Robot grasping and placing tool fixture for toy doll skeletons

A technology of tooling fixtures and robots, which is applied to household appliances, other household appliances, and household components, etc., can solve the problems of lack of pick-and-place devices, low work efficiency, and high personnel requirements, so as to increase working hours, work quickly, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

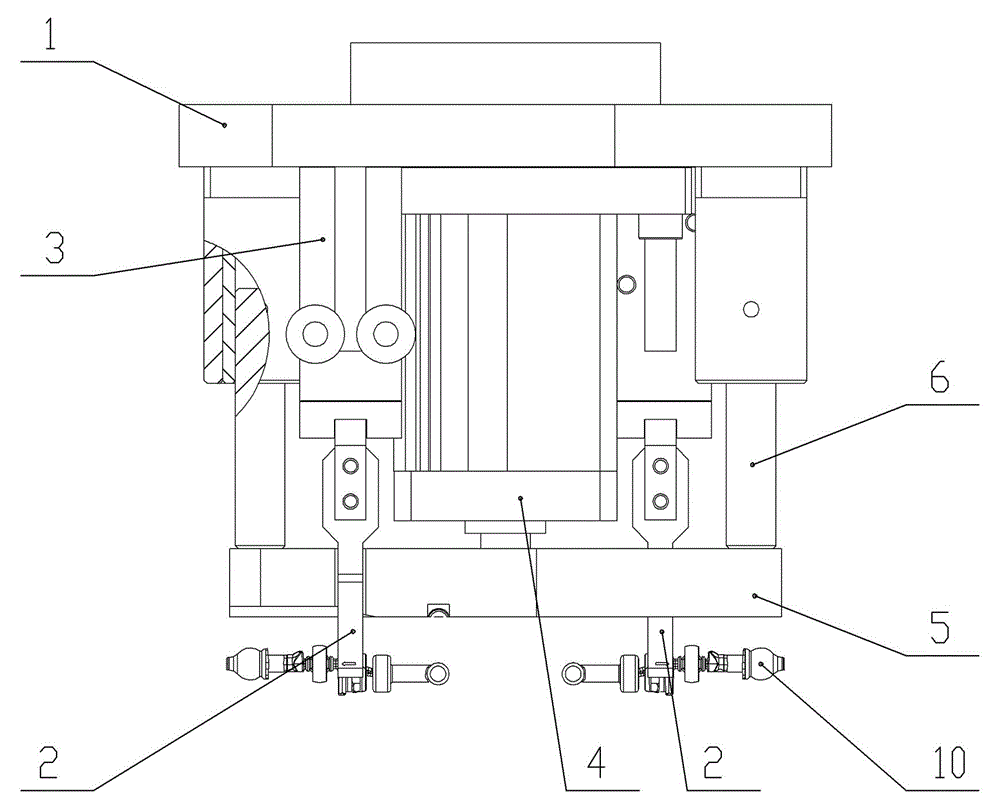

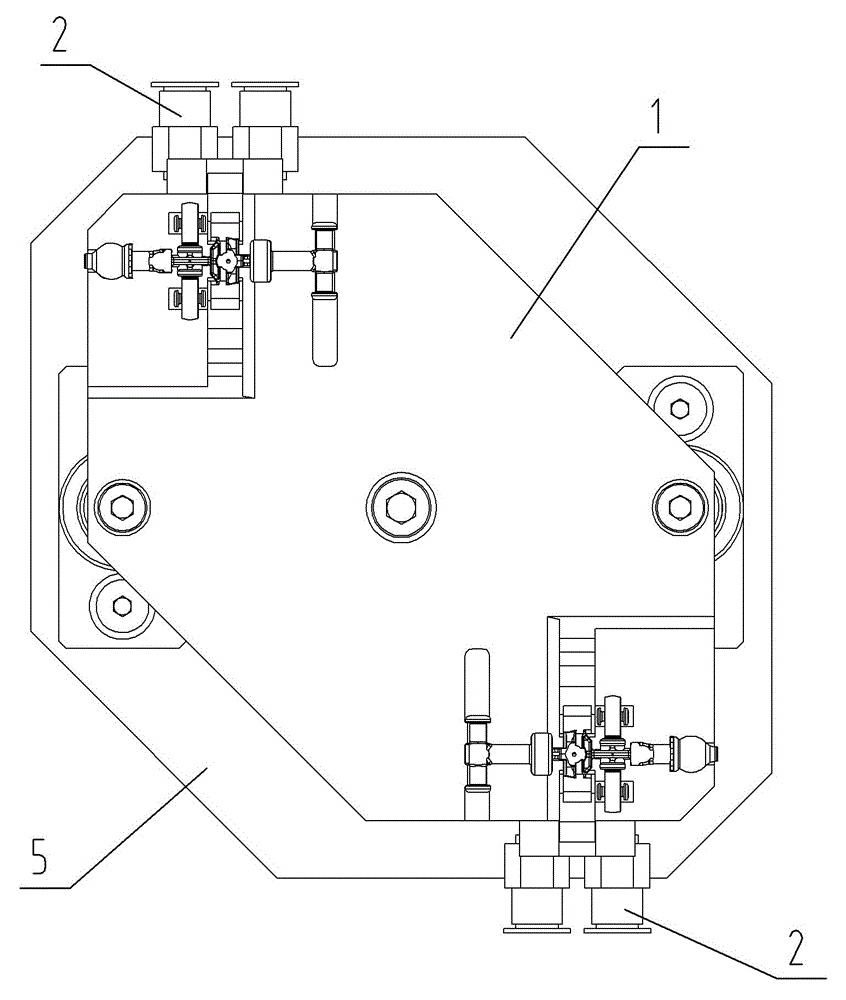

[0009] A gripping fixture for a doll toy skeleton robot, including a mounting plate 1 mounted on a robot manipulator (not shown) and moving with the manipulator, a claw hook 2 that can be opened and closed to grab and place a doll toy skeleton 10, and a driving claw The hook moves and drives the air claw drive cylinder 3 for opening and closing the claw hook. A telescopic cylinder 4 is also installed on the mounting plate. The telescopic direction of the cylinder points to the doll toy skeleton grasped by the claw hook. The end of the cylinder is equipped with a pressing block 5 , and when the cylinder is stretched, the pressing block can be pressed on the skeleton of the doll toy and exert an outward thrust on the skeleton of the doll toy.

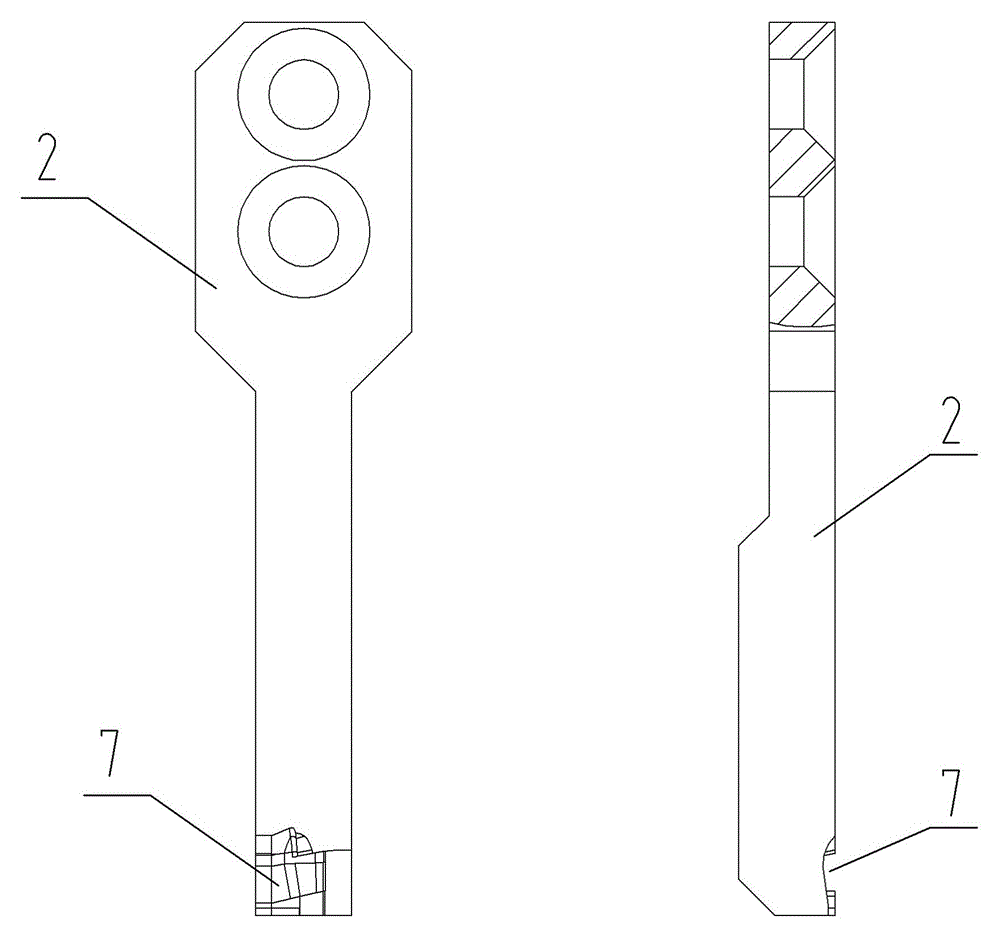

[0010] The grasping end of the claw hook 2 grabbing the doll toy skeleton is provided with a groove 7, and the shape of the groove is consistent with the grasped part of the doll toy skeleton. The setting of the groove can make the grip m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com