Method for supersonic wave-microwave combined treatment on three-compound combination flooding mixed scale

A ternary composite and synergistic treatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as increased crude oil workload, oil layer damage, adverse effects, etc. Eco-friendly, easy-to-remove, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

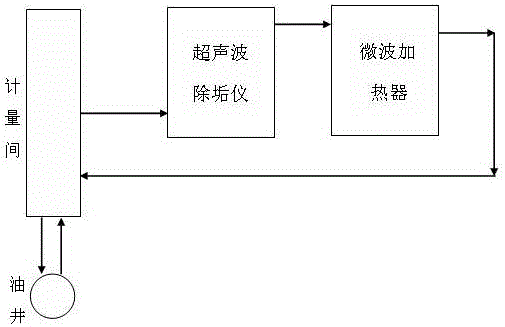

[0022] like figure 1 As shown, this method of using ultrasonic and microwave synergistic treatment of mixed scale of ASP flooding is that the oilfield produced fluid first enters the ultrasonic descaling device through the metering room (or before a certain process node with serious scaling), and the temperature At 20-60°C, use ultrasonic waves to remove and prevent scale, the ultrasonic frequency is 40-59 kHz, the ultrasonic intensity is 70%-100%, and the action time is 15 minutes; then microwave is used to accelerate the sedimentation of scale at the sewage settling tank Speed, the microwave power is 400-1000 W, and the microwave time is 3 minutes; then the oilfield produced fluid after microwave treatment is settled and continues to enter the next process node.

Embodiment 1

[0025] Take control example 1 to simulate ternary production fluid, and measure its ion content at room temperature of 20°C without the action of ultrasonic waves and microwaves.

[0026] If the combination of ultrasonic and microwave is not used, the scale-forming ions in the solution will gradually decrease and form scale, which will affect the normal production of the oil field. When changing different ultrasonic and microwave action conditions, measure the concentration of scale-forming ions in the solution. The higher the concentration, the more effective the combined effect of ultrasonic-microwave, reducing the chance of scaling.

Embodiment 2

[0028] Take control example 1 to simulate ternary production fluid, and let it act on it at room temperature 20°C, ultrasonic frequency 40kHz, ultrasonic intensity 70%, for 15 minutes; then measure the content of each ion after microwave 400W, microwave time 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com