Flexible wind deflector

A windshield and flexible technology, applied in the field of heavy-duty automobile parts manufacturing, can solve problems such as serious hot air backflow, and achieve the effects of reducing air leakage, reducing gaps, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

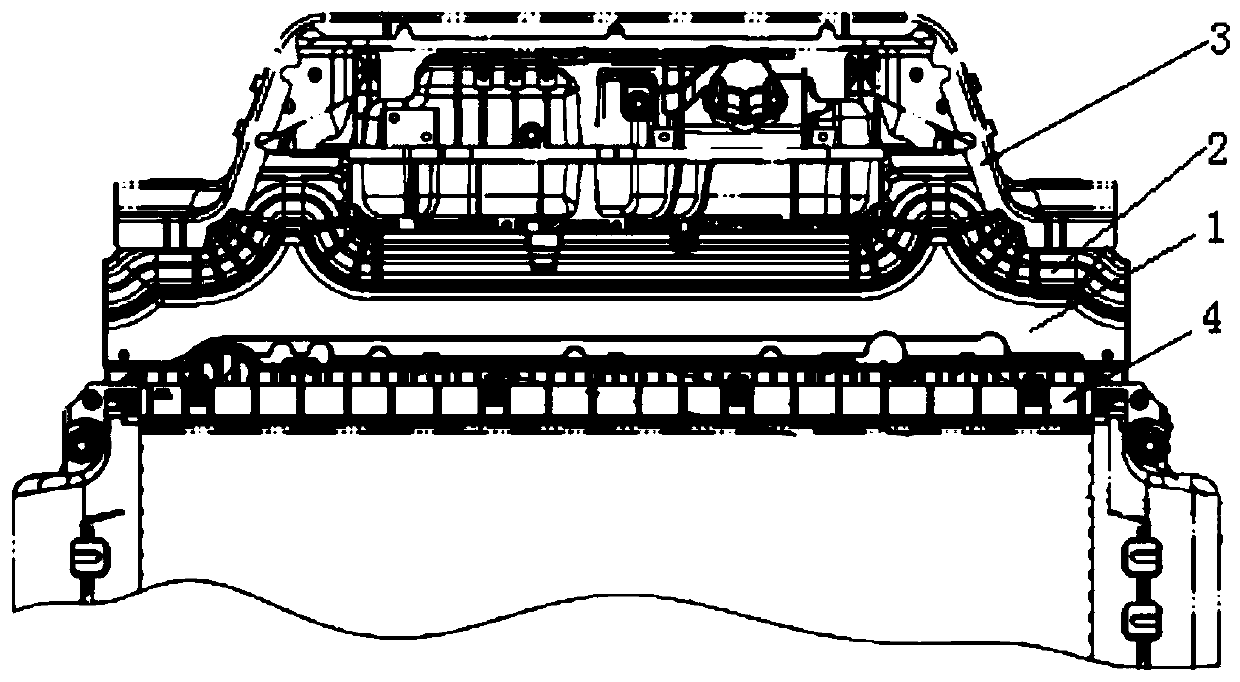

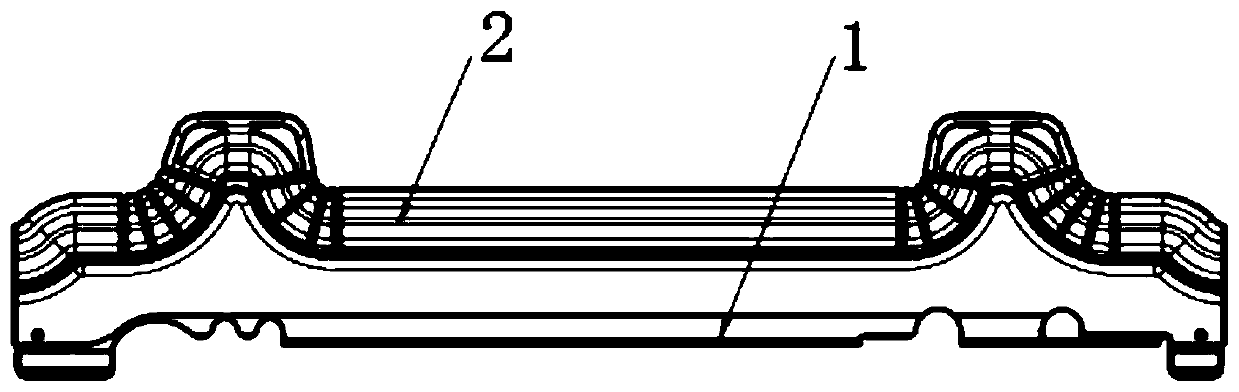

[0039] Such as Figure 2~4 , the flexible windshield of the present invention includes a composite supporting steel plate 1 and flexible rubber 2, which can be bonded by vulcanization, thermal bonding or glue, preferably vulcanization bonding, and the peel strength is greater than 7kN / m, ensuring that the rubber and the steel plate The connection is firm and will not fall off.

[0040] Such as Figure 5 , Image 6 The side of the supporting steel plate 1 in contact with the flexible rubber 2 is provided with a number of peak-shaped protrusions 1-1, and the other side is provided with a number of through holes 1-2 and a number of gaps 1-3 according to the structure of the cooling module 4, including the upper water pipe The gaps, the mounting holes for the deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com