Method for preparing lutein feed additive

A feed additive, lutein technology, applied in the field of preparation of lutein feed additive, can solve the problems of insoluble, unlikely feed additive, use, etc., and achieve the effect of high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Mix 100g lutein extract (15.8% lutein content), 10g glycerin, 50g coconut oil and 1g ethoxyquinoline, heat at 60°C for 3 minutes, and dissolve each other to form an oil phase;

[0043] 2) Add dropwise 30g of 50% mass concentration of potassium hydroxide aqueous solution to the oil phase obtained in step 1), while controlling the high-speed shear rate to be 10000rpm, close the high-speed shear after the lye dropwise addition, and continue saponification with stirring at 500rpm rotating speed , the whole process control temperature is 80°C;

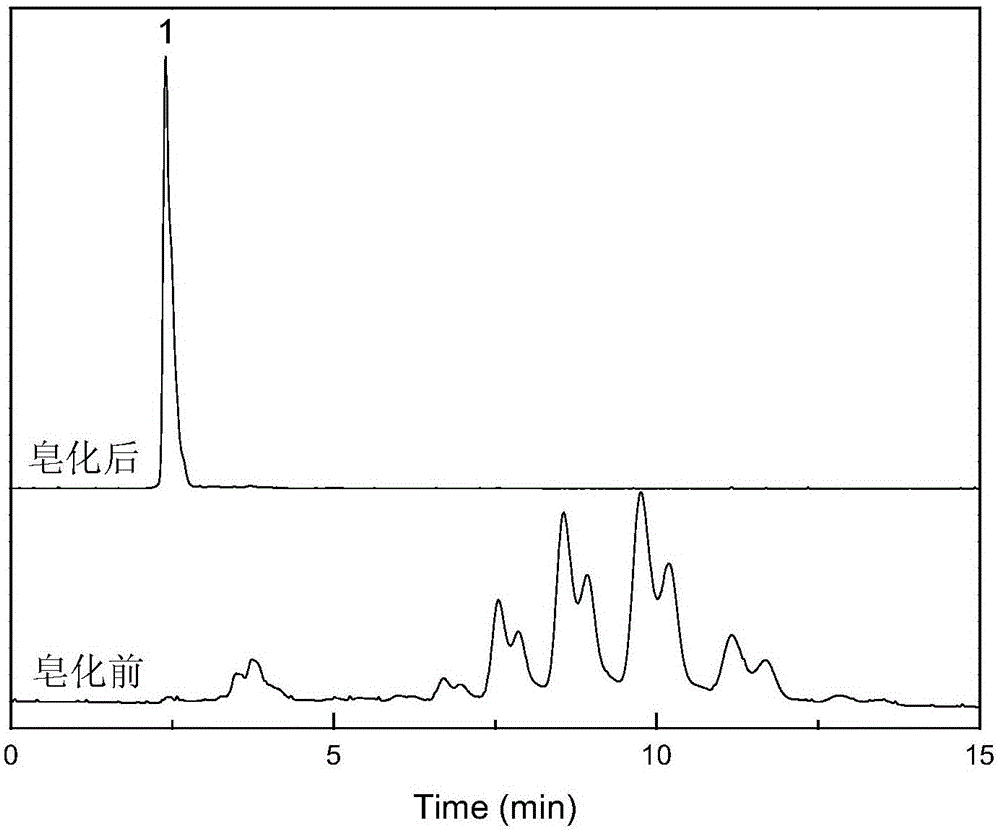

[0044] 3) After HPLC detects that the saponification rate of lutein ester is greater than 97%, continue to add 100 g of tallow, stir and dissolve at 500 rpm to form a lutein oil solution;

[0045] 4) Add dropwise 50g of 30% mass concentration of sodium hydroxide aqueous solution to the lutein oil solution obtained in step 3). The whole process is controlled at a temperature of 80° C. and a mechanical stirring speed of 500 rpm. Wh...

Embodiment 2

[0059] 1) Mix 100kg lutein extract (15.2% lutein content), 100kg glycerin, 30kg soybean oil, and 0.1kg BHT, heat at 40°C for 10 minutes, and dissolve each other to form an oil phase;

[0060] 2) in the oil phase that step 1) obtains, drip the potassium hydroxide of 60kg40% mass concentration, control the high-speed shear rate simultaneously to be 3000rpm, close the high-speed shear after the lye dropwise is finished, stir and continue saponification at 100rpm rotating speed, The whole process control temperature is 40 ℃;

[0061] 3) After HPLC detects that the saponification rate of lutein ester is greater than 97%, continue to add 50kg of palm oil, stir and dissolve at 200rpm to become a lutein oil solution;

[0062] 4) In step 3) the potassium hydroxide of 10kg45% mass concentration is added dropwise in the lutein grease solution that obtains, and whole process control temperature is 40 ℃, and mechanical stirring speed is 100rpm, and insulation reaction makes viscosity reach...

Embodiment 3

[0066] 1) Mix 100kg lutein extract (15.7% lutein content), 80kg glycerin, 40kg corn oil, and 0.5kg tocopherol, heat at 50°C for 5 minutes, and dissolve each other to form an oil phase;

[0067] 2) in the oil phase that step 1) obtains, drip the sodium hydroxide of 40kg42% mass concentration, control the high-speed shear rate simultaneously to be 5000rpm, close the high-speed shear after the lye dropwise is finished, stir and continue saponification at 300rpm rotating speed, The whole process control temperature is 60°C;

[0068] 3) After HPLC detects that the saponification rate of lutein ester is greater than 97%, continue to add 40kg of lard, stir and dissolve at 250rpm to become a lutein oil solution;

[0069] 4) Add dropwise sodium hydroxide of 20kg38% mass concentration to the lutein oil solution obtained in step 3), the temperature of the whole process is controlled to be 70°C, the mechanical stirring speed is 400rpm, and the insulation reaction makes the viscosity reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com