Suspended load type transformer

A technology for transformers and hanging beams, which is applied in the directions of installation/support/suspension of transformer/inductor magnetic cores, transformer/reactors, etc. It can solve the problems of bumping into brackets or utility poles and installation difficulty, so as to prevent bumping and reduce installation Difficulty, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

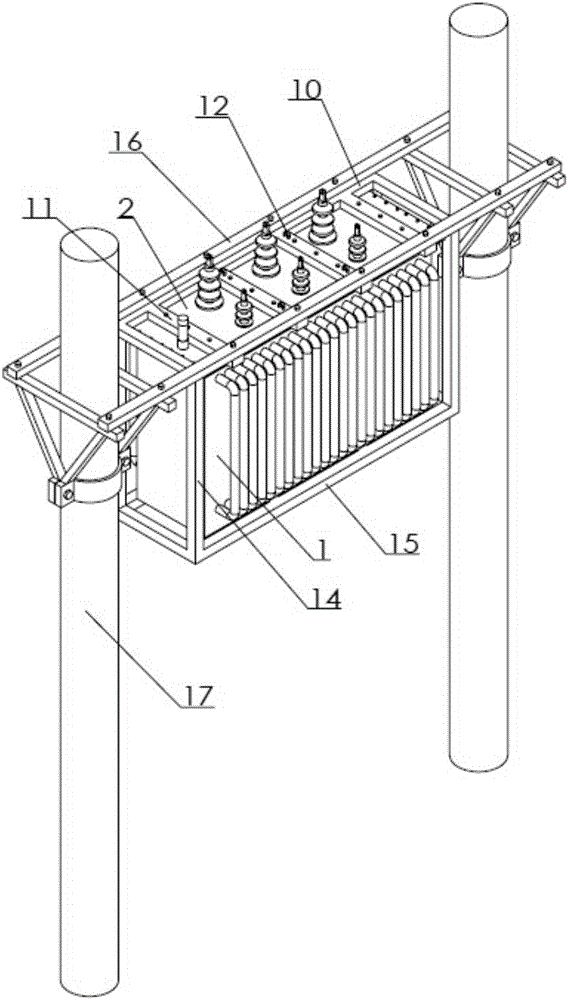

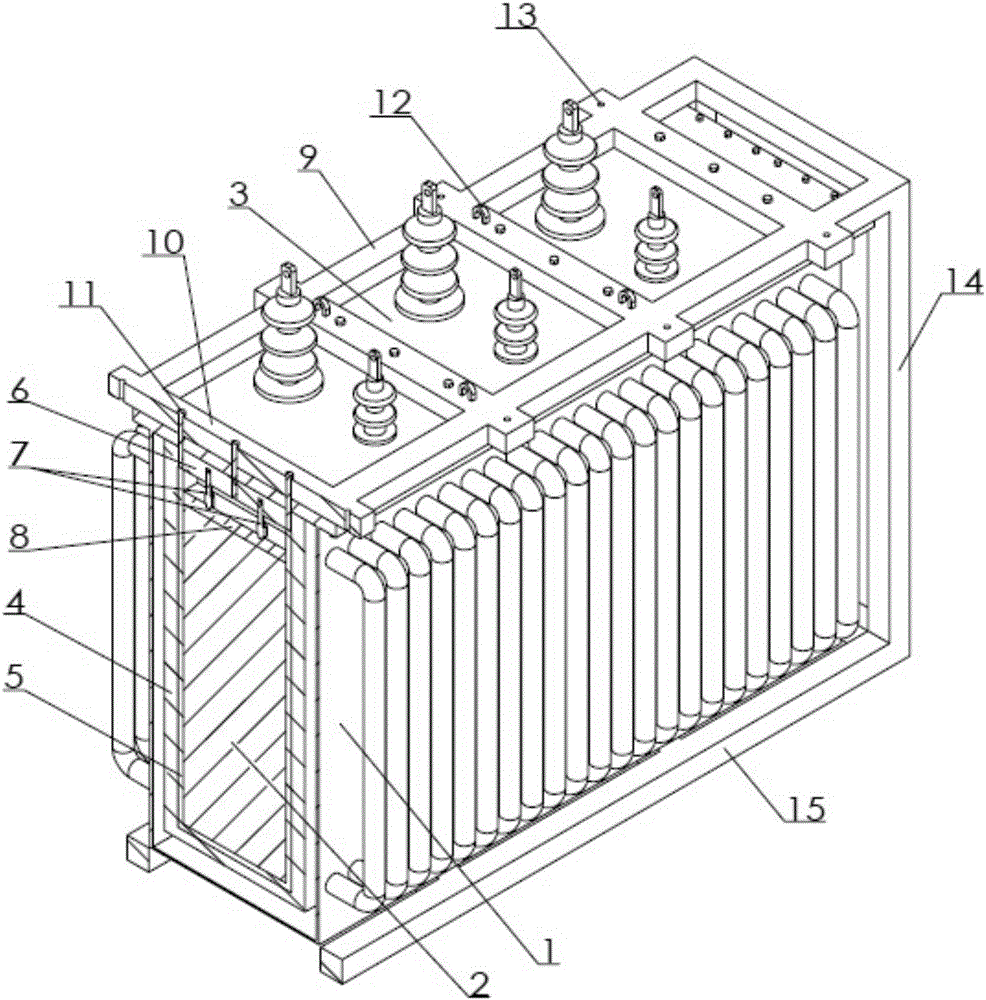

[0013] Embodiments of the present invention are as figure 1 , 2 As shown, the hoisting transformer includes an oil tank 1 and an iron core 2. The iron core is located in the oil tank. The oil tank has an upper cover 3. A frame 4 is fixed on the iron core. The frame and the iron core are connected by an insulating block 5. The frame There is a hanging beam 6 in contact with the upper cover, and the hanging beam is connected with an insulating fixing block 8 tightly fastened on the iron core through a screw rod 7 to ensure the integrity of the iron core and the frame. The upper cover is provided with a hanger 9 to hang The frame is provided with a beam 10 aligned with the hanging beam, and the beam is fixedly connected with the hanging beam through the bolt 11 passing through the upper cover. The hanger is provided with a lifting hook 12 and a mounting hole 13. The lifting hook is used for lifting, and the mounting hole For connection and installation, the two ends of the hange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com