a barrel dispenser

A dispenser and barrel technology, applied in liquid distribution, distribution devices, packaging, etc., can solve the problems of reducing the competitive advantage of manufacturers, affecting the taste and quality of beer, and unreliable sealing, so as to ensure the service life and sealing effect Strong, improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

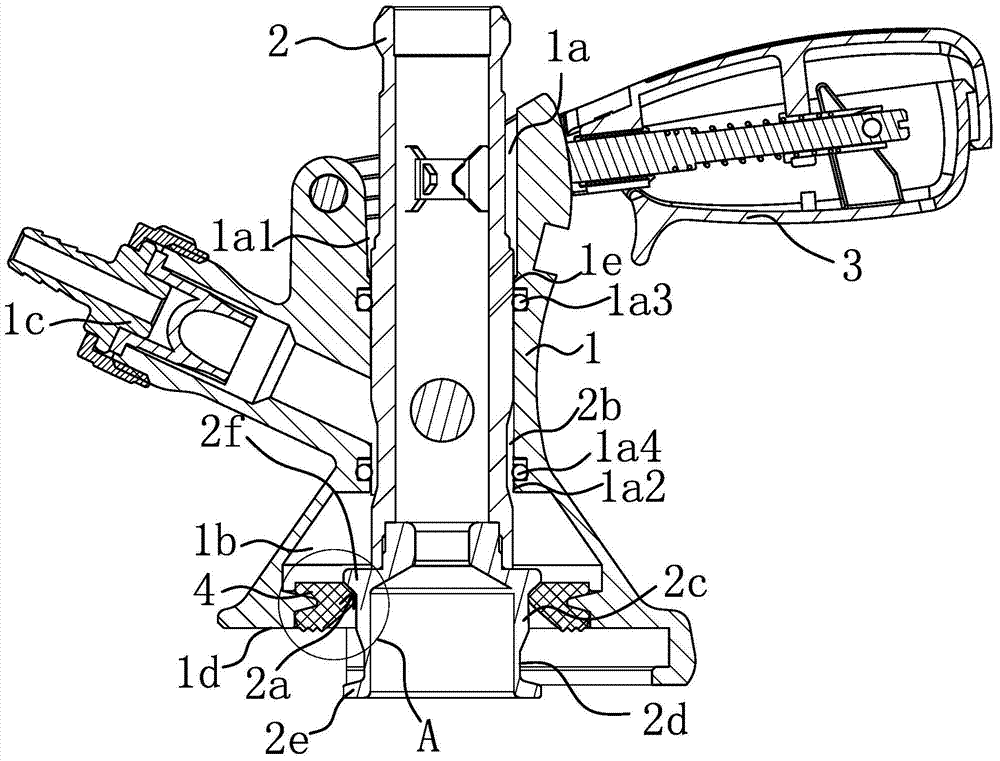

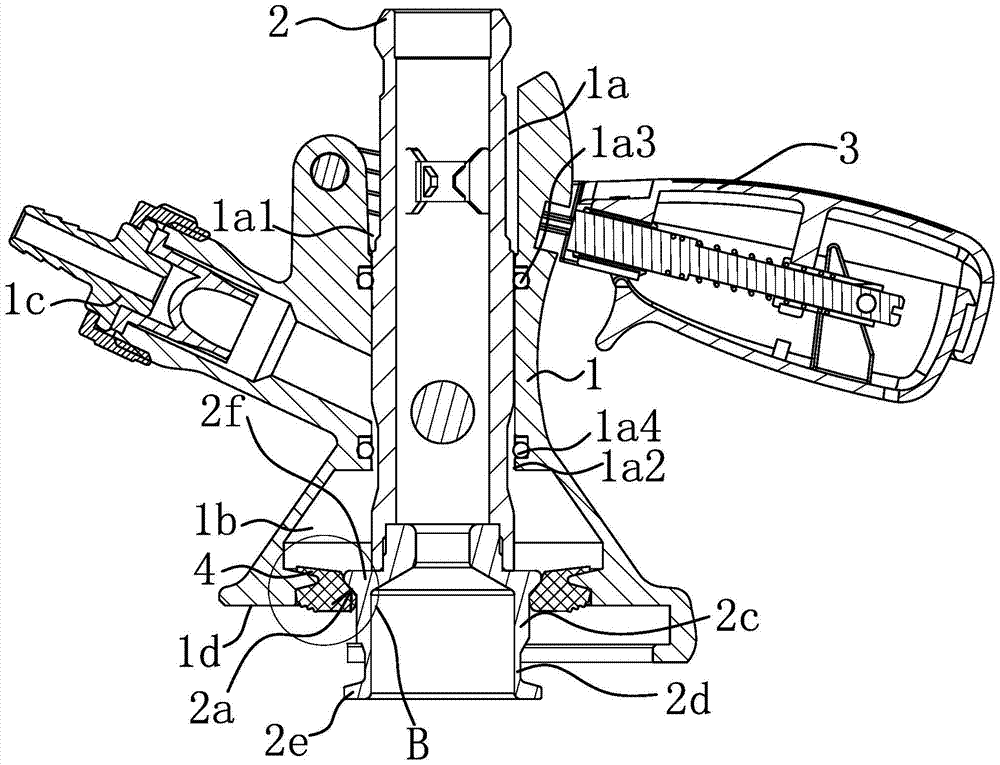

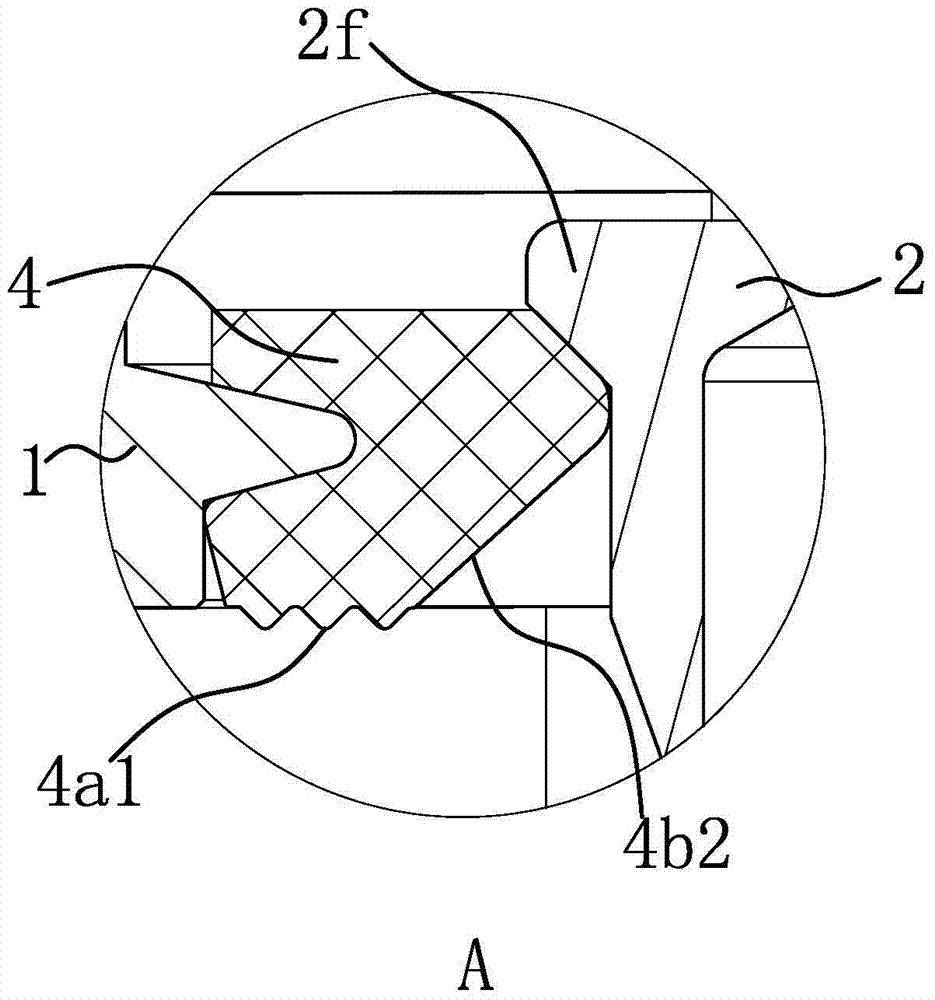

[0045] Such as Figures 1 to 6 As shown, a wine barrel dispenser includes a valve body 1, a wine outlet pipe 2 and a handle 3 capable of driving the wine outlet pipe 2 to move. The valve body 1 has a through installation hole 1a and a ventilation chamber 1b communicating with the installation hole 1a , the wine outlet pipe 2 is set in the installation hole 1a and can move up and down in the installation hole 1a. The side of the valve body 1 has an air intake pipe 1c communicating with the installation hole 1a. The present invention uses a sealing gasket 4 with a special structure. The distributor is effectively sealed, and the gasket 4 is fixed in the vent chamber 1b and is made of rubber. Figure 5 , Image 6 As shown, the gasket 4 includes a gasket body 4a. The gasket body 4a is cylindrical and has a convex ring 4a1 on the lower end surface of the gasket body 4a. Due to the small contact surface, the force on the location of the convex ring 4a1 increases, so , the sealing ...

Embodiment 2

[0057] Such as Figure 7 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the number of positioning pieces 4b is 5, of course, the number of positioning pieces 4b can also be other numbers, as long as it is reasonable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com