an m-type turbojet engine

An engine and turbine technology, applied in the field of M-type turbojet engines, can solve problems such as unfavorable engine maintenance, complex concentric shaft structure, and difficult assembly, so as to improve engine efficiency, reduce occurrence probability, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

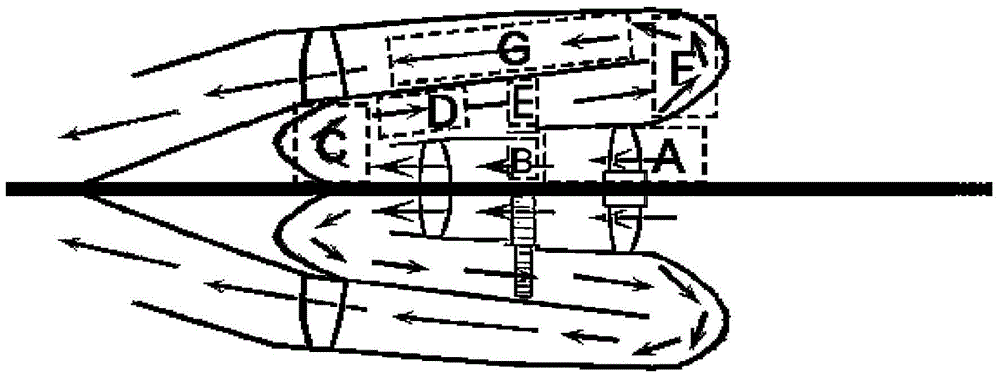

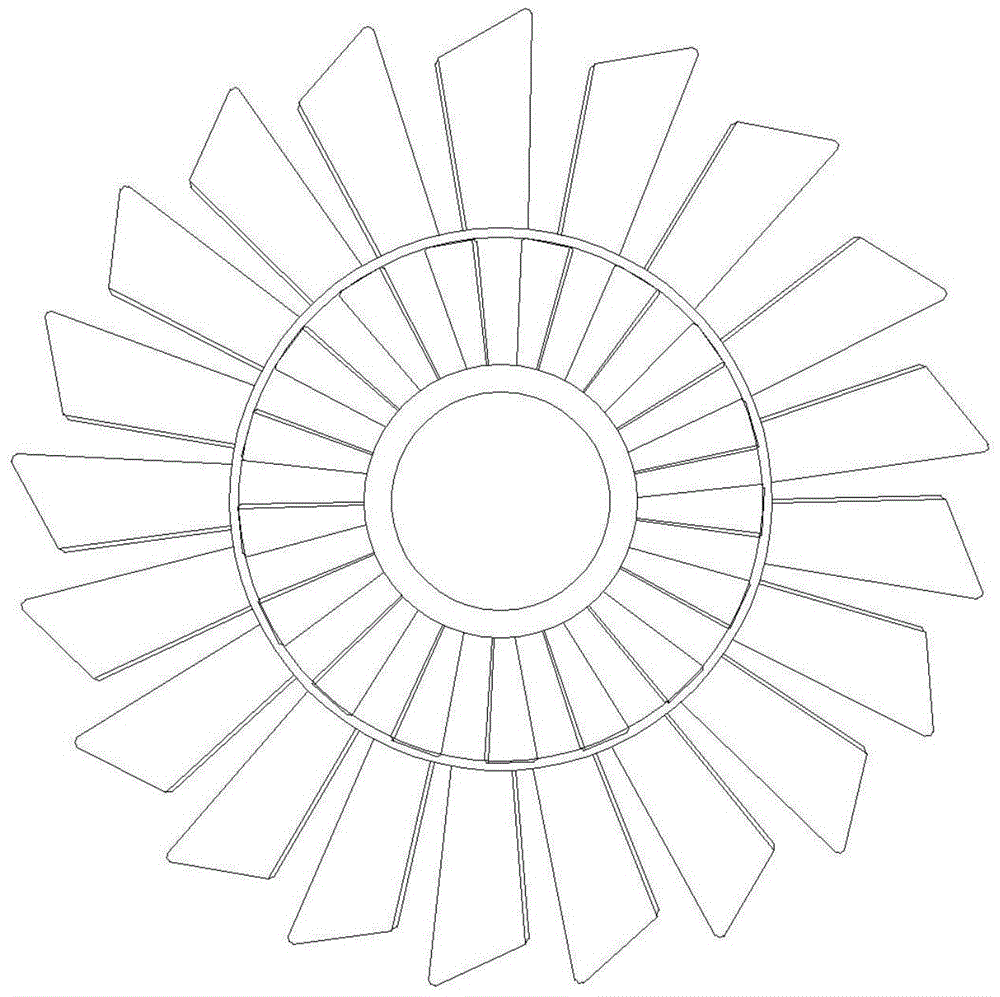

[0032] Under normal working conditions, the gas enters the compressor B from the air inlet A, enters the first return cavity C after being pressurized by the fan, and is diverted so that the direction of the airflow is reversed, enters the combustion chamber D, mixes with fuel, burns and expands to The post-injection does work, enters the turbine E, and drives the turbine. Since the turbine E and the compressor B are integrated as a fan blade, the turbine E actually drives the compressor B to rotate, and the high-temperature and high-pressure gas passes through the turbine and then is guided by the return chamber F , the direction is reversed again, jetting backwards, powering the engine with reaction force.

[0033] The principle of the M-type engine of the present invention is the same as that of an ordinary turbine engine. The back cavity is used to adjust the airflow direction, and the turbine-compressor integrated fan blade disc is used, which eliminates the complicated an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com