Cabin water-washing device for 8200T chemical/product oil tanker

A product oil tanker and water washing technology, which is applied to the cleaning equipment of ship tanks, oil tankers, transportation and packaging, etc., can solve the problems of inconvenient operation and high risk of crude oil tank washing, and can expand the scope of cleaning and avoid crude oil fires. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

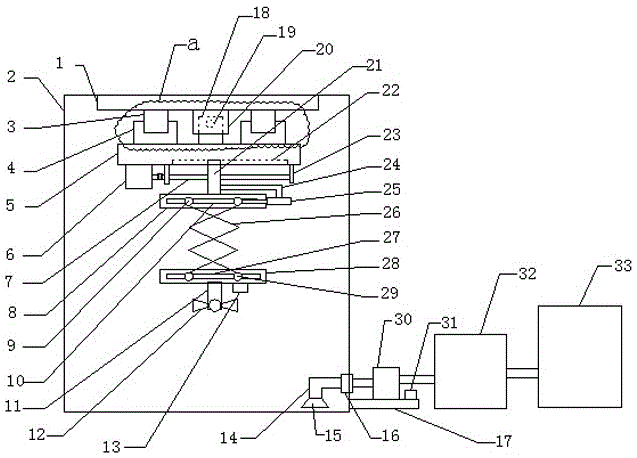

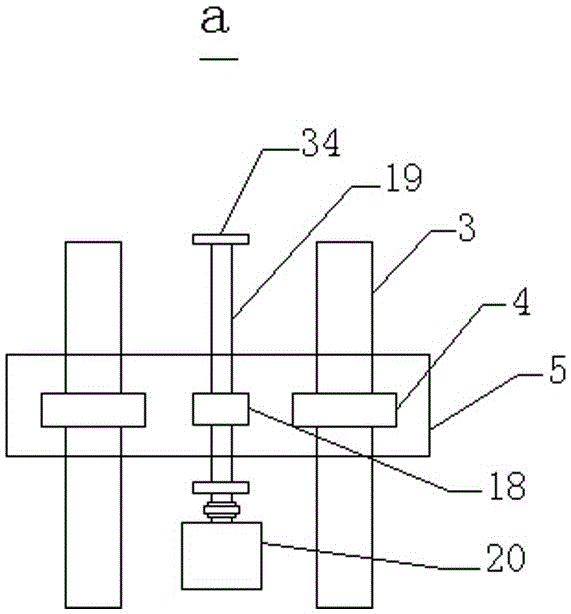

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The present invention is a water tank washing device for an 8200T chemical product oil tanker, comprising a top plate 1, a cabin 2, a slide rail 3, a slider 4, a horizontal plate 5, a first motor 6, a first lead screw 7, a first support plate 8, a first A pin shaft 9, a first hollow 10, a bracket 11, a washing machine 12, an inert gas ejection device 13, a support tube 14, a suction head 15, a pipe connection 16, a machine base 17, a second nut 18, and a second screw 19. The second motor 20, the first screw nut 21, the slideway 22, the first bearing frame 23, the support frame 24, the cylinder 25, the scissor arm 26, the second hollow 27, the second support plate 28, and the second pin shaft 29. Water pump 30, controller 31, sewage purification device 32, water storage tank 33 and second bearing frame 34, pipeline interface 16 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com