Method and apparatus for deicing of high voltage wire

A technology for high-voltage wires and ice bodies, which is applied in the field of deicing methods and devices for power transmission lines, can solve problems such as low efficiency, difficult application, and large power consumption, and achieve the effects of reducing energy consumption, removing quickly and efficiently, and buffering shocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

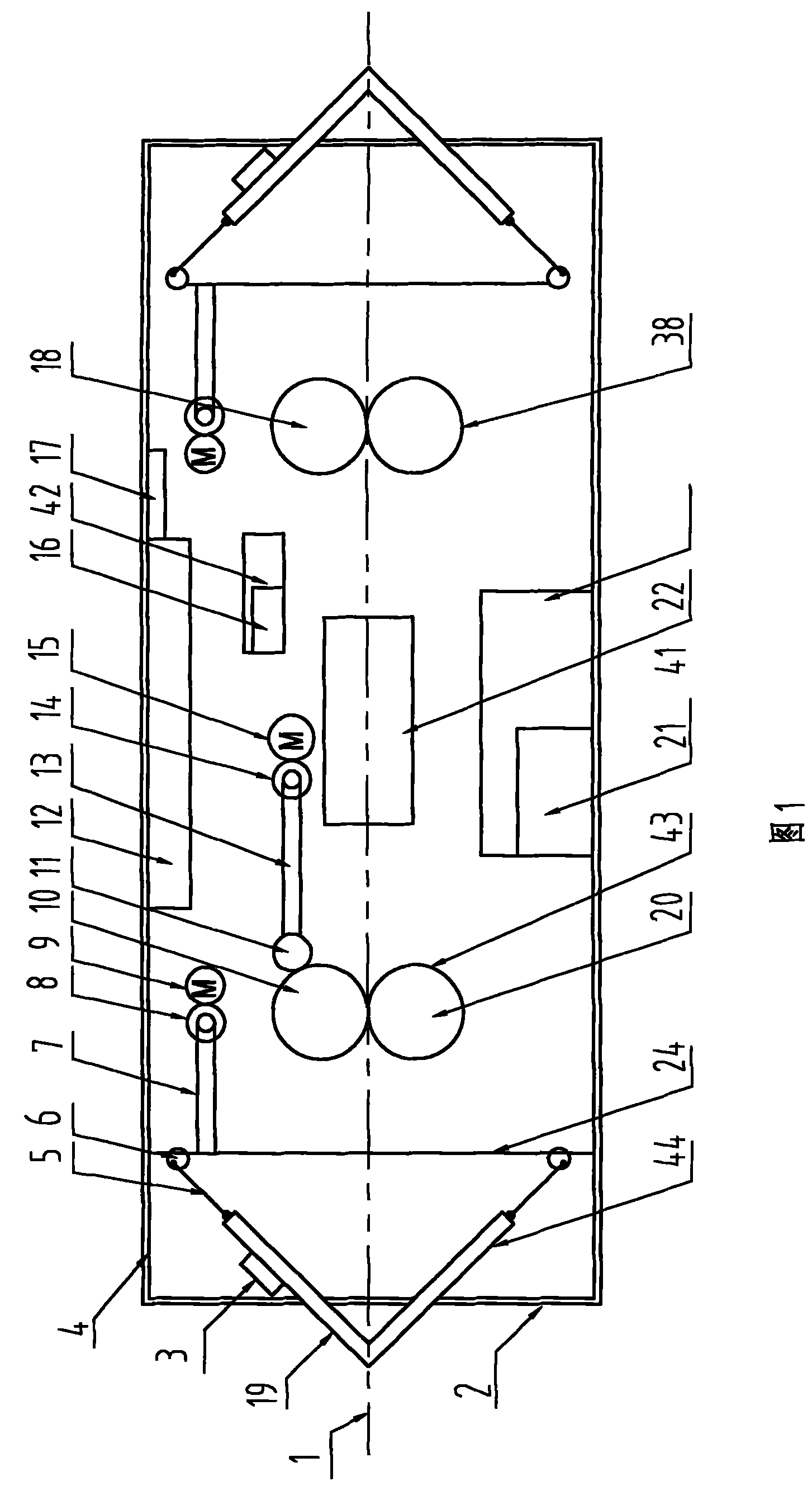

[0037] Such as figure 1 As shown, the present invention includes a power supply mechanism 41, a detection control mechanism 42, a traveling mechanism 43 and a deicing mechanism 44, which are all arranged in the casing 2, the high-voltage transmission line 1 passes through the casing 2, and the deicing mechanism 44 is located at the walking The left and right sides of mechanism 43. A heating device 4 is evenly arranged on the inner surface of the housing 2 , and the heating device 4 is powered by a power supply mechanism 41 .

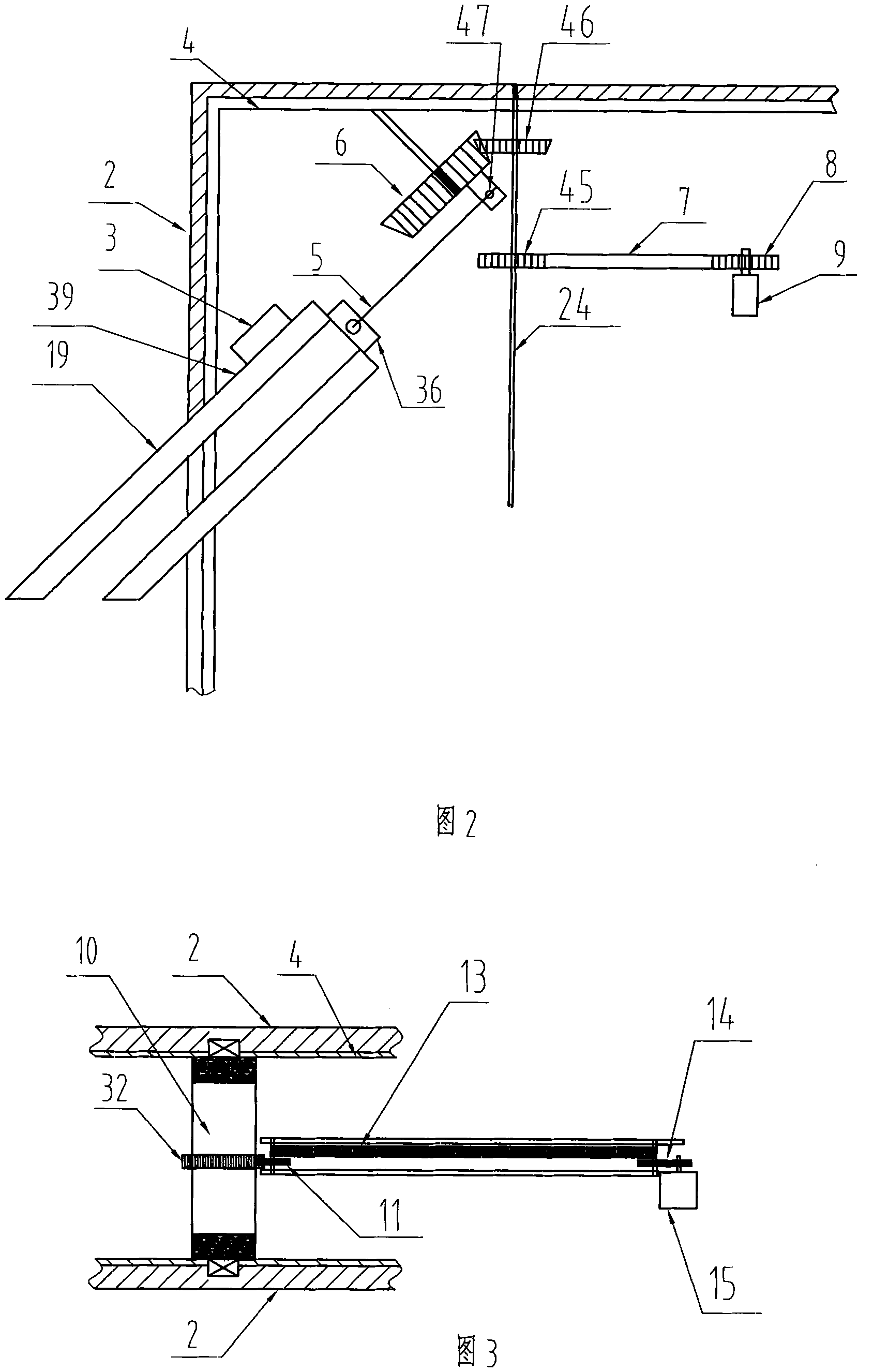

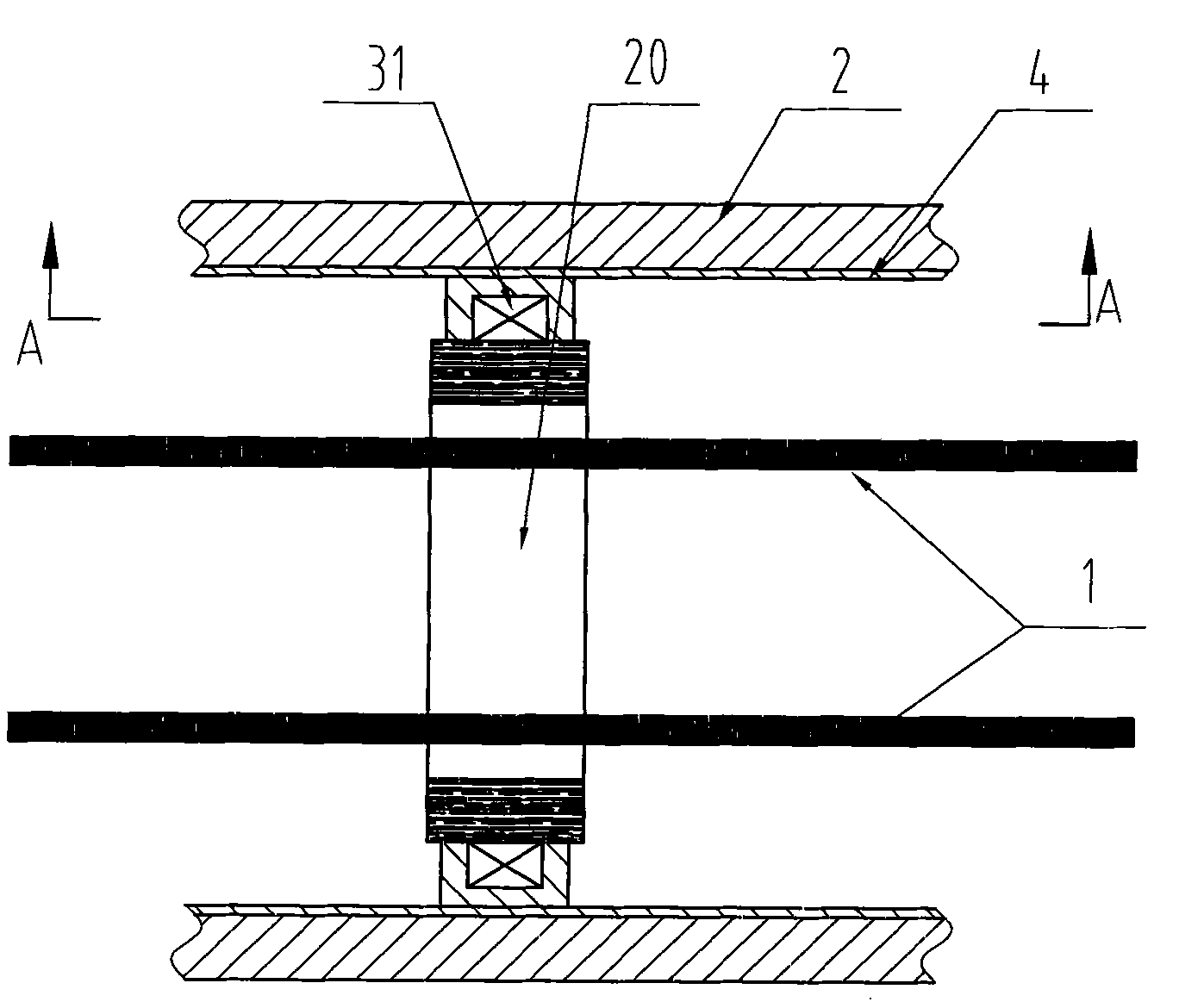

[0038] Such as figure 1 , 3 , 4, and 5, the traveling mechanism 43 includes the traveling wheel 10, the supporting wheel 18 and the relative pressure wheels 20, 38 below the two. 18 and the relative pressure wheel 38 below it passes through, and the front and rear ends of the road wheel 10 and the support wheel 18 are provided with bearings 31 and are clamped on the front and rear sides of the casing 2. Such as Figure 4 , 6As shown, the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com