An on-line detection, screening and recovery device

A detection device and recycling device technology, applied in the field of on-line detection screening and recycling device, can solve the problems of poor quality of parts, mixing of parts into qualified parts, disadvantage of other workpieces, etc., and achieves simple structure, high accuracy and continuous operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

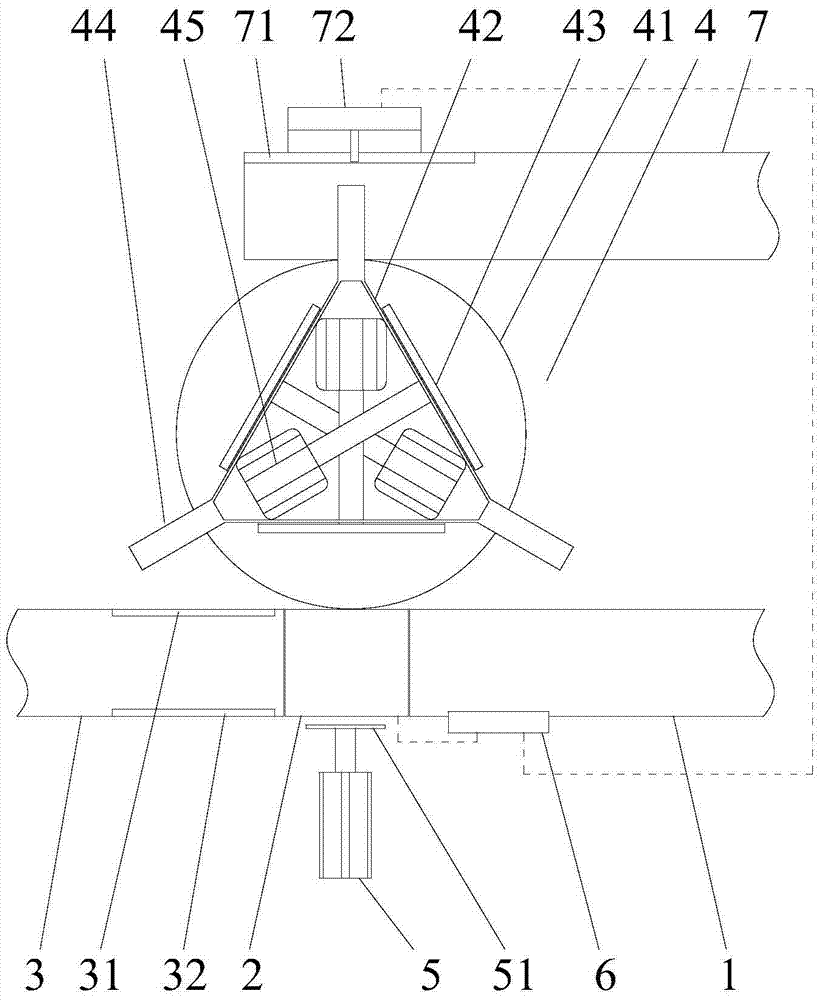

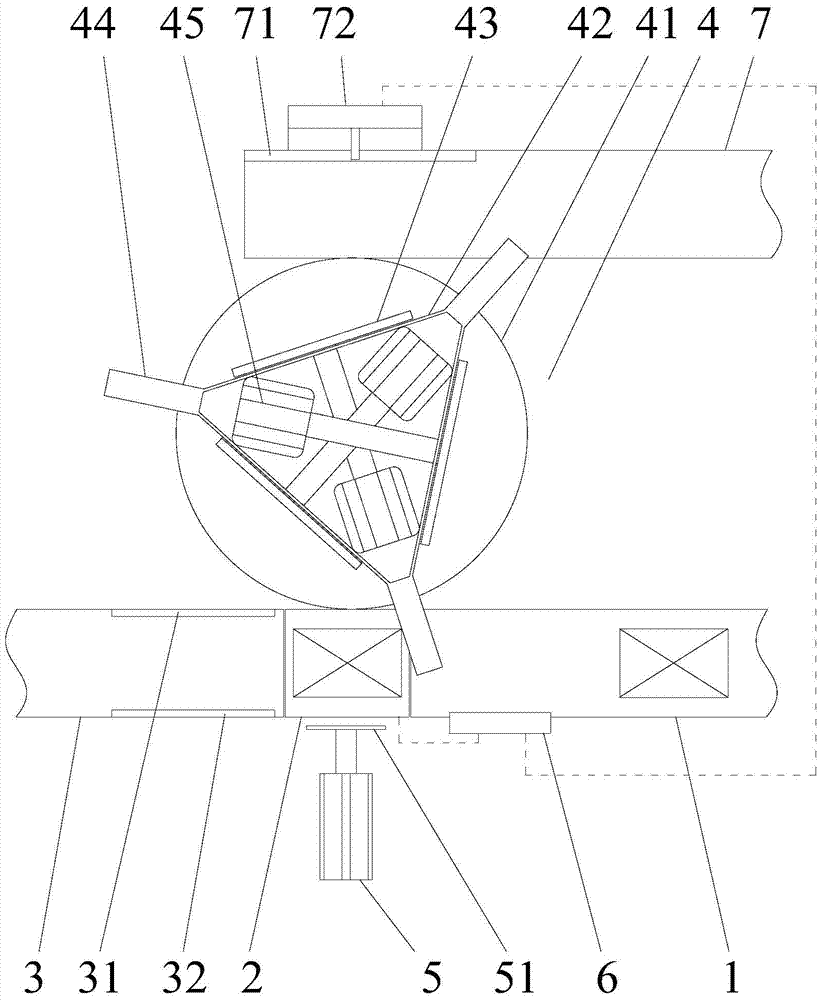

[0019] Such as Figure 1 to Figure 6 As shown, an on-line detection, screening and recovery device includes a feed line 1, an on-line detection device 2, a discharge line 3, a waste transfer plate 4, a control device 6 and a recovery line 7; the waste transfer plate 4 is set On one side of the online detection device 2; the other side of the online detection device 2 is provided with a waste removal cylinder 5; the end of the waste removal cylinder 5 is connected with a waste removal push plate 51; the waste transfer The disc 4 includes a load turntable 41; the load turntable 41 is fixed with a fixed plate 42 to form an equilateral triangle space; Plate 44; the pusher plate 44 can push the parts on the online detection device 2 into the discharge line 3; the regular triangle space is provided with three recovery cylinders 45 arranged in cross-stack; The piston rod of the recovery cylinder 45 passes through the fixed plate 42 vertically and is connected with a recovery push pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com