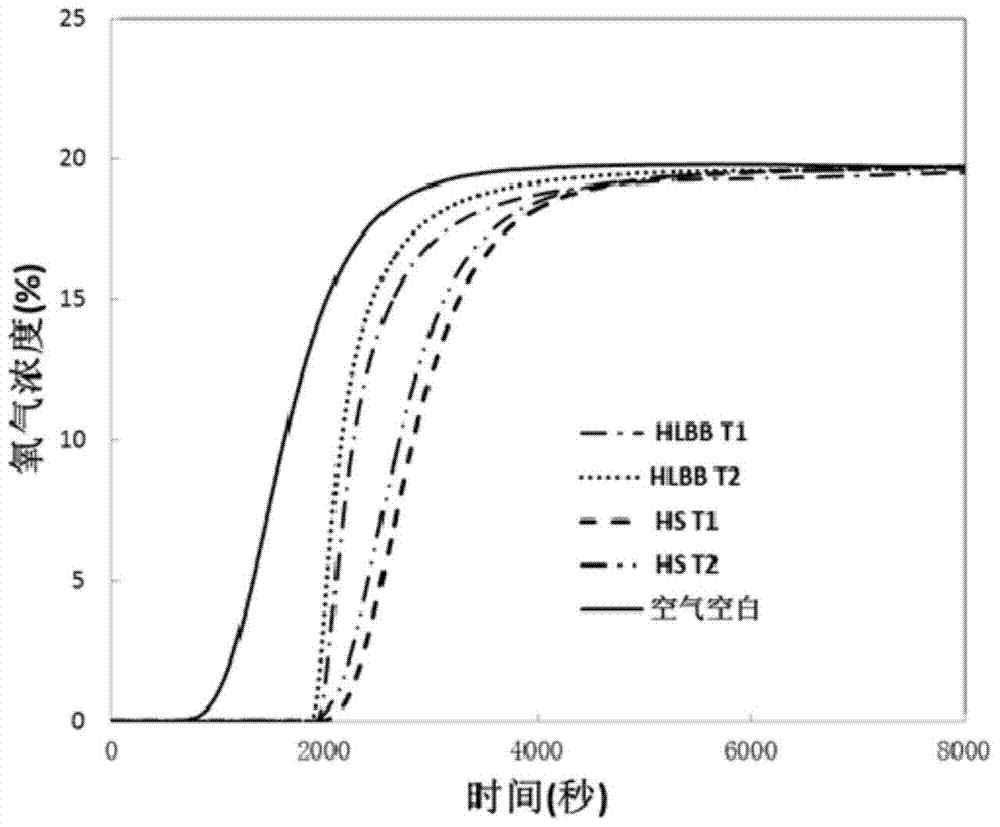

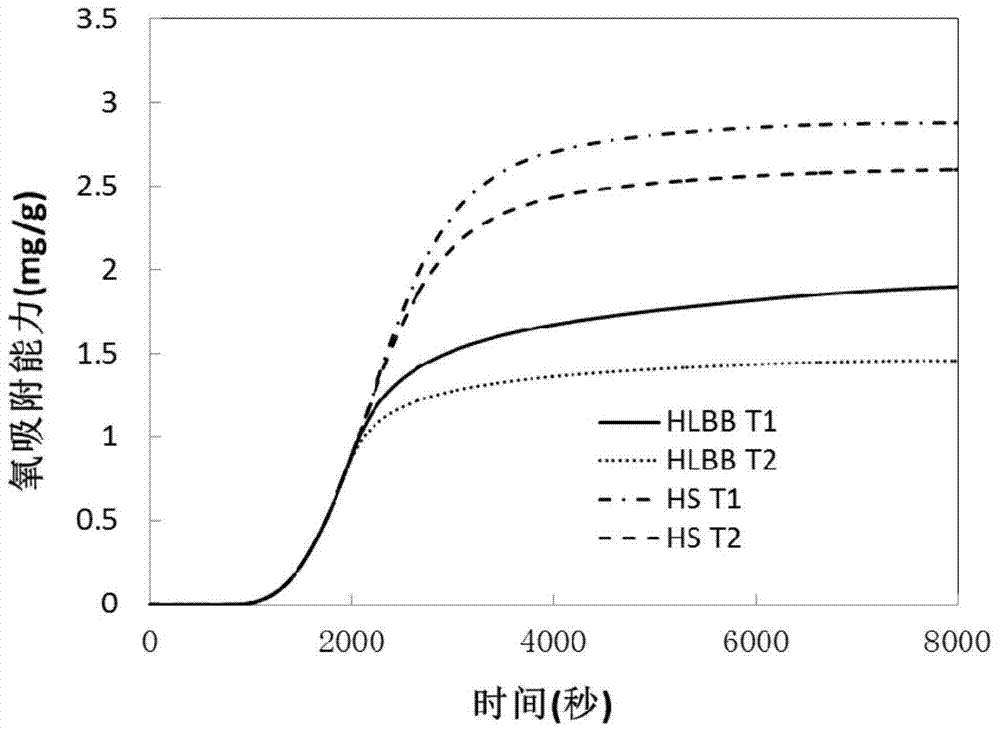

[0070] according to figure 2 When obtaining Qair=20ml / min, ρair=1.11g / ml, Wcoal=40g, t0=0 seconds, t=8000 seconds, the oxygen adsorption capacity D (8000) of semi-coke HLBB T2 is 1.46mg / g.

Embodiment 3

[0072] This example is used to illustrate the method for measuring the oxygen adsorption capacity of semi-coke provided by the present invention.

[0073] According to the method of embodiment 1, difference is, with Heishan coal sample (being called for short HS coal sample, its industrial analysis and elemental analysis result are shown in following table 3 and table 4, the benchmark of industrial analysis and elemental analysis all is air drying base, while elemental analysis is only for organic matter, excluding ash and moisture) instead of HLBB coal samples. The obtained semi-joke is denoted as HS T1.

[0074] according to figure 2 When obtaining Qair=20ml / min, ρair=1.11g / ml, Wcoal=40g, t0=0 seconds, t=8000 seconds, the oxygen adsorption capacity D (8000) of semi-coke HS T1 is 2.88mg / g.

[0075] table 3

[0076]

[0077] Table 4

[0078]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com