Light large-flow low-level draining pump

A large-flow, light-weight technology, applied to pumps, parts of pumping devices for elastic fluids, pump devices, etc., can solve problems such as increased gap between suction inlet and impeller, time-consuming and labor-intensive effects on pump flow and head, etc. Achieve maximum time efficiency, convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

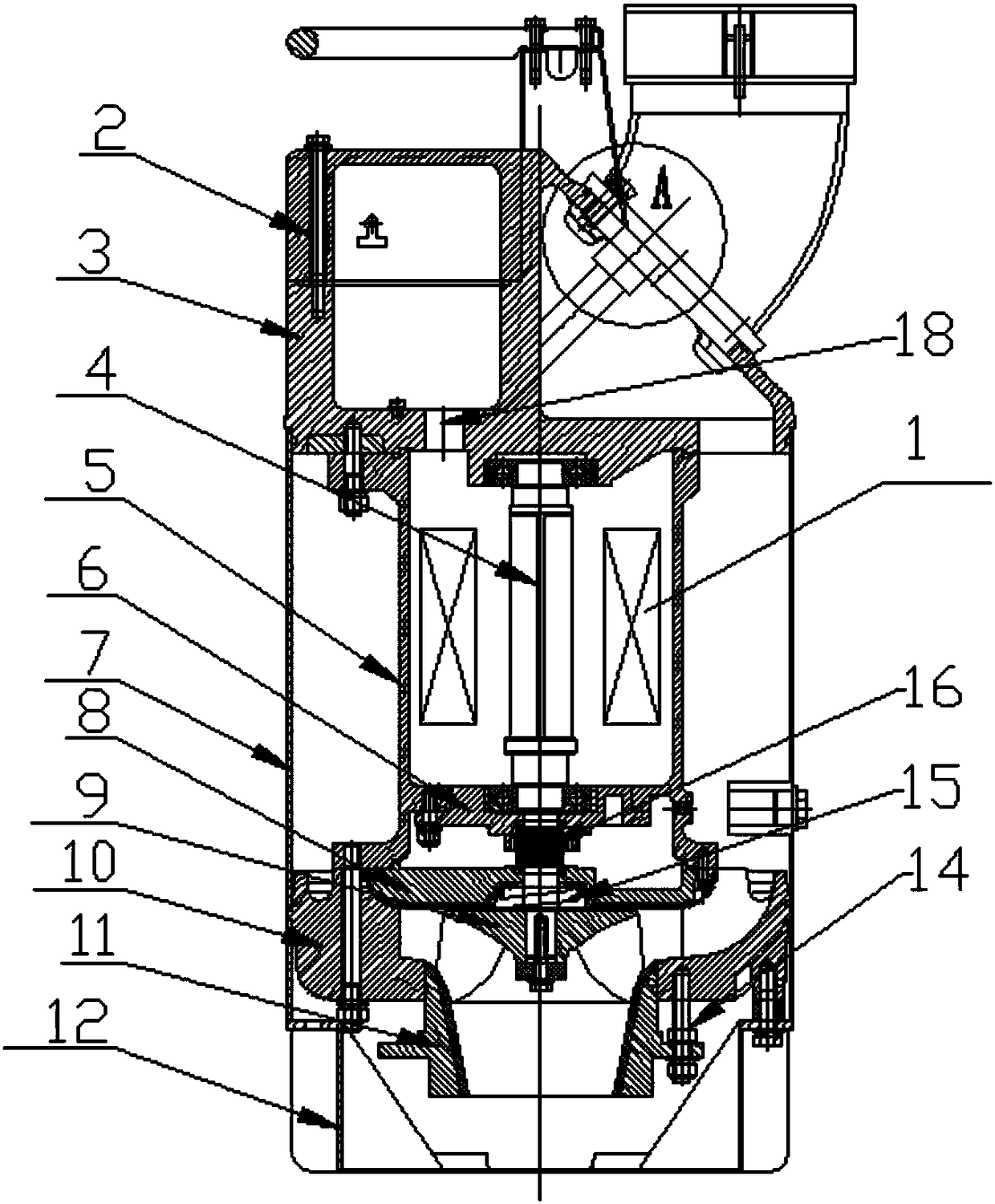

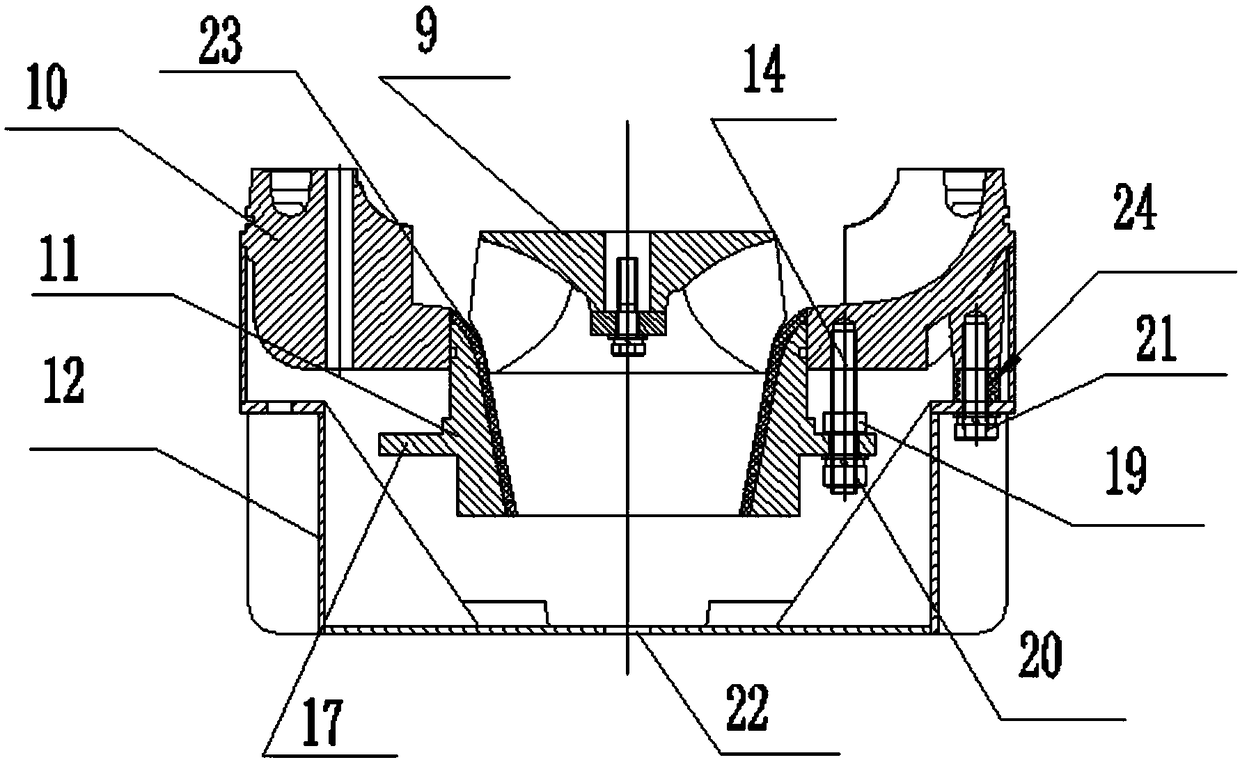

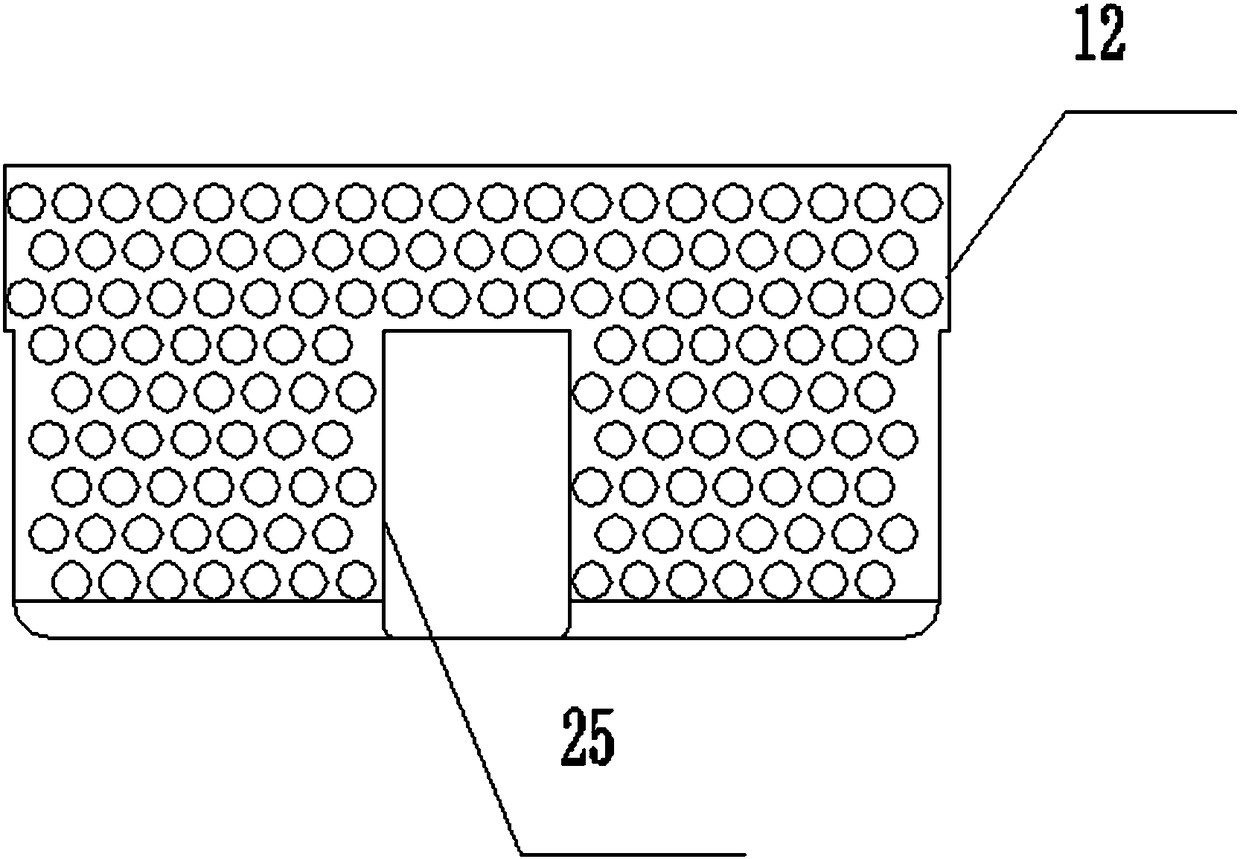

[0030] Light-duty high-flow and low-liquid-level suction and discharge pump, which includes a pump casing 7, a motor 1 installed in the pump casing, a water pump end cover 10 fixedly installed at the bottom of the pump casing, an adjustable suction inlet 11, and a filter-shaped water pump base 12 , the adjustable suction port is installed on the end of the water pump end cover, the outer wall of the suction port is provided with a flange 17, and the flange is provided with a plurality of flange through holes, and the water pump end cover is connected with the flange A plurality of end cover blind holes are provided at the corresponding positions of the edge through holes, and the water pump end cover and the adjustable suction inlet are connected by adjusting bolts 14 installed between the corresponding flange through holes and the end cover blind holes. On the adjusting bolt, an upper adjusting nut 19 and a lower adjusting nut 20 are respectively arranged on the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com