Flush valve

A technology of flushing valve and valve cover, applied in the field of flushing valve, can solve the problems of inconvenient control, affecting the activity space of cattle, time-consuming and labor-intensive, etc., and achieves the effect of convenient operation, simple structure and guaranteed flushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

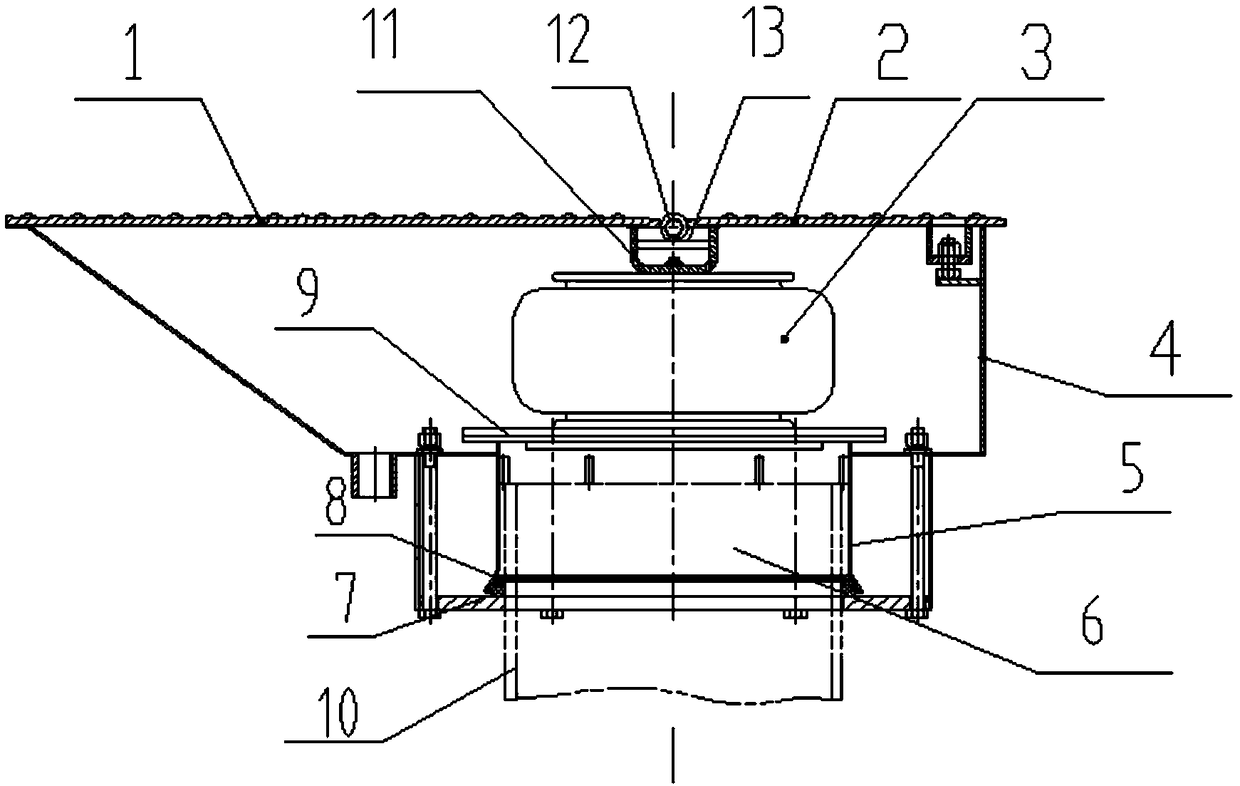

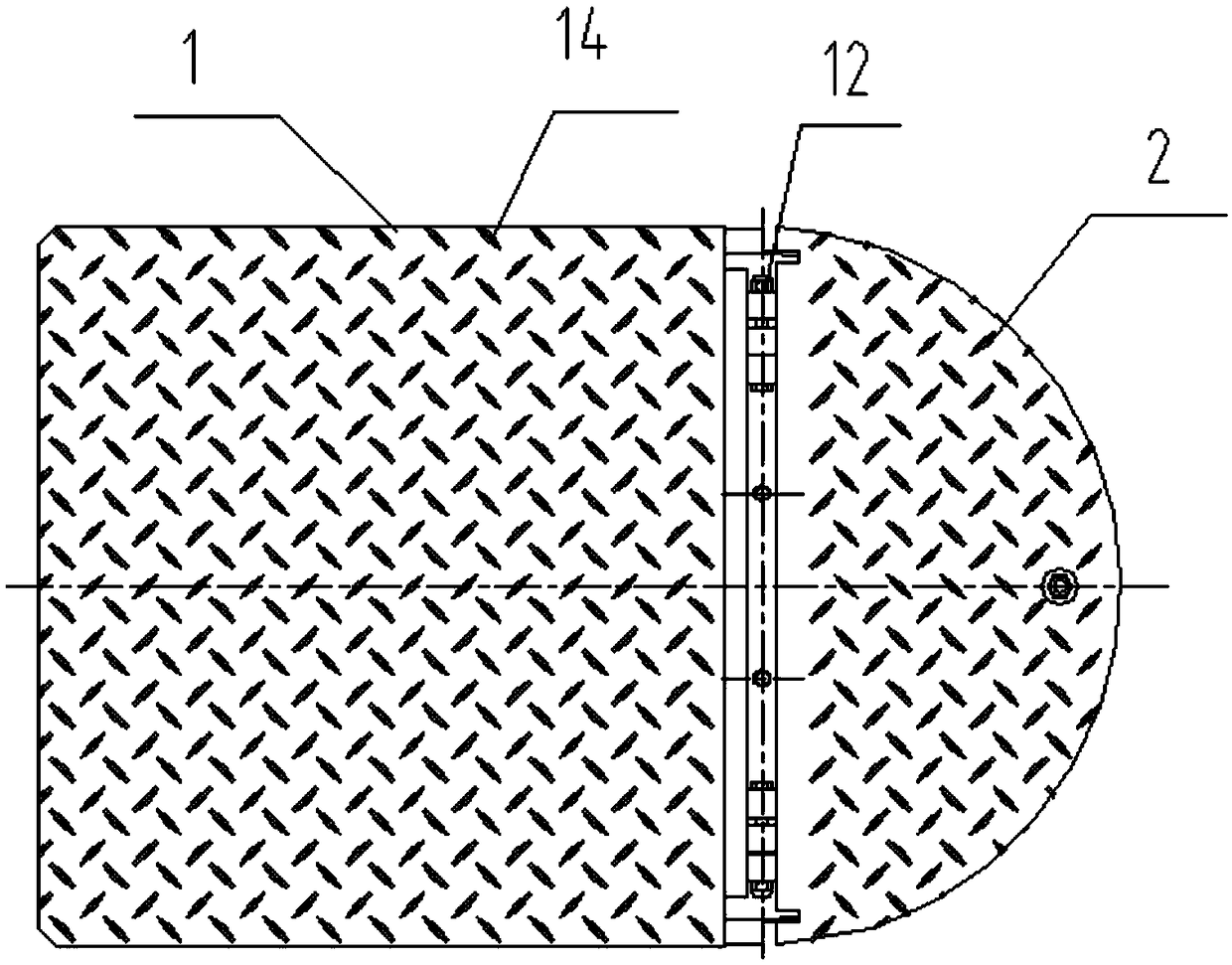

[0017] A flushing valve includes a base 5, a valve body fixedly mounted on the base, and a valve cover mounted on the valve body. A through hole 6 is provided in the middle of the base, and a flushing pipe 10 is provided at the through hole. The body includes an enclosure 4, a C-shaped beam 11, a valve plate 9 and an airbag 3 fixedly installed on the valve plate. The valve plate is sealed at the through hole of the base, and both ends of the beam are fixedly connected to the enclosure. The top of the airbag is fixedly connected to the bottom plate of the cross beam, a support plate 13 is fixedly installed between the two side plates of the cross beam, a hinge shaft 12 is fixedly installed on the support plate, and the valve cover includes a front valve, 1 and a rear end The valve cover 2, the front valve cover and the rear valve cover are hinged by the hinge shaft 12 on the support plate, the other end of the rear valve cover is fixedly connected with the enclosing plate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com