Hybrid Current Sensor Assembly

A technology of current sensor and hall sensor, which is applied to the components of electrical measuring instruments, measuring current/voltage, instruments, etc., which can solve the problems of production cost and product volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

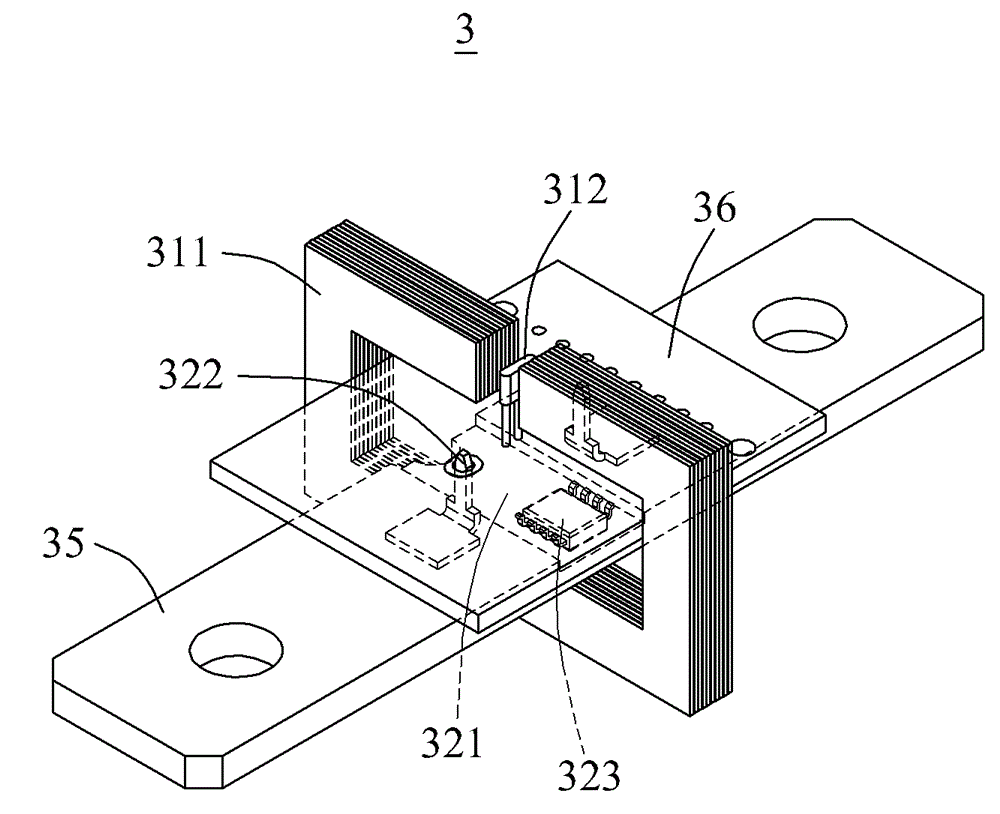

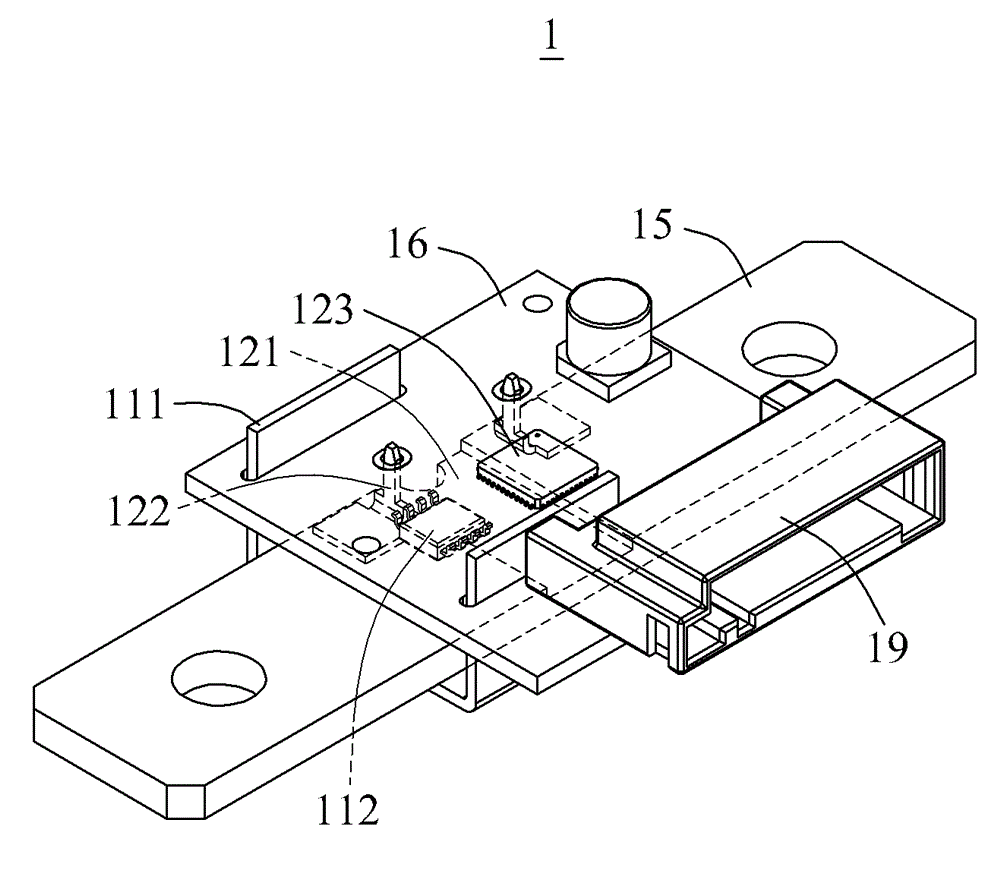

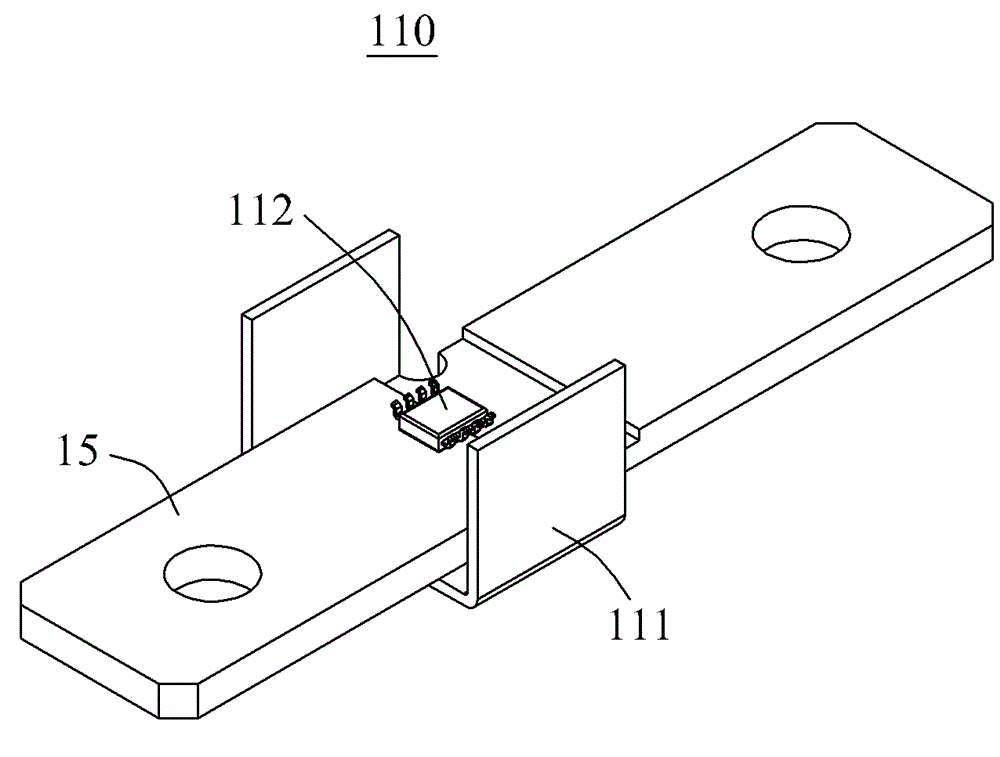

[0034] Hereinafter, some example embodiments will be described in detail with reference to the accompanying drawings. With regard to the reference numerals assigned to elements in the figures, it should be noted that, wherever possible, the same elements will be designated by the same reference numerals, even if shown in different figures. Likewise, in the description of the embodiments, when it is considered that a detailed description of a well-known related structure or function would cause an obscure explanation of the present disclosure, such description will be omitted.

[0035] Additionally, terms such as first, second, A, B, (a), (b), etc., may be used herein to describe components. Each of these terms is not used to define an element, order, or sequence of the corresponding member, but merely to distinguish the corresponding member from the other member(s). It should be noted that if a member is described in the specification as being "connected", "coupled" or "coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com