Discharging method for automotive glass guide rail cutting machine

A technology for automotive glass and cutting machines, applied in metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems of difficult collection of guide rails and scraps, achieve flexible design and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

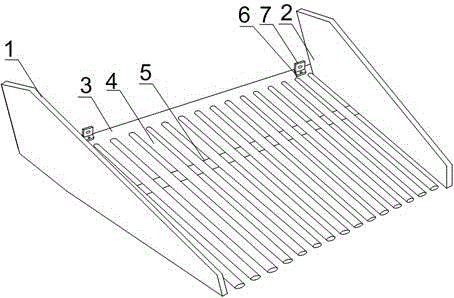

[0020] Such as figure 1 As shown, in the present invention, firstly, the bottom plate which is inclined along the guide rail along the feeding port slides down automatically under the action of its own gravity. Chips leak out, and the inclination angle of the bottom plate can affect the sliding speed of the guide rail. When the inclination angle is lower than 45°, the sliding speed of the guide rail slows down, while the processing rate of the punching head remains unchanged. The guide rail is easy to block the discharge port, which is not conducive to the collection of workers. When the inclination angle is higher than 60°, the guide rail slides too fast, which is easy to cause scattered discharge of the guide rail in the collection frame, and the guide rail that slides continuously will soon be collected. When the frame is full, the scraps generated during processing will slide along with the guide rails to the collection frame below the feeding port; the feeding port includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com