Device and method for repairing nuclear fuel assembly

A nuclear fuel assembly and repair method technology, applied in the direction of reactor fuel elements, nuclear engineering, nuclear power generation, etc., can solve problems such as waste of nuclear resources, single rod damage, and inability to continue to be put into the reactor for re-operation, etc. resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0042] The invention provides a nuclear fuel assembly repair method.

[0043] The method includes steps as follows:

[0044] Step 1, disassembling the upper nozzle 13 of the nuclear fuel assembly 10 to be repaired;

[0045] Step 2, taking out the fuel rod 12 to be replaced;

[0046] Step 3, inserting a new fuel rod into the original hole position of the fuel rod 12;

[0047] Step 4, install the upper tube base 13 .

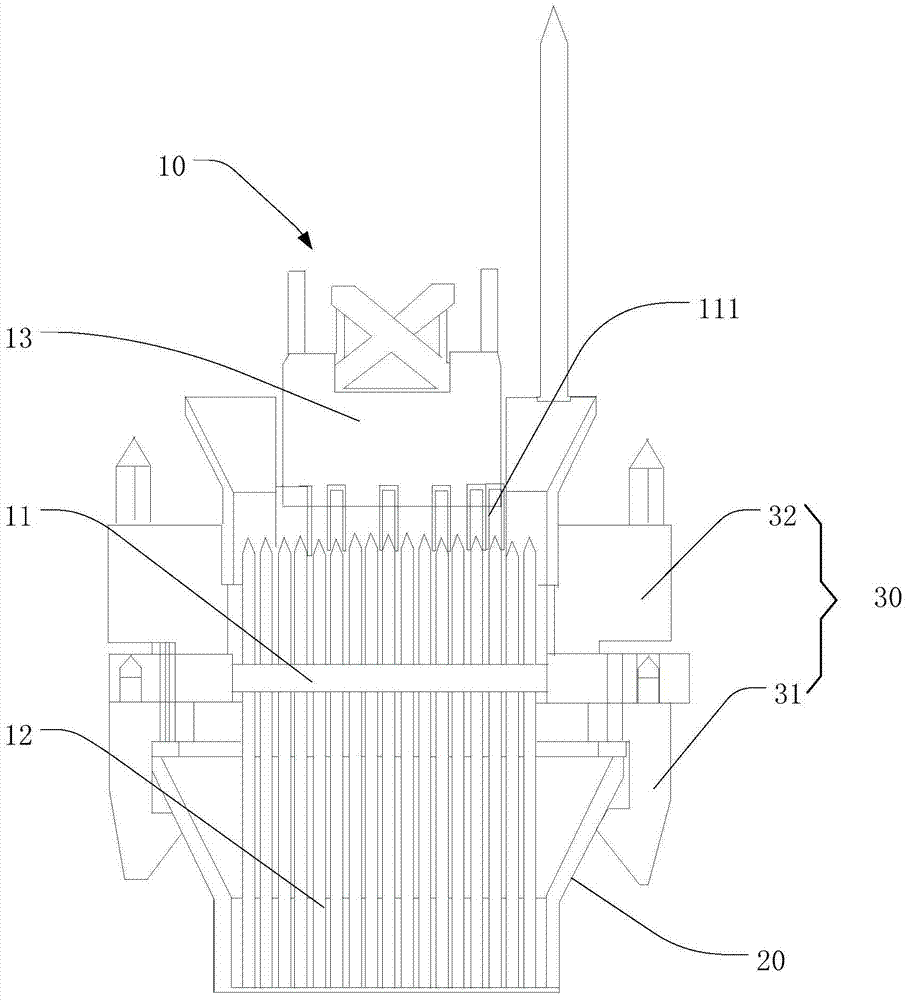

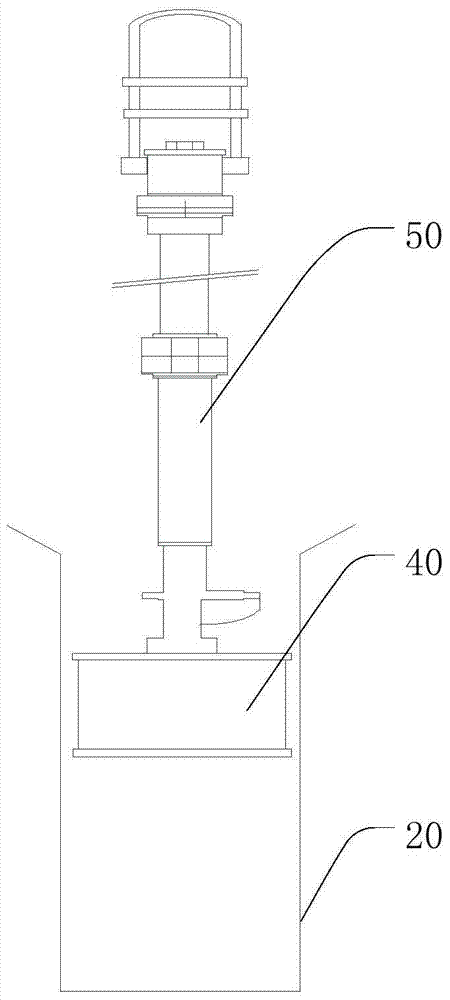

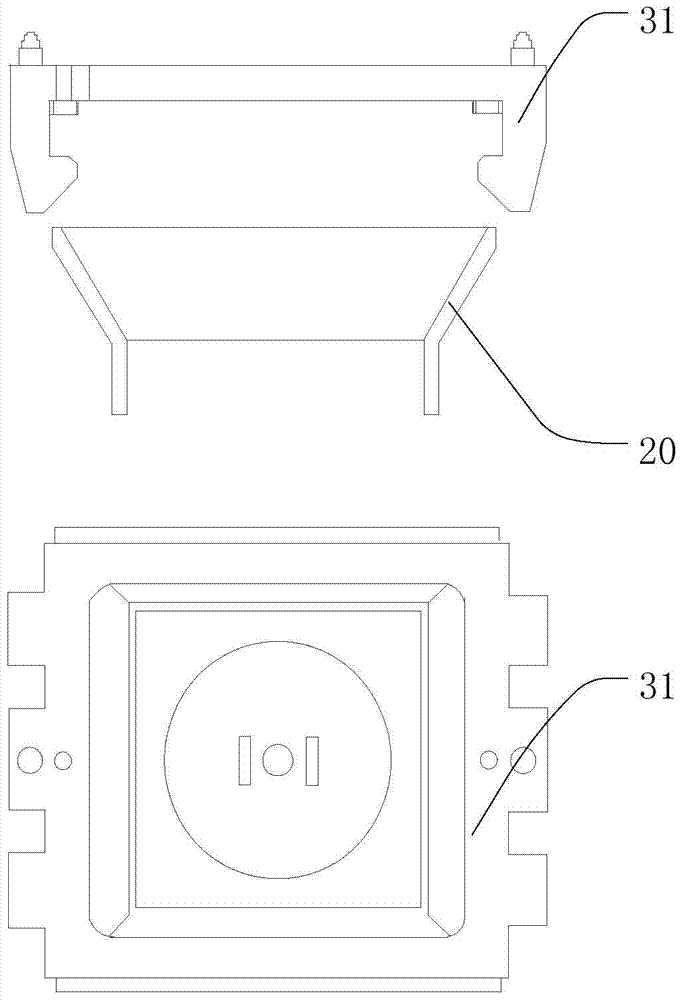

[0048] refer to figure 1 The nuclear fuel assembly 10 includes a frame 11, a fuel rod 12 vertically inserted in the frame, a lower socket (not shown in the figure) arranged at the bottom of the frame 11, and an upper socket 13 arranged at the upper end of the frame 11. There are more than 200 fuel rods 12 in the framework 11. In addition to the fuel holes for accommodating the fuel rods 12, the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com