Kerb drainage system and kerb drainage method for transformer substation

A technology for drainage systems and substations, applied in waterway systems, sewer systems, water supply devices, etc., can solve problems such as inconvenient blockage, increased engineering volume, and land occupation, so as to reduce the possibility of water accumulation and reduce the occupied area , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

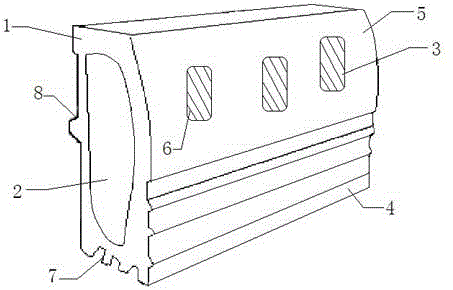

[0017] combined with Figure 1-3 , to further describe the present invention:

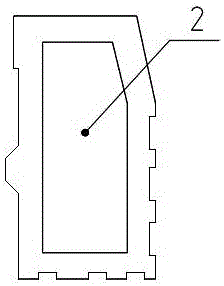

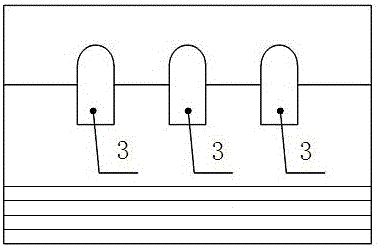

[0018] The curb drainage system for substations mentioned in the present invention includes a base body 1, the base body 1 is made of resin concrete, a plurality of base bodies 1 are connected end to end in sequence, and the front end surface of the base body 1 is connected to the top of the base body 1 through an arc-shaped connecting body 5, The arc-shaped connecting body 5 is provided with three water inlet holes 3, and the inner middle of the base body 1 is horizontally provided with a drainage channel 2, and the water inlet holes 3 are connected to the drainage channel 2, and the water inlet holes 3 are A filter screen 6 is provided. One end of the base 1 is provided with a bayonet, and the other end of the base 1 is provided with a slot. When the two bases are connected, they are connected through the bayonet and the slot.

[0019] Among them, the back of the base 1 is provided with a fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com