False twist texturing machine

一种加工机、假捻的技术,应用在纺织品和造纸等方向,能够解决作业性变差、难以确保空间等问题,达到确保作业空间、降低应力、提高品质的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

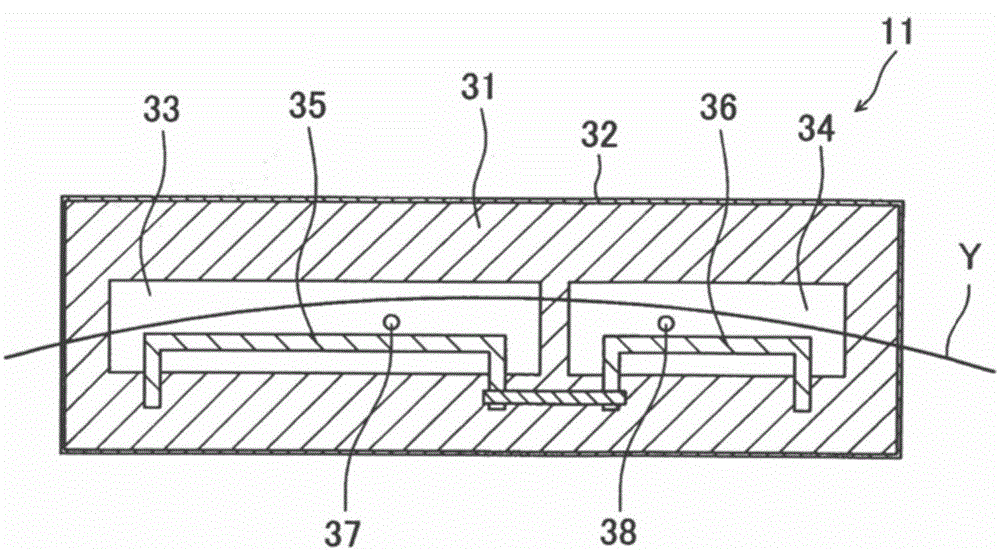

[0031] Embodiments of the present invention will be described below. In this embodiment, a false twist processing machine for producing a highly stretchable processed yarn by applying false twist to a thermoplastic synthetic fiber such as polyester or polyamide to provide crimp will be described.

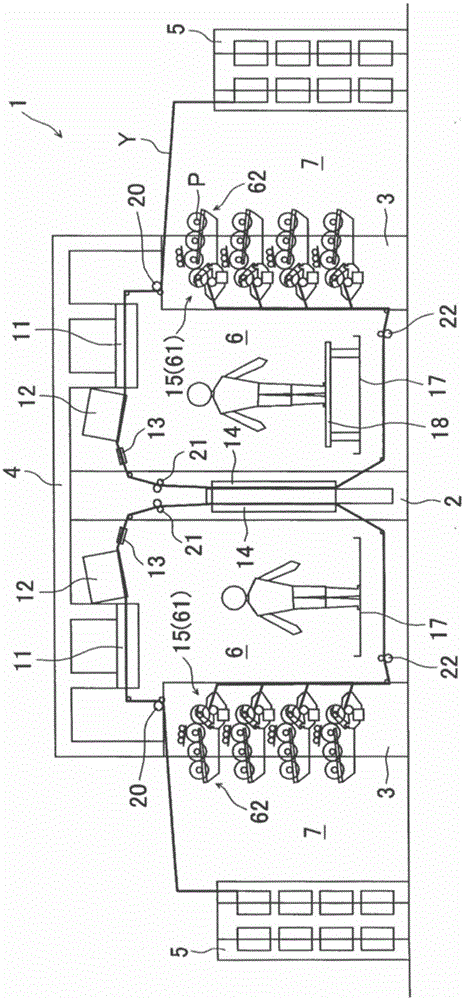

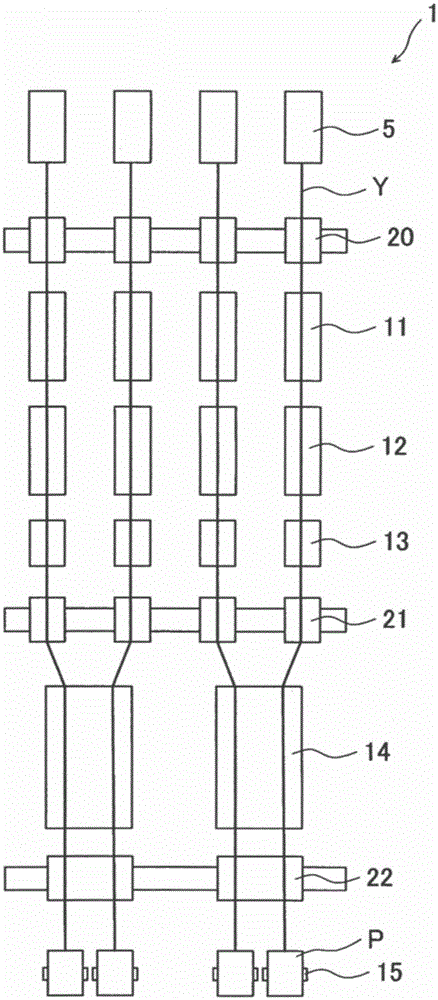

[0032] First refer to figure 1 The general structure of the false twist processing machine will be described. Such as figure 1 As shown, the false twist processing machine 1 has a main body 2 extending in the vertical direction and two winding seats 3. The two winding seats 3 are separated from the working space 6 and are respectively arranged on the main body 2 opposite to the main body 2. at an axisymmetric position for the axis. On the side opposite to the working space 6 of the winding base 3, there is a space 7 for the worker to take the fully wound package P that has been wound by a winding device 15 described later installed on the winding base 3. . In addition, the fals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com