Soil stabilizer based on copper slag as well as preparation and application method of soil stabilizer

A soil curing agent and copper slag technology, applied in the field of building materials, can solve the problems of poor workability of slag, poor economic and environmental benefits, easy cracking, etc., and achieve poor chemical stability, good curing effect, and the effect of enhancing alkalinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the above-mentioned soil curing agent comprises: stirring and mixing water glass, water reducing agent, shrinkage reducing agent and water evenly to obtain a solution; mixing copper slag powder, phosphogypsum, ceramic waste mold gypsum, volcanic rock powder in Tibet, carbide slag and The aluminum slime was mixed and dry mixed for 3 minutes to obtain a dry mix.

[0046] The method for using the above-mentioned soil stabilizer includes dry mixing the dry mixture with the soil for 5 minutes, then adding the solution and stirring for 10 minutes to obtain the stabilized soil; wherein the doping amount of the soil stabilizer is 10%-30% of the mass of the soil.

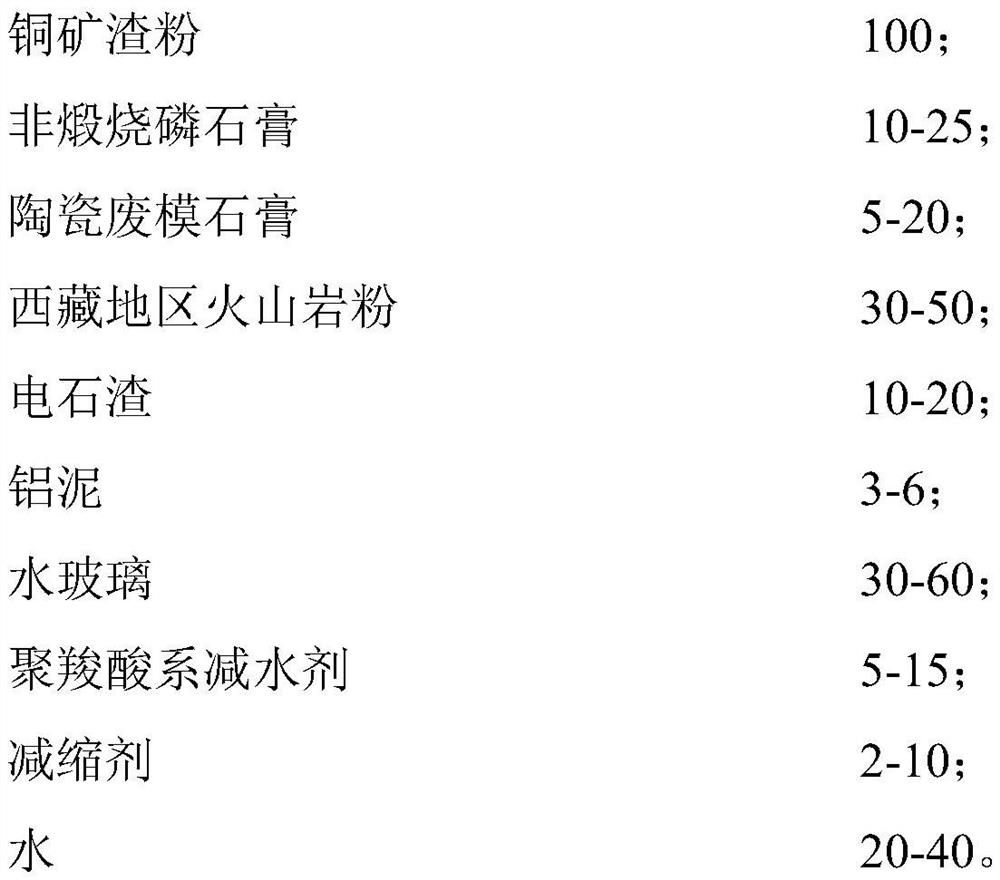

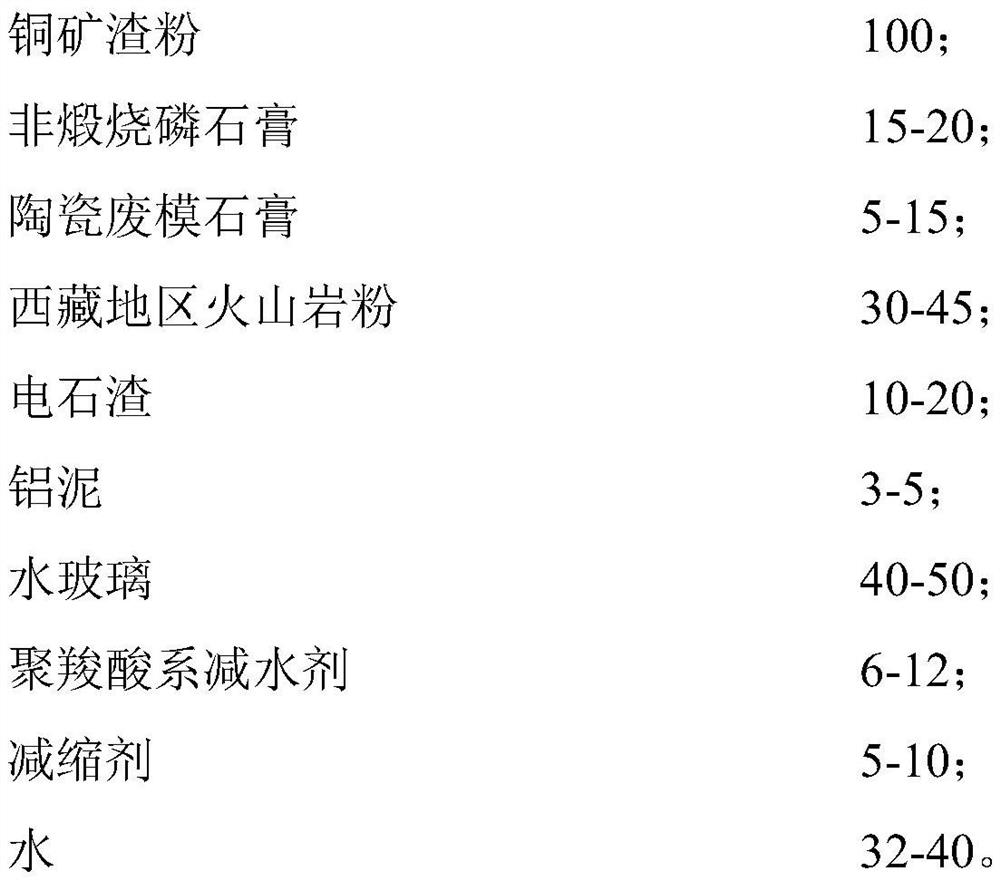

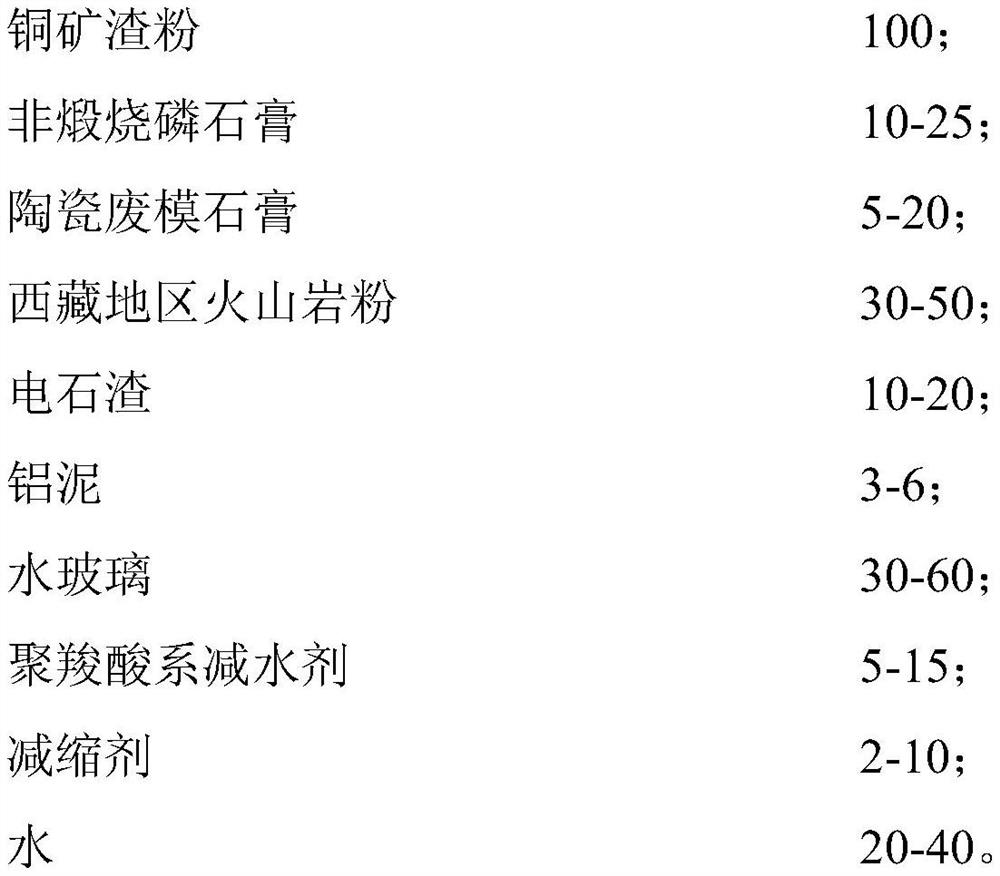

Embodiment

[0049] A soil curing agent based on copper slag, the preparation method of which is as follows: according to the distribution ratio of each component in Table 1, water glass, polycarboxylate water reducing agent, shrinkage reducing agent and water are stirred and mixed evenly to obtain a solution, and the copper Slag powder, non-calcined phosphogypsum, ceramic waste mold gypsum, Tibet volcanic rock powder, carbide slag and aluminum mud were mixed and dry mixed for 3 minutes to obtain a dry blend.

[0050] The average particle size of the copper slag powder used is 15 μm, the mass content of FeO is 28%, and the SiO 2 The mass content is 35%, Al 2 o 3 The mass content is 5%, and the CaO mass content is 19%. Non-calcined phosphogypsum is obtained by drying the original phosphogypsum at 60°C for 24 hours. The average particle size of the non-calcined phosphogypsum is 50 μm, and CaSO 4 The mass content is 68%. The specific surface area of ceramic waste mold plaster is 300m 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com