Sealing method for cesium foam of cesium-beam tube

A useful, cesium beam technology, used in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effects of easy implementation, enhanced sealing effect, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

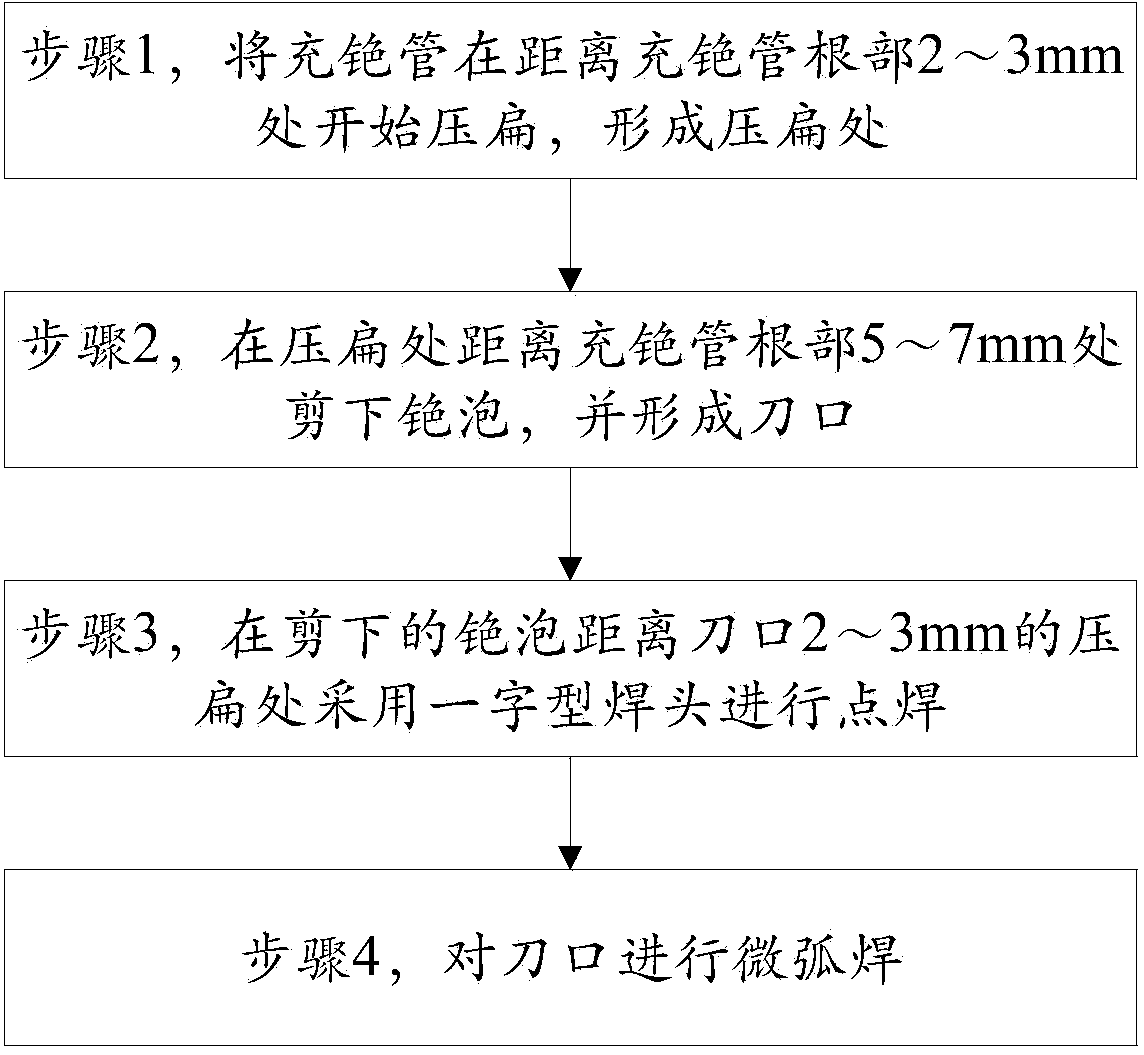

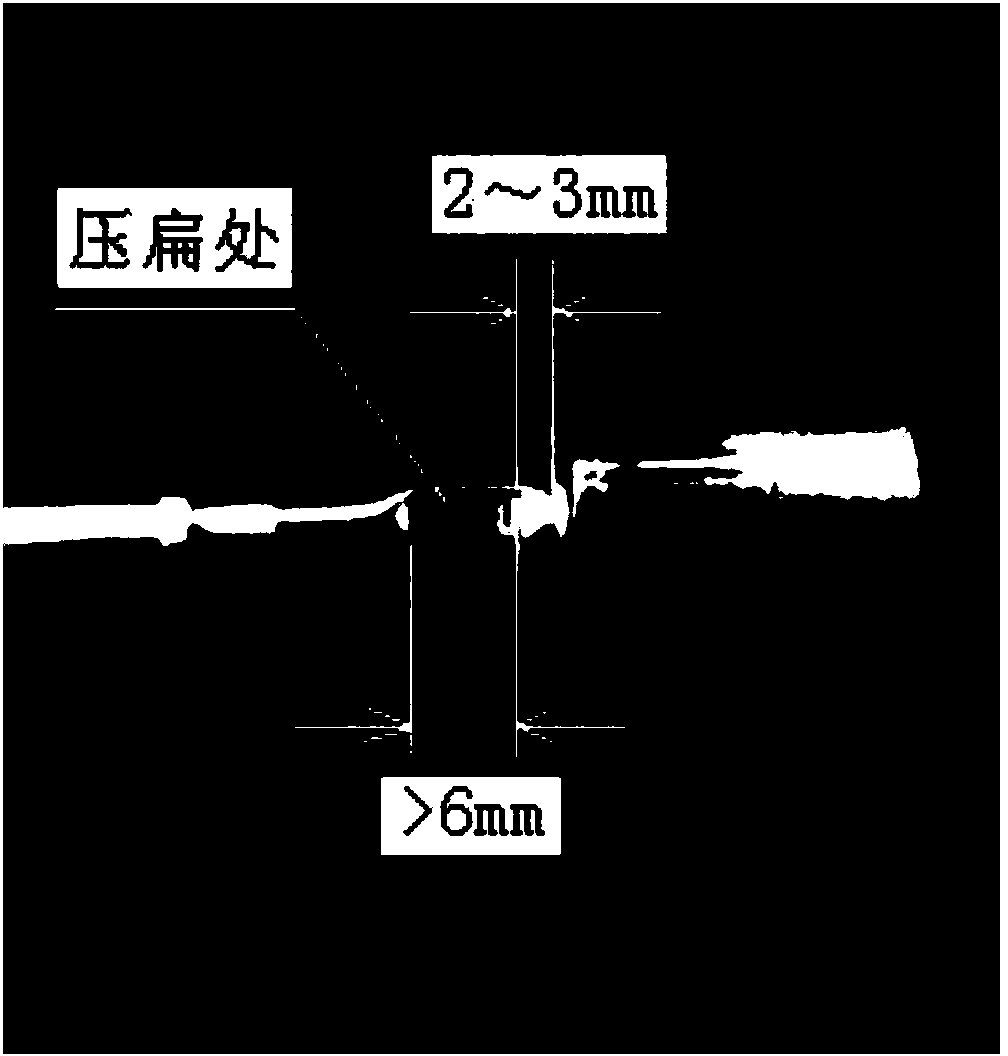

[0028] First, replace the cutter head of the hydraulic pliers with a flat cutter head. The long side of the rectangular surface of the cutter head is 50mm, and the short side is 10mm. Squeeze the cesium-filled tube near the root of the cesium-filled tube at a distance of 2-3 mm from the cesium bubble. The maximum pressure of the hydraulic clamp is 5 MPa to ensure that the width of the flattened part does not exceed 5 mm. This is the internal structure of the cesium furnace for the size of the flattened part. The basic requirements of different cesium furnace structures can be different. Replace the cutter head of the hydraulic pliers with a cold welding cutter head, and cut the cesium-filled tube at a place 5-7 mm from the root of the cesium-filled tube at the flattened part, forming a sealed knife edge at the cut-off point, see image 3 At this time, the maximum pressure of the hydraulic clamp is 35MPa, hold it for 10 seconds and release the hydraulic clamp. Replace the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com