Frozen-type grouting hole-sealing device

A hole sealer and grouting technology, which is used in sealing/sealing, gas discharge, safety devices, etc., can solve the problems of low and serious compressive strength of polyurethane sealing, poor sealing performance of mechanical elastic sealing to drilling holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

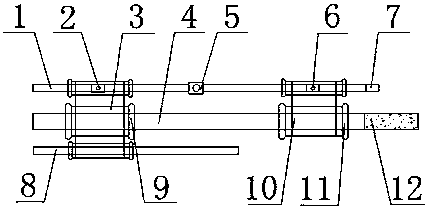

[0015] A frozen type grouting hole sealing device, comprising a bladder grouting pipeline 1, a gas extraction pipe 4 and a water inlet pipeline 8, and the bladder grouting pipeline 1 is sequentially provided with first blasting valves from left to right 2. The pressure relief valve 5 and the second blasting valve 6. The right side of the second blasting valve 6 is a plug 7. The gas extraction pipe 4 is connected to the bladder grouting pipeline 1 through a large pipe collar 9 and a small pipe collar 11. connection, a first pouch 3 is provided at the joint of the large pipe collar 9, a second pouch 10 is provided at the joint of the small pipe collar 11, the rightmost end of the gas drainage pipe 4 is a sealing flower pipe 12, and the water inlet pipe 8 It is fixed below the gas extraction pipe 4 through a large pipe collar 9 . An application method of a frozen grouting hole sealing device is: placing the grouting hole sealing device in the coal seam hole, pumping liquid carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com