Control method for normal operation of variable-frequency magnetic suspension centrifugal type central air-conditioning unit

A normal operation, central air-conditioning technology, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., can solve problems such as low-voltage failure, startup failure, low opening of electronic expansion valve, etc., to achieve stable temperature and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

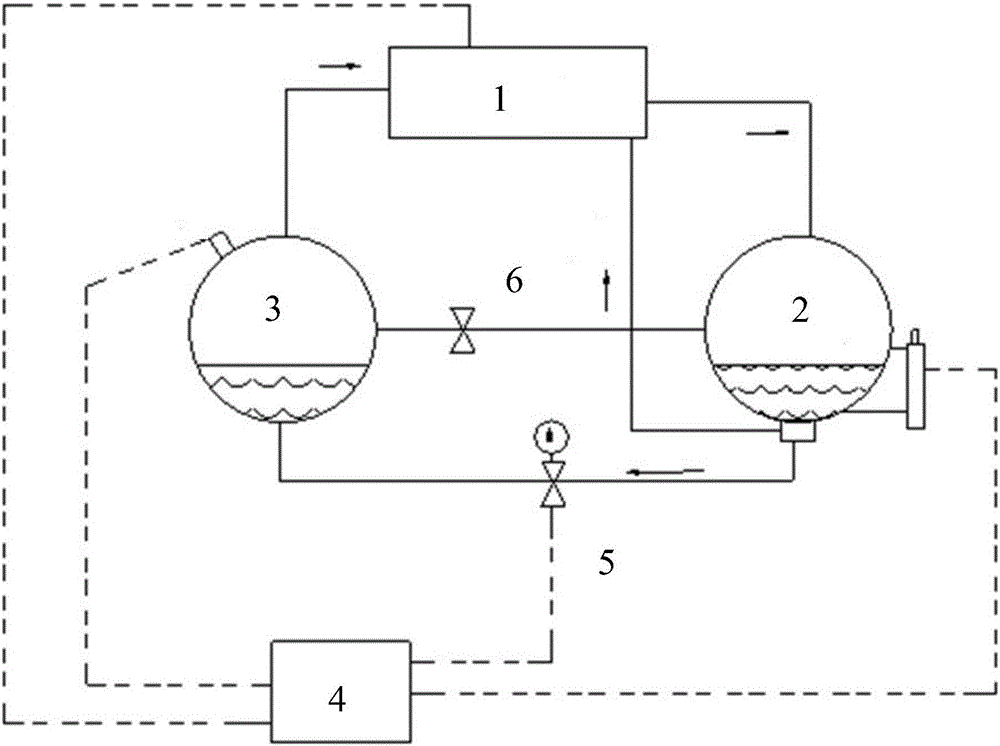

[0026] A control method for the normal operation of a variable frequency magnetic levitation centrifugal central air-conditioning unit. The hardware system includes a compressor 1, a condenser 2, an evaporator 3, and a bypass valve 6 that are sequentially connected through pipelines, and the outlet of the condenser 2 is connected to the evaporator. The inlets of 3 are connected, and an electronic expansion valve 5 is arranged between them; the compressor 1, condenser 2 and evaporator 3 are connected to the input end of the external computer controller 4, and the output end of the computer controller 4 is connected to the electronic expansion valve 5 ; The refrigerant flows in the circulation pipeline, and the steps of the control method are as follows:

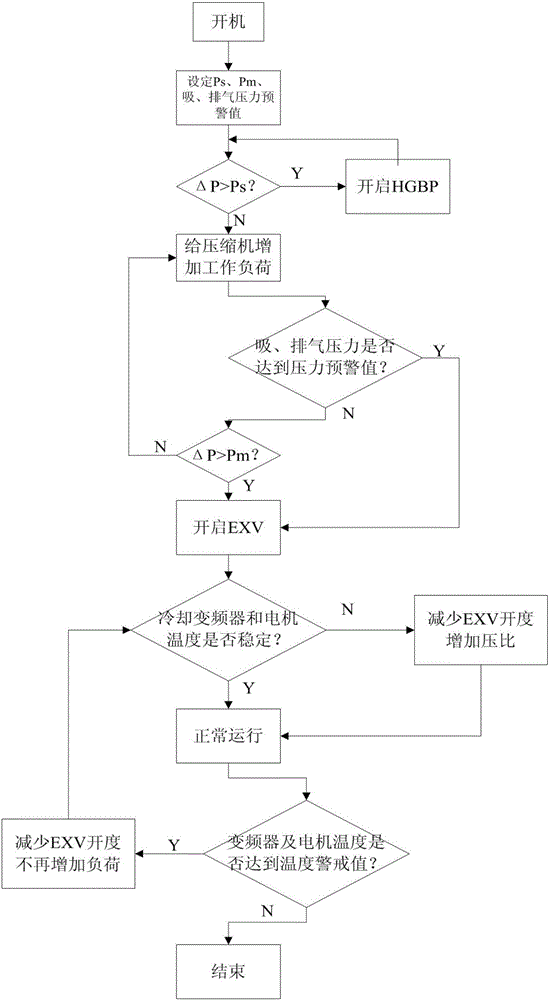

[0027] (1) Set the warning pressure ratio of the compressor 1, the minimum pressure ratio of the refrigerant cooling cycle, the early warning value of the exhaust pressure of the compressor 1 and the early warning value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com