Patents

Literature

56results about How to "Prevent affecting the sealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

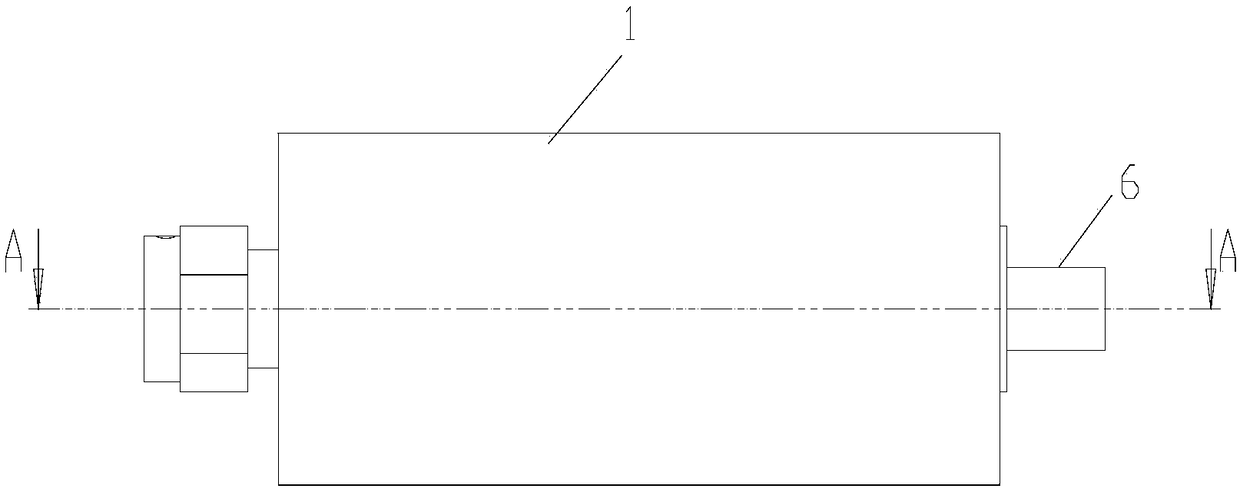

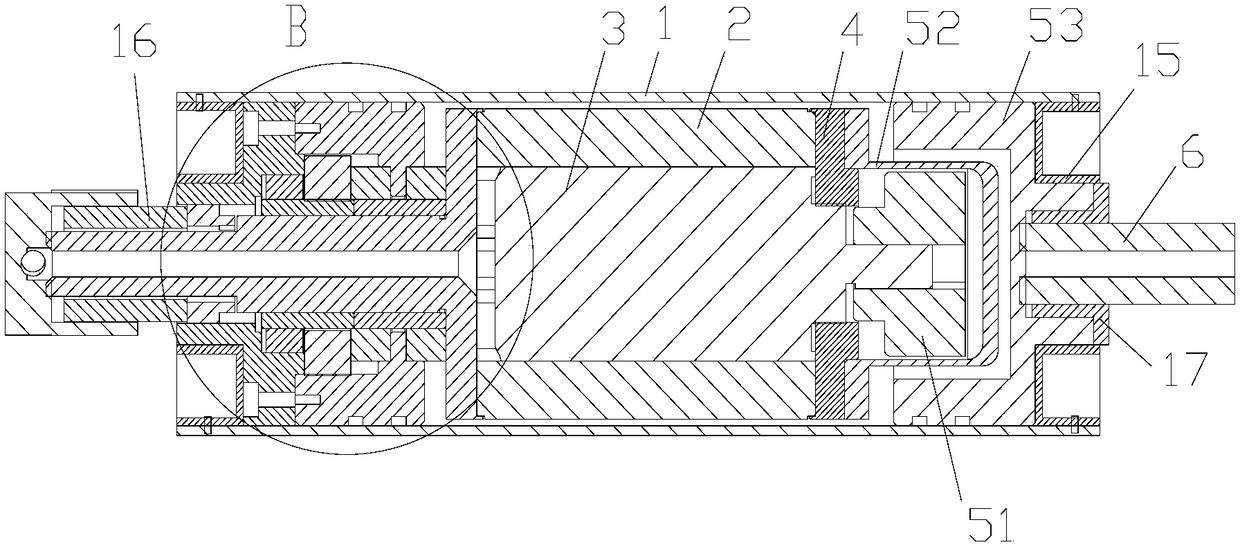

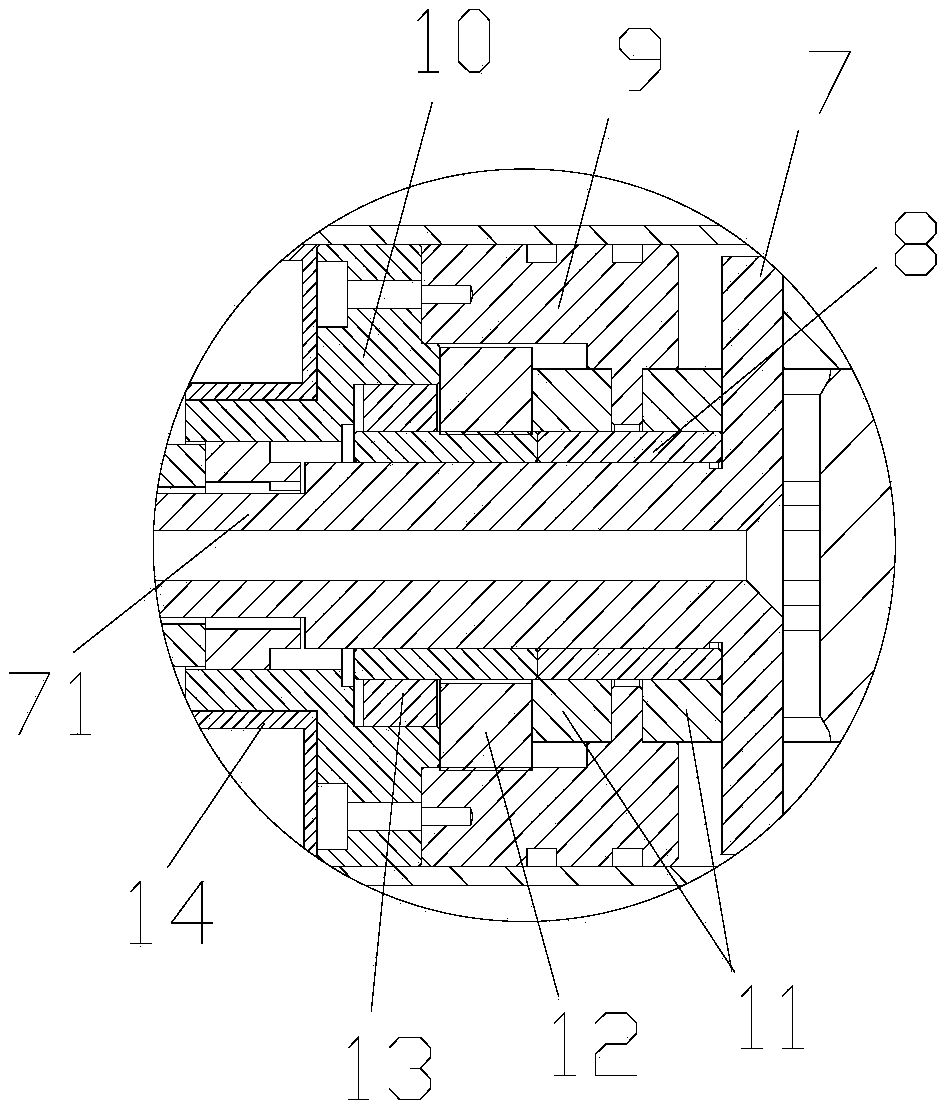

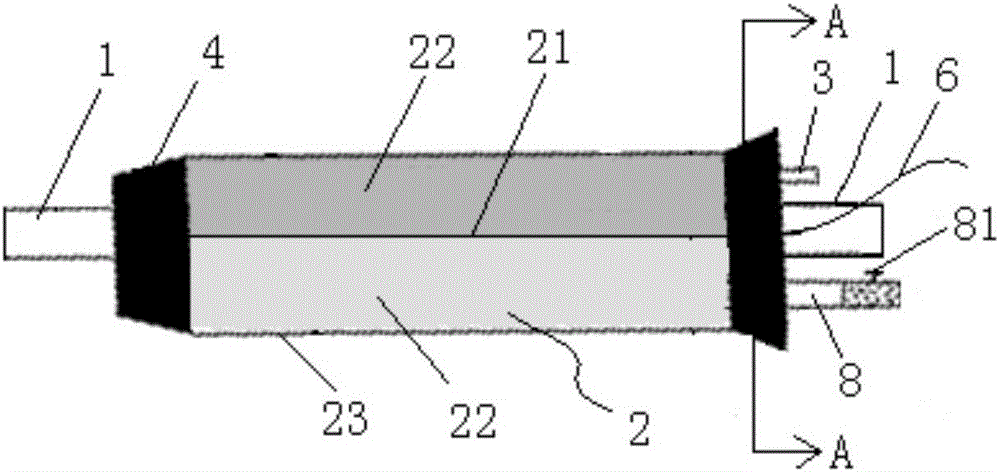

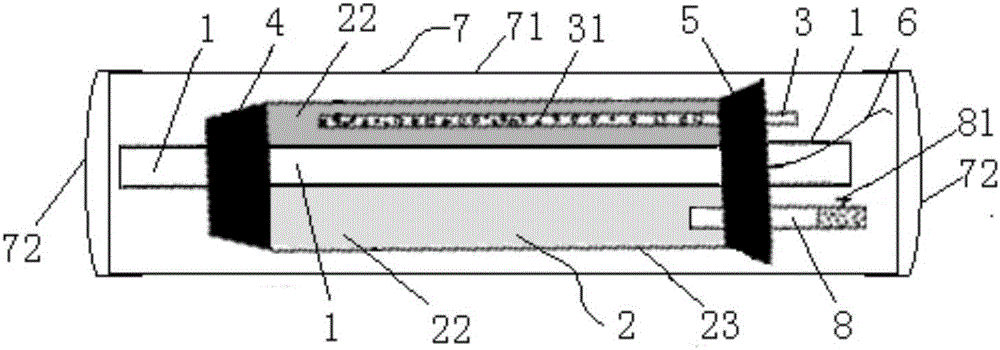

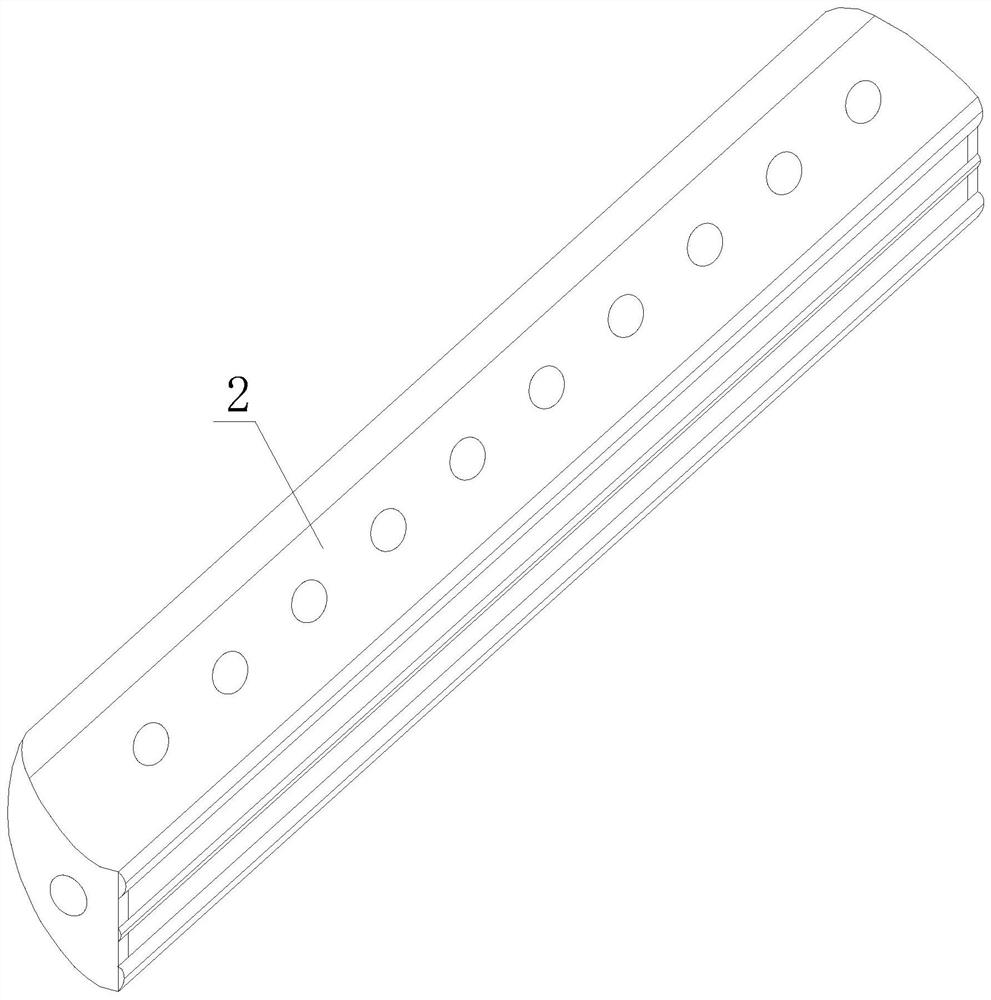

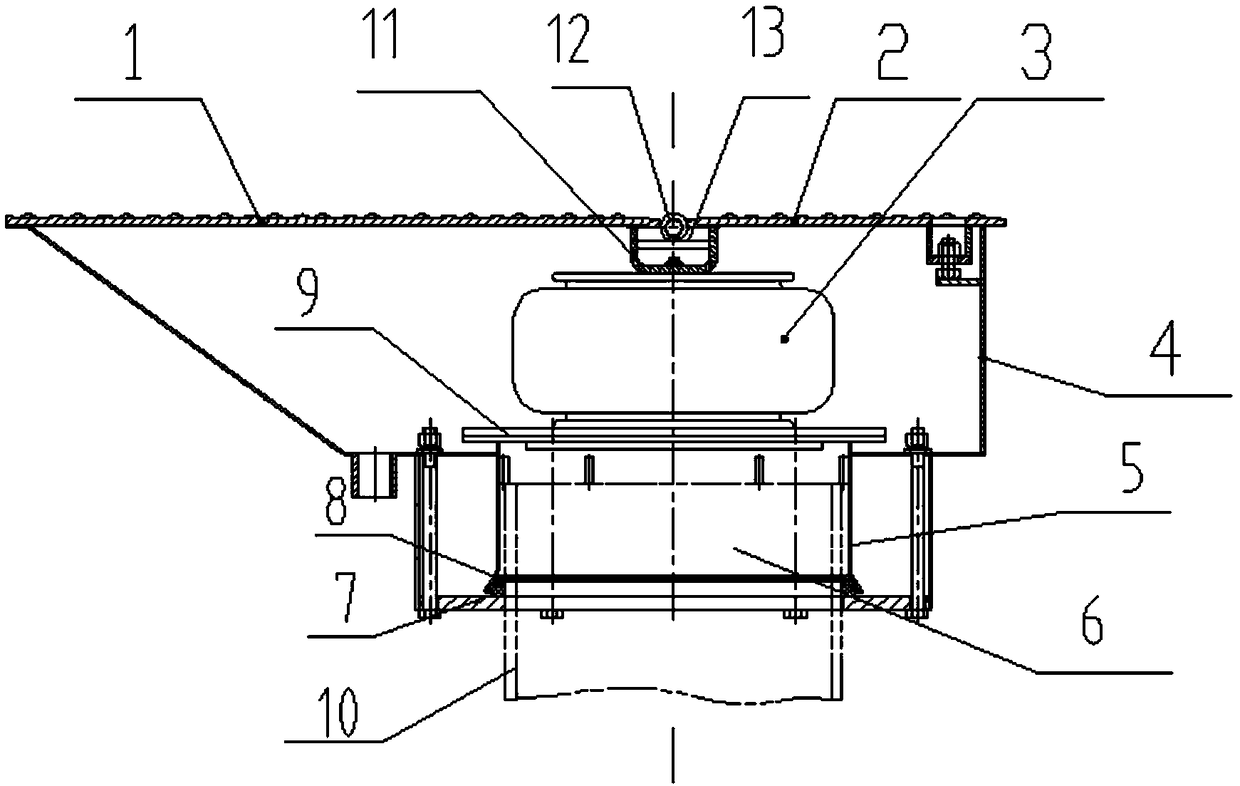

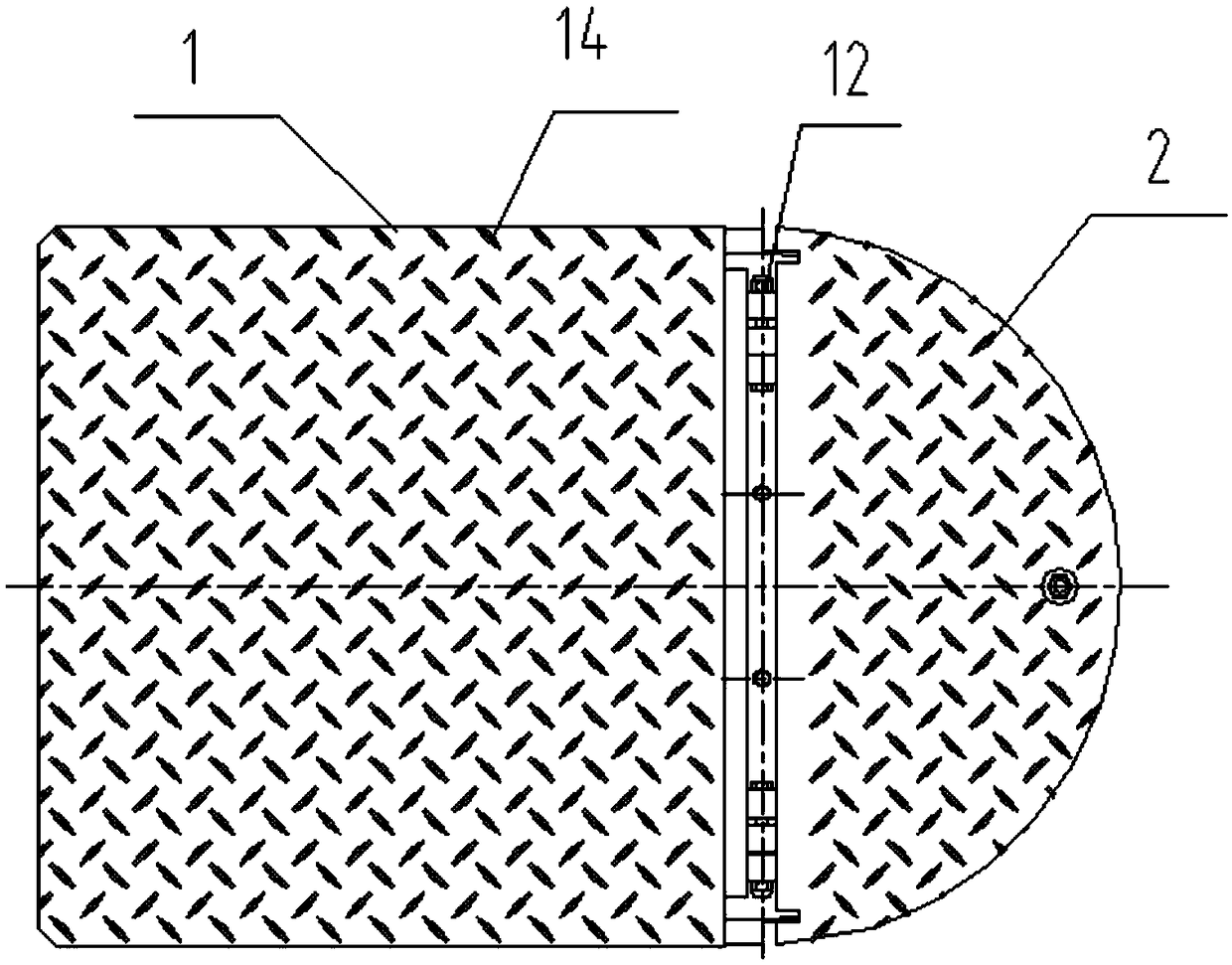

Driving roller

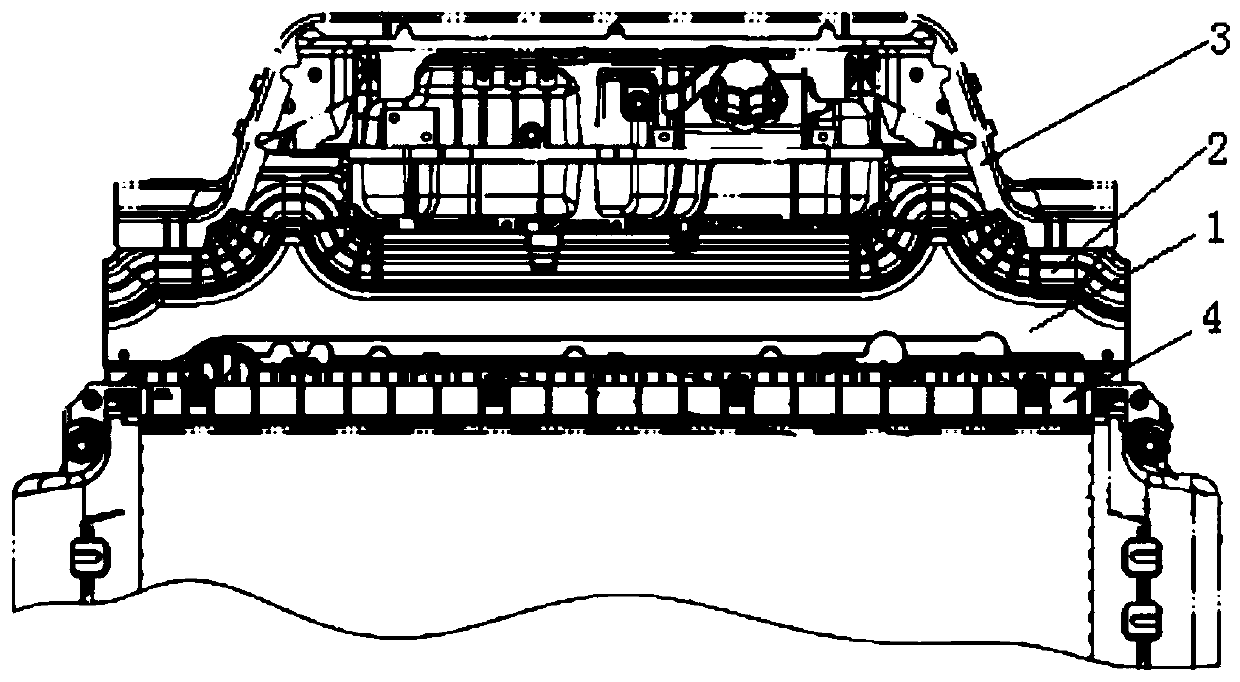

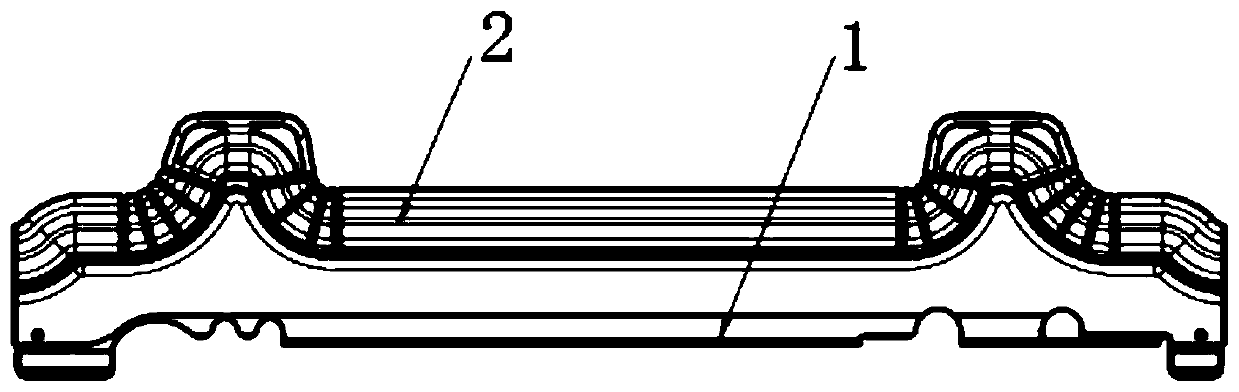

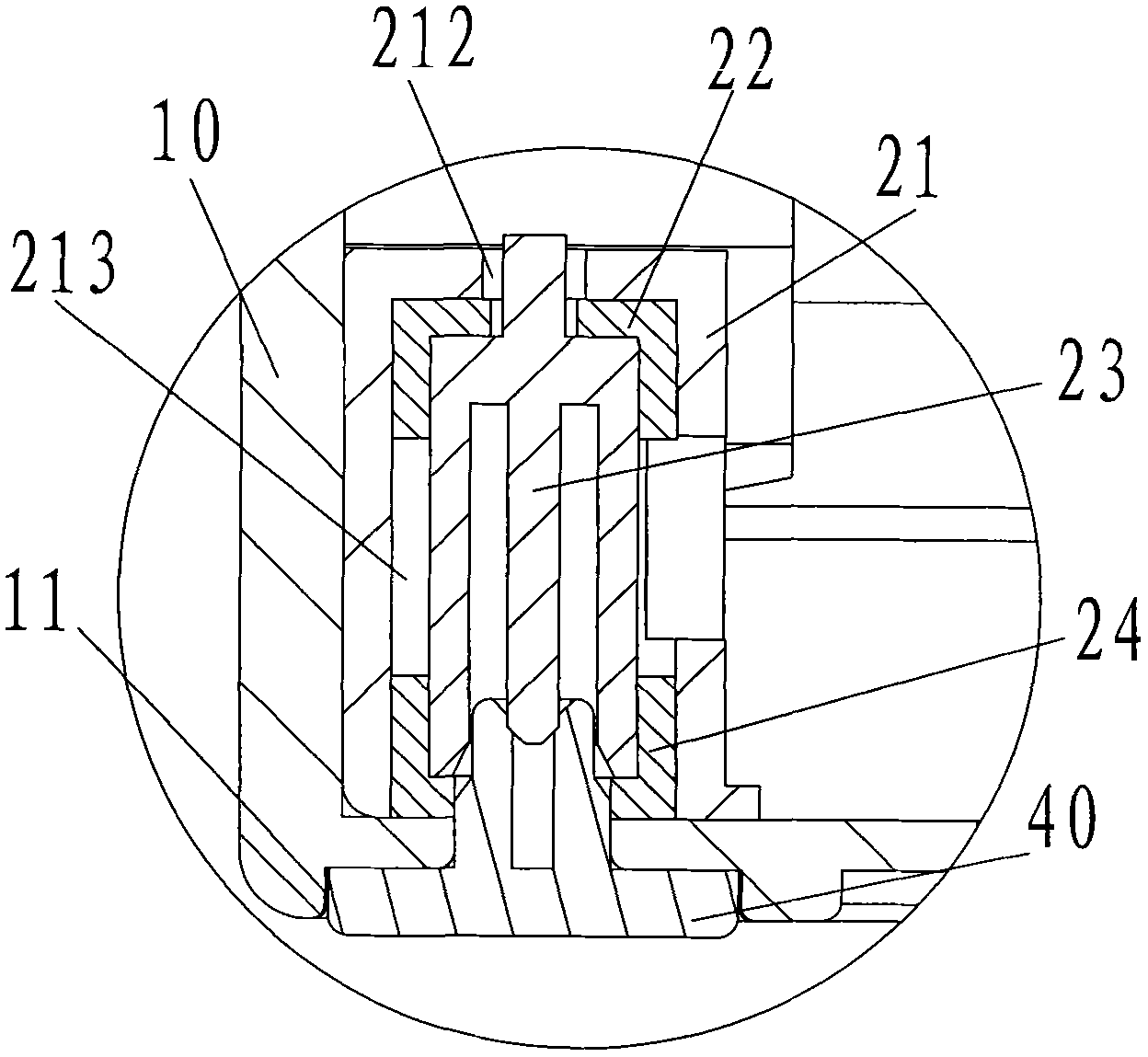

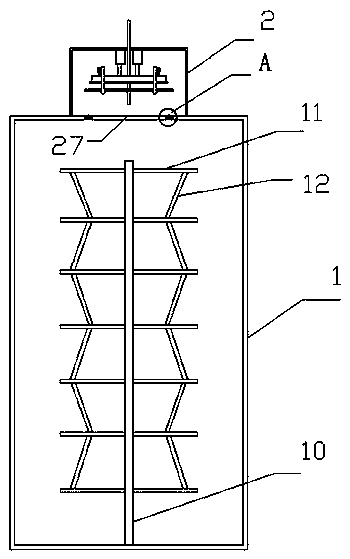

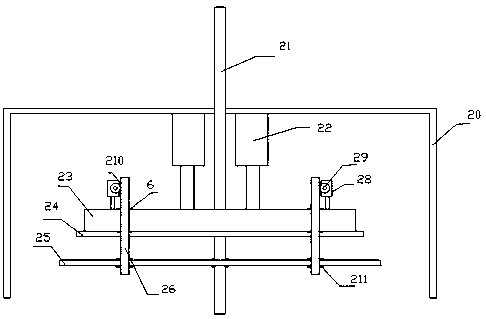

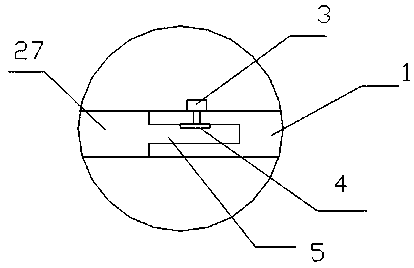

ActiveCN108506636AGood waterproof performanceIncrease contact areaEngine sealsShaftsPropellerEngineering

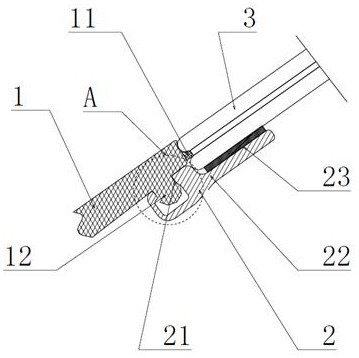

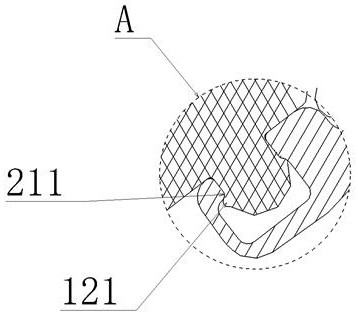

The invention discloses a driving roller. The driving roller comprises an outer cylinder and an inner cylinder arranged inside the outer cylinder, a motor is fixedly arranged inside the inner cylinder, the output shaft of the motor sleeves with a first rotating piece, and the outer peripheral surface of the first rotating piece is fixedly connected with the inner wall of the outer cylinder in a sealing mode; and the other end of the inner cylinder is provided with a second connecting piece, and the inner cylinder and the outer cylinder are rotationally connected together through the second connecting piece, wherein the second connecting piece is hermetically connected with the inner cylinder and the outer cylinder correspondingly. The driving roller has the beneficial effects that the motor is fixedly arranged inside the inner cylinder in a sealing mode, so that the waterproof performance is good; the inner cylinder and the outer cylinder are enabled to be connected rotationally through the first connecting piece and the second connecting piece, the outer cylinder is sleeved with the shell with spiral blades, when the roller of the robot is in contact with the inner wall or the sludge of the pipeline, friction is carried out by rotating of a spiral roller to the inner wall of the pipeline or the sludge to drive the pipeline robot to move forward, so that the contact area is large, and slipping is avoided; and when the roller of the robot is suspended in water, the spiral roller is equivalent to a propeller, the spiral roller rotates to be drained away water backwards and drives the pipeline robot to move forwards.

Owner:南京管科智能科技有限公司

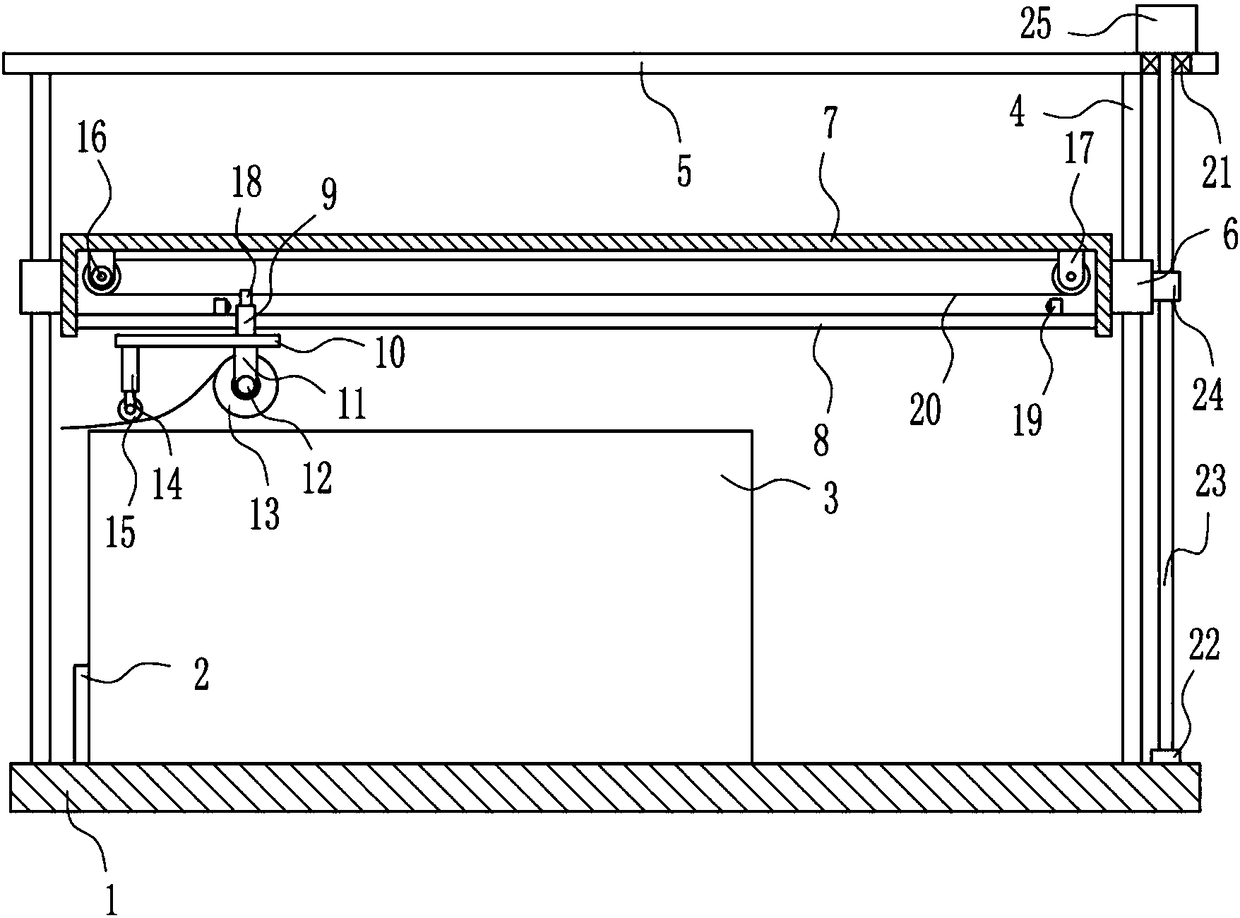

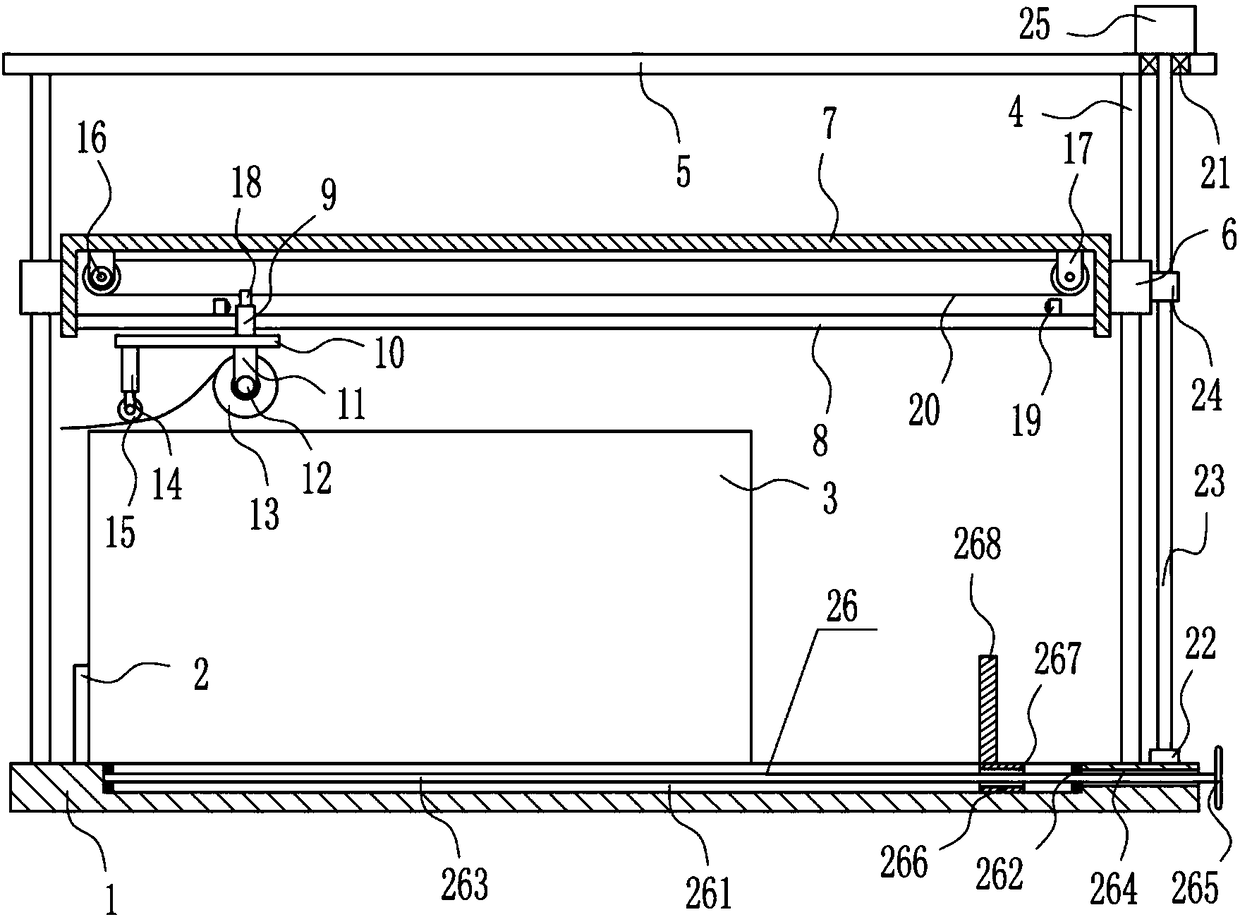

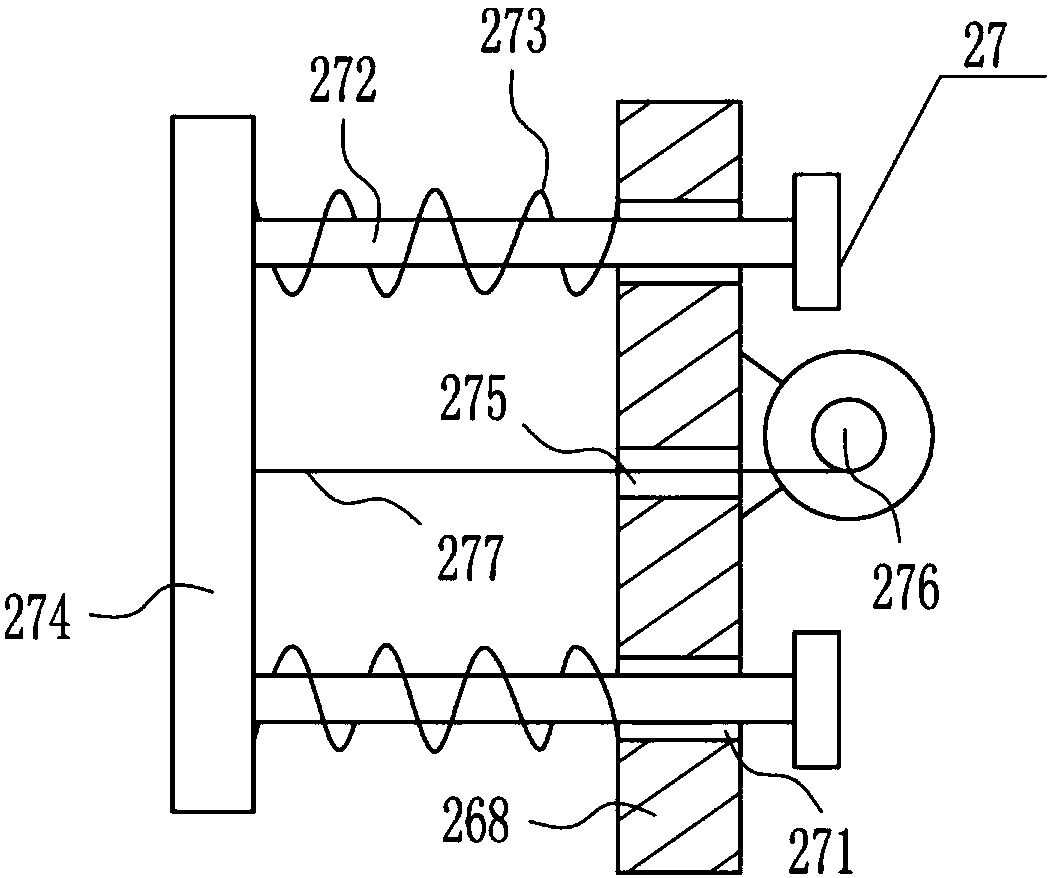

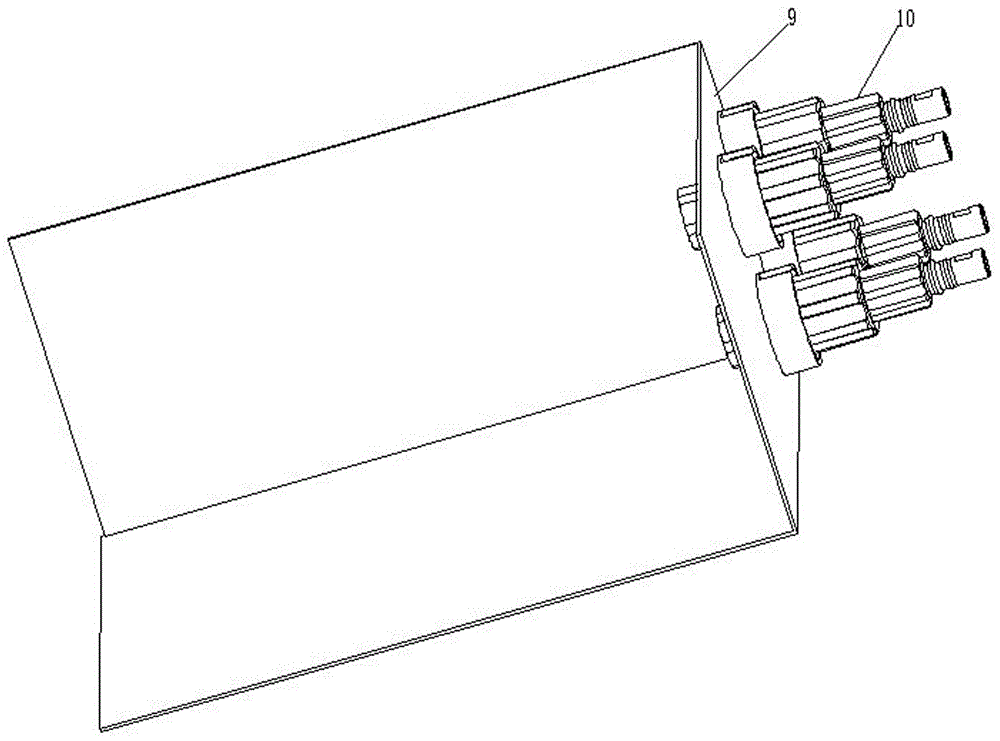

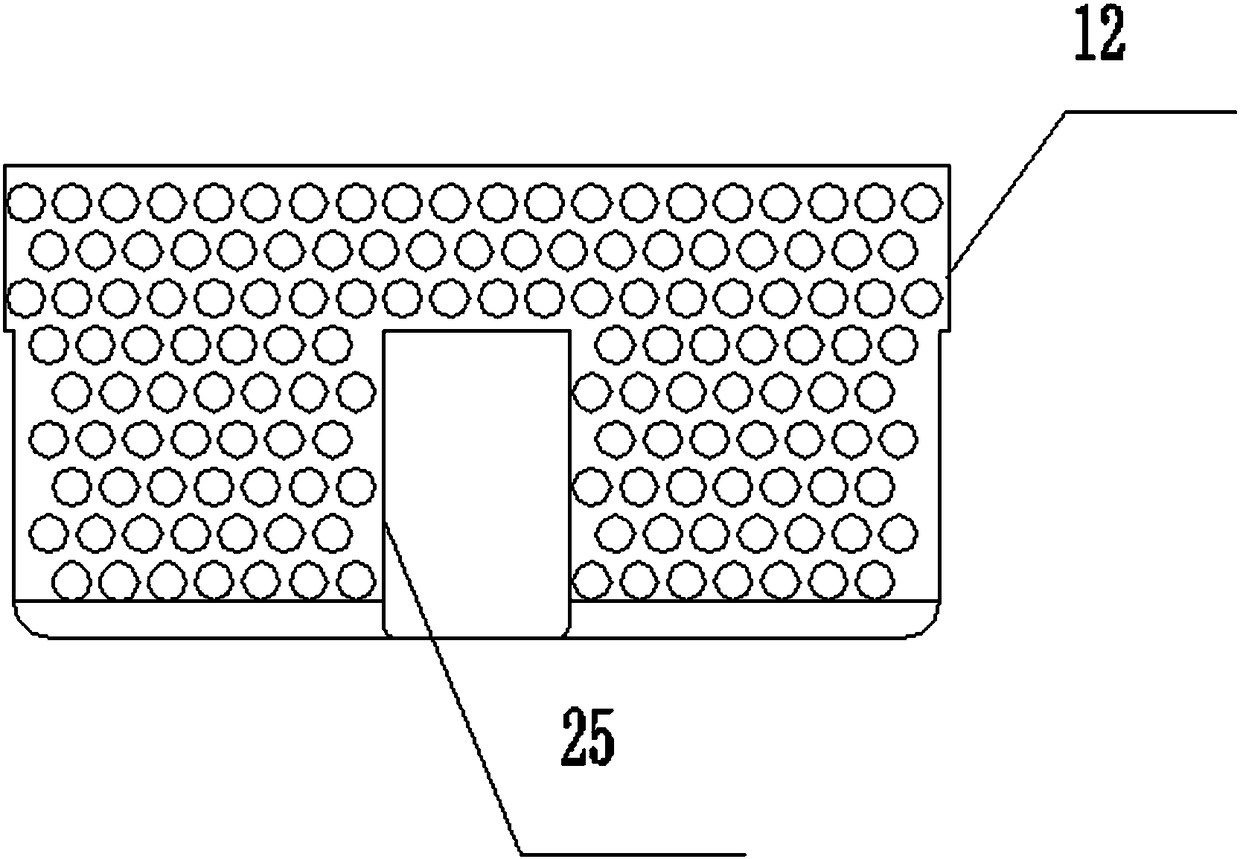

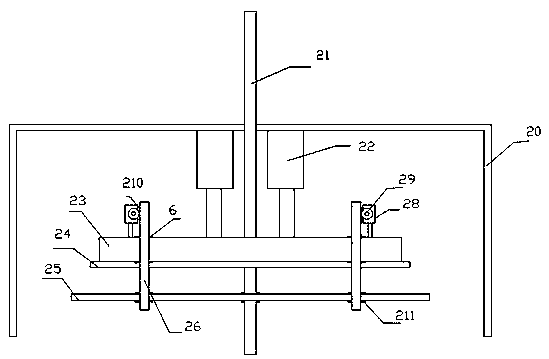

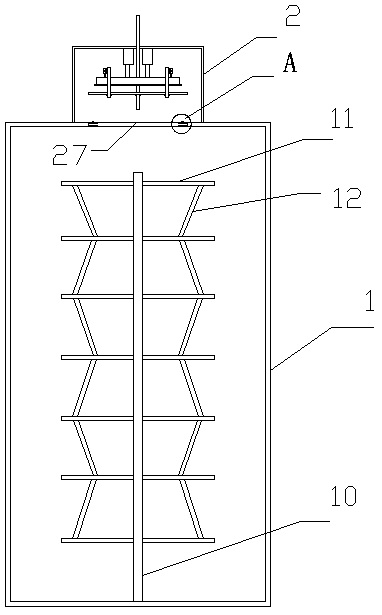

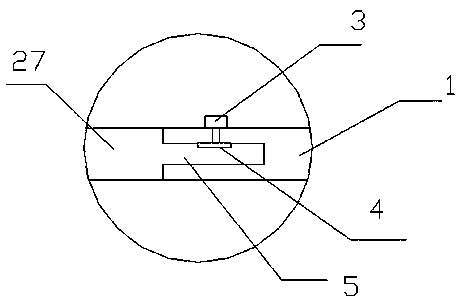

Carton sealing device for adhesive tape packaging

InactiveCN108438360AFast sealingPrevent affecting the sealing effectWrapper twisting/gatheringEngineeringCarton

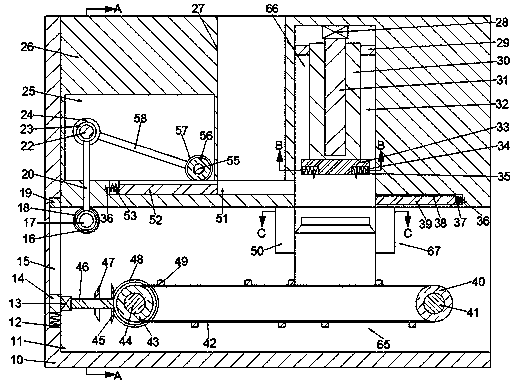

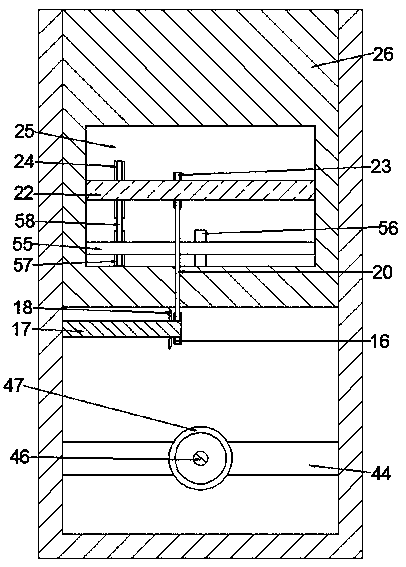

The invention relates to a carton sealing device, in particular to a carton sealing device for adhesive tape packaging. The carton sealing device for adhesive tape packaging aims at achieving the technical purposes of saving time and labor, being good in carton sealing speed and capable of fixing a carton. According to the technical scheme, the carton sealing device for adhesive tape packaging comprises a bottom plate, a limiting plate, guide rods, a top plate, guide sleeves, a frame body, a transverse rod, a sliding sleeve, a transverse plate, a vertical plate, a fixing rod, a first air cylinder, a pressing roller, an electric wheel and the like, the guide rods are installed on the left side and the right side of the top of the bottom plate, the guide rods are sleeved with the guide sleeves, the frame body is installed between the inner side faces of the guide sleeves on the left side and the right side, and the transverse rod is installed between the lower portion of the left side face and the lower portion of the right side face inside the frame boy. A carton can be fixed through a fixing device so as to be prevented from moving and affecting the carton sealing effect, adhesivetape can be notched through the effect of a cutter head, operators can tear off the adhesive tape more conveniently, and the effects that time and labor are saved, the carton sealing speed is high, and the carbon can be fixed are achieved.

Owner:王林华

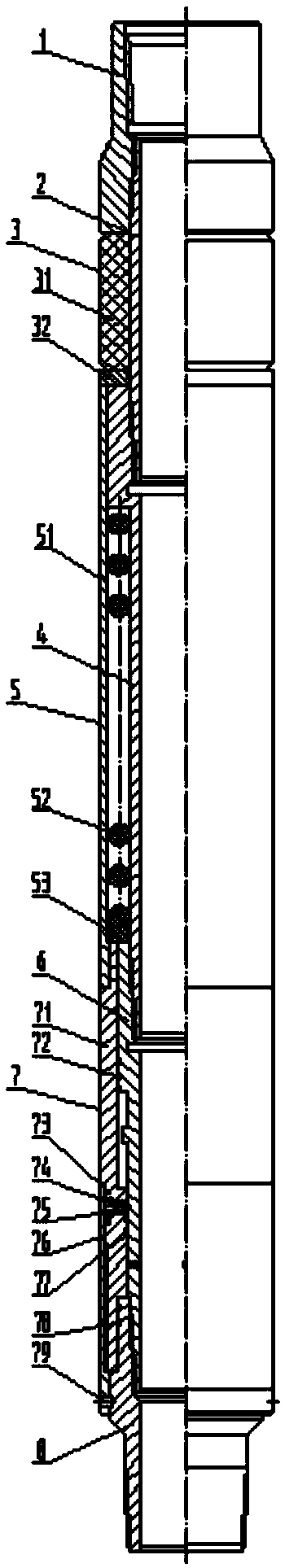

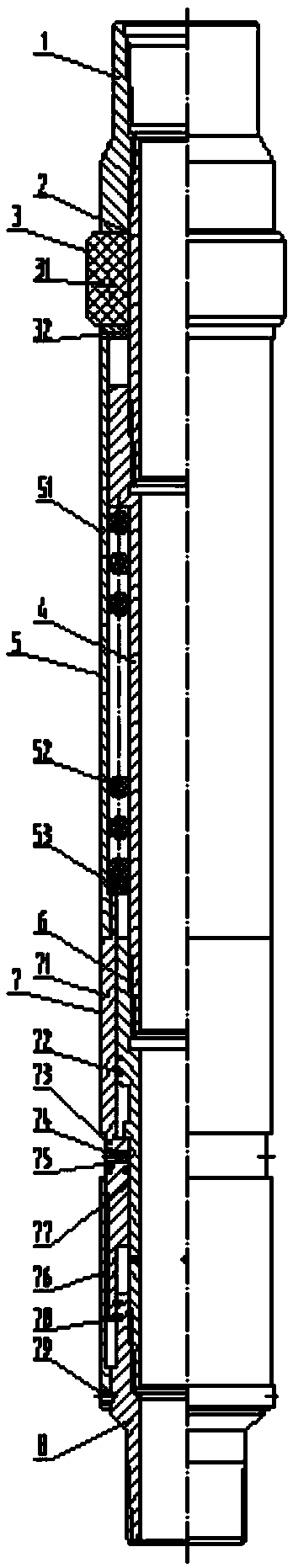

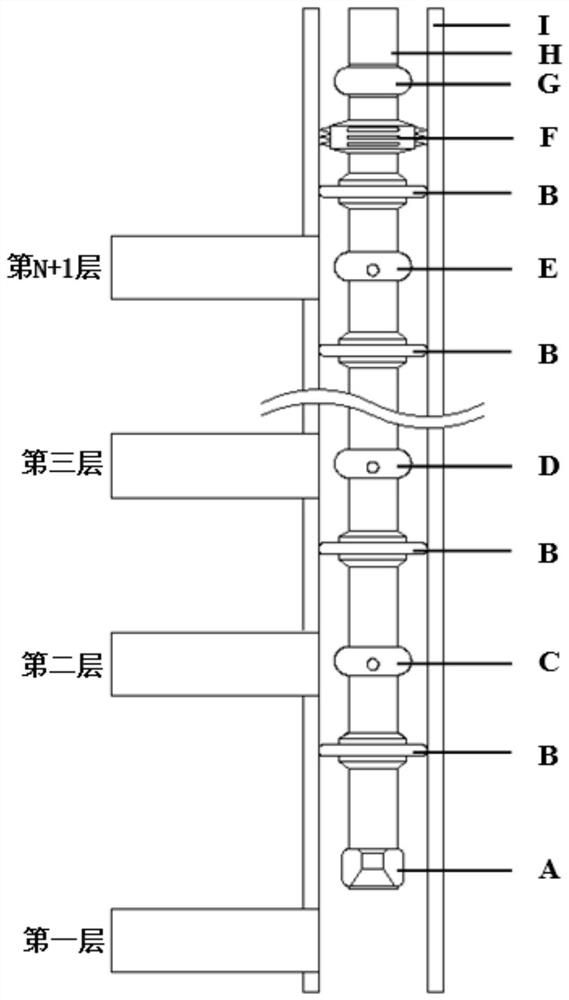

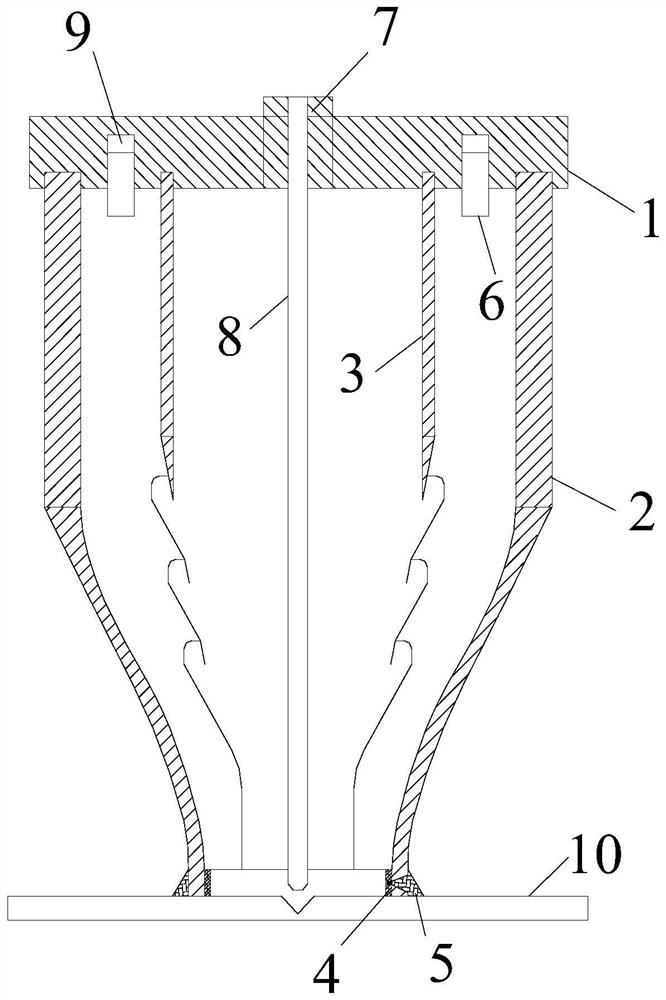

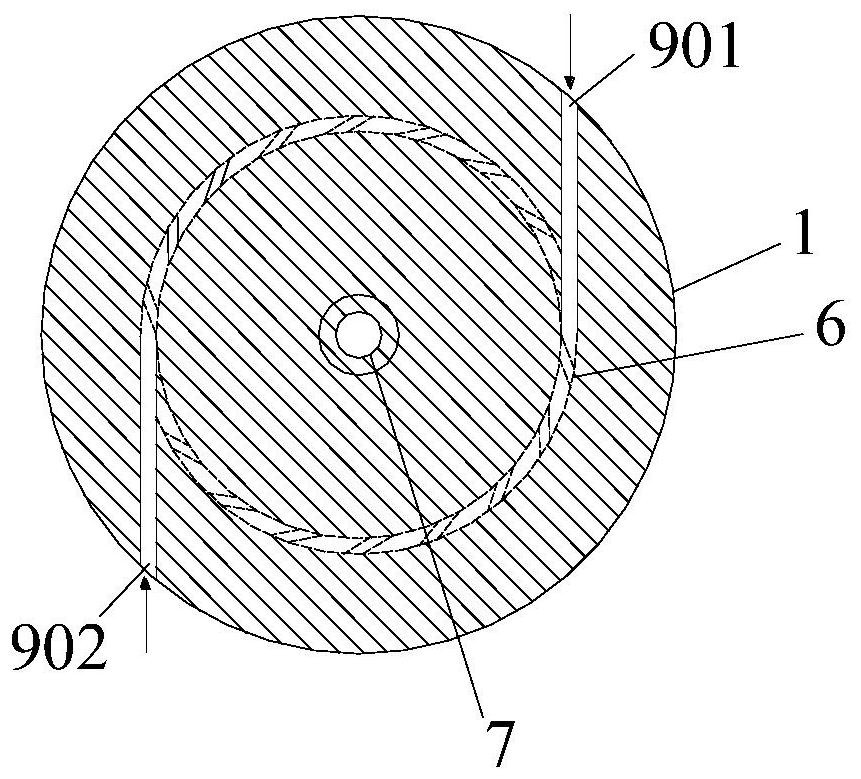

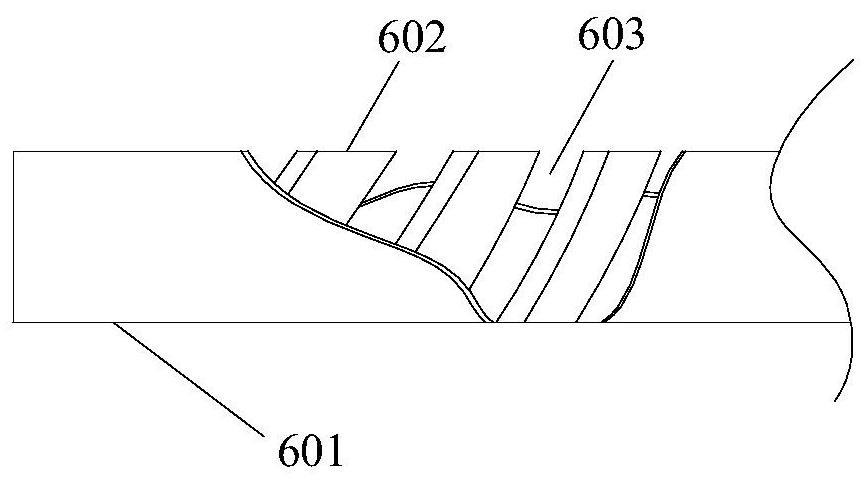

Non-throttling self-service unsealed packer

InactiveCN109538182AEasy to controlWithstand large pressure differenceFluid removalSealing/packingDual effectEngineering

The invention discloses a non-throttling self-service unsealed packer which comprises an upper connector, an upper central pipe, a sealing mechanism, a spring central pipe, a spring self-service unsealing mechanism, a lower central pipe, a setting-dissoluble unsealing mechanism and a lower connector. No throttling or setting needs to be conducted for the non-throttling self-service unsealed packer, and the setting process is convenient to control; limiting steps are arranged in the packer, it is avoided that the sealing effect is affected by the excessive compression of a rubber cylinder; by means of the compressed rubber cylinder, the borne pressure difference is large, and the setting effect is good and stable; large-discharge and large-scale cracking construction refitting can be realized; by means of the spring self-service unsealing mechanism, unnecessary advanced setting generated in the pipe column put-down process is avoided; after cracking construction ends, the rubber cylinder of the packer is rapidly unsealed under the dual effects of the rebound force of the rubber cylinder and the self-service unsealing force of a spring; by means of the setting-dissoluble unsealing mechanism, under the high pressure in a well, the rapid unsealing of the packer can still be ensured.

Owner:CNPC BOHAI DRILLING ENG

Cabin door sealing system and tidal power generator set applying same

ActiveCN105370181AEasy to control contact pressureEasy to adjustSealing arrangementsVessel hatches/hatchwaysUnderwaterEngineering

The invention discloses a cabin door sealing system which comprises a sealing part. The sealing part comprises a deforming air bag, wherein a retaining seat is arranged at the bottom of the deforming air bag, a sealing lip is arranged at the top, the sealing lip is jacked up and a static seal is formed when the deforming air bag is inflated to expand. The invention further provides a tidal power generator set applying the cabin door sealing system. The cabin door sealing system is reliable in sealing, convenient to maintain, long in serve life and low in cost and provides a sealing scheme low in cost and convenient to operate for a mechanism often needing scheduled maintenance and arranged underwater, especially for a maintenance cabin door of the tidal power generator set.

Owner:GUODIAN UNITED POWER TECH

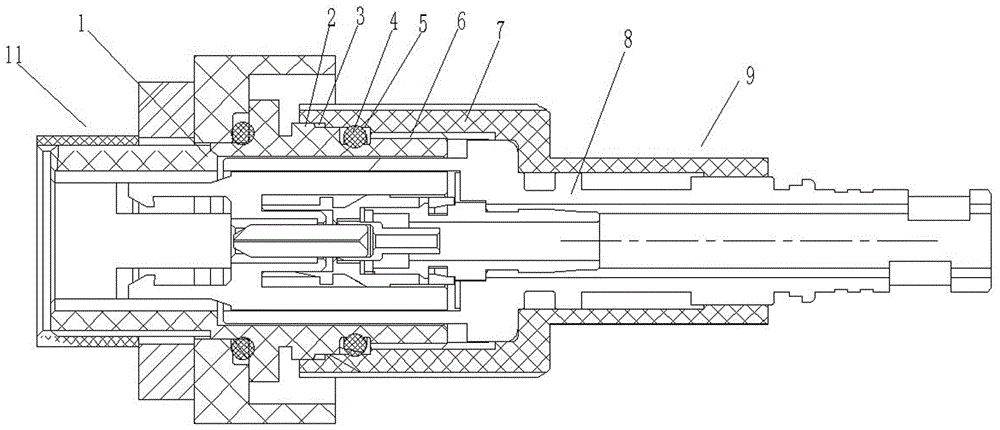

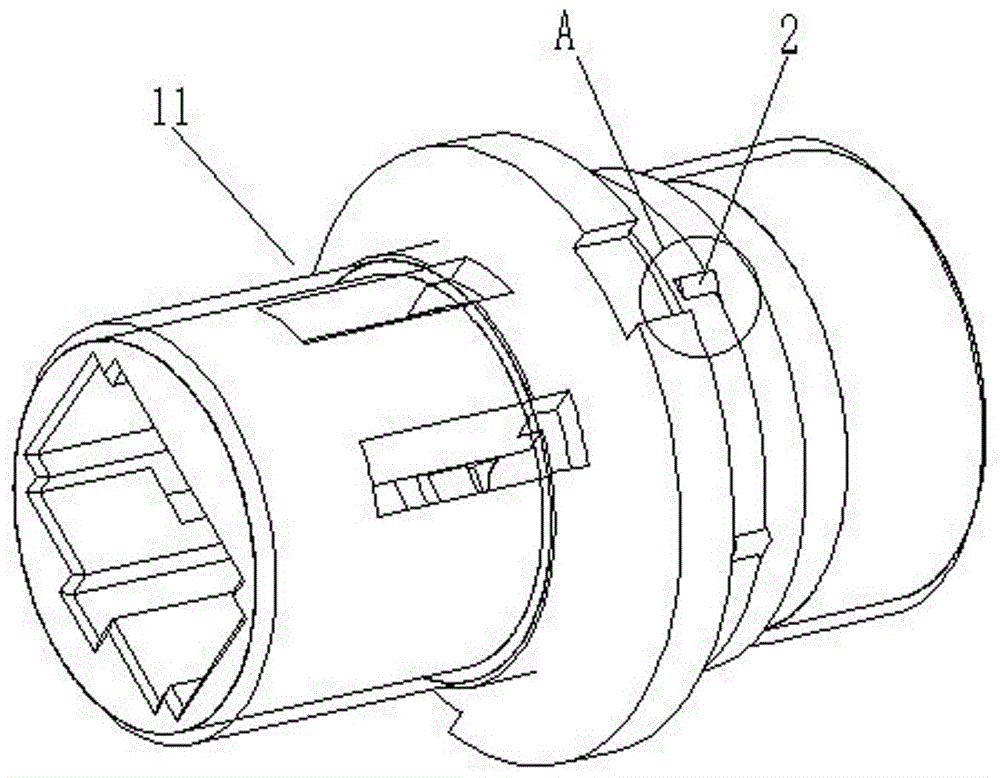

Cylinder filling adaptor

ActiveCN101832468ANo leaksPrevent leakageContainer filling methodsContainer discharging methodsElastomerGas cylinder

The invention provides a cylinder filling adaptor, which aims to solve the problem that the conventional cylinder filling adaptor has the drawbacks of having low sealing and airtight performance and damaging a cylinder component, and comprises an inner core and a connecting sleeve, wherein the inner core is internally provided with an air flue, an elastic body is sleeved around the outside of a connection part at the near end of the inner core, and the outer side, adjacent to the connection part, on the periphery of the inner core is provided with a protrusion; the connecting sleeve is comprised of a connecting section and a thrust section, the connecting section has a cylinder structure with a positively-rotatable internal threads, and the thrust section is an inner step arranged at the far end of the connecting sleeve, the connecting sleeve is sleeved on the inner core from the far end of the inner core with the thrust section clamped at the position of the protrusion of the inner core and the connecting section matched with the positively-rotatable internal thread at the external wall of the inflation inlet to make the connection part, with the elastic body, of the inner core enter the cylinder part at the inner wall of an inflation inlet to form sealed fit. The cylinder filling adaptor has the advantages of avoiding gas leakage in a gas filling process and avoiding damaging the cylinder components in installation and use.

Owner:北京北机机电工业有限责任公司

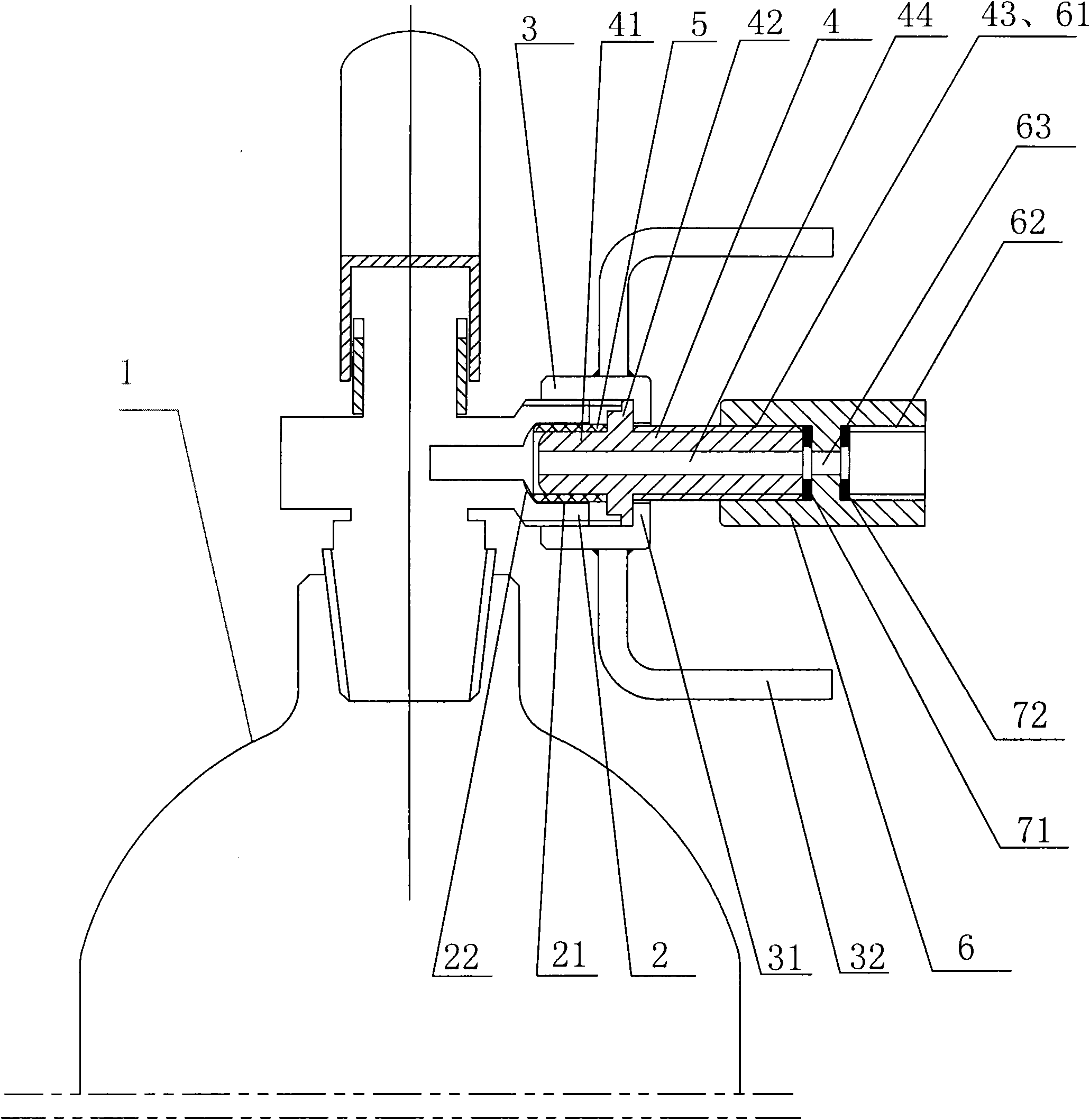

Air seal mechanism for front end of main shaft

PendingCN111360694AEasy accessAvoid enteringEngine sealsGrinding machine componentsStructural engineeringMechanics

The invention relates to the technical field of main shafts, and discloses an air seal mechanism for the front end of a main shaft. The air seal mechanism comprises a rotor, wherein a dustproof coveris arranged outside the rotor, a waterproof cover is fixed at the front end of the dustproof cover, the rear end of the dustproof cover abuts against a bearing, a bearing seat is arranged on the outerring of the bearing, the front end of the bearing abuts against a bearing pressing plate, the front end of the bearing pressing plate is provided with the dustproof cover, the dustproof cover abuts against an annular spraying plate, the dustproof cover and the annular spraying plate form annular air bags, and the front end of the dustproof cover abuts against the waterproof cover and forms an annular L-shaped gap; when the main shaft is inflated, the compressed air enters the air bags and is at a high pressure, the air bags are at a low pressure, the air flows to the air bags, then the compressed air of the air bags is discharged outside due to the low pressure outside, when the main shaft runs at a high speed, the generated centrifugal pump pressure is outside, the situation that due tothe negative pressure pumped inwards by a centrifugal pump, external cooling water is sucked into the main shaft is effectively prevented, the air seal protection at the front end of the main shaft iseffectively improved, and compared with other modes, the waterproof effect is superior.

Owner:深圳市爱贝科精密工业股份有限公司

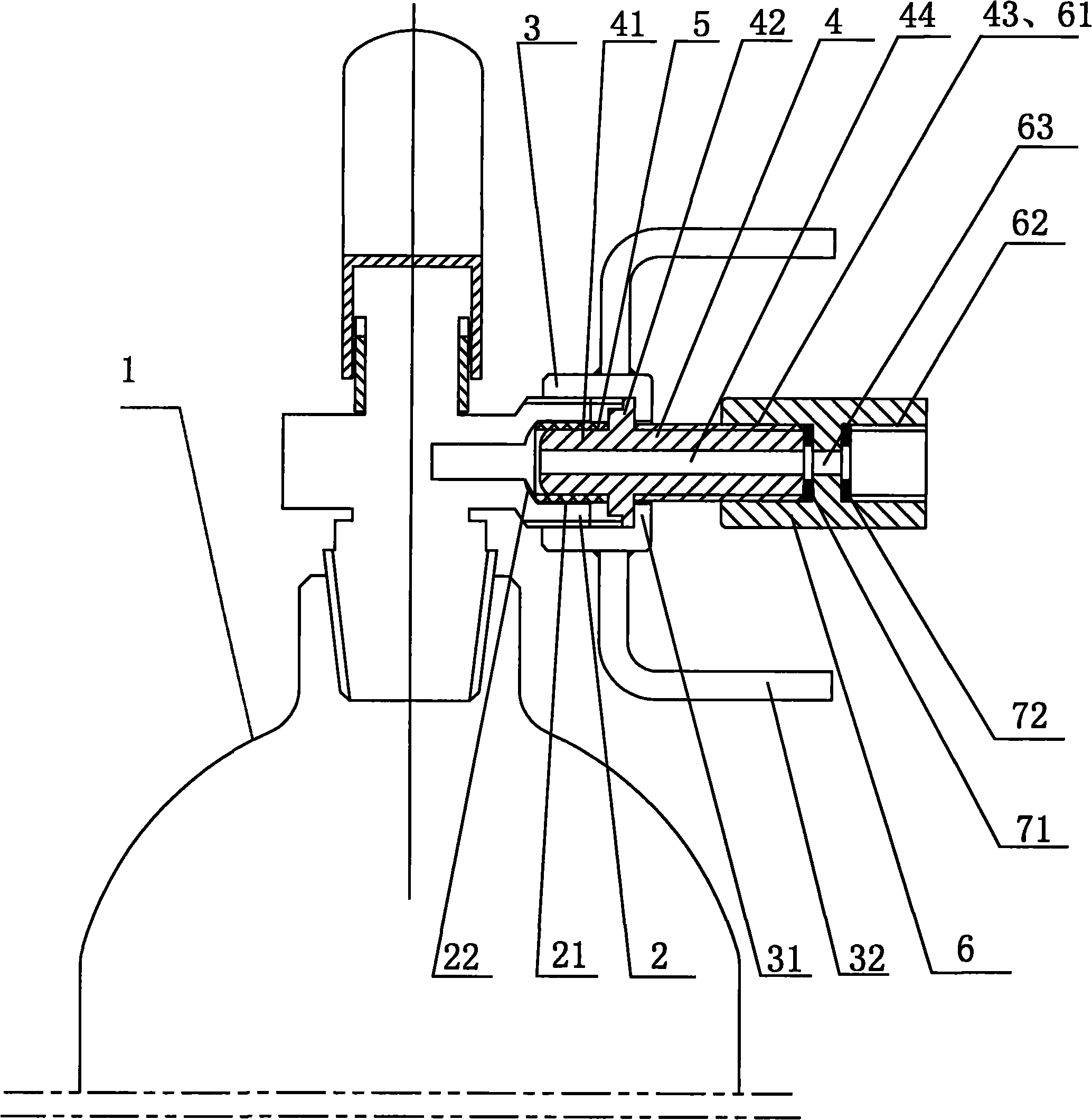

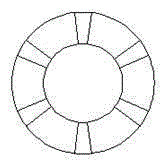

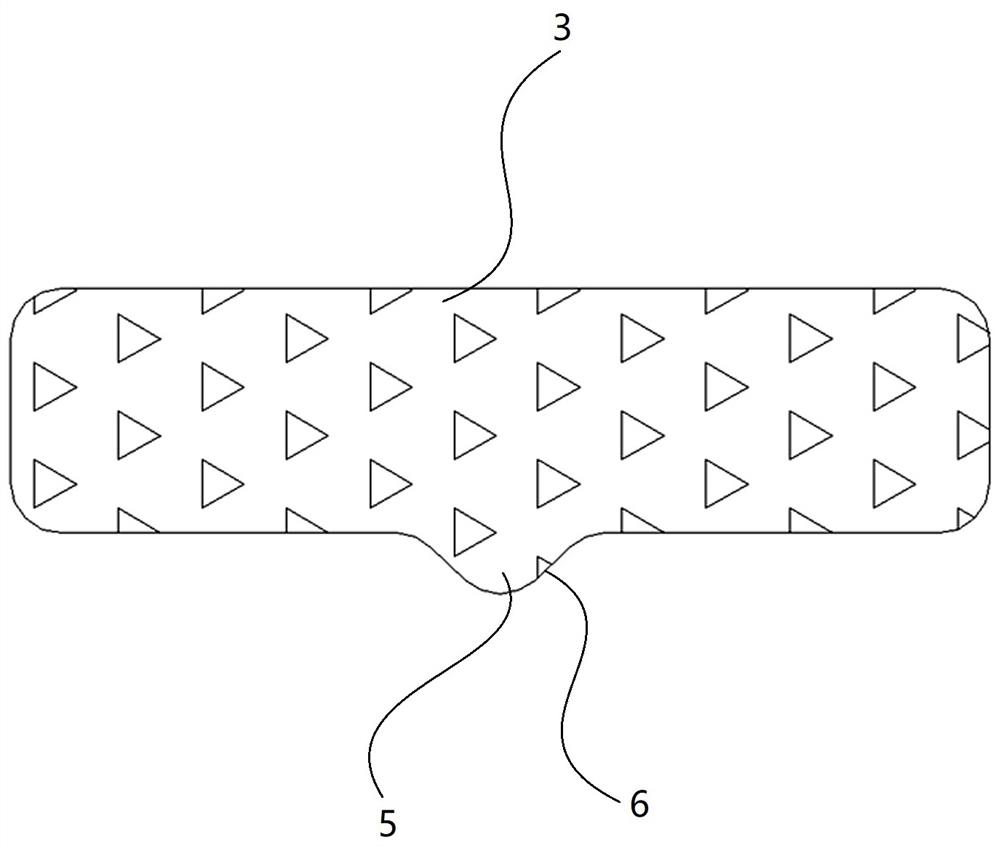

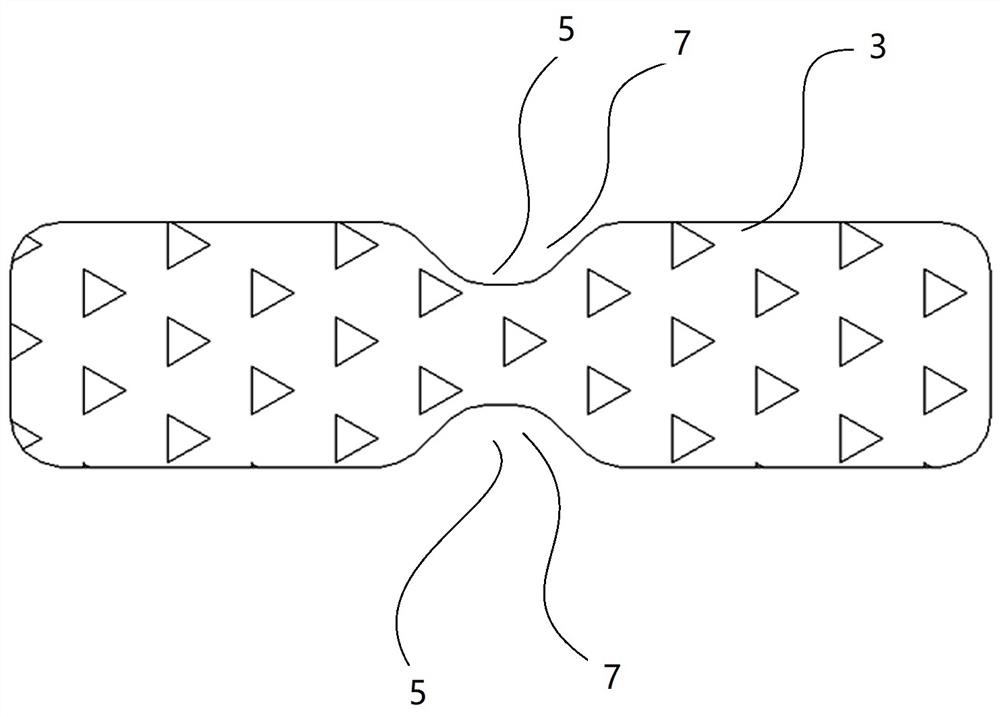

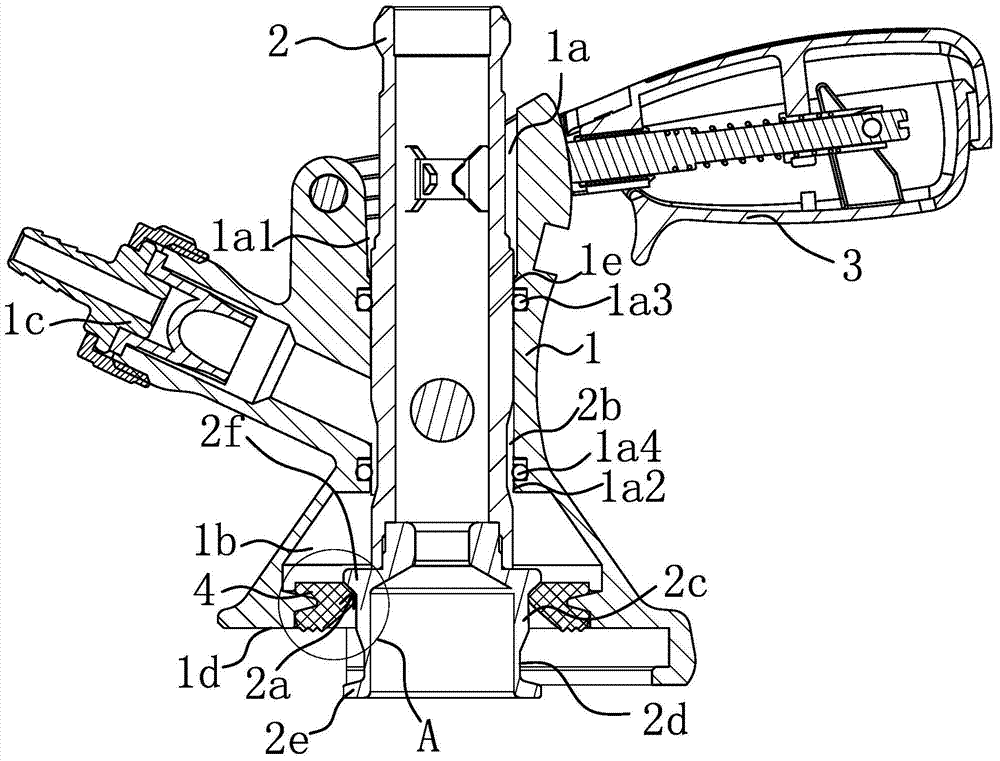

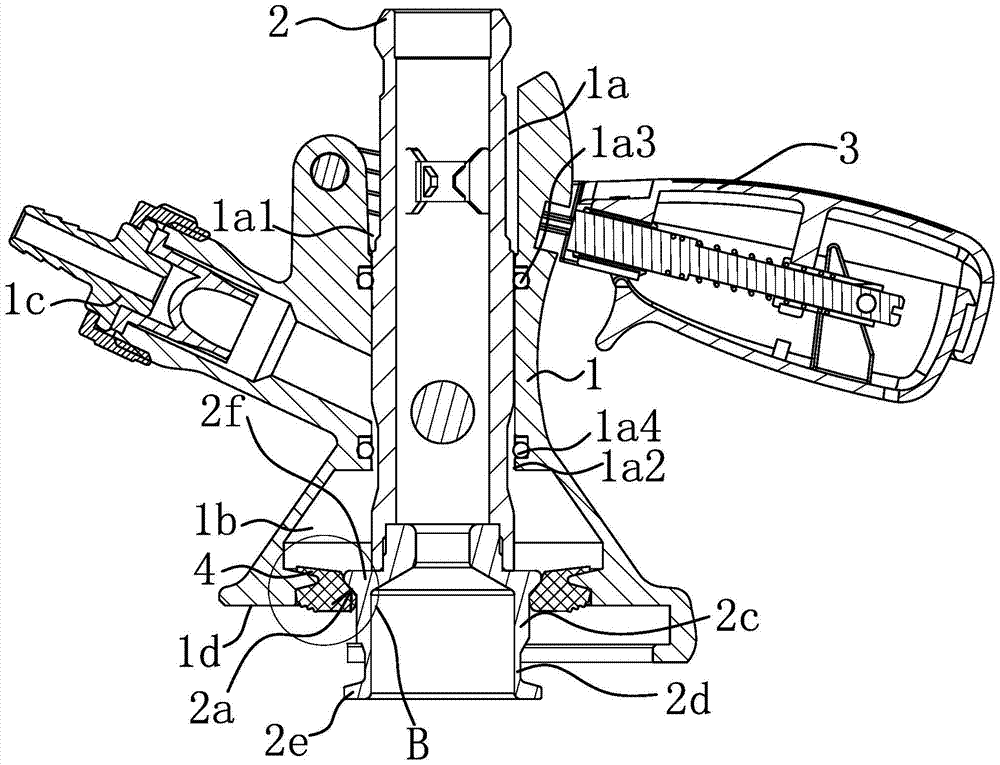

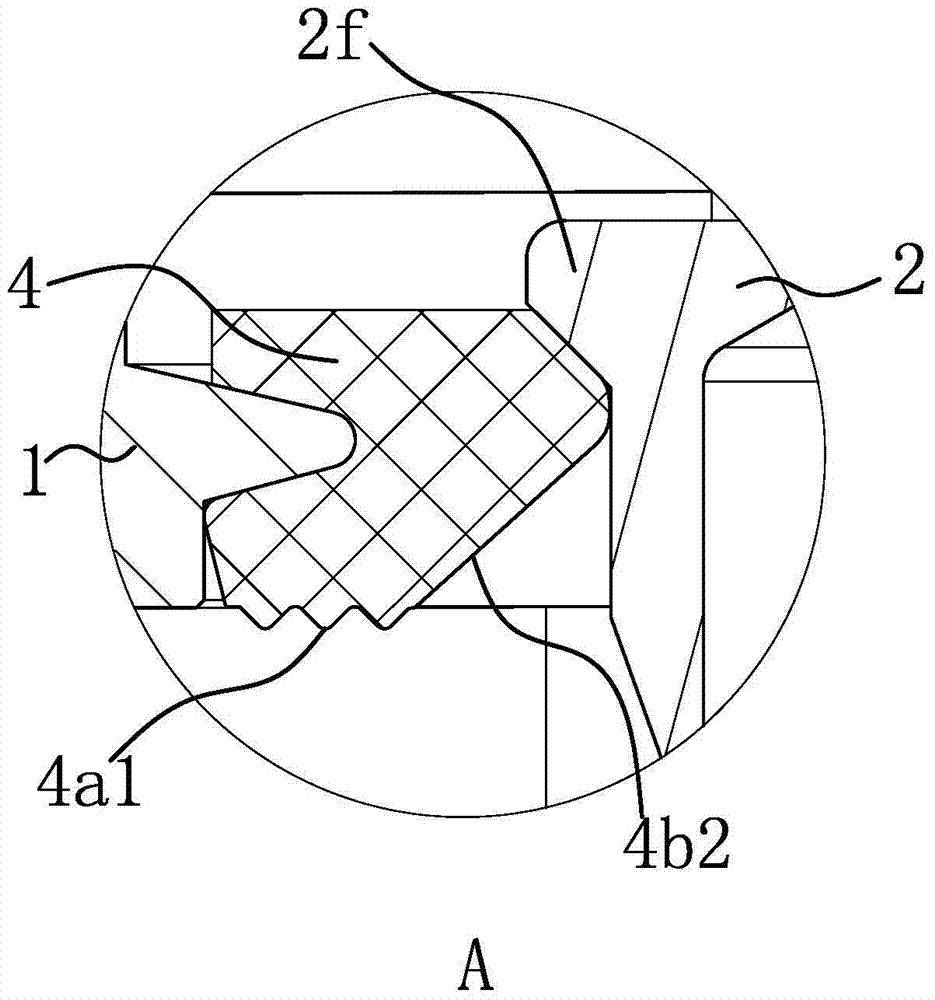

Connector, adaptive connector and anti-loose connector assembly

ActiveCN105932484AAchieve sealingRealize anti-looseningEngagement/disengagement of coupling partsCouplings bases/casesLoose toothMechanical engineering

The invention relates to a connector, an adaptive connector and an anti-loose connector assembly. The anti-loose connector assembly comprises the connector and the adaptive connector, the front ends of which are in plug connection mutually when used. The connector comprises a connector housing provided with an external thread. The adaptive connector comprises a nut provided with an internal thread. The connector housing is provided with connector anti-loose teeth. The nut is provided with nut anti-loose teeth cooperated with the connector anti-loose teeth. The outer circumference of the connector housing is provided with a seal ring. The inner circumference of the nut is provided with a seal matching surface for being in seal matching with the seal ring. The invention provides the anti-loose connector assembly capable of realizing both anti-loosening and seal effects, and the connector and the adaptive connector used in the anti-loose connector assembly.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

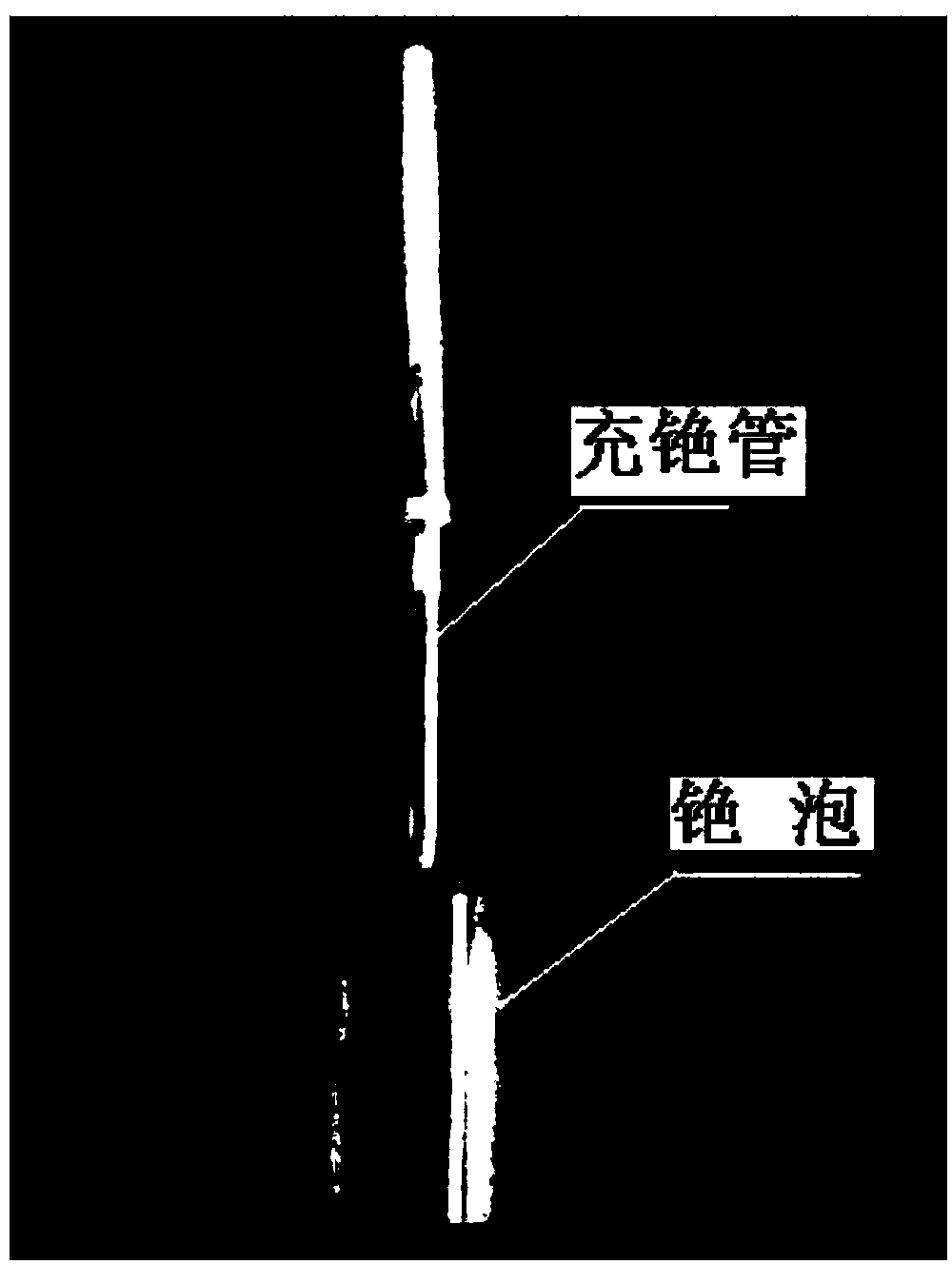

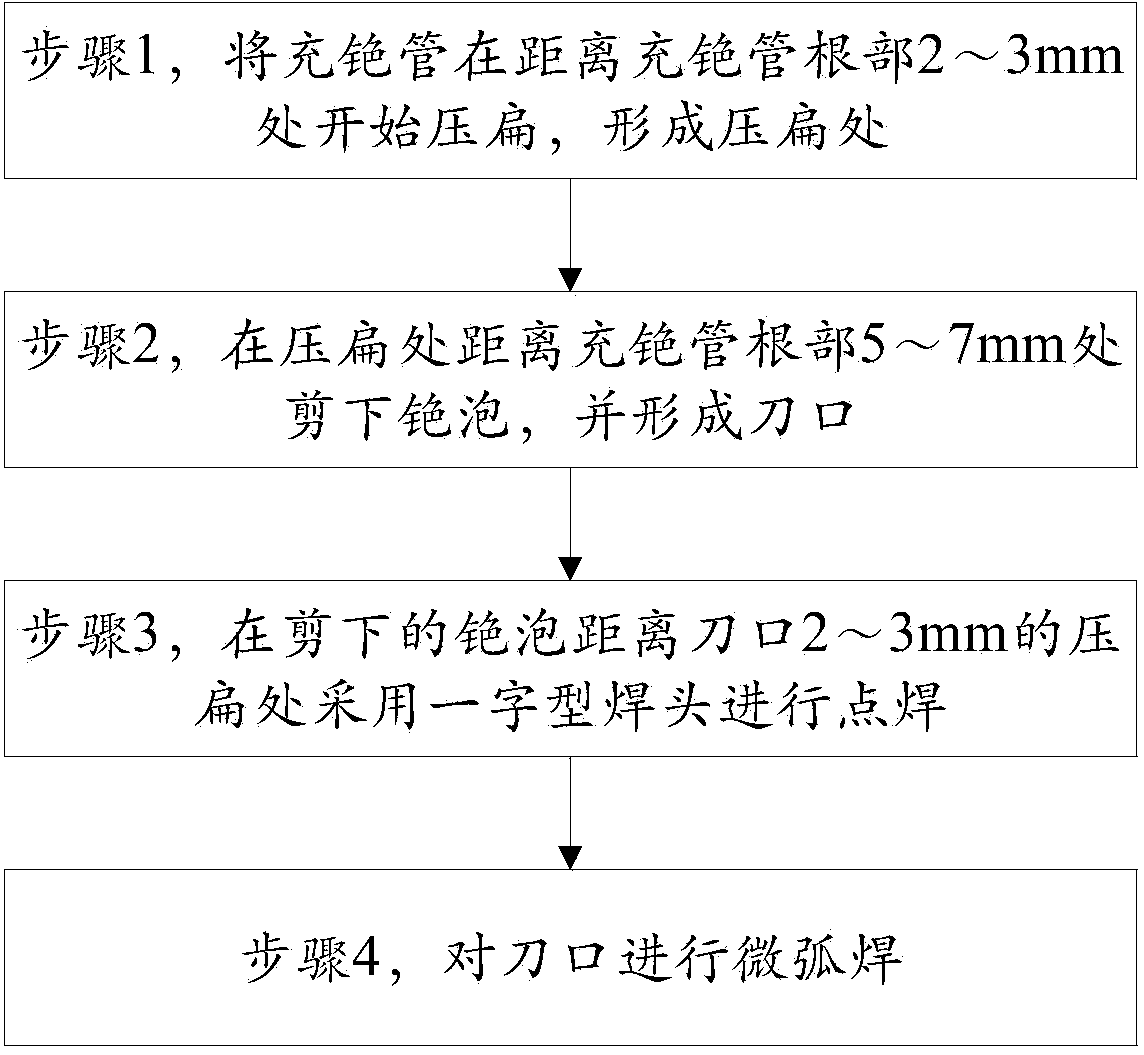

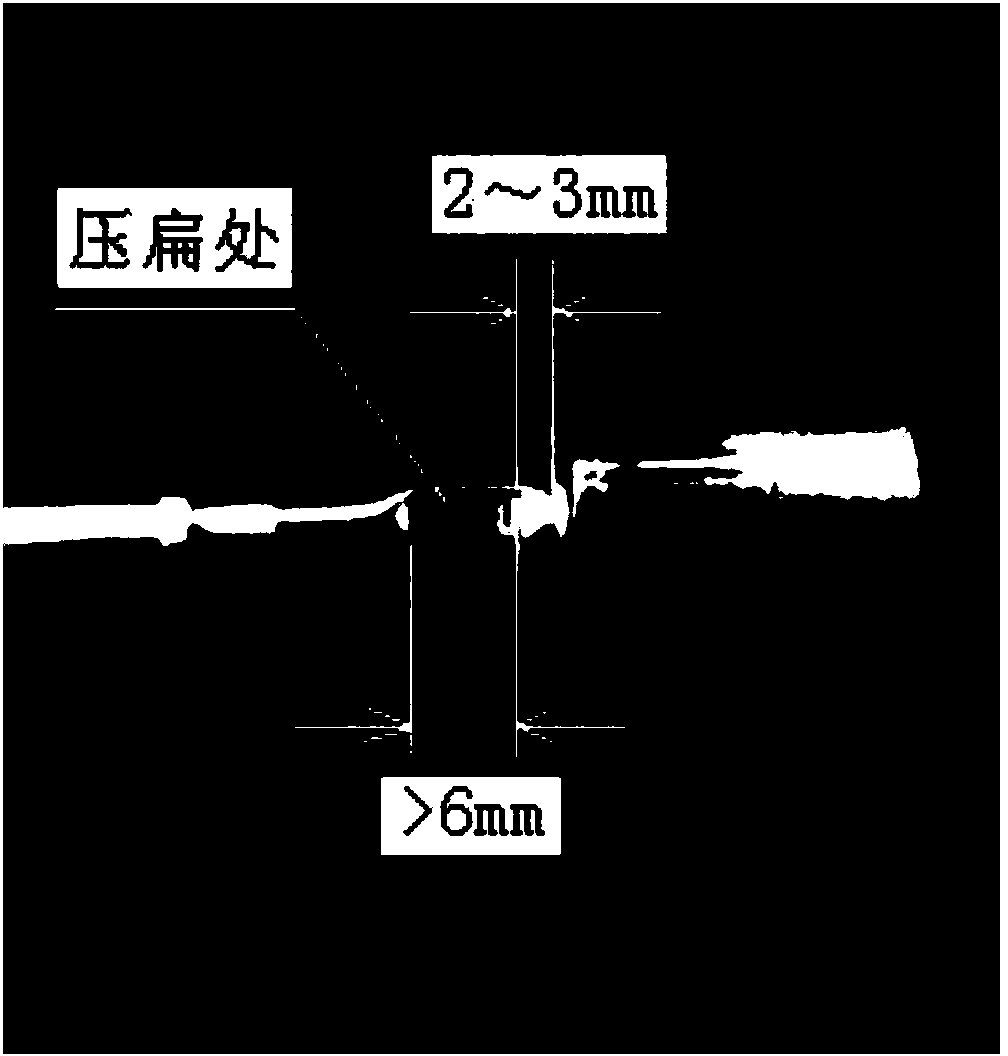

Sealing method for cesium foam of cesium-beam tube

The invention discloses a sealing method for cesium foam of a cesium-beam tube. According to the sealing method provided by the invention, the sealing problem of metal cesium foam of the cesium-beam tube is effectively solved, the sealing effect at a cesium foam position is increased, the step is simple and the method is easily realized. According to the invention, a three-sealing mode is adopted, so that the sealing effect of the cesium foam position is greatly enhanced. Firstly, a cesium-filled pipe wall is flattened, the stress possibly generated at a cutter opening is eliminated and air is prevented from entering into the cesium foam so that the metal cesium is prevented from being polluted; the cesium foam is cut off at a flattened part and the cutter opening is formed, and then the cesium foam is sealed for the first time; the flattened part is spot-welded, the pipe wall is fused, a sealing effect is achieved, and the sealing effect is prevented from being influenced by the steam cesium sprayed in the cesium foam under high temperature when the cutter opening is welded, so that the sealing is performed for the second time; lastly, the cutter opening is tiny arc-welded and the cutter opening is firmly sealed, so that the sealing is performed for the third time. Through the three times of sealing, the sealing effect is better.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Hole sealing device for drilled hole

InactiveCN105822255AAvoid generation and developmentEasy to operateGas removalSealing/packingDrill holeMechanical engineering

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

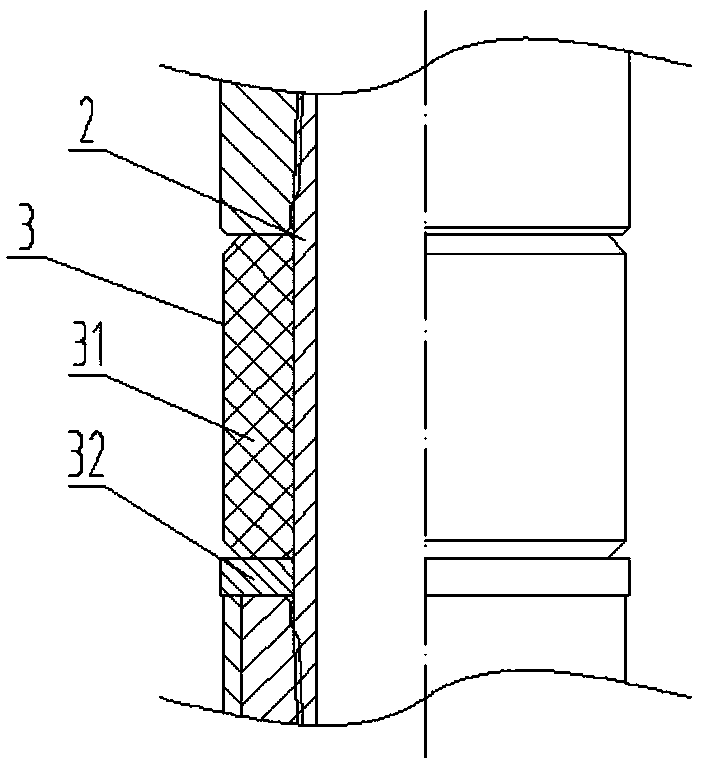

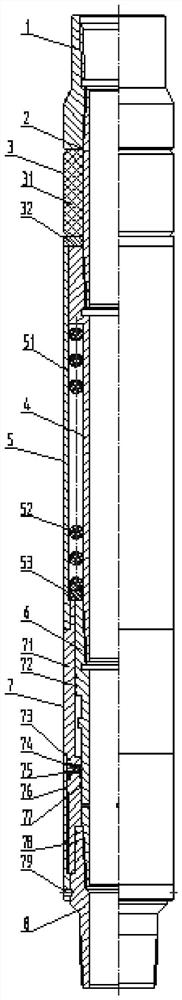

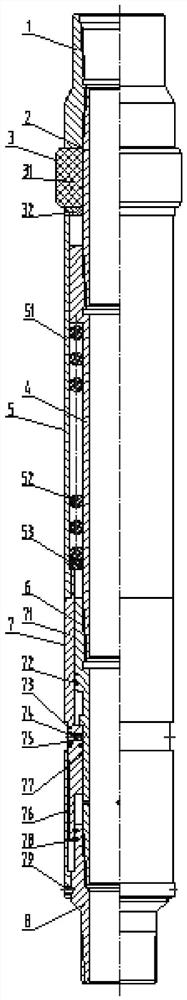

Sealing structure for high temperature revolution equipment and static equipment, and use method of same

InactiveCN104930848APrevent affecting the sealing effectRotary drum furnacesThermal deformationEngineering

The invention relates to the production field of alumina and concretely relates to a sealing structure for high temperature revolution equipment and static equipment, and a use method of the same. The sealing structure can prevent a sealing device used in a sealed connection part between the high temperature revolution equipment and the static equipment losing efficacy due to thermal formation caused by high temperature. The sealing structure comprises the static equipment, the revolution equipment, revolution rings, a water pipe, a sealing structure, a sealing device and a cylinder gap, wherein the cylinder bottom part of the revolution ring (I) is connected with the revolution equipment; a gap is formed between a cylinder body part of the revolution ring (I) and a cylinder body of the revolution equipment; one end of the pressurized water pipe extends into the gap; cooling water can be injected to the gap by the pressurizing water pipe; the external side of the revolution ring (I) is provided with a revolution ring (II); and a gap is reserved between the revolution ring (II) and a static ring. A certain gap is reserved between the sealing device and the cylinder body of the revolution equipment and the cylinder body can be sprayed by the water pipe, so thermal deformation of the sealing device due to excessive high temperature of the cylinder body can be avoided and sealing effect can be maintained.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

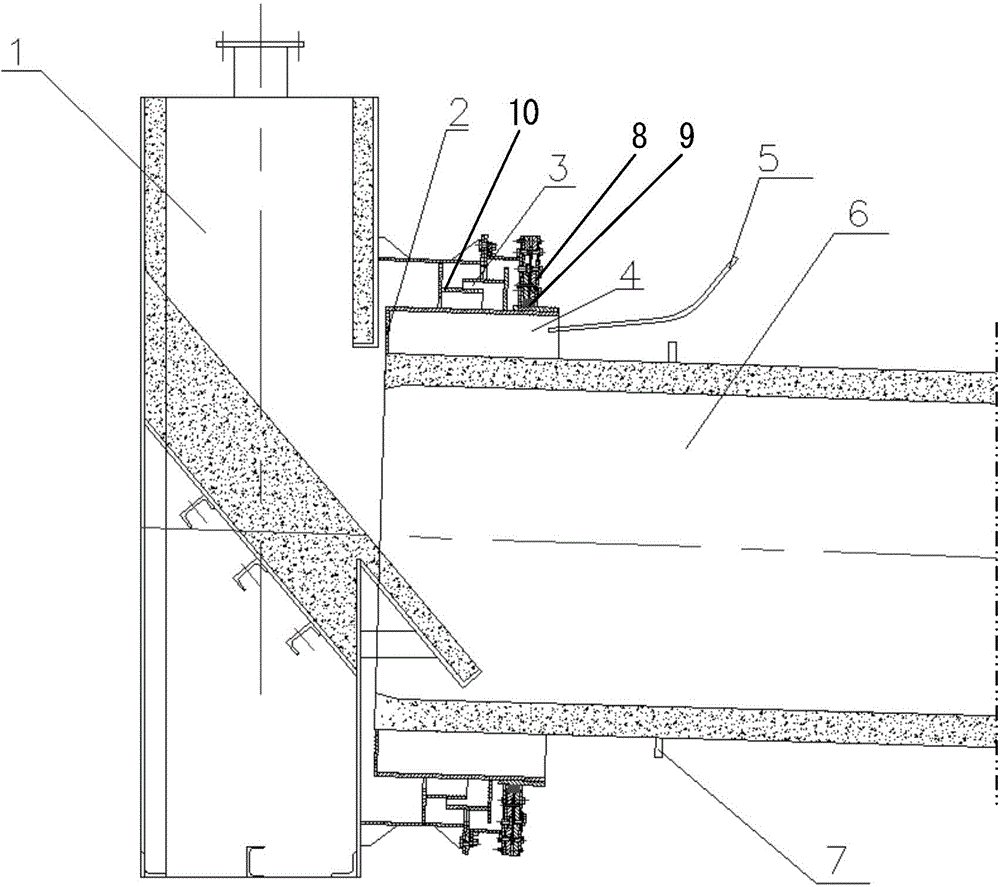

Throttling-free multistage layered fracturing pipe column and multistage layered fracturing construction method

The invention discloses a throttling-free multistage layered fracturing pipe column and a multistage fracturing construction method. The pipe column comprises a horn mouth, a plurality of throttling-free self-service deblocking packers, throttling-free sand blasting sliding sleeves, sand prevention hydraulic anchors and hydraulic safety joints which are sequentially connected through oil pipes from bottom to top. In each throttling-free sand blasting sliding sleeve, a plurality of sand blasting holes are formed in a sand blasting sliding sleeve body, a throttling-free inner sliding sleeve is fixed in each sand blasting sliding sleeve body through a plurality of shear pins and seals the sand blasting holes, and comprises an outer cylinder and an inner cylinder with the axial length smallerthan that of the outer cylinder, and the inner cylinder sleeves the inner side of the bottom end of the outer cylinder through a connecting part in a manner that a gap exists; and the inner diameter of the inner cylinder of each stage of throttling-free sand blasting sliding sleeve is gradually increased from bottom to top. According to the non-throttling multistage layered fracturing pipe column,the purpose of completing multistage layered fracturing and layer combining production solving by tripping in the pipe column once can be achieved, bottom-to-top step-by-step fracturing constructionis achieved, and the sand conveying efficiency and the fracturing construction safety can be remarkably improved through the corresponding fracturing construction method.

Owner:CNPC BOHAI DRILLING ENG +1

Flexible wind deflector

The invention discloses a flexible wind shield, and belongs to the technical field of heavy-duty car part manufacturing. A supporting steel plate and the flexible rubber are compounded into a whole, the flexible rubber in contact with the cab floor is matched with the cab floor in shape, gaps of the cab floor are shielded, and air leakage is reduced; the supporting steel plate in contact with thecooling module is provided with a plurality of through holes or notches for various pipelines and other structures to penetrate through according to the structure of the cooling module, so that the gap between the flexible wind deflector and the cooling module is greatly reduced, the hot air backflow prevention effect is good, and the heat dissipation efficiency of the cooling module is improved.Peak-shaped protrusions on the supporting steel plate increase the combination area of the supporting steel plate and the flexible rubber, and the combination strength is improved. The wrinkled protrusions and the annular grooves are formed in the flexible rubber, before the cab does not bounce, the upper portion of the flexible rubber and the floor of the cab are sealed, hot air backflow is prevented, and after the cab bounces, the flexible rubber and the cab can still be well sealed through compression and springback deformation.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

Maintenance-free alarming light

InactiveCN101793383ASimple structureSolve Assembly Issues for Landscape Mounted SealsElectric circuit arrangementsProtective devices for lightingElectricityEffect light

The invention relates to a maintenance-free alarming light, comprising a light housing and a lighting assembly, wherein the lighting assembly is arranged in the light housing, a mounting hole for a charging port is arranged on the light housing, a permanent seat for the charging port is arranged in the light housing, the permanent seat for the charging port is provided with an accommodation space which is provided with a charging female seat, one end of the charging female seat which is electrically connected with the lighting assembly is provided with a sealing ring for the charging female seat, the open end of the charging female seat is provided with a sealing ring for the charging port which pops up the light housing, and the opening of the charging female seat is communicated with the mounting hole for the charging port. The structure of the charging port of the maintenance-free alarming light in the invention is simple and reliable, and the assembly problem of transverse installation sealing of the charging port can be solved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

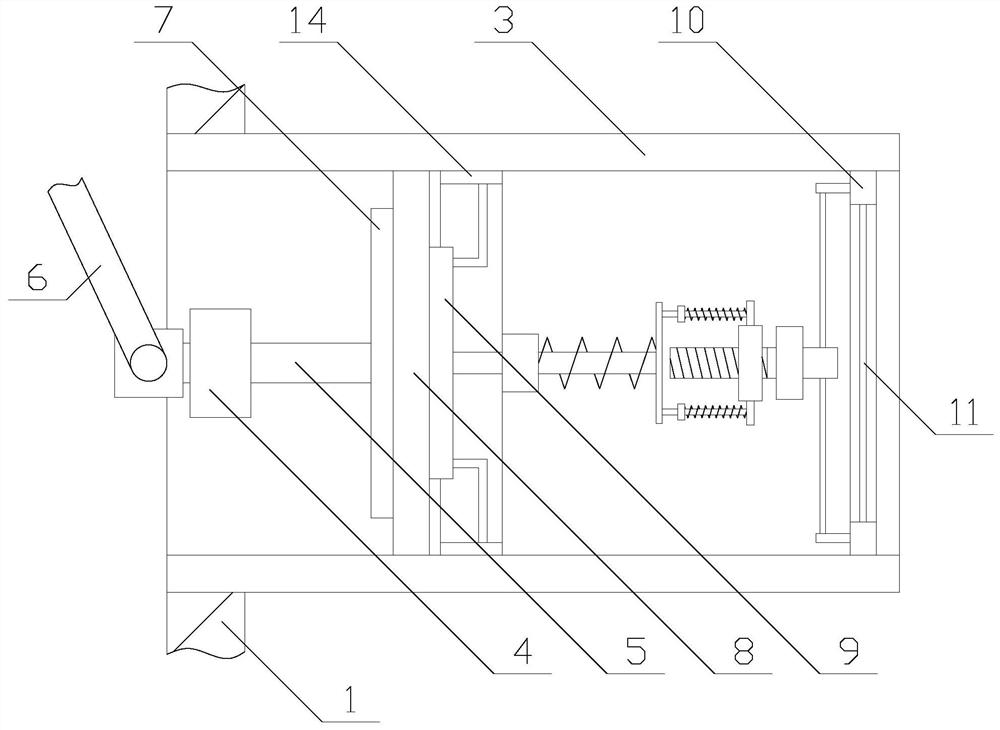

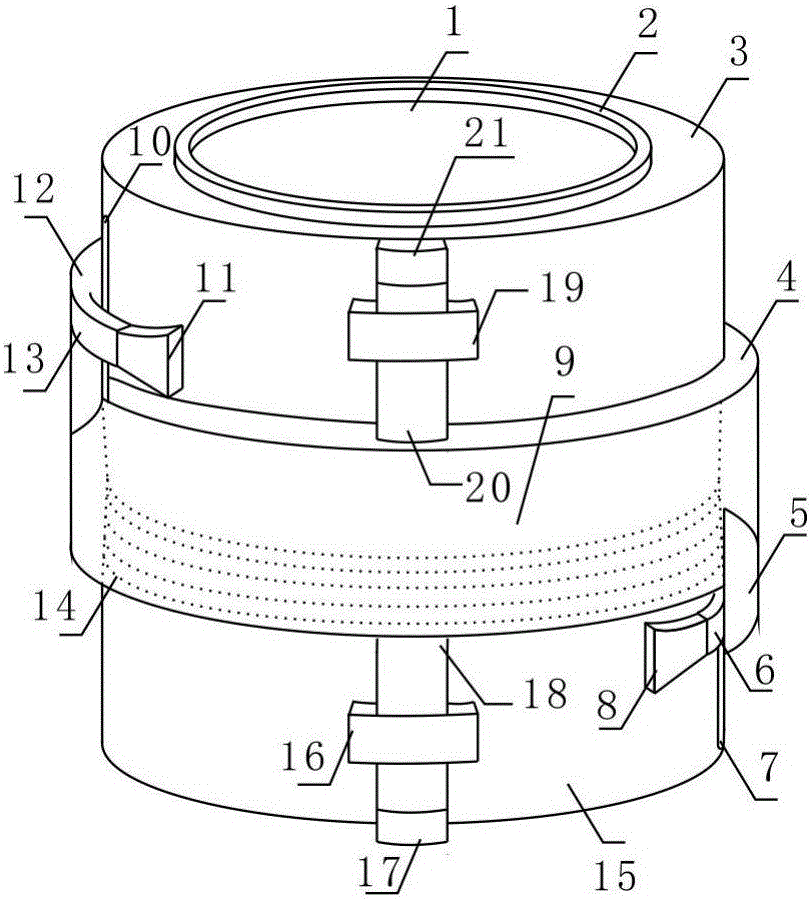

Reaction kettle

InactiveCN108854922AImprove sealingEasy to operateChemical/physical/physico-chemical stationary reactorsEngineering

The invention discloses a reaction kettle. The reaction kettle comprises a kettle body and a sealing cover, wherein the sealing cover comprises a door-shaped bracket, a guide rod, an air cylinder A, acover body, a flexible sealing ring A, a flexible sealing plate, a guide column and a guide column drive mechanism, wherein the base of the air cylinder A is mounted on the door-shaped bracket; the ejector rod of the air cylinder A is connected with the cover body; the flexible sealing ring A is fixed to the bottom of the cover body; the flexible sealing plate is sealed and fixedly connected withthe guide rod; the guide column sequentially passes through the cover body, the flexible sealing ring A and the flexible sealing plate from top to bottom; one guide column drive mechanism drives oneguide column to slide up and down in the cover body; the flexible sealing plate is fixedly connected with the guide column in a sealing mode; a ring-shaped inner groove is formed in the opening of thetop of the kettle body; and the outer diameter of the ring-shaped inner groove is greater than or equal to the diameter of the flexible sealing plate. The reaction kettle improves the reaction kettlecover; and the reaction kettle sealing cover can seal the reaction kettle very well, so that the sealing effect is good.

Owner:湖州翔润化工有限公司

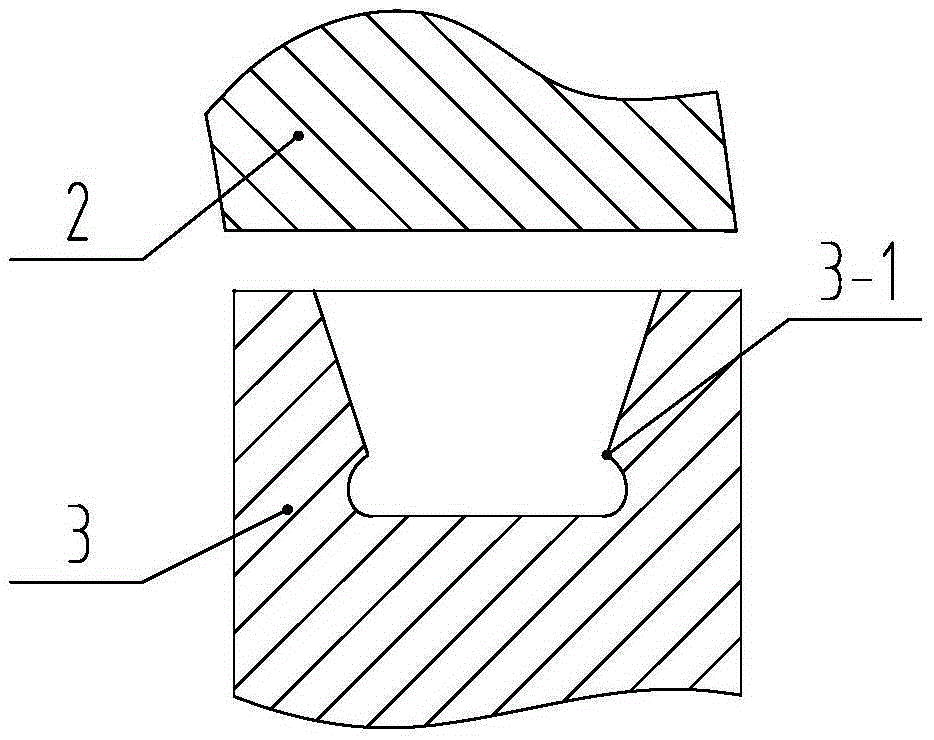

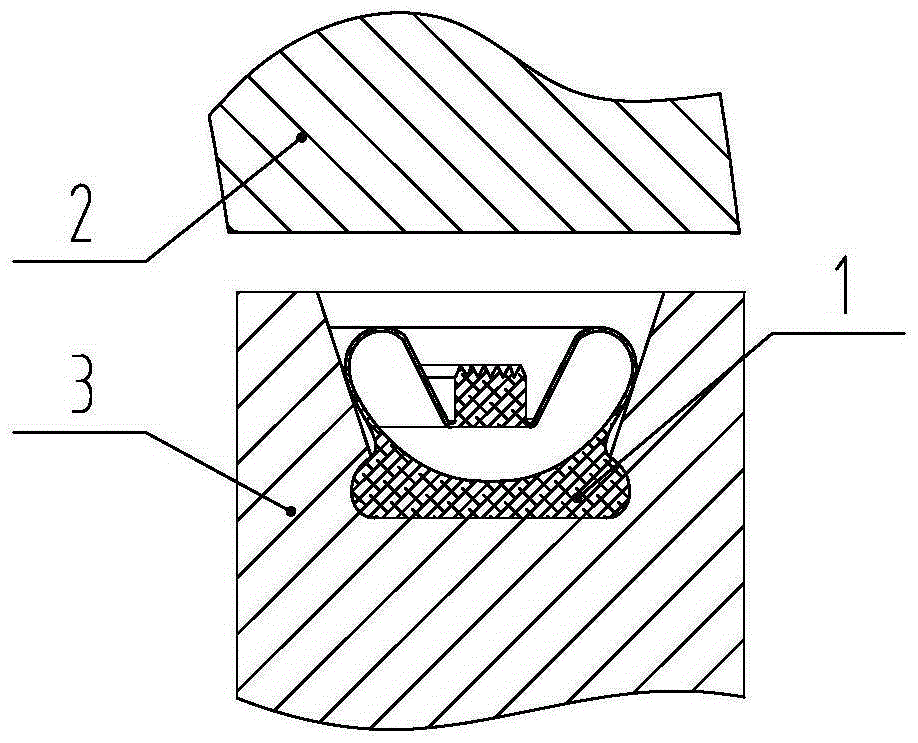

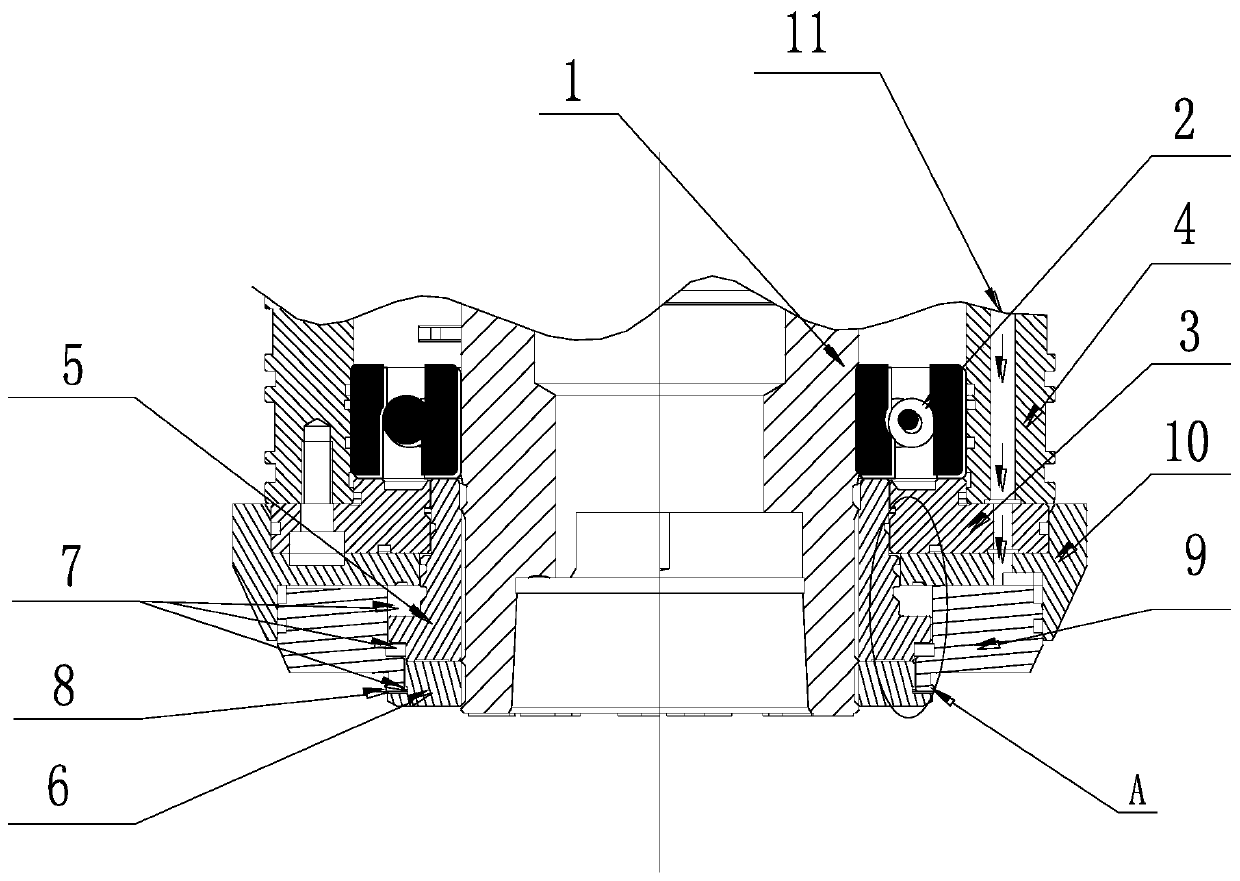

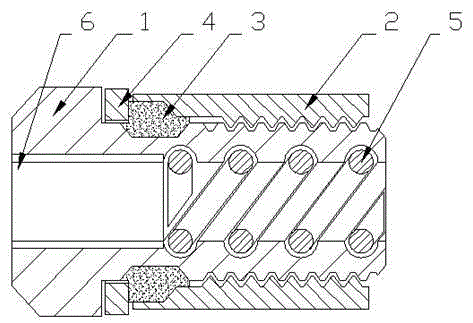

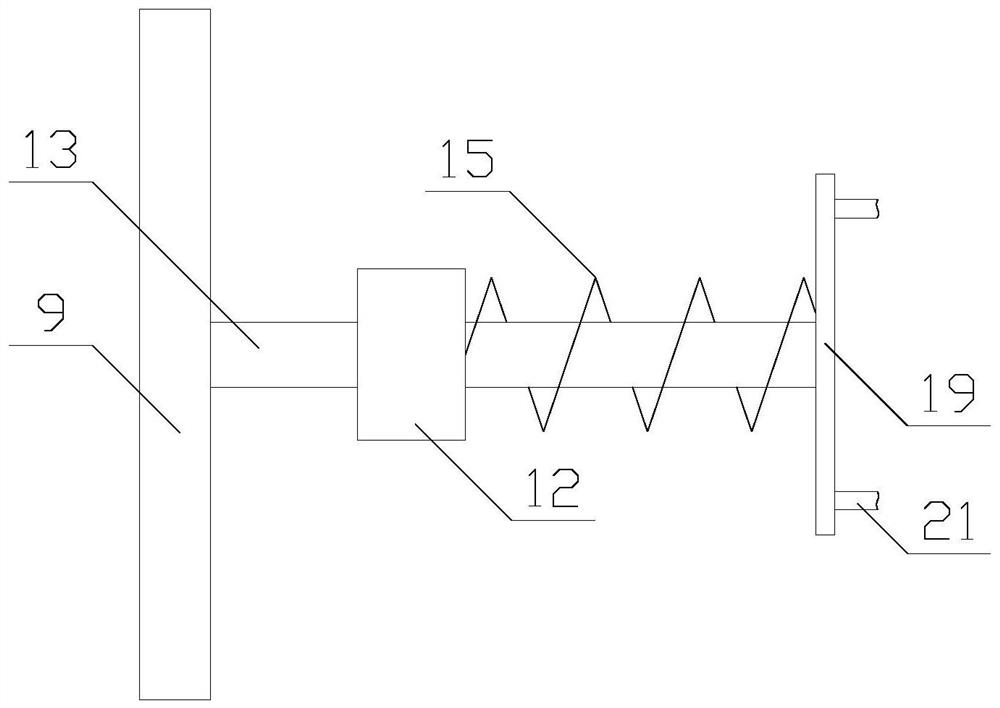

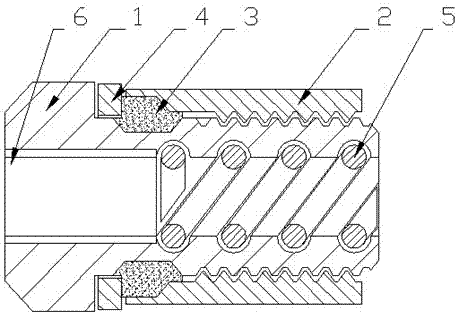

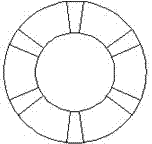

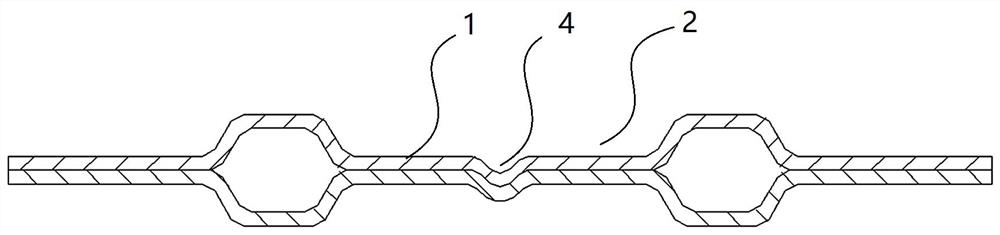

A kind of oil pipe joint

ActiveCN103791180BPrevent affecting the sealing effectImprove tightening effectJoints with sealing surfacesScrew threaded jointsCoil springEngineering

The invention relates to an oil pipe joint, comprising a joint main body and a locking sleeve. The joint main body is a hollow cylinder, an equipment connection part is arranged at one axial end of the hollow cylinder, and a The pipe connection part; the outer wall of the hollow cylinder of the pipe connection part is provided with threads, the locking sleeve is sleeved on the outer wall of the hollow body through threads, and the inner wall of the hollow body of the pipe connection part is provided with a spiral groove. A coil spring is inlaid in the spiral groove, and several linear grooves are arranged on the wall surface of the hollow main body of the pipe connection part; the equipment connection part is set according to the specific working conditions of the equipment; the present invention adds a coil spring to the inner wall of the expansion plug, It improves the tightening effect, and at the same time prevents the plastic deformation of the joint metal from affecting the sealing effect under long-term compression.

Owner:NANTONG AMC MACHINERY

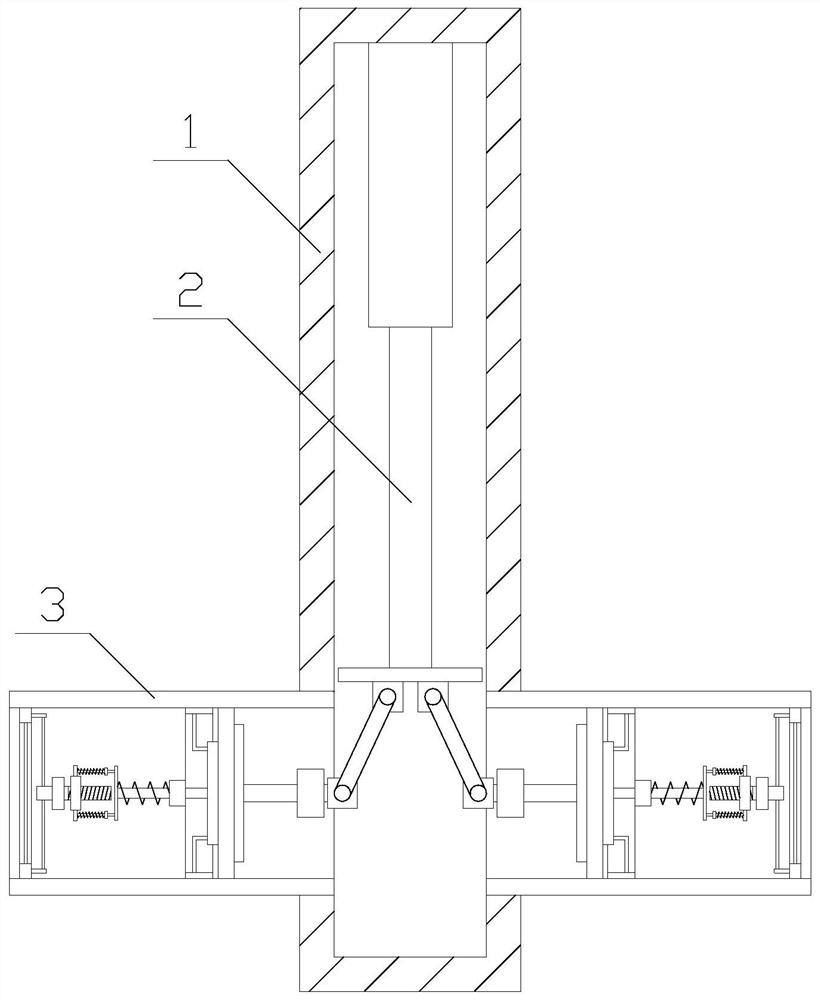

Pipeline transportation equipment for natural gas

InactiveCN113404868APlay a buffer functionFunction as a shock absorberOperating means/releasing devices for valvesDispersed particle filtrationHydraulic cylinderThermodynamics

The invention relates to pipeline transportation equipment for natural gas. The pipeline transportation equipment comprises a valve body, a hydraulic cylinder and two connecting pipes, wherein the hydraulic cylinder is vertically arranged at the top of the inside of the valve body; the two connecting pipes are separately and horizontally arranged on the two sides of the valve body; two filtering perforated pipes communicate through the valve body; the two connecting pipes are coaxially arranged; the hydraulic cylinder is positioned above the connecting pipes; the valve body is provided with two sealing mechanisms and two filtering mechanisms; the sealing mechanisms and the filtering mechanisms are in one-to-one correspondence with the connecting pipes; and the sealing mechanisms comprise supporting blocks, push rods, connecting rods, extrusion plates, air bags, supporting disks and supporting assemblies. According to the pipeline transportation equipment for the natural gas, the sealing performance is improved through the sealing mechanisms, and the sealing effect is prevented from being affected by gaps generated by wear and tear. Moreover, the function of filtering out impurities in the natural gas is achieved through the filtering mechanisms.

Owner:广州图腾电子商贸有限责任公司

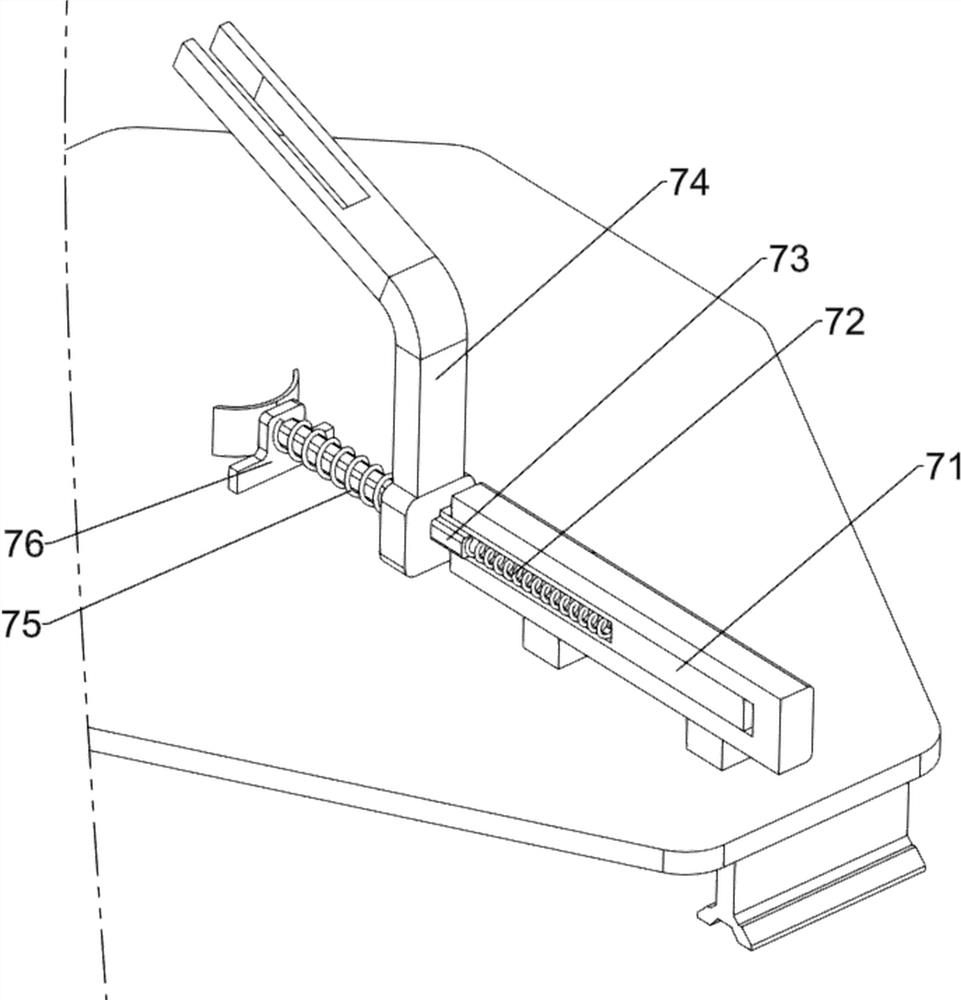

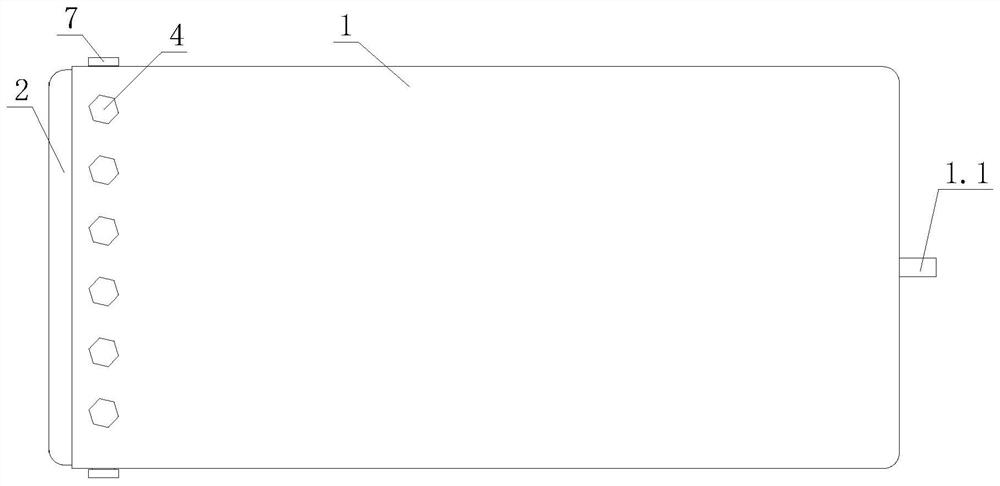

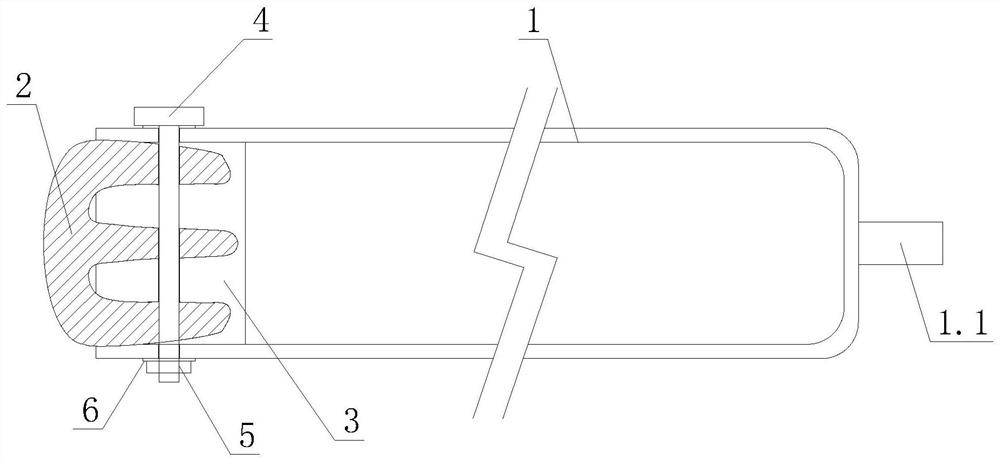

Oil pipe joint

ActiveCN103791180APrevent affecting the sealing effectImprove tightening effectJoints with sealing surfacesScrew threaded jointsCoil springPipe

The invention relates to an oil pipe joint. The oil pipe joint comprises a joint body and a locking sleeve. The joint body is a hollow cylinder, an equipment connection part is arranged at one axial end of the hollow cylinder, and a pipeline connection part is arranged at the other axial end of the hollow cylinder. Threads are arranged on the hollow-cylinder outer wall of the pipeline connection part, and the locking sleeve is connected to the hollow-cylinder outer wall in a sleeved mode through the threads; a spiral groove is formed in the hollow-cylinder inner wall of the pipeline connection part, and a coil spring is embedded into the spiral groove; a plurality of line grooves are formed in the hollow-cylinder wall surface of the pipeline connection part. The equipment connection part is arranged according to specific working conditions of equipment. Because the coil spring can be additionally arranged in the inner wall of an expansion bolt, the expansion effect is improved, and influence of plastic deformation of joint metal under long-time pressing on the sealing effect is avoided as well.

Owner:NANTONG AMC MACHINERY

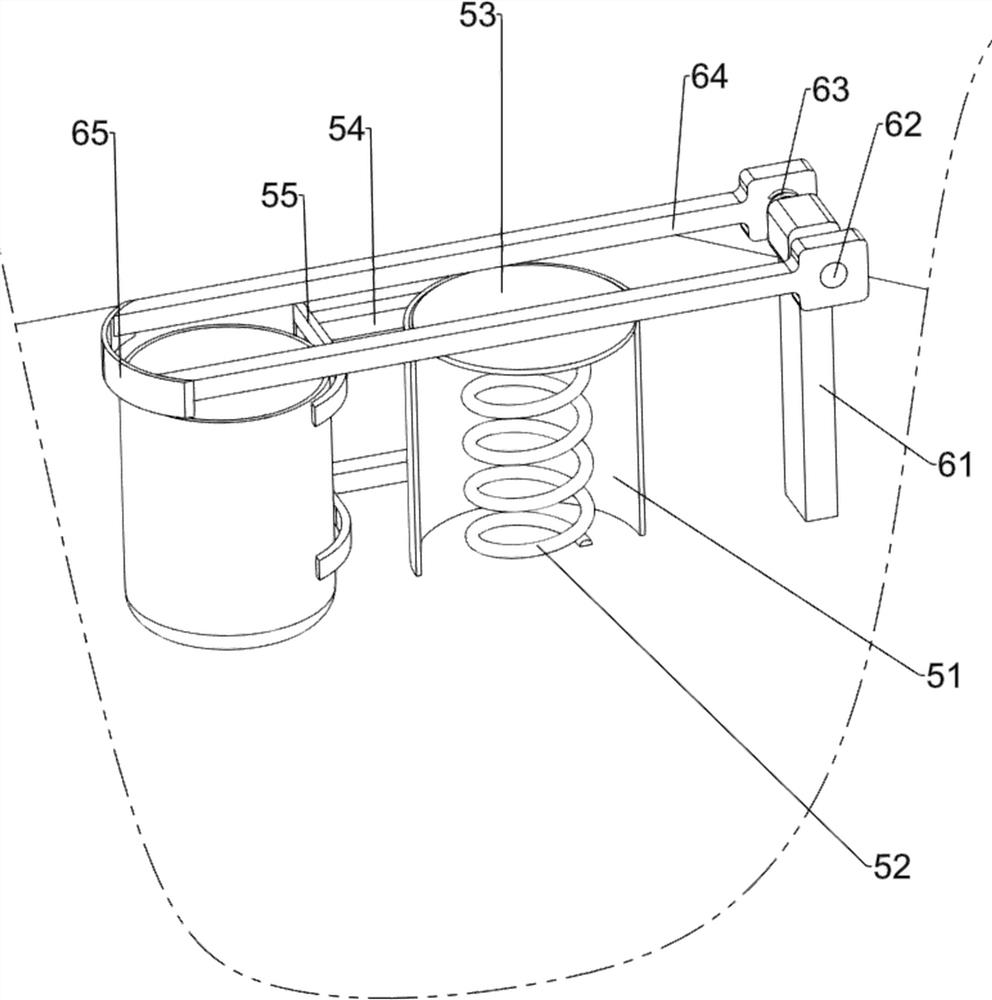

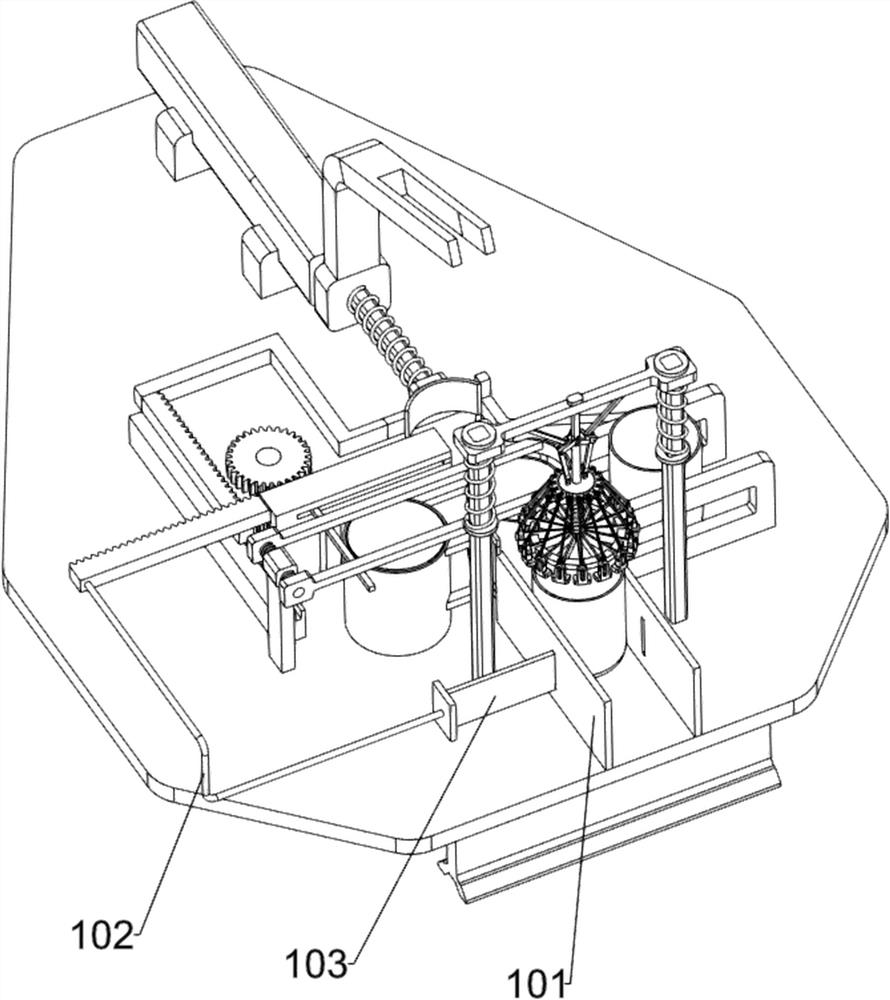

Capping device for oil drum in workshop

The invention relates to a capping device, in particular to a capping device for an oil drum in a workshop. The technical program to be solved by the invention is to provide the capping device for the oil drum in the workshop. The capping device does not consume physical strength and is high in efficiency. The capping device for the oil drum in the workshop comprises a base; two support blocks mounted on the base; a pressing mechanism mounted on the base; and an edge sealing mechanism mounted on the pressing mechanism. The capping device is provided with a drum cap storage mechanism, a drum cap can be bounced automatically under the acting force of a third spring so as to be conveniently stored by a worker. The capping device is provided with a limiting mechanism, the drum cap can be accurately placed on the oil drum under the effect of a second baffle, so that the situation that the capping effect is affected due to the fact that the drum cap cannot be accurately placed is prevented. The capping device is provided with a pushing mechanism, and the oil drum does not need to be manually moved and a first sliding rod does not need to be controlled to move by controlling a cylinder when the device is used, so that the burden of the worker is reduced.

Owner:杨政年

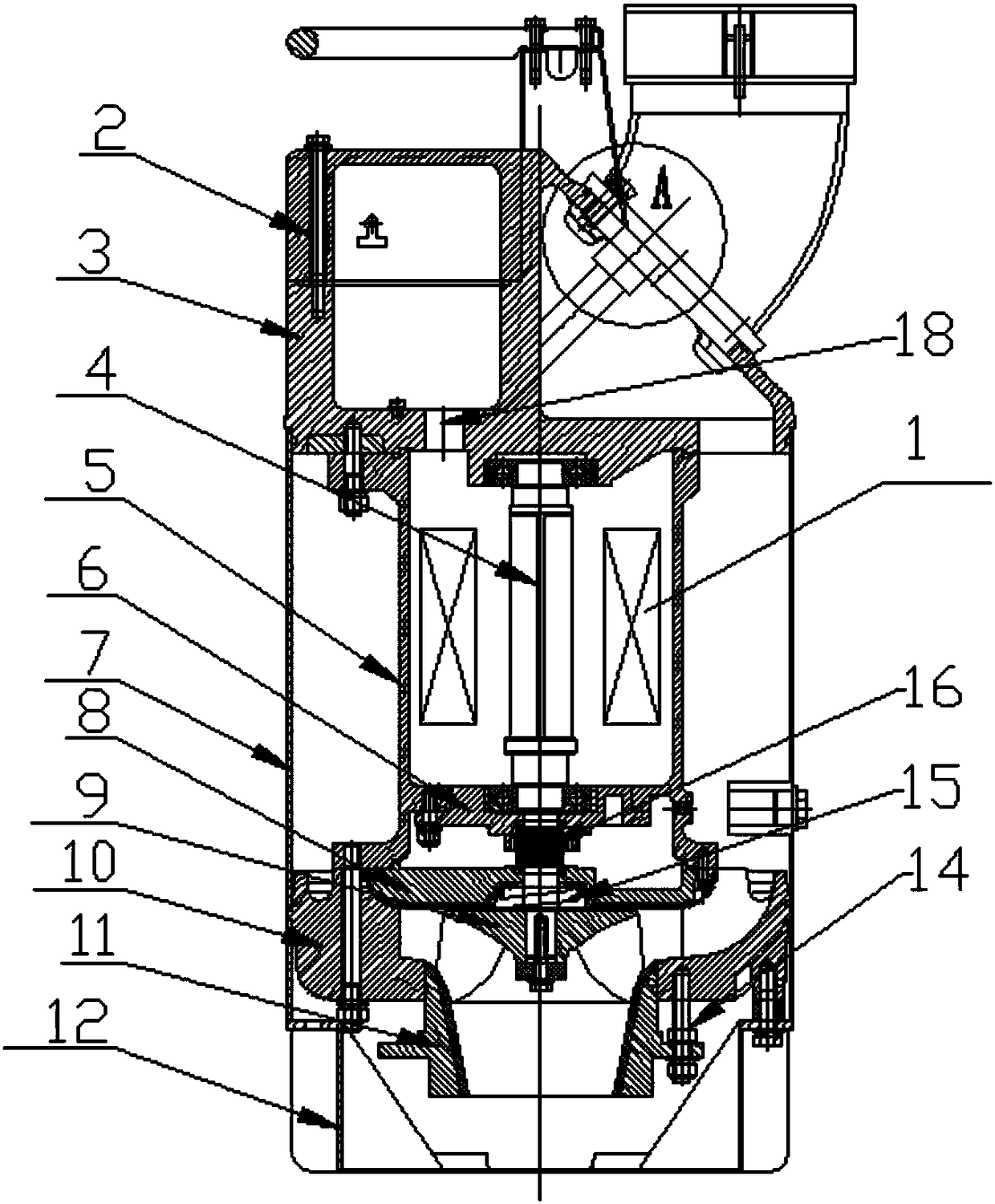

Light large-flow low-level draining pump

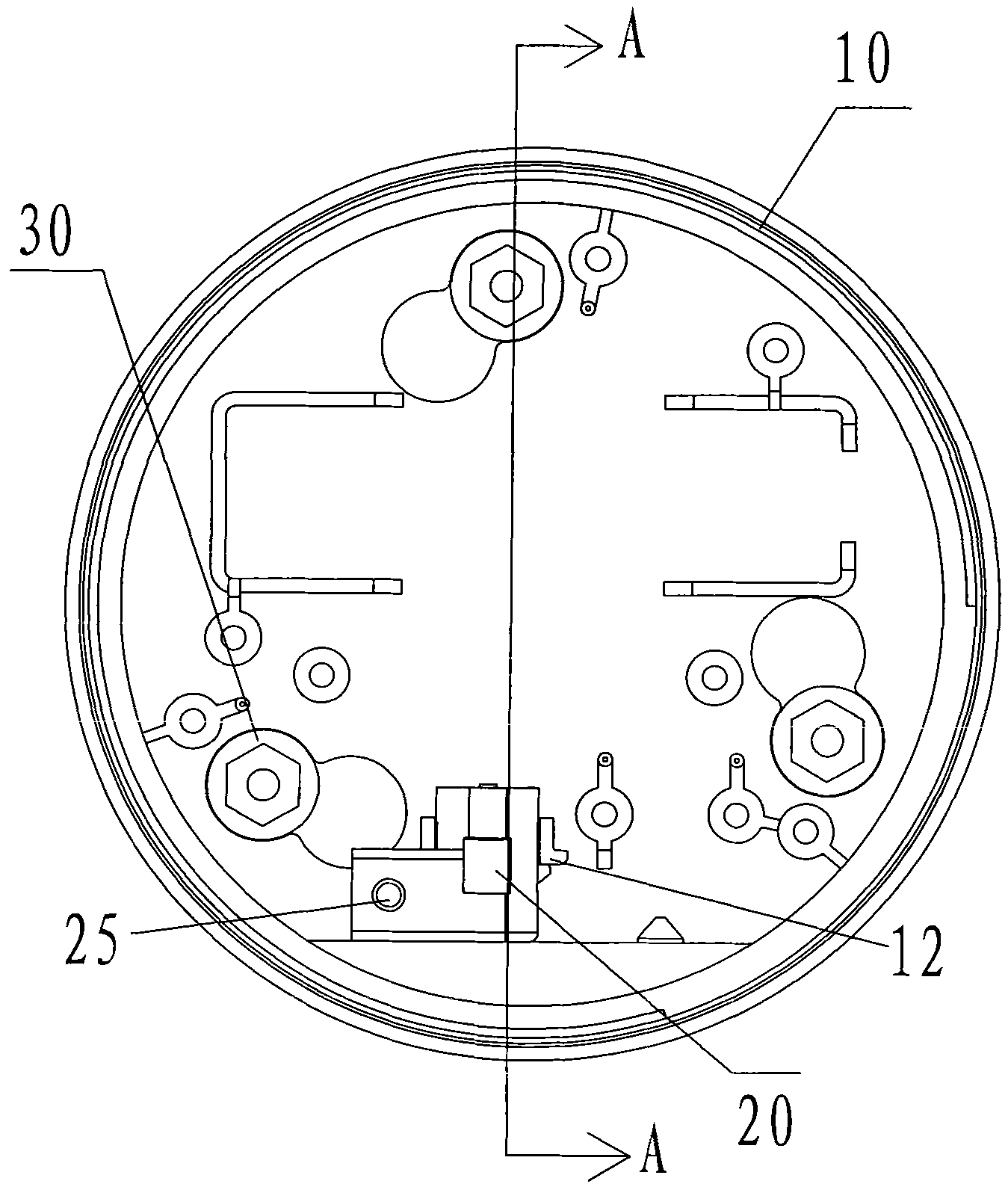

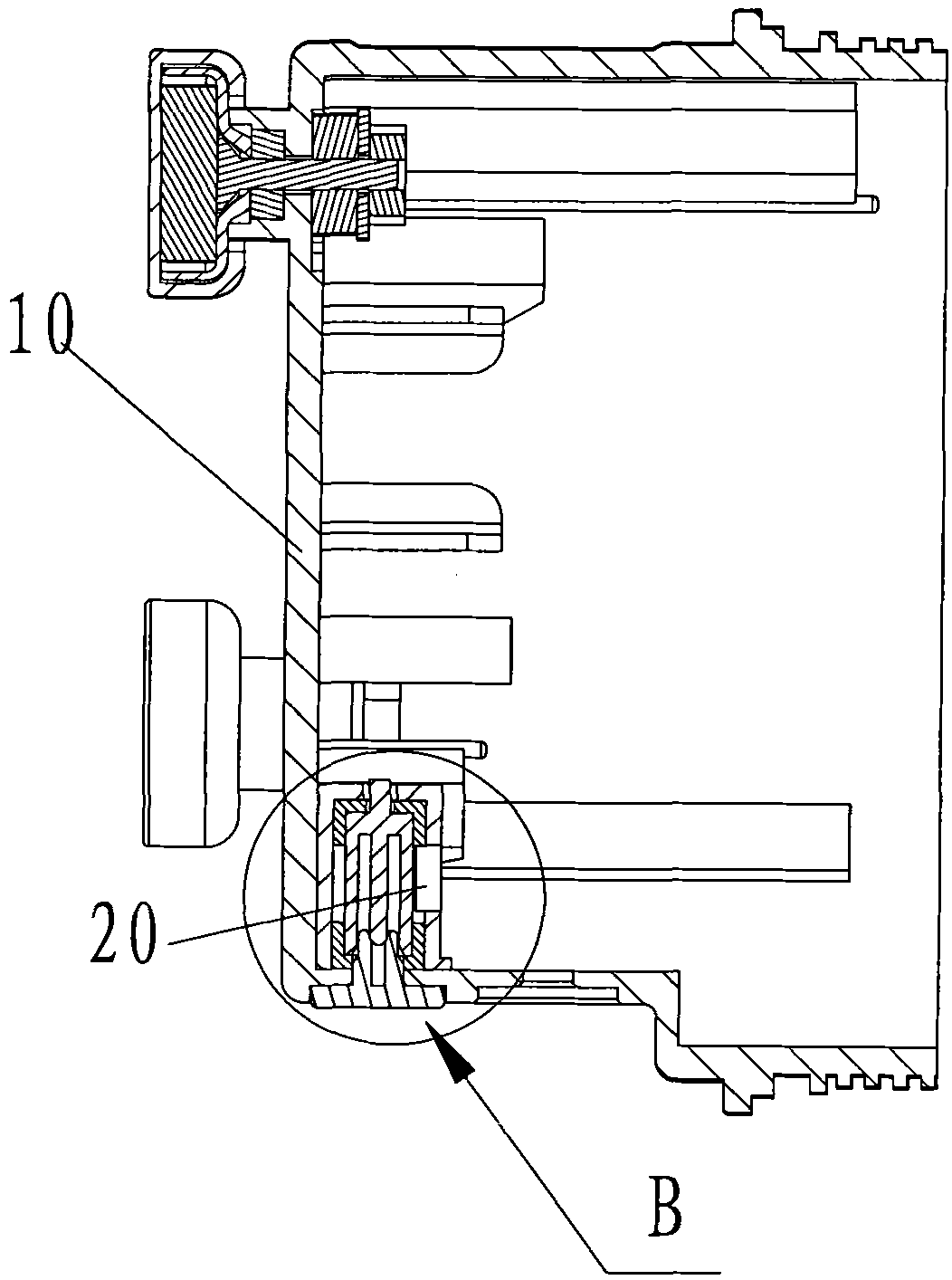

PendingCN108443164AAvoid corrosionPerformance unchangedPump componentsPump installationsPulp and paper industryStreamflow

The invention relates to the field of water pumps, and particularly relates to a light large-flow low-level draining pump. The light large-flow low-level draining pump comprises a pump case, a motor,a water pump end cover, an adjustable suction inlet and a filter screen type water pump base, the adjustable suction inlet is installed on the end of the water pump end cover, a flange is arranged onthe outer wall of the suction inlet, a plurality of flange through holes are formed in the flange, a plurality of end cover blind holes are formed in the water pump end cover, the water pump end coveris connected with the adjustable suction inlet by virtue of an adjusting bolt, an upper adjusting nut and a lower adjusting nut are respectively arranged on the adjusting bolt on the upper and lowersides of the flange, the filter screen type water pump base comprises a bottom plate and a side wall, the bottom plate is a plane, a plurality of draining holes are formed in the bottom plate, the side wall is of a filter screen type structure, a plurality of inward concave ways are formed in the side wall, and the base is fixedly connected with the water pump end cover by virtue of fastening bolts at the inward concave ways. The light large-flow low-level draining pump has the advantages of the simple structure, convenience in operation and time and labor saving, a water pump is prevented from being damaged, and the flow lift of the water pump is prevented from being reduced.

Owner:汉能(天津)应急装备有限公司

Sealing cover of reaction kettle

InactiveCN108854923AThere will be no problem of poor sealingDepressed and stableChemical/physical/physico-chemical stationary reactorsEngineeringMechanical engineering

The invention discloses a sealing cover of a reaction kettle. The sealing cover comprises a door-shaped bracket, a guide rod, an air cylinder A, a cover body, a flexible sealing ring A, a flexible sealing plate, guide columns and a guide column drive mechanism, wherein the guide rod is mounted on the door-shaped bracket through a guide sleeve; the base of the air cylinder A is mounted on the door-shaped bracket; the ejector rod of the air cylinder A is connected with the cover body; the guide rod sequentially passes through the cover body, the flexible sealing ring A and the flexible sealing plate from top to bottom; the two guide columns sequentially pass through the cover body, the flexible sealing ring A and the flexible sealing plate from top to bottom; one guide column drive mechanismdrives one guide column to slide up and down in the cover body; the flexible sealing plate is fixedly connected with the guide columns in a sealing mode; and the diameter of the flexible sealing plate is greater than the opening diameter of the top of the kettle body. The sealing cover improves the reaction kettle cover; through the action of the reaction kettle sealing cover, good sealing effectcan be achieved on the reaction kettle, and the sealing effect is good.

Owner:湖州翔润化工有限公司

Sealing and positioning auxiliary structure for sealing and positioning sealing groove and sealing part

PendingCN112467168APrevent affecting the sealing effectGuaranteed positioning accuracySealing/support meansEngineeringMechanical engineering

Owner:SHANGHAI ZHIZHEN NEW ENERGY EQUIP CO LTD

a barrel dispenser

The invention provides a wine barrel dispenser, which belongs to the technical field of wine drinking equipment. It solves the problem of poor sealing between the existing dispenser and the wine spear after they are assembled. The wine barrel dispenser of the improved structure includes a valve body, a wine outlet pipe and a handle capable of driving the wine outlet pipe to move. The valve body is fixed with an annular gasket made of rubber, and the gasket includes a gasket body. And several positioning pieces all connected with the gasket body, the gasket body is cylindrical and has several convex rings on the lower end surface of the gasket body, the upper side of the positioning piece has a The inclined pressure receiving inclined surface has a sealing inclined surface inclined upward along the center of the gasket on the lower side, and the wine outlet pipe has a pressing inclined surface matched with the pressure receiving inclined surface. The wine barrel distributor of the improved structure cooperates with the wine spear and has good sealing effect.

Owner:TALOS TECH CORP

One-step formed detachable pure rubber pressure bag

The invention relates to the technical field of pressure bag equipment, and provides a one-step formed detachable pure rubber pressure bag. The pressure bag comprises a pressure bag body; a connectingnozzle is arranged on the pressure bag body; the end, away from the connecting nozzle, of the pressure bag body is open; a clamp is inserted into the opening; the joint of the pressure bag body and the clamp is filled with an adhesive tape; a plurality of first screws are inserted into the upper end face of the pressure bag body in a threaded penetrating mode; and screw holes corresponding to thefirst screws are formed in the clamp. The one-step formed detachable pure rubber pressure bag overcomes the defects in the prior art, is reasonable in design and compact in structure, and solves theproblems that an existing pressure bag can only use gas and water as pressure media, cannot be repaired and has no repairing value. The one-step formed detachable pure rubber pressure bag adopts the detachable pressure bag through simple structural combination, can use gas and water hydraulic oil as pressure media, and is high in practicability and easy to popularize and apply. Meanwhile, the pressure bag can be detached and repaired and maintained, and the service life of the pressure bag is prolonged.

Owner:康米克斯硫化科技无锡有限公司

Flush valve

PendingCN108757952ASimple structureEasy to operateOperating means/releasing devices for valvesAnimal housingEngineeringMechanical engineering

The invention relates to the field of animal husbandry equipment, in particular to a flush valve. The flush valve comprises a base, a valve body fixedly installed on the base and a valve deck installed on the valve body; a through hole is formed in the middle of the base; a flushing pipeline is arranged at the through hole; the valve body comprises an enclosing board, a C-shaped cross beam, a valve board and an air bag fixedly installed on the valve board; the valve board is plugged at the through hole of the base; the two ends of the cross beam are fixedly connected with the enclosing board;the top of the air bag and a bottom board of the cross beam are fixedly connected; a supporting board is fixedly installed between two side boards of the cross beam and fixedly provided with a hingedshaft; the valve deck comprises a front valve deck body and a rear valve deck body which are hinged through the hinged shaft on the supporting board; the other end of the rear valve deck body is fixedly connected with the enclosing board of the valve body through a bolt; and the air bag communicates with a pneumatic press through an electronic valve. The flush valve is simple in structure and convenient to operate, and does not affect the movement space of cows.

Owner:天津中博农畜牧设备科技有限公司

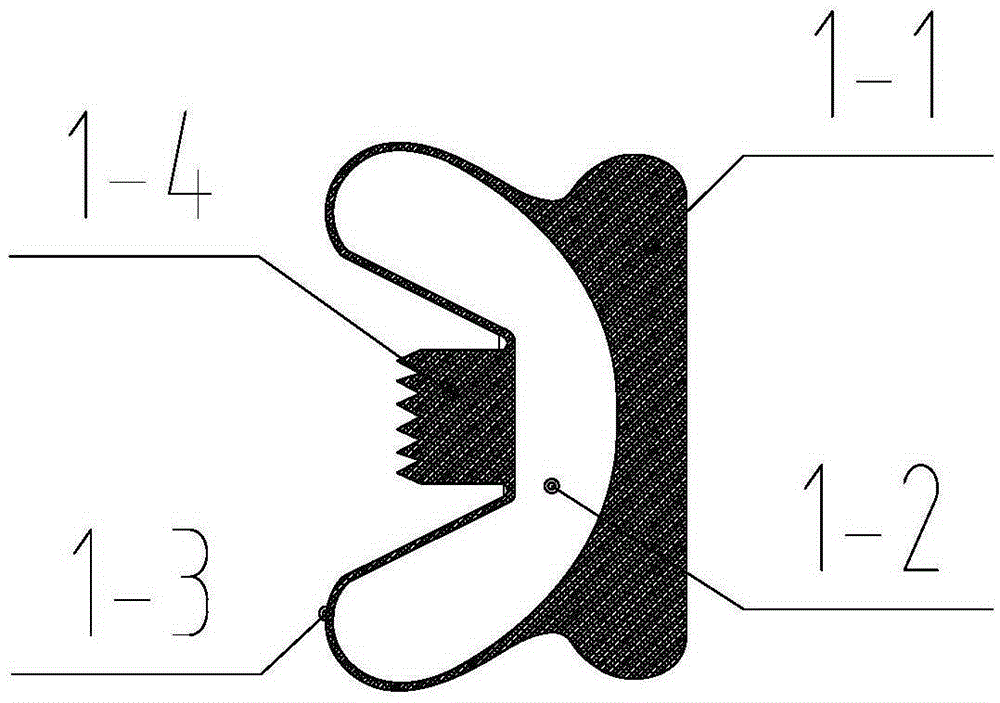

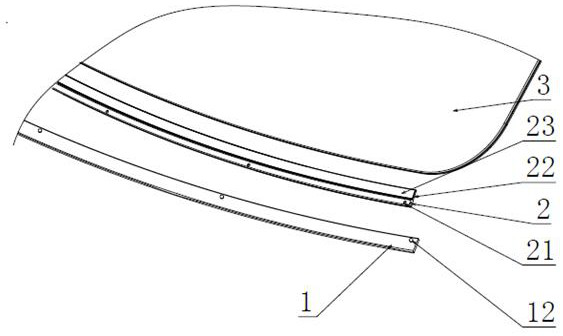

Sealing system of vehicle window glass

PendingCN114274742AImprove rigidityPrevent affecting the sealing effectWindowsEngine sealsInterference fitWindshield

The invention discloses a vehicle window glass sealing system which comprises vehicle window glass and further comprises a clamping plate of a long-strip-shaped structure, one end, in the width direction, of the clamping plate is a window frame connecting end, and the other end of the clamping plate is a glass connecting end. The clamping connector is in a long strip shape arranged along the edge of the vehicle window glass, the two ends in the width direction of the clamping connector are connected between the vehicle window glass and the clamping plate, the end, connected with the vehicle window glass, of the clamping connector is provided with a strip-shaped clamping connector supporting body, and the side face of the clamping connector supporting body is fixed to the side face of the vehicle window glass through a layer of clamping connector fixing glue in an adhesive mode. Clamping head mounting holes are distributed in the side face of the end, connected with the clamping plate, of the clamping head at intervals in the length direction, and clamping ball pins are correspondingly arranged on the clamping plate and clamped and fixed in the clamping head mounting holes in an interference fit mode. The sealing device has the advantages of being simple in structure, good in sealing effect and durability, convenient to assemble and free of influence on the appearance, and is particularly suitable for being installed and implemented on a front windshield of a car window.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Bottle mouth cork packaging device for filling medicine

InactiveCN110980611APrevent affecting the sealing effectThreadless stopper insertionEngineeringCork stopper

The invention discloses a bottle mouth cork packaging device for filling medicine. The bottle mouth cork packaging device comprises a work box and a work cavity formed in the work box. The work cavityis opened towards the upper right side. A conveying device capable of conveying bottled medicine is arranged at the bottom of the work cavity. A work block is fixedly arranged on the upper side of the inner wall of the left side of the work cavity. A material storage cavity with an upward opening is formed in the work block. A cork used for packaging is installed in the material storage cavity. By means of the bottle mouth cork packaging device, full-automatic packaging can be conducted on a to-be-sealed medicine bottle full filled with liquid medicine; the medicine bottle can be transportedinto a clamping device through the conveying device of the bottle mouth cork packaging device, the clamping device can sufficiently fix the medicine bottle, and the situation that due to the fact thatthe cork inclines during packaging, the sealing effect is influenced is prevented; the cork used for packaging can be fixed to arc-shaped fixing plates through a fixing block; and the fixing block with the cork can slide downwards through a power device, and the bottle mouth of the medicine bottle is packaged through the cork.

Owner:慈溪市纵深包装有限公司

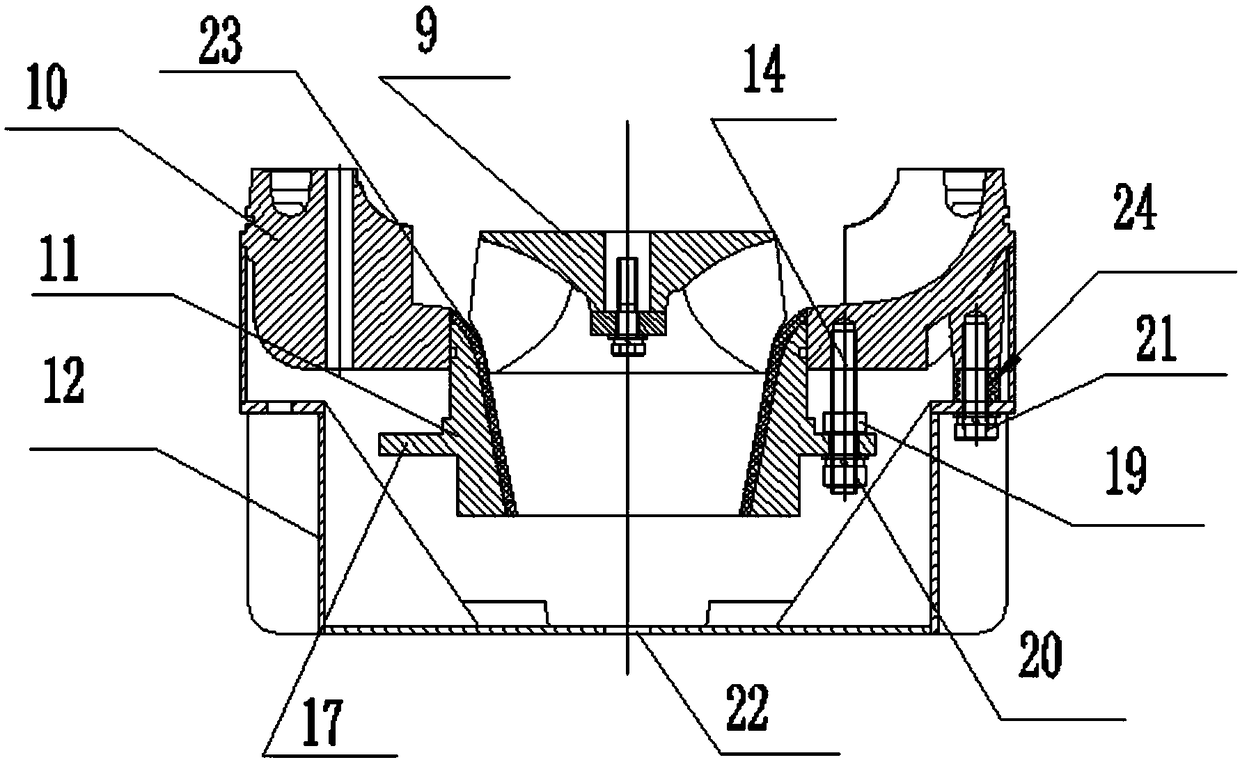

Submersible sand pump

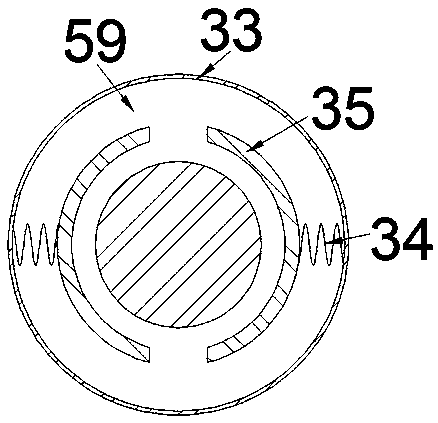

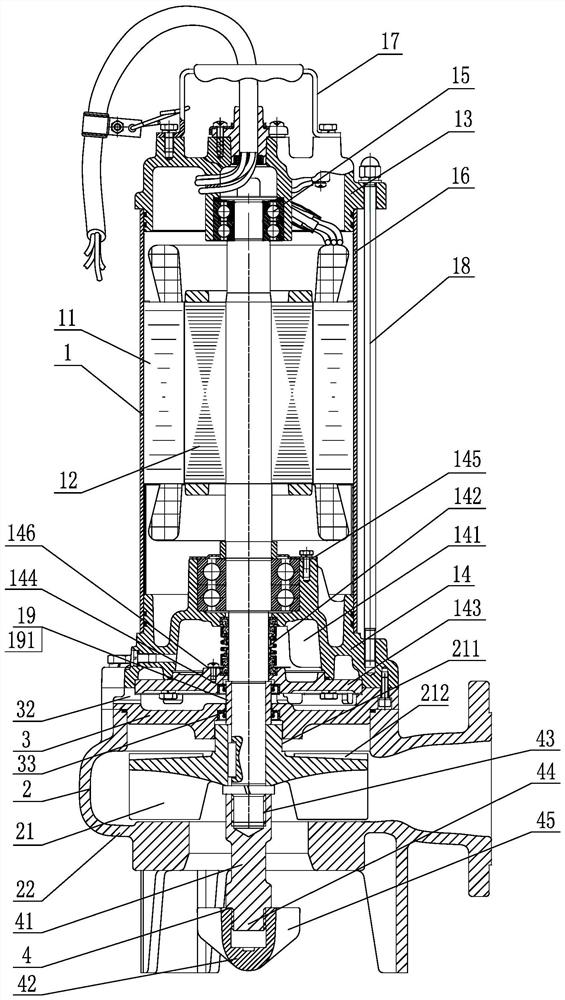

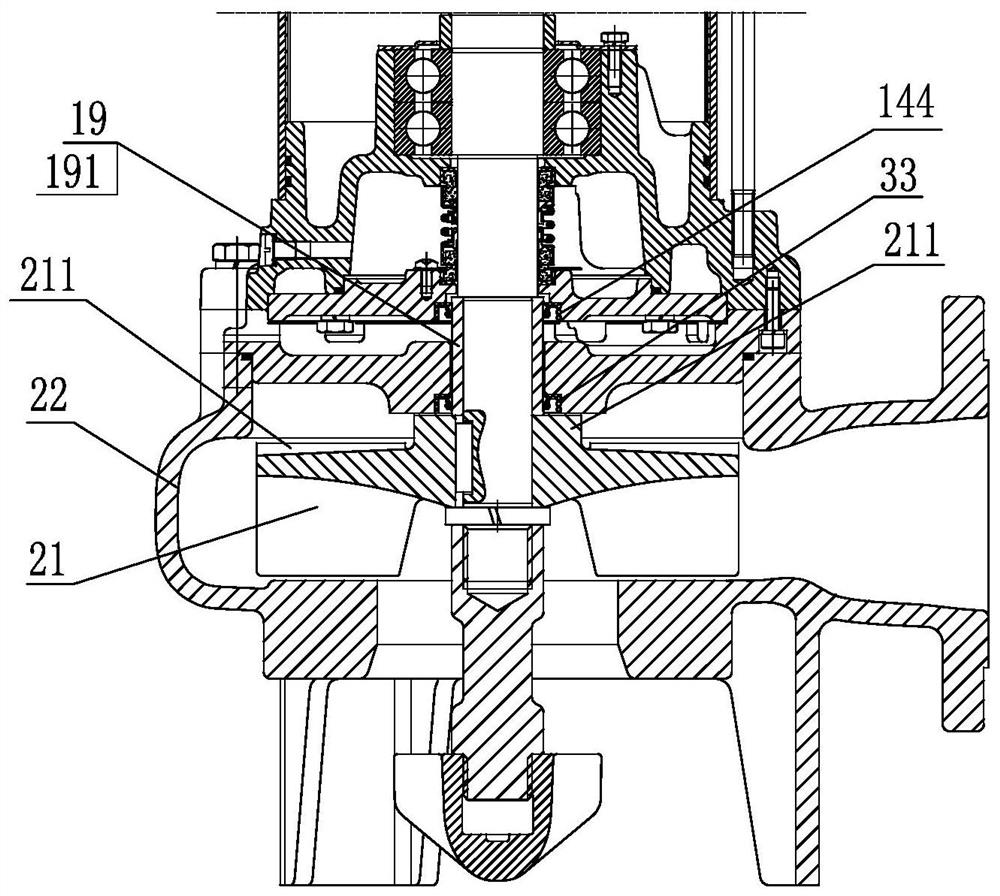

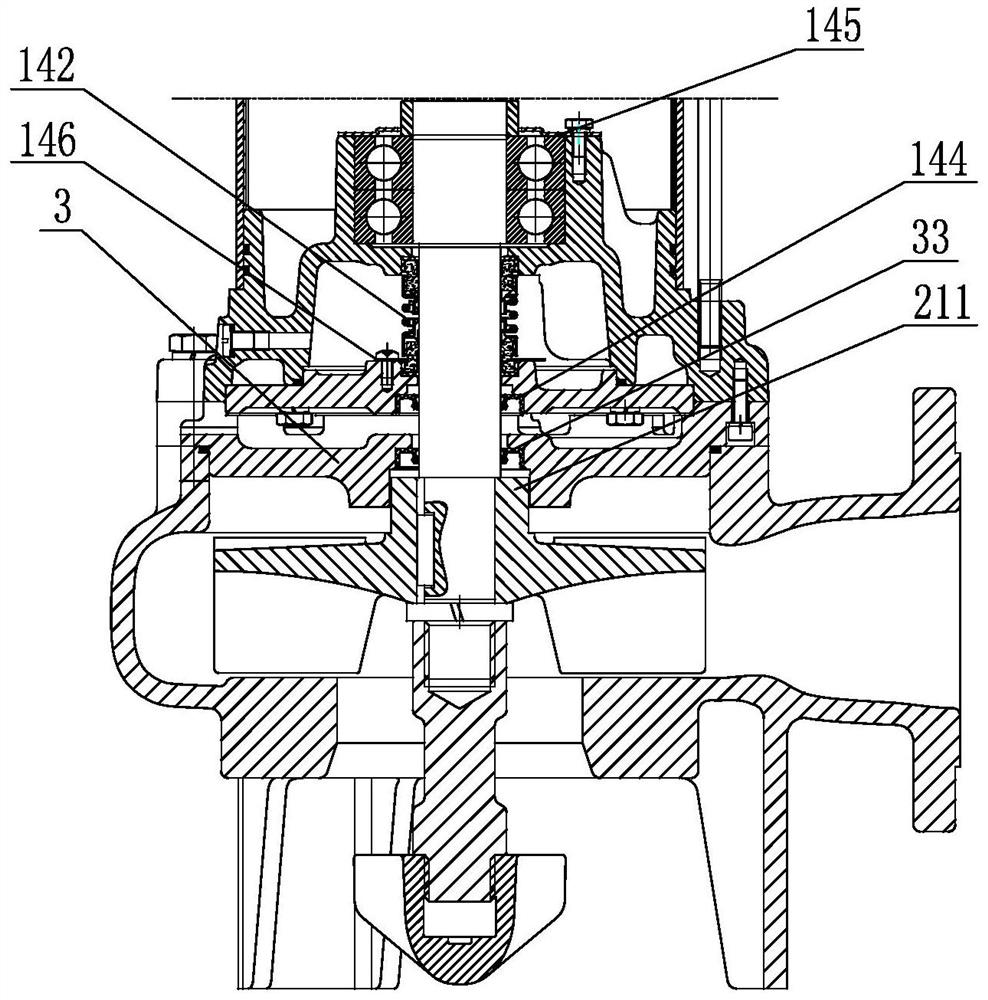

PendingCN113819069AEnsure safetyImprove securitySpecific fluid pumpsPump componentsElectric machineryEnd face mechanical seal

The invention discloses a submersible sand pump. The submersible sand pump comprises a motor and a centrifugal pump body, wherein the motor comprises a stator, a rotor, an upper bearing seat, a lower bearing seat, bearings at the two ends, a motor shell, a handle and a connecting screw for connecting the upper bearing seat and the lower bearing seat, the lower bearing seat is provided with a mechanical seal cavity and a sealing cover, and a double-end-face mechanical seal is installed in the mechanical seal cavity; a sand prevention sealing ring is further arranged at the central axis position of the outer side of the sealing cover, the centrifugal pump body comprises an impeller and a pump volute, a sand separation disc is installed between the motor and the centrifugal pump body, radial separation ribs are arranged in an inner cavity of the sand separation disc, and a sand discharging opening leading to the outside is formed in the outermost edge position between every two adjacent radial separation ribs; and a sand separation sealing ring is arranged at the position of a shaft hole of an outer cavity of the sand separation disc, and a flange is arranged at the position, close to the shaft hole, of the back of the impeller and seals the sand separation sealing ring. The submersible sand pump has the beneficial effects of reducing damage of fine sand to a water pump seal, prolonging the service life of the motor and a submersible pump and reducing the use cost.

Owner:GUANGDONG RUIRONG PUMP IND

Soldering method in high humidity environment

ActiveCN109047988BSimple structureEasy to useWelding coupling meansHigh humidityStructural engineering

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Electrical sealing sleeve for connecting device

InactiveCN105042073AImprove sealingPrevent affecting the sealing effectEngine sealsEngineeringMechanical engineering

Owner:CHENGDU GUANGMAI TECH

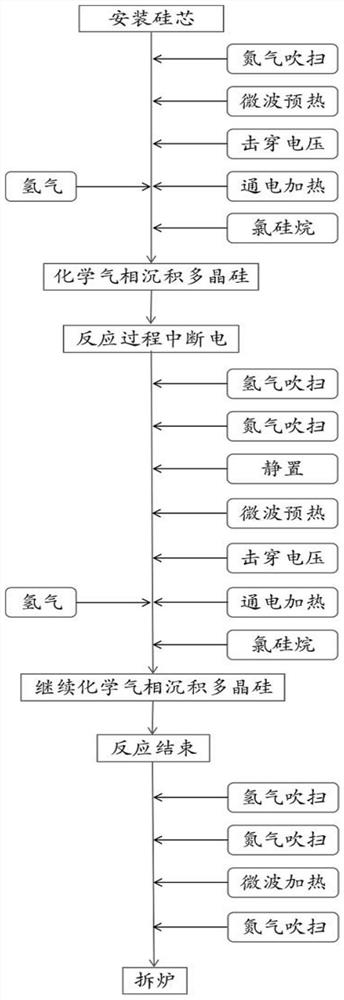

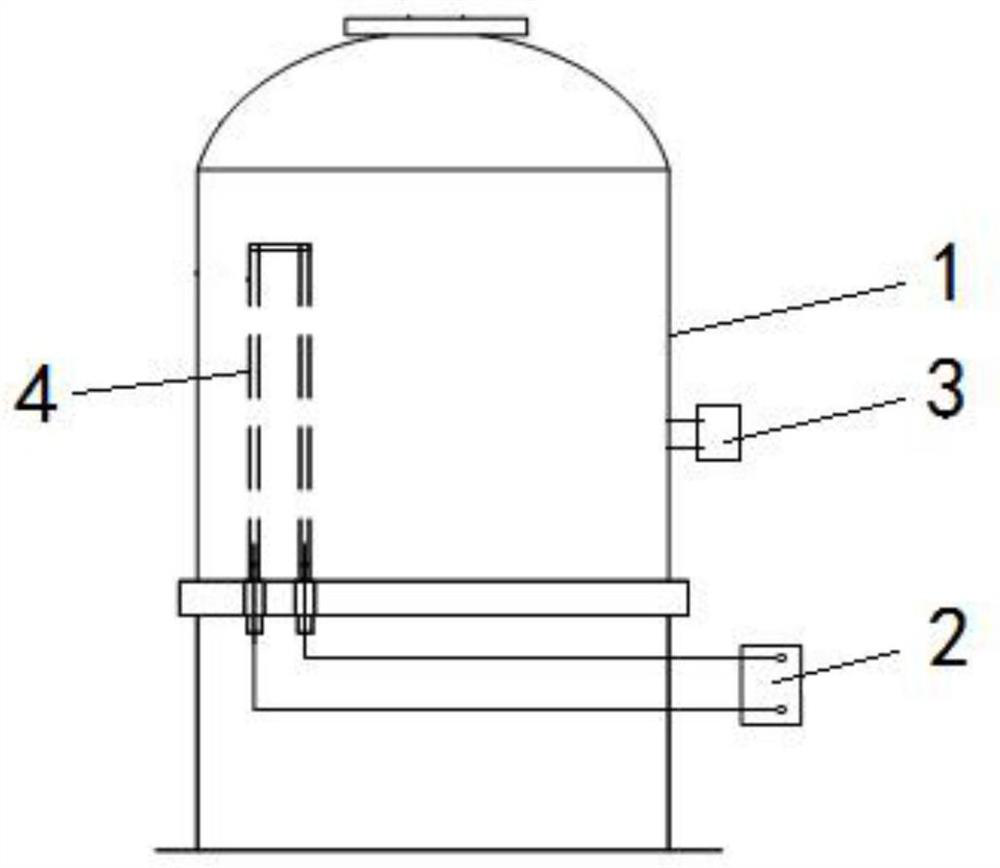

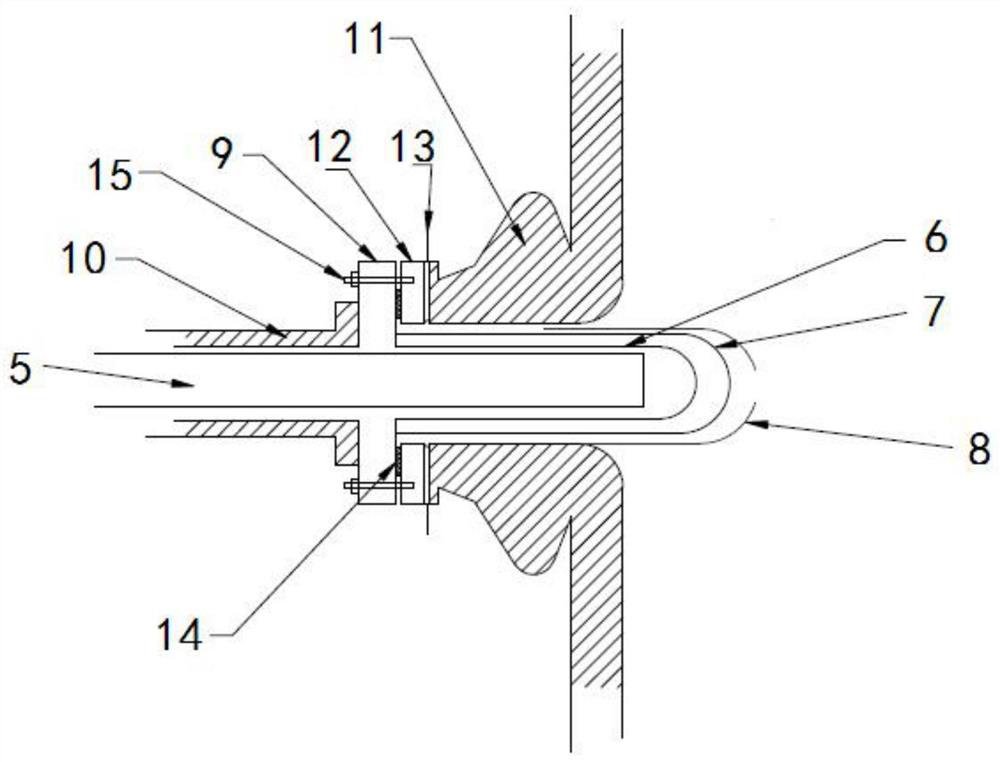

Method and system for producing polysilicon

The invention provides a method for producing polysilicon, which comprises the following steps: before the reaction starts, first use microwaves to heat the silicon core in the reduction furnace to the first set temperature, and then apply current after the silicon core is broken down, so as to Chemically deposit polysilicon on the surface of the core to obtain silicon rods; during the reaction process, if the power is cut off on the silicon rods, the silicon rods are heated to the second set temperature by using microwaves before restarting after the power failure, and then the silicon rods are struck. After piercing, current is applied to continue to chemically deposit polysilicon on the surface of the silicon rod. The present invention also provides a polysilicon production system, which includes an energy feeding unit and a protection unit. The energy feeding unit includes an energy feeding antenna, and the energy feeding antenna is arranged at an opening on the reduction furnace that can communicate with the interior of the reduction furnace for generating and emitting Microwave; the protection unit is used to separate the energy feeding antenna from the atmosphere in the reduction furnace to protect the energy feeding antenna. The invention can realize stable growth of polysilicon, obtain polysilicon products with good performance, and improve product quality.

Owner:XINTE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com