A device for splitting bamboo poles

A technology of bamboo poles and pipes, which is applied in sugarcane machining, manufacturing tools, mechanical equipment, etc., can solve the problems of bamboo damage and other problems, and achieve the effects of easy cracking, strong toughness, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

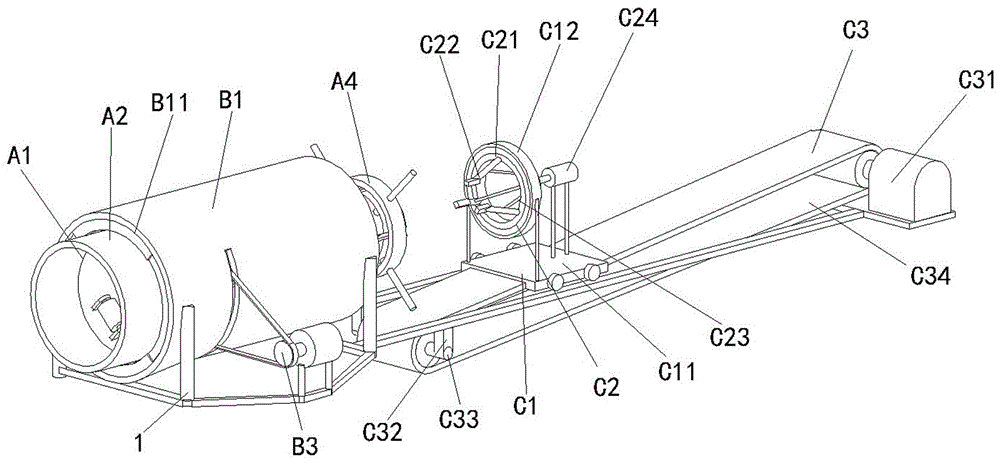

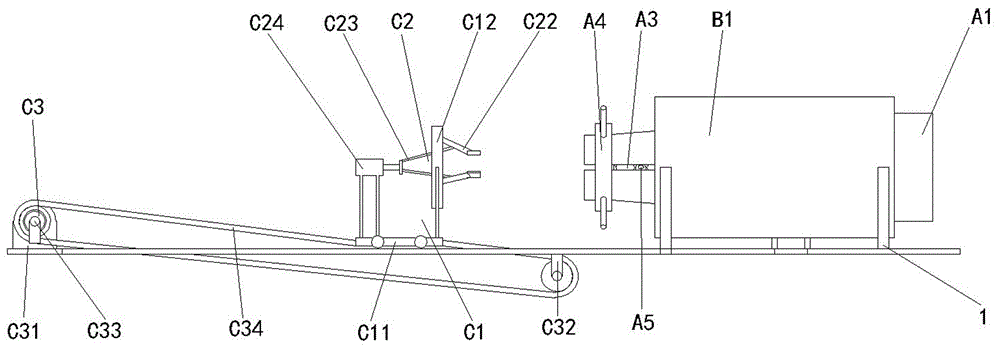

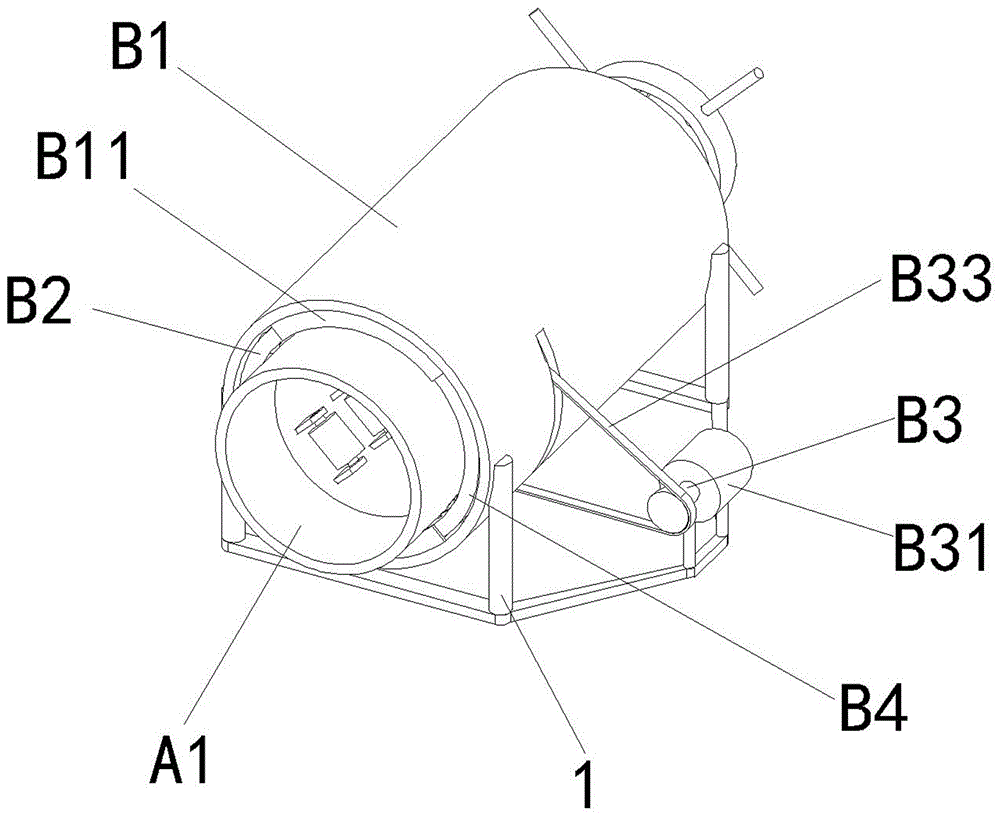

[0040] The following combined with the accompanying drawings figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 The present invention is described in further detail. A device for splitting bamboo poles. A bracket body 1 is fixedly connected with a casing body B1; a pipe container A1 is arranged inside the casing body B1, and a rotating structure group B2 is arranged between the pipe container A1 and the casing body B1. The rotating structure group B2 is provided with two groups of rotating structural units B4. The rotating structural unit B4 includes eight balls B41 and a ball bracket B42 for placing the balls B41. The thickness of the ball bracket B42 is smaller than the diameter of the balls B41. The balls B41 are evenly distributed between the pipe container A1 and the sleeve body B1; the ball bracket B42 is provided with a clamping hole B43 to accommodate the balls B41 and make them rotate freely....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com