No pressure roller dust removal vacuum conveying device and method

A conveying device and vacuum technology, which is applied in the field of non-pressure roller dust removal and vacuum conveying devices, can solve the problem that the structure of electrostatic paper feeding and dust removal rubber roller cannot be widely used, the structure of electrostatic paper feeding and dust removal rubber roller is complex, and the installation of the structure is not convenient. and other problems, to achieve the effect of simple structure, perfect function and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

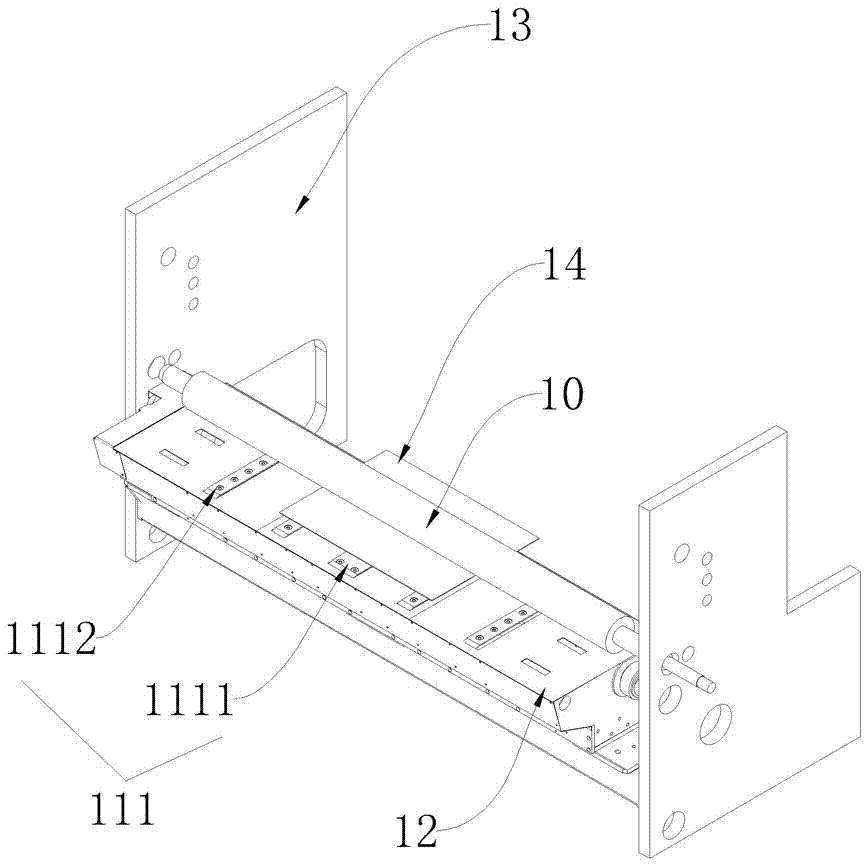

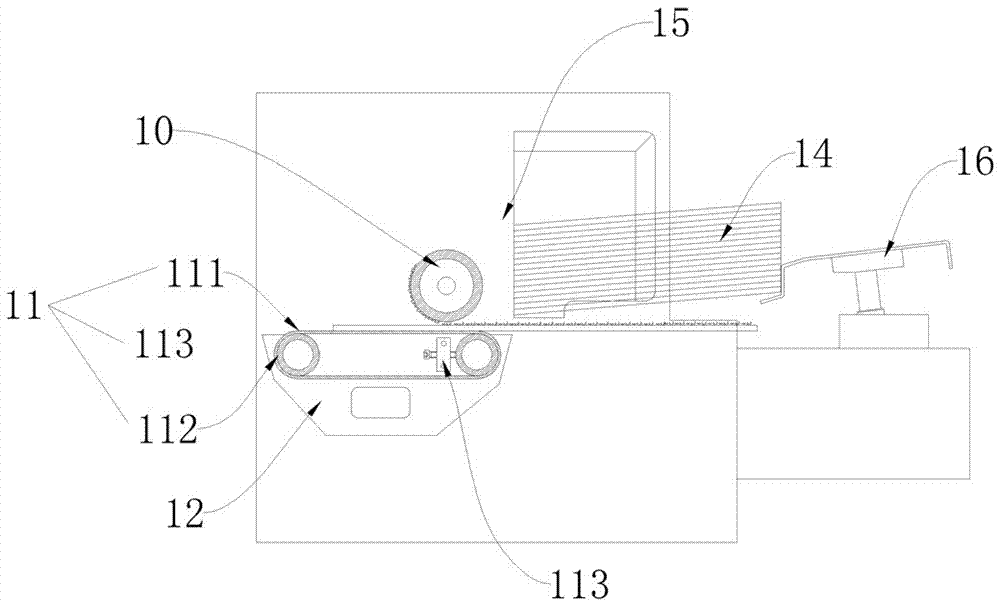

[0037] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

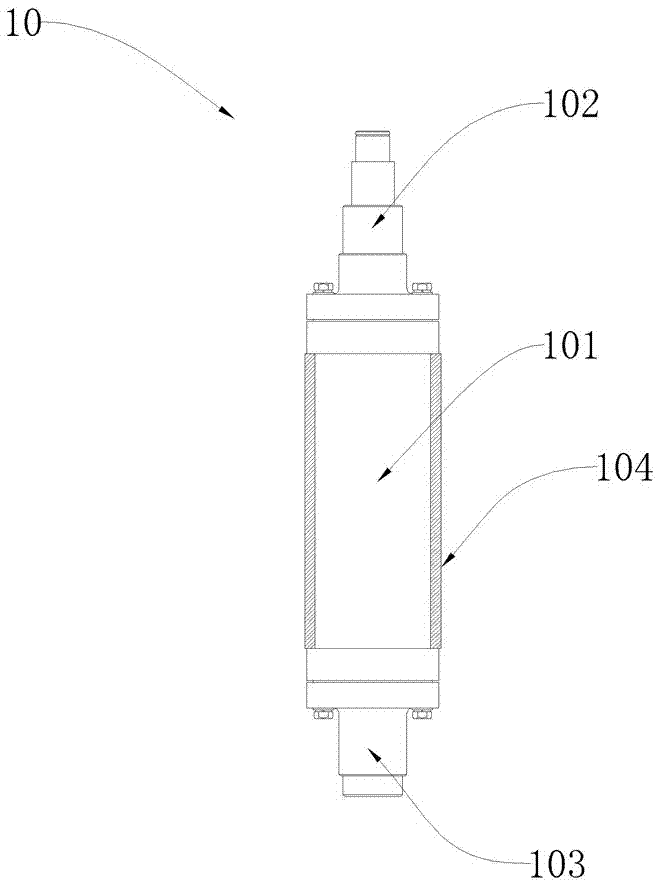

[0038] refer to Figure 1-3 , a pressureless roller dust removal vacuum conveying device of the present invention includes a dust removal roller 10, multiple sets of belt transmission structures 11, a vacuum bellows 12, a support frame 13 and a corrugated cardboard 14, and the dust removal roller 10 includes a long shaft head 102 and a short shaft head 103 And the roll body 101, one end of the roll body 101 is fixedly connected to the long shaft head 102, and the other end is fixedly connected to the short shaft head 103, and multiple sets of belt transmission structures 11 are fixed on the vacuum bellows 12, the long shaft head 102 and the short shaft head 103 They are respectively fixed in the positioning holes on the support frame 13, and the corrugated cardboard 14 is placed on the belt conveying structure 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com