A continuous silicon carbon negative electrode coated dynamic CVD deposition furnace

A deposition furnace and negative electrode technology, applied in the field of CVD deposition furnace, can solve problems such as poor sealing performance, and achieve the effects of good sealing effect, improved safety, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

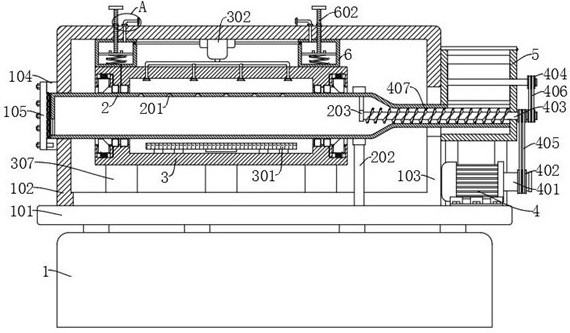

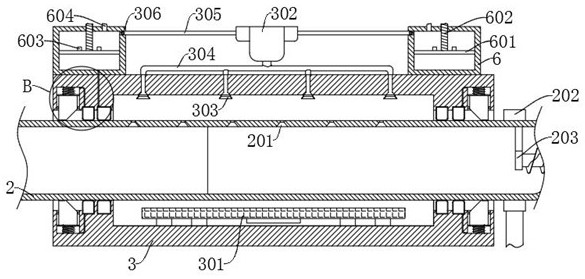

[0036] refer to Figure 1-2 with Figure 5-7, a continuous silicon carbon negative electrode coated dynamic CVD deposition furnace, comprising a base 1 and a furnace tube 2, a support plate 101 is fixedly connected to the base 1, and a support member 202 for supporting the furnace tube 2 is provided on the top of the support plate 101, The support plate 101 is also slidably connected with a cover body 102 matched with the furnace tube 2. The cover body 102 can be slidably connected to the support plate 101 through slide rails, etc. After the cover body 102 slides, the furnace tube 2 can be exposed, which is convenient for operation; The inner wall of the cover body 102 is supported by the cylinder body 3 through the support block 307, and the furnace tube 2 is provided with a fine hole 201, and the fine hole 201 is placed inside the cylinder body 3, so that all the discharged gas is placed in the cylinder body 3 to avoid leakage , the support plate 101 is also provided with a...

Embodiment 2

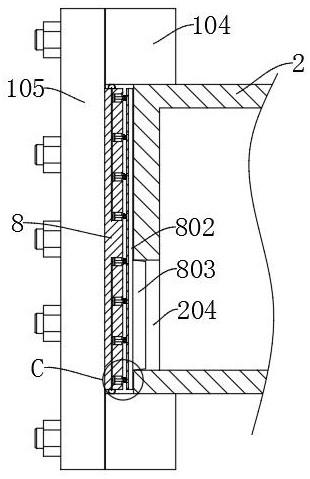

[0045] refer to figure 1 , image 3 with Figure 8 , a continuous silicon carbon negative electrode coated dynamic CVD deposition furnace, comprising a base 1 and a furnace tube 2, a support plate 101 is fixedly connected to the base 1, and a support member 202 for supporting the furnace tube 2 is provided on the top of the support plate 101, The support plate 101 is also slidably connected with a cover body 102 matched with the furnace tube 2. The cover body 102 can be slidably connected to the support plate 101 through slide rails, etc. After the cover body 102 slides, the furnace tube 2 can be exposed, which is convenient for operation; The inner wall of the cover body 102 is supported by the cylinder body 3 through the support block 307, and the furnace tube 2 is provided with a fine hole 201, and the fine hole 201 is placed inside the cylinder body 3, so that all the discharged gas is placed in the cylinder body 3 to avoid leakage , the support plate 101 is also provide...

Embodiment 3

[0050] refer to figure 1 with Figure 4 , a continuous silicon carbon negative electrode coated dynamic CVD deposition furnace, comprising a base 1 and a furnace tube 2, a support plate 101 is fixedly connected to the base 1, and a support member 202 for supporting the furnace tube 2 is provided on the top of the support plate 101, The support plate 101 is also slidably connected with the cover body 102 matched with the furnace tube 2; the inner wall of the cover body 102 supports the cylinder body 3 through the support block 307, and the furnace tube 2 is provided with a fine hole 201, and the fine hole 201 is placed in the cylinder Inside the body 3 , a feeding mechanism matched with the furnace tube 2 is also provided on the support plate 101 .

[0051] Feeding mechanism comprises feed box 5, is provided with filling pad 503 in the feed box 5, is connected with feed shaft 501 in rotation in the feed box 5, is provided with the rotating plate 502 that offsets with filling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com