Method and system for producing polysilicon

A production method and polysilicon technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems affecting polysilicon, increase the resistance of silicon rods, affect the insulation performance of insulating components, etc., and achieve strong pressure bearing capacity and isolation The effect of heat capacity and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

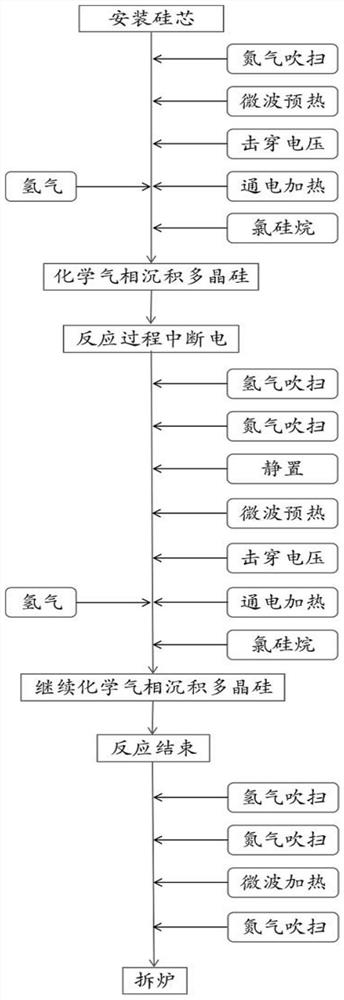

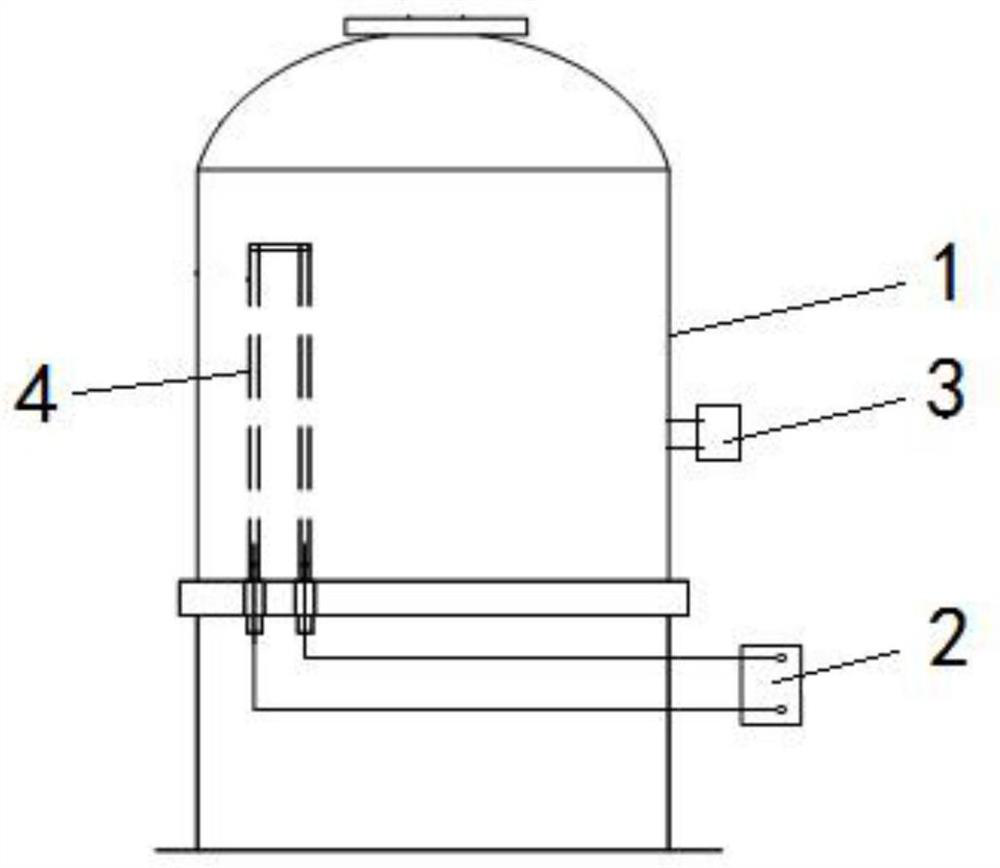

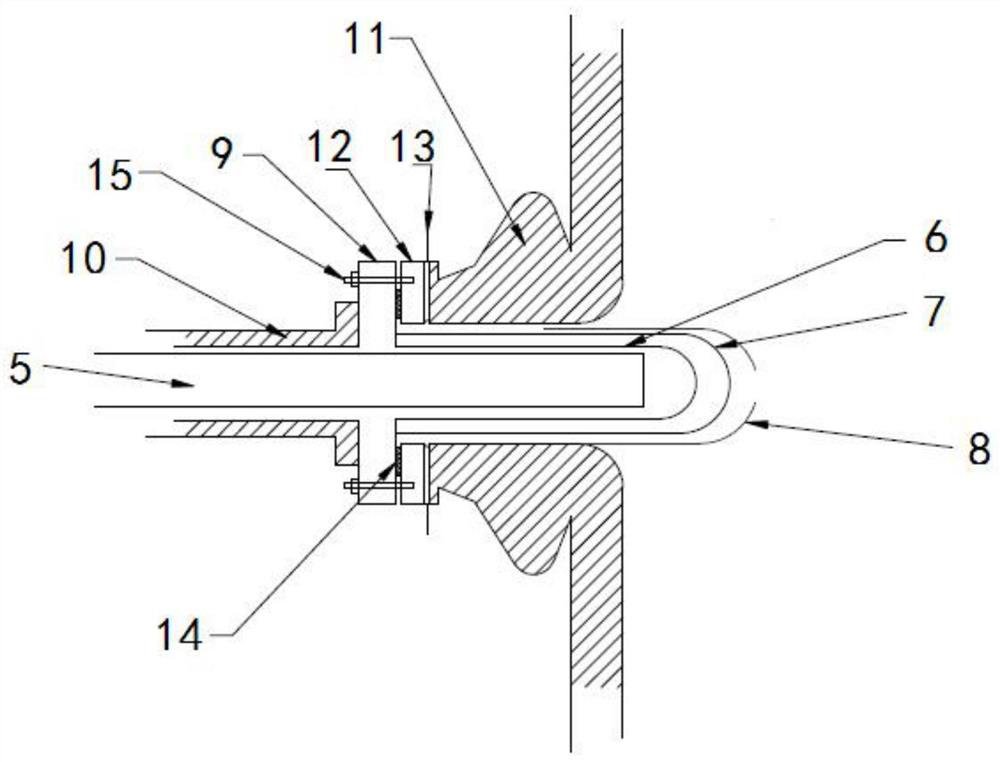

[0054] This embodiment discloses a method for producing polycrystalline silicon, which uses hydrogen gas and chlorosilane as raw materials. Before the reaction starts, the silicon core in the reduction furnace is heated to a first set temperature by microwave, and then the silicon core is broken down and then applied electric current to chemically deposit polysilicon on the surface of the silicon core to obtain a silicon rod; during the reaction process, if the power is cut off from the silicon rod, the silicon rod is heated to the second set temperature by microwave before restarting after power off. Then, after the silicon rod is broken down, a current is applied to continue the chemical deposition of polysilicon on the surface of the silicon rod.

[0055] Further, the polysilicon production method in this embodiment further includes: after the reaction is completed, cutting off the current on the silicon rod, and heating the silicon rod to a third set temperature with microw...

Embodiment 2

[0108] The present embodiment discloses a method for producing polysilicon, comprising the following steps:

[0109] Step S1-0: Preparation Phase

[0110] Prepare the silicon core. In this example, 48 silicon cores with a length of 3 m and a resistivity of 20-100 Ω·cm were prepared. The shape of the silicon core is circular. Then, the above-mentioned silicon core is placed in a reduction furnace with 24 pairs of rods, and the following steps are performed:

[0111] S100, nitrogen gas is replaced in the reduction furnace, so that the nitrogen concentration in the reduction furnace is ≧99%, and the air pressure in the reduction furnace is adjusted to 0.02-0.2MPaG.

[0112] Specifically, nitrogen is first introduced into the reduction furnace to replace nitrogen in the reduction furnace. When the nitrogen concentration in the reduction furnace is greater than or equal to 99%, the introduction of nitrogen is stopped, and the air pressure in the reduction furnace is adjusted to ...

Embodiment 3

[0143] The present embodiment discloses a method for producing polysilicon, comprising the following steps:

[0144] Step S1-0: Preparation Phase

[0145] Prepare the silicon core. In this example, 36 silicon cores with a length of 2 m and a resistivity of 20-100 Ω·cm were prepared. The shape of the silicon core is square. Then, the above-mentioned silicon core is placed in a reduction furnace, and the following steps are performed:

[0146] S100, nitrogen gas is replaced in the reduction furnace, so that the nitrogen concentration in the reduction furnace is ≧99%, and the air pressure in the reduction furnace is adjusted to 0.02-0.2MPaG.

[0147] Specifically, nitrogen is first introduced into the reduction furnace to replace nitrogen in the reduction furnace. When the nitrogen concentration in the reduction furnace is greater than or equal to 99%, the introduction of nitrogen is stopped, and the air pressure in the reduction furnace is adjusted to 0.1 MPaG. When the redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com