Double-valve-element electronic thermostat based on vehicle type carrying hydrodynamic retarder

A technology of hydraulic retarder and thermostat, which is applied in machine/engine, engine cooling, coolant flow control and other directions, can solve problems such as large error, wear and shorten the use time of retarder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

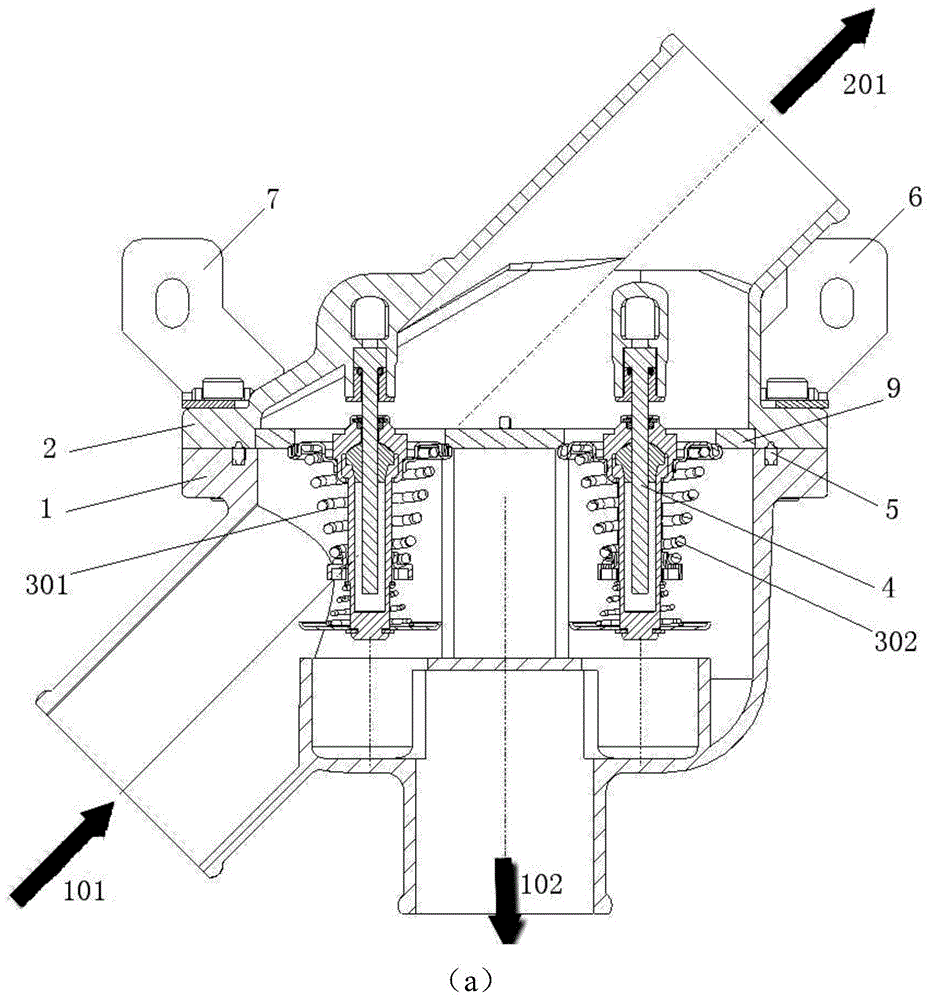

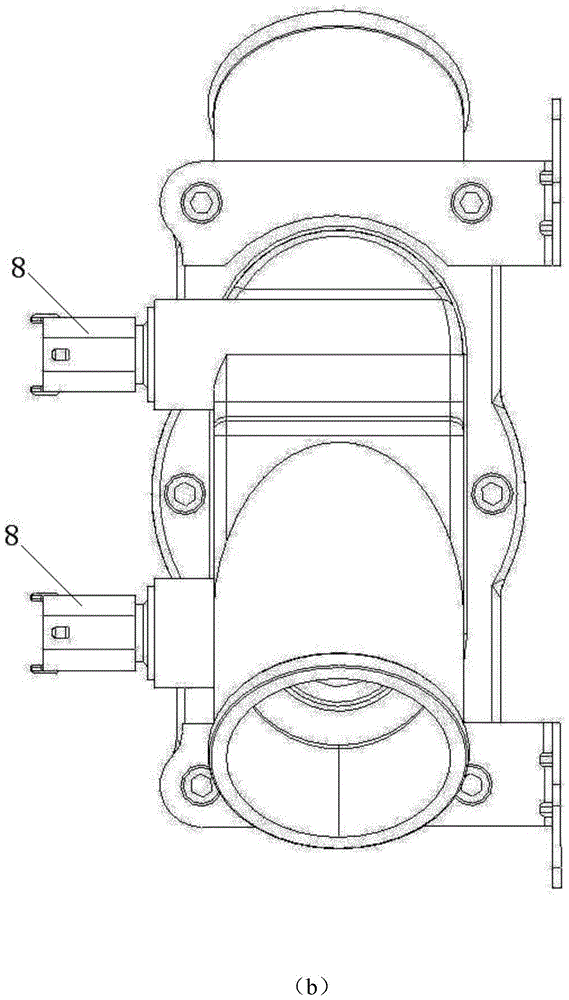

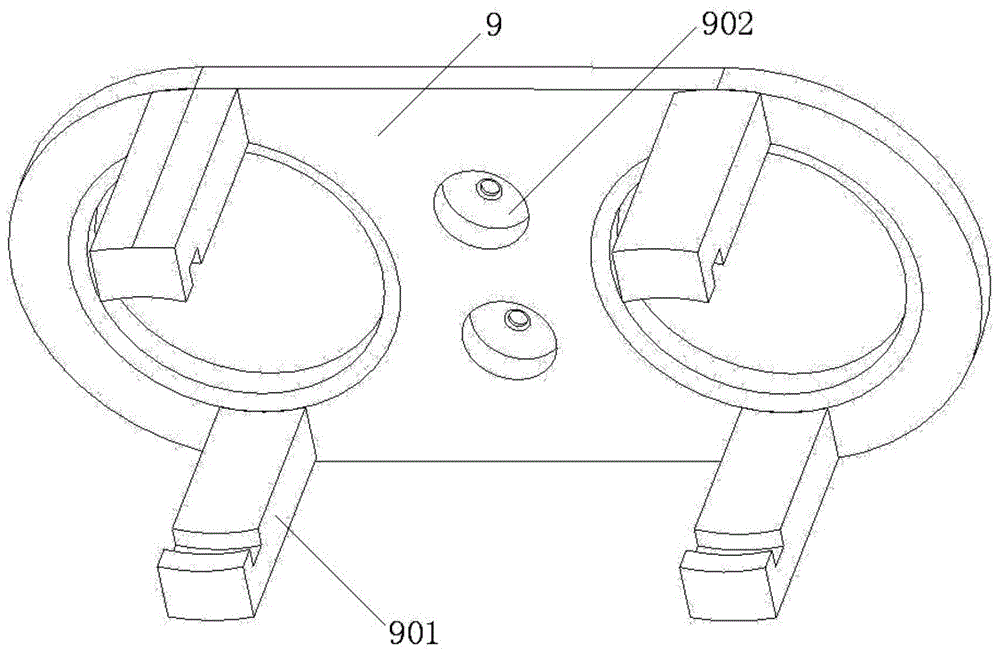

[0025] like Figure 1 to Figure 3 As shown, the present invention is a dual-spool electronic thermostat based on a vehicle equipped with a hydraulic retarder, which includes a supporting base 1 and an upper cover 2, and an internal cavity is formed between the base 1 and the upper cover 2 , and the base 1 is provided with a water inlet 101 connected to the retarder coolant outlet, the small circulation outlet 102 is connected to the water pump inlet, and the upper cover 2 is provided with a large circulation outlet 201 connected to the vehicle radiator, and through the vehicle radiator It is connected to the water inlet of the water pump, and the water outlet of the water pump is connected to the coolant inlet of the retarder; a transition plate 9 is provided between the base 1 and the upper cover plate 2, and the large circulation outlet of the first thermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com