Intelligent driving type self-rotation electric-control screw

A technology of driving and rotating motors, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulties, inconvenient, and difficult inspection by operators, so as to ensure work efficiency, strong work performance, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

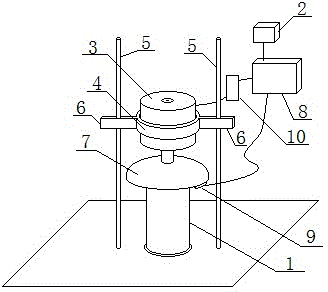

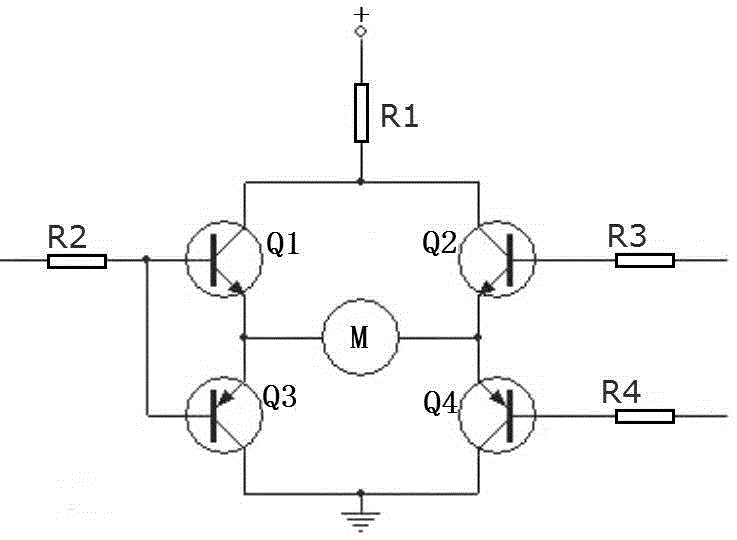

[0023] Such as figure 1As shown, an intelligently driven self-rotating electric control screw designed by the present invention includes a screw body 1 and a screw cap 7 fixedly arranged on the top of the screw body 1; it also includes a fixed snap ring 4, a rotating motor 3, at least one Positioning rod 5, a control module 8, and external power supply module 2, ranging sensor 9, motor drive circuit 10 connected with control module 8 respectively; Rotating motor 3 is connected with control module 8 through motor drive circuit 10; Wherein, external The power supply module 2 supplies power to the distance measuring sensor 9 through the control module 8, and at the same time, the external power supply module 2 supplies power to the rotating motor 3 through the control module 8 and the motor drive circuit 10 in turn; the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com